Cold-rolled high-strength steel used for automobile structural member and manufacture method of cold-rolled high-strength steel

A technology for automobile structure and cold-rolled steel plate, which is applied in the production and manufacture of high-strength cold-rolled steel plate, cold-rolled steel plate and steel plate manufacturing field. The grain is uniform and fine, and the effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

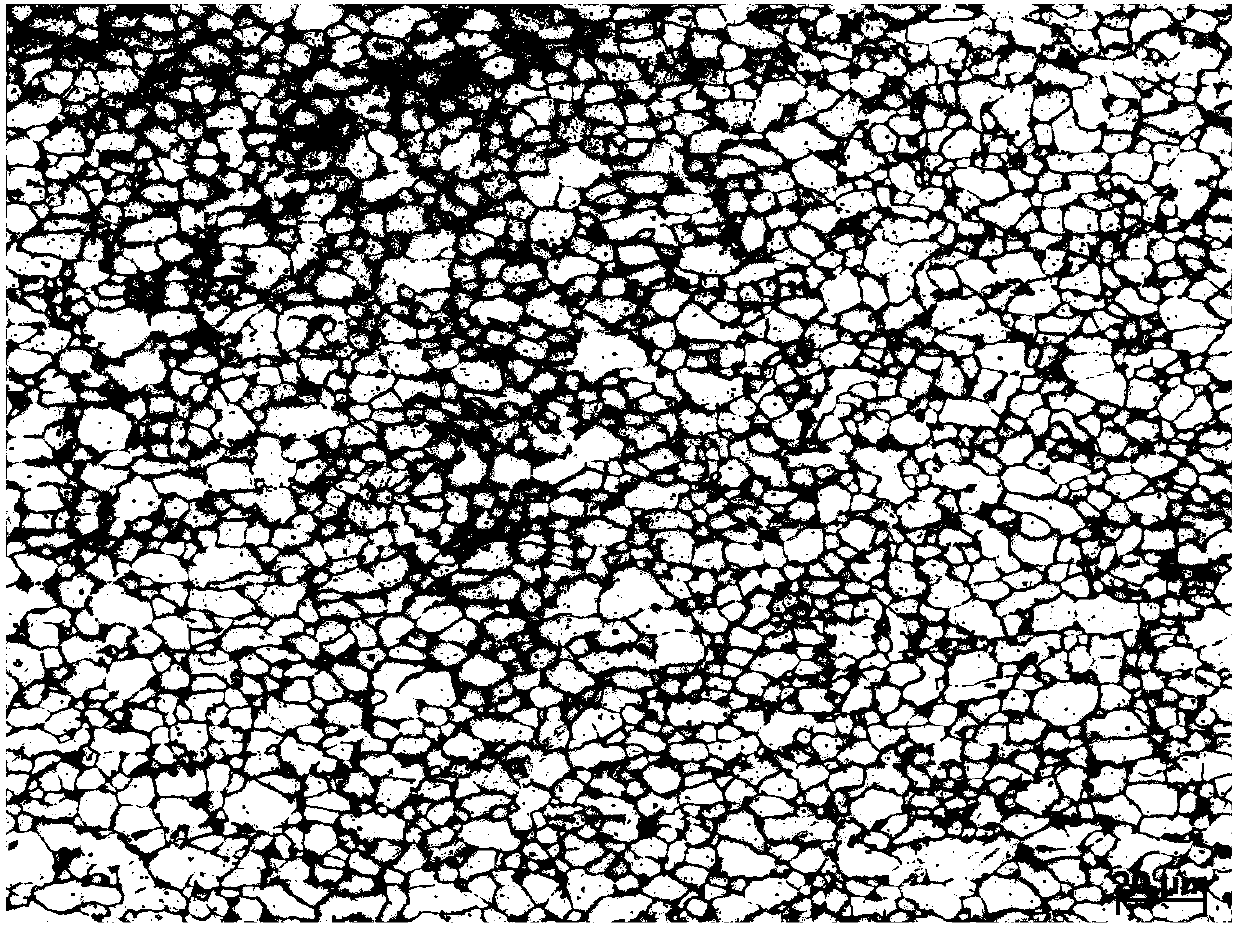

Image

Examples

Embodiment 1

[0027] The composition of the continuously cast slab obtained by RH refining and casting is as follows (mass percentage): C, 0.06%; Mn, 0.79%; Si, 0.01%; P, 0.014%; S, 0.0041%; Als, 0.034%; %; Ti, 0.015%; the balance is Fe and unavoidable impurities. The continuous casting slab is heated to 1210°C in a walking heating furnace, the holding time is 155min, the final rolling temperature is 870°C, the front cooling is adopted, and the coiling temperature is 582°C to obtain a 4.0mm thick hot-rolled steel coil; hot-rolled coil Pickling after uncoiling, continuous rolling by 5-stand rolling mill to obtain 1.5mm thick rolled hard steel coil, the cold rolling reduction is 62.5%. After the hard-rolled steel coil is uncoiled, the steel plate enters the continuous annealing furnace after surface cleaning. The annealing soaking temperature is 767°C, the soaking holding time is 125s, and the smooth elongation is 1.91%.

[0028] The high-strength steel manufactured according to the above co...

Embodiment 2

[0030] The composition of the continuously cast slab obtained by RH refining and casting is as follows (mass percentage): C, 0.07%; Mn, 0.82%; Si, 0.01%; P, 0.009%; S, 0.006%; Als, 0.036%; %; Ti, 0.014%; the balance is Fe and unavoidable impurities. The continuous casting slab is heated to 1210°C in a walking heating furnace, the holding time is 165min, the final rolling temperature is 861°C, the front cooling is adopted, and the coiling temperature is 575°C to obtain a 3.5mm thick hot-rolled steel coil; hot-rolled coil After uncoiling, it is pickled and continuously rolled by a 5-stand rolling mill to obtain a 1.2mm thick hard steel coil with a cold rolling reduction of 65.7%. After the hard-rolled steel coil is uncoiled, the steel plate enters the continuous annealing furnace after surface cleaning. The annealing soaking temperature is 787°C, the soaking time is 105s, the elongation of flattening is 1.80%, and the elongation of tension straightening is 0.2%.

[0031] The hi...

Embodiment 3

[0033] The composition of the continuously cast slab obtained by RH refining and casting is as follows (mass percentage): C, 0.06%; Mn, 0.90%; Si, 0.01%; P, 0.014%; S, 0.0042%; Als, 0.035%; %; Ti, 0.019%; the balance is Fe and unavoidable impurities. The continuous casting slab is heated to 1230°C in a walking heating furnace, the holding time is 155min, the final rolling temperature is 878°C, the front cooling is adopted, and the coiling temperature is 584°C to obtain a 3.5mm thick hot-rolled steel coil; hot-rolled coil After uncoiling, it is pickled and rolled continuously by a 5-stand rolling mill to obtain a 1.0mm thick rolled hard steel coil with a cold rolling reduction of 71.4%. After the hard-rolled steel coil is uncoiled, the steel plate enters the continuous annealing furnace after surface cleaning. The annealing soaking temperature is 778°C, the soaking holding time is 84s, and the smooth elongation is 1.63%.

[0034] The high-strength steel manufactured according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com