Anorthite light refractory brick and preparation method thereof

A technology of anorthite and refractory bricks, which is applied in the field of anorthite lightweight refractory bricks and its preparation, can solve the problems of low thermal conductivity, small pore size, and high porosity, and achieve excellent performance, remarkable energy-saving effect, and convenient production organization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

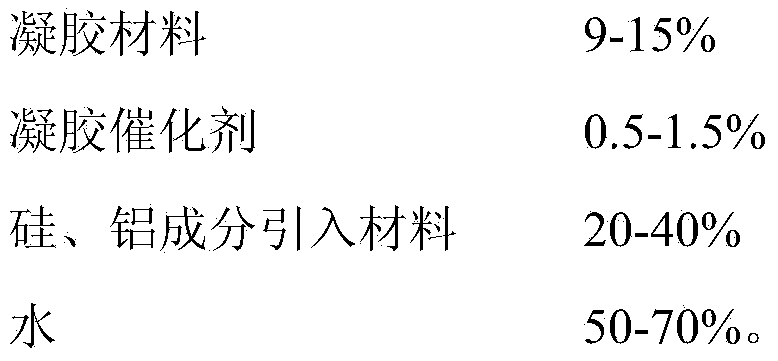

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

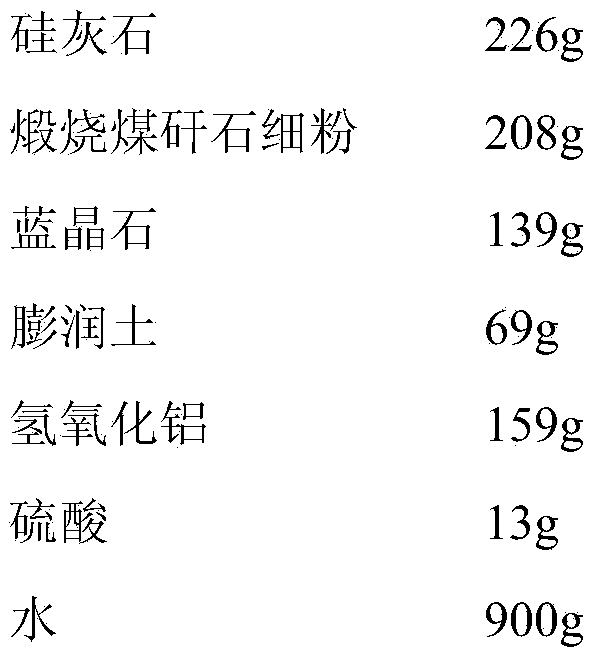

[0038] Ingredients:

[0039]

[0040] crafting process

[0041] (1) Measure and prepare raw materials according to the above ratio, clinker (anorthite brick return material, the same below) is optional;

[0042] (2) First add wollastonite to water and mix;

[0043] (3) Then, control the temperature at 30°C, add sulfuric acid, and stir to form a gel system;

[0044] (4) Add the remaining powder in turn, and finally add bentonite to form a uniform mixture of various raw materials; add appropriate amount of water as needed;

[0045] (5) Drying and calcination process

[0046] Pour the mixed material into a mold of suitable size, maintain at room temperature or heat appropriately (during this process, the temperature is controlled at 20°C) for 12 hours to form a preliminarily cured wet billet, and then remove the mold and transfer the wet billet to the drying equipment for drying dry;

[0047] Put the dried brick into the calcination furnace, and after 2 hours, it will rea...

Embodiment 2

[0053] Ingredients:

[0054]

[0055] crafting process

[0056] (1) Measure and prepare raw materials according to the above ratio, clinker (anorthite brick return material, the same below) is optional;

[0057] (2) First add wollastonite to water and mix;

[0058] (3) Then, control the temperature at 50°C, add sulfuric acid, and stir to form a gel system;

[0059] (4) Add the remaining powder in turn to form a uniform mixture of various raw materials; add appropriate amount of water as needed;

[0060] (5) Drying and calcination process

[0061] Pour the mixed material into a mold with a suitable size, control the temperature at 105°C, and keep it for 1 hour to form a preliminarily cured wet billet, then remove the mold and transfer the wet billet to the drying equipment for drying;

[0062]Put the dried billet into the calcination furnace, and after 12 hours, it will reach 1400°C. The calcination and drying time should be adjusted according to the heating rate. Burn ...

Embodiment 3

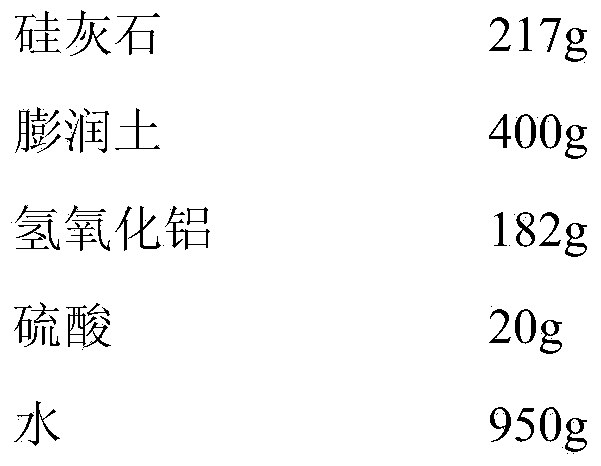

[0068] Ingredients:

[0069]

[0070]

[0071] crafting process

[0072] (1) Measure and prepare raw materials according to the above ratio, clinker (anorthite brick return material, the same below) is optional;

[0073] (2) First add wollastonite to water and mix;

[0074] (3) Then, control the temperature at 40°C, add sulfuric acid, and stir to form a gel system;

[0075] (4) Add the remaining powder in turn to form a uniform mixture of various raw materials; add appropriate amount of water as needed;

[0076] (5) Drying and calcination process

[0077] Pour the mixed material into a mold of suitable size, maintain at room temperature or heat appropriately (during this process, the temperature is controlled at 50°C) for 18 hours to form a preliminarily cured wet billet, and then remove the mold and transfer the wet billet to the drying equipment for drying dry;

[0078] Put the dried billet into the calcination furnace, and after 6 hours of rapid heating, it will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com