Method for avoiding steel plate surface hot sending direct loading cracks

A red delivery and direct loading technology, applied in the field of steelmaking, can solve the problems of long heating time of warm or cold billets, reduce the temperature of continuous casting slabs into the furnace, prolong the time of continuous casting slabs in the furnace, etc., and achieve short , Reduce gas consumption and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

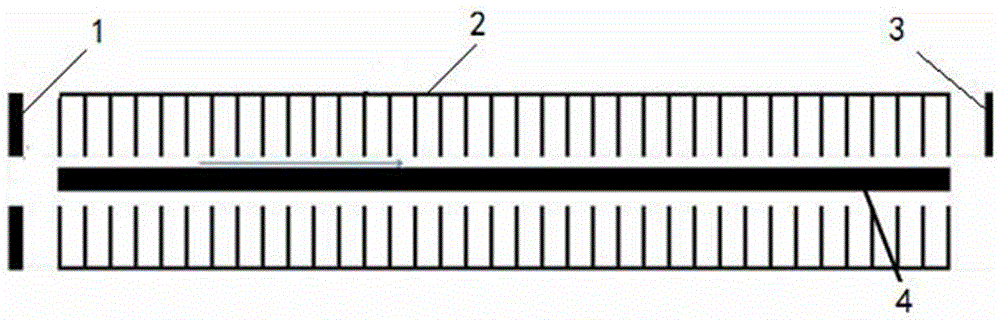

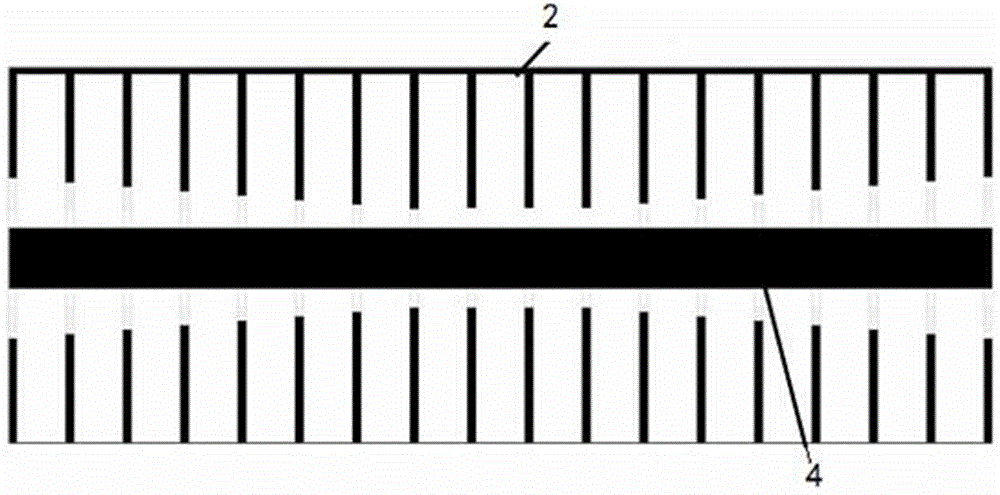

[0016] A new method to avoid "red-send direct loading cracks" on the surface of steel plates after rolling. Ni=0.10%~0.20%, the slab thickness is 260mm. Specific steps are as follows:

[0017] (1) After the continuous casting slab 4 is cut into a fixed length, the burrs on the continuous casting slab 4 are removed by the deburring device 1, and then transported to the specially designed rapid cooling device 2 area.

[0018] (2) The high-strength and high-density fast cooling device installed on the conveying roller table of the continuous casting slab 4 implements high-intensity and high-density impingement jet cooling on the upper surface of the continuous casting slab 4 for 121 seconds; spray cooling on the lower surface for 165 seconds, and measured The upper surface temperature of the continuous casting slab 4 was 545°C. The water quality of the continuous casting slab 4 cooling impact jet water adopts the continuous casting secondary cooling water, and the pressure is c...

Embodiment 2

[0023] A new method for avoiding "red-sending and straight-loading cracks" on the surface of steel plates after rolling. Ni=0.30%~0.50%; slab thickness=300mm. Specific steps are as follows:

[0024] (1) After the continuous casting slab 4 is cut into a fixed length, the burrs on the continuous casting slab 4 are removed by the deburring device 1, and then transported to the specially designed rapid cooling device 2 area.

[0025] (2) Through the specially designed high-strength and high-density fast cooling device installed on the conveying roller table of the continuous casting slab 4, the continuous casting slab 4 is subjected to high-strength and high-density impinging jet cooling on the upper surface for 145 seconds; spray cooling on the lower surface for 200 seconds Seconds, the surface temperature of the upper continuous casting slab 4 was measured to be 528°C. The water quality of the continuous casting slab 4 cooling impact jet water adopts the continuous casting sec...

Embodiment 3

[0030] A new method for avoiding "red-sending and straight-loading cracks" on the surface of steel plates after rolling. Ni=0.64%~0.66%, the slab thickness is 300mm. Specific steps are as follows:

[0031] (1) After the continuous casting slab 4 is cut into a fixed length, the burrs on the continuous casting slab are removed by the deburring device 1, and then transported to the specially designed rapid cooling device 2 area.

[0032] (2) Through the specially designed high-strength and high-density fast cooling device installed on the conveying roller table of the continuous casting slab 4, the continuous casting slab 4 is subjected to high-strength and high-density impinging jet cooling on the upper surface for 150 seconds; spray cooling on the lower surface for 210 seconds Seconds, the surface temperature of the upper continuous casting slab 4 was measured to be 511°C. The water quality of the continuous casting slab 4 cooling impact jet water adopts the continuous castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com