Method for preparing multi-component niobium alloy ingot

A niobium alloy and multi-component technology, which is applied in the field of preparation of multi-component niobium alloy ingots, can solve the problems of complex process, difficult composition and high cost, and achieve the effects of simple preparation process, convenient production organization and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of Nb-41Ti-5Al Alloy Ingot

[0031] Step 1, carry out the proportioning weighing of raw material according to the composition of Nb-41Ti-5Al alloy ingot;

[0032] Step 2. Wrap the metal particle aluminum with aluminum foil with a thickness of ≤0.15 mm to prepare an alloy package 3;

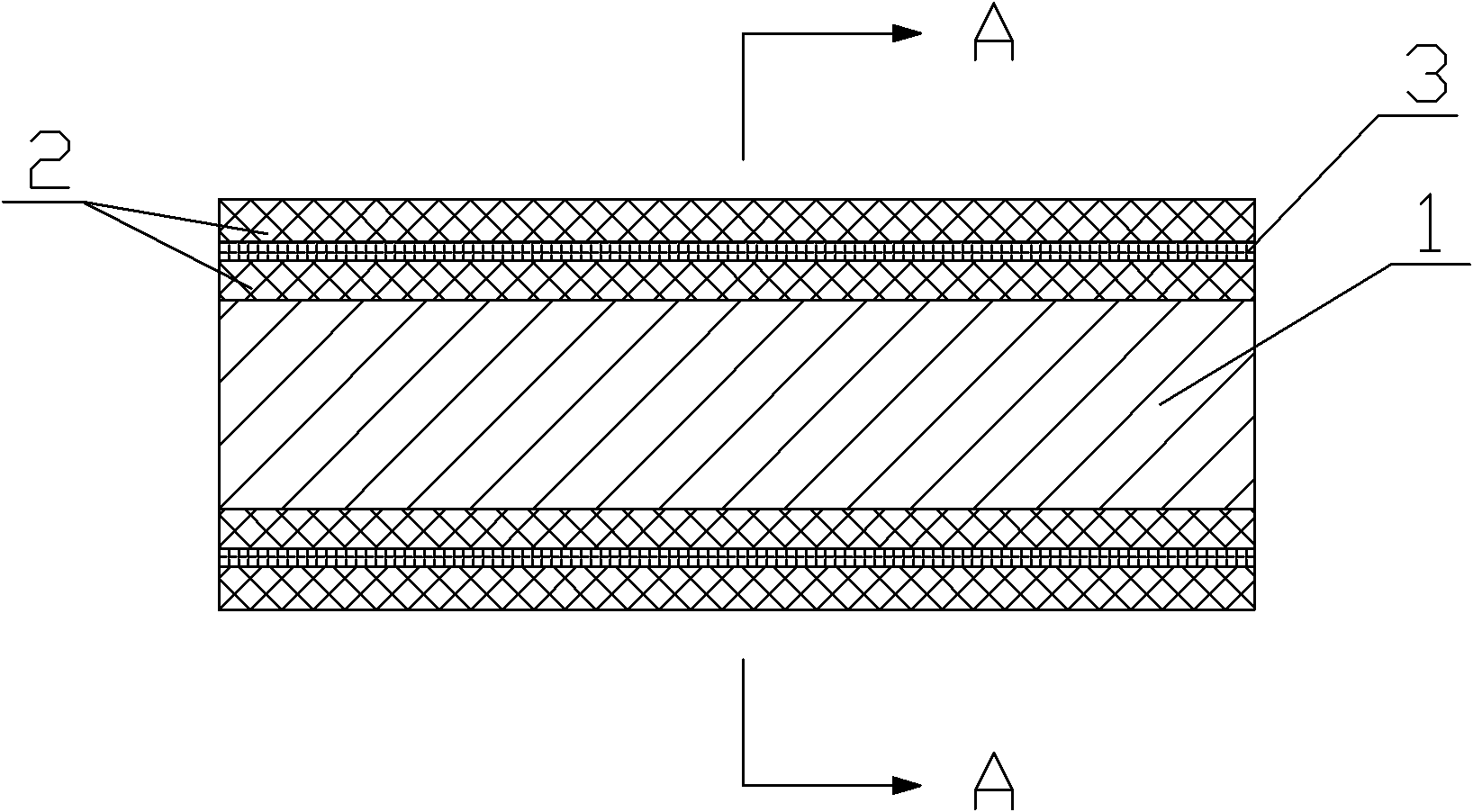

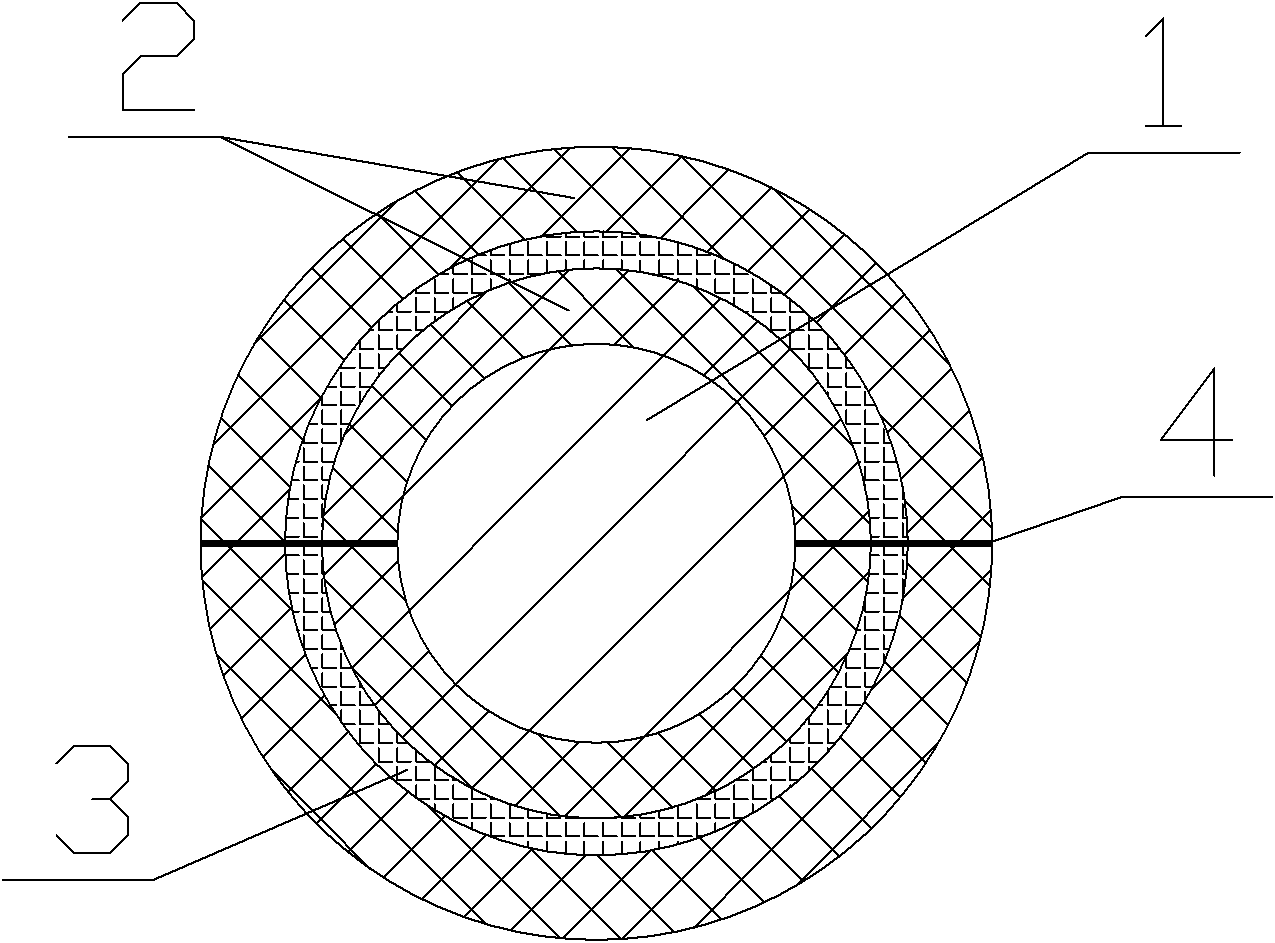

[0033] Step 3: Place the spongy base metal 2 on the mould, then evenly place the alloy package 3 described in step 2 on the spongy base metal 2, and place another layer of spongy base metal on the alloy package 3 2. Sponge titanium, which is pressed into a semicircular electrode 4 with a semicircular cross-section on a press with a semicircular compact;

[0034] Step 4. Under the protection of argon gas with a mass purity ≥ 99.99%, place the pure niobium rod 1 at the center of the electrode 4 described in the step 3 of the two sections, and weld it by argon arc welding to form a complete electrode;

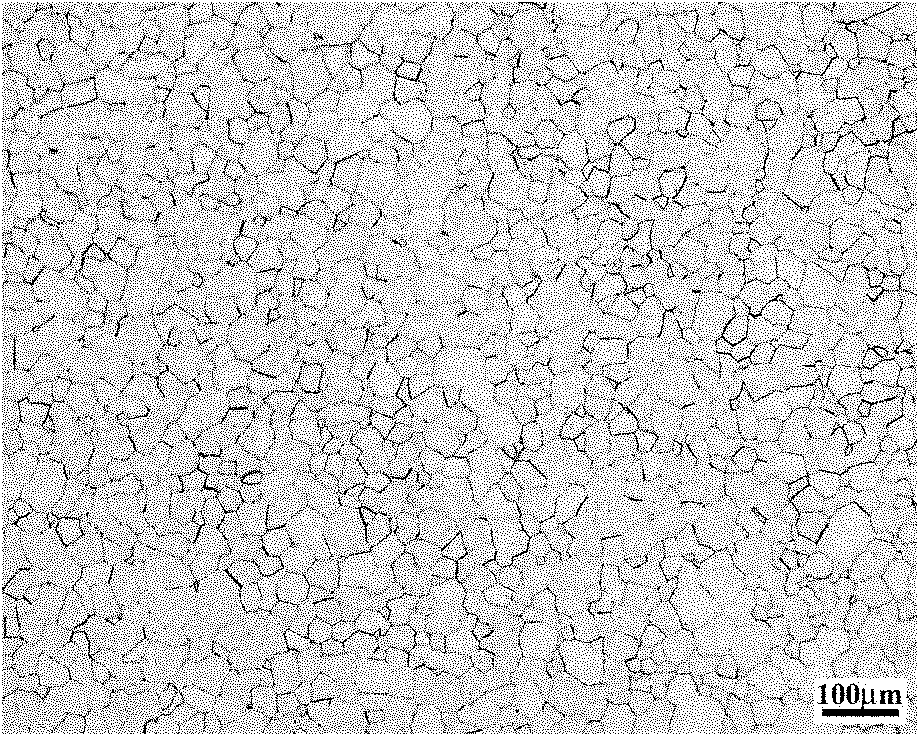

[0035] Step 5. Place the complete electrode described in step 4 in a vacuum c...

Embodiment 2

[0041] Preparation of Nb-37Ti-8Al-5Cr Alloy Ingot

[0042] Step 1, carry out the proportioning weighing of raw material according to the composition of Nb-37Ti-8Al-5Cr alloy ingot;

[0043] Step 2: Mix metal particle aluminum and metal particle chromium and wrap it with aluminum foil with a thickness of ≤0.15 mm to prepare an alloy package 3;

[0044] Step 3: Place the spongy base metal 2 on the mould, then evenly place the alloy package 3 described in step 2 on the spongy base metal 2, and place another layer of spongy base metal on the alloy package 3 2. Sponge titanium, which is pressed into a semicircular electrode 4 with a semicircular cross-section on a press with a semicircular compact;

[0045] Step 4. Under the protection of argon gas with a mass purity ≥ 99.99%, place the pure niobium rod 1 at the center of the electrode 4 described in the step 3 of the two sections, and weld it by argon arc welding to form a complete electrode;

[0046] Step 5. Place the complete ...

Embodiment 3

[0052] Preparation of Nb-32Ti-8Al-3V-1Zr Alloy Ingot

[0053] Step 1, carry out the proportioning weighing of raw material according to the composition of Nb-32Ti-8Al-3V-1Zr alloy ingot;

[0054] Step 2. Mix the aluminum particles with the vanadium particles and wrap them with aluminum foil with a thickness of ≤0.15 mm to prepare an alloy package 3;

[0055] Step 3: Place the spongy matrix metal 2 (sponge titanium and sponge zirconium) on the mold, then place the alloy package 3 described in step 2 evenly on the spongy matrix metal 2, and then place another one on the alloy package 3. A layer of spongy base metal 2 (titanium sponge and zirconium sponge), pressed into a semicircular electrode 4 with a semicircular cross-section on a press;

[0056] Step 4. Under the protection of argon gas with a mass purity ≥ 99.99%, place the pure niobium rod 1 at the center of the electrode 4 described in the step 3 of the two sections, and weld it by argon arc welding to form a complete elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com