Reciprocating-piston compressor body

A compressor and reciprocating technology, applied in the field of compressors, can solve the problems that cannot fully reflect the advantages of the crank and slider mechanism, and achieve the effects of low cost, easy transportation, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

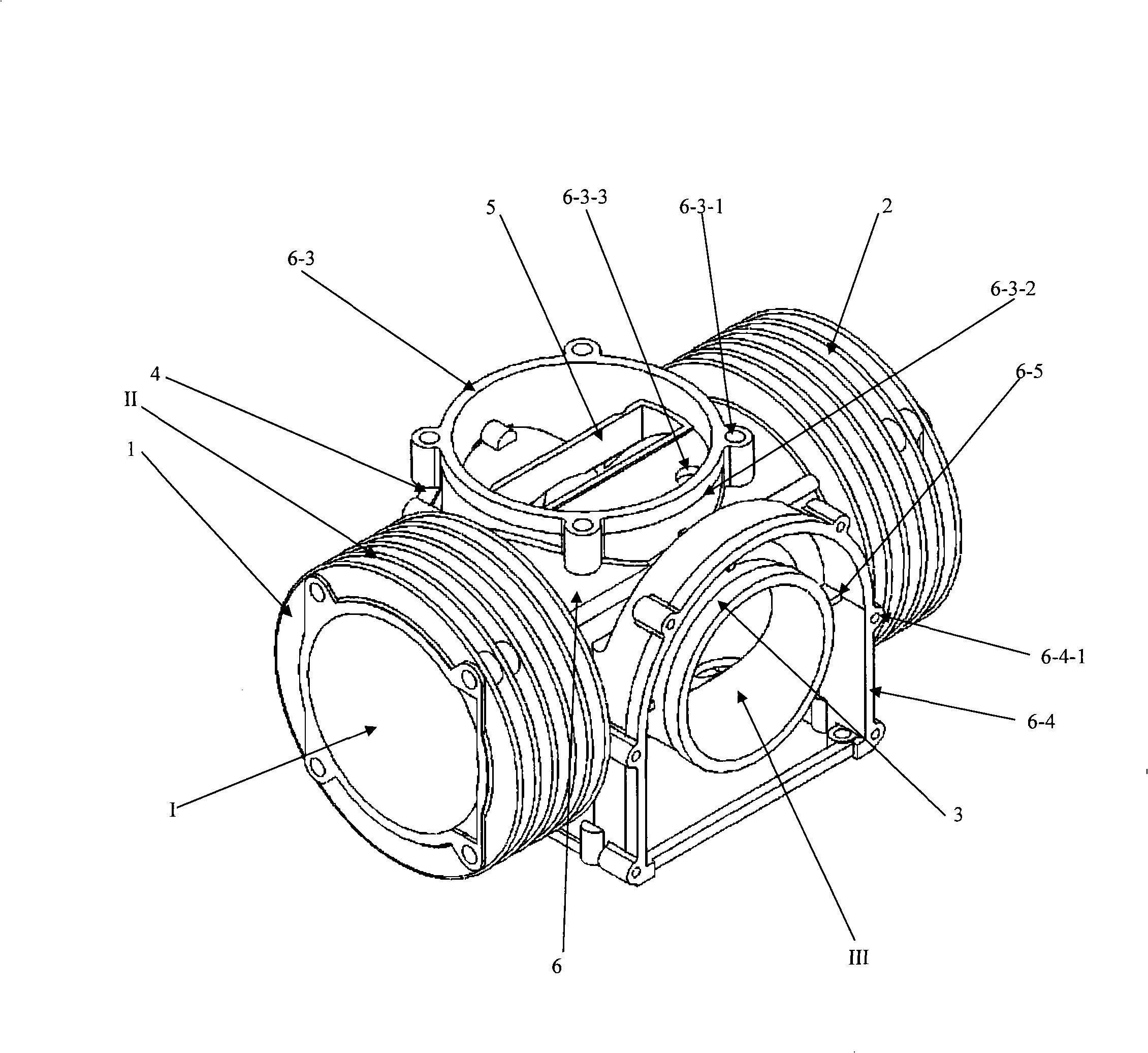

[0025] The first embodiment of the present invention provides a compressor body adopting a crank circular slider mechanism. The compressor adopts a piston with a working part at both ends and a single working part piston that functions as a starting balance slider. The compressor constitutes an inverted T-shaped three-cylinder compressor.

[0026] According to the structural principle of the above-mentioned crank circular slider mechanism, the body needs to provide movement space for the piston and the dynamic balance slider, and provide support for the crankshaft.

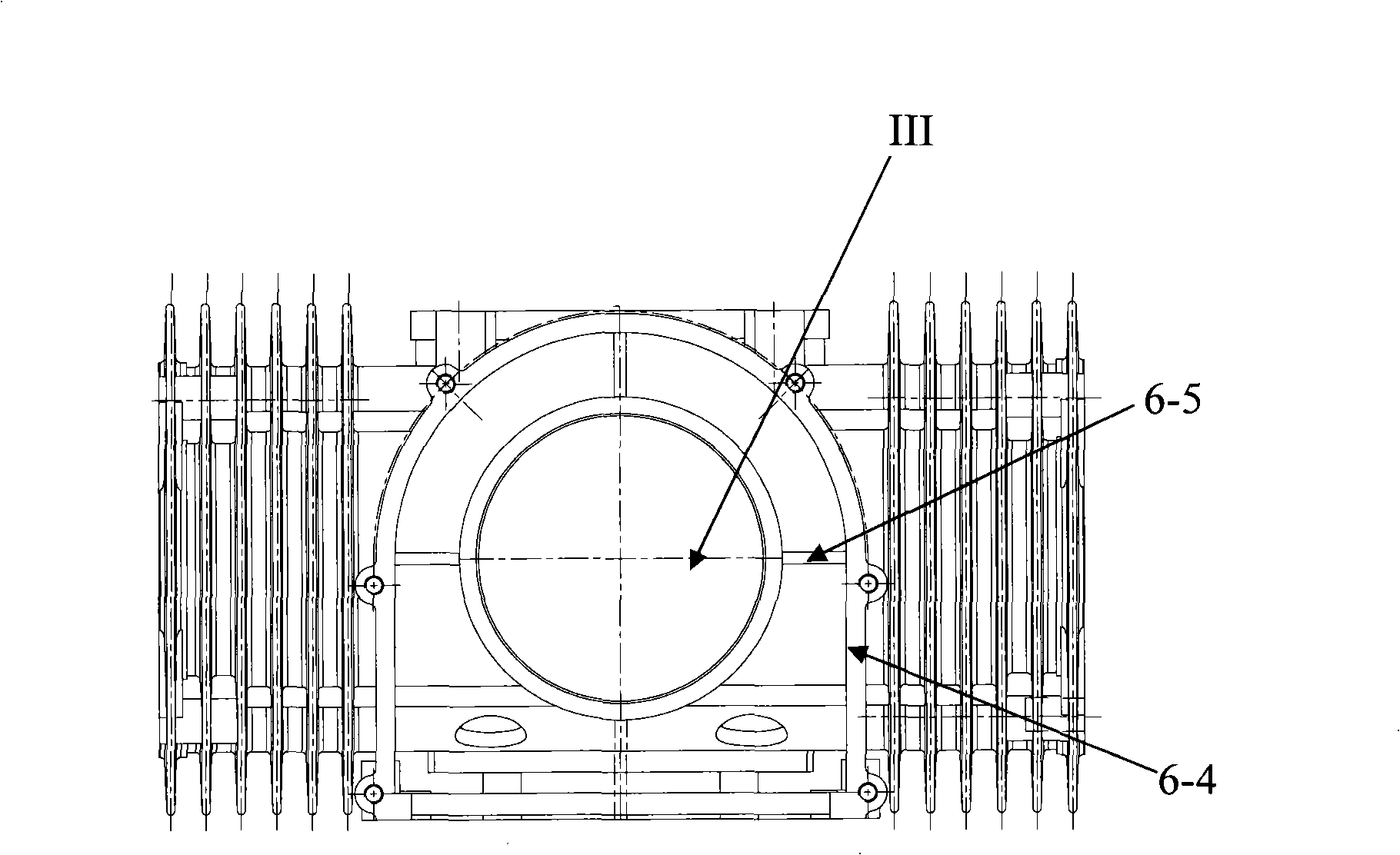

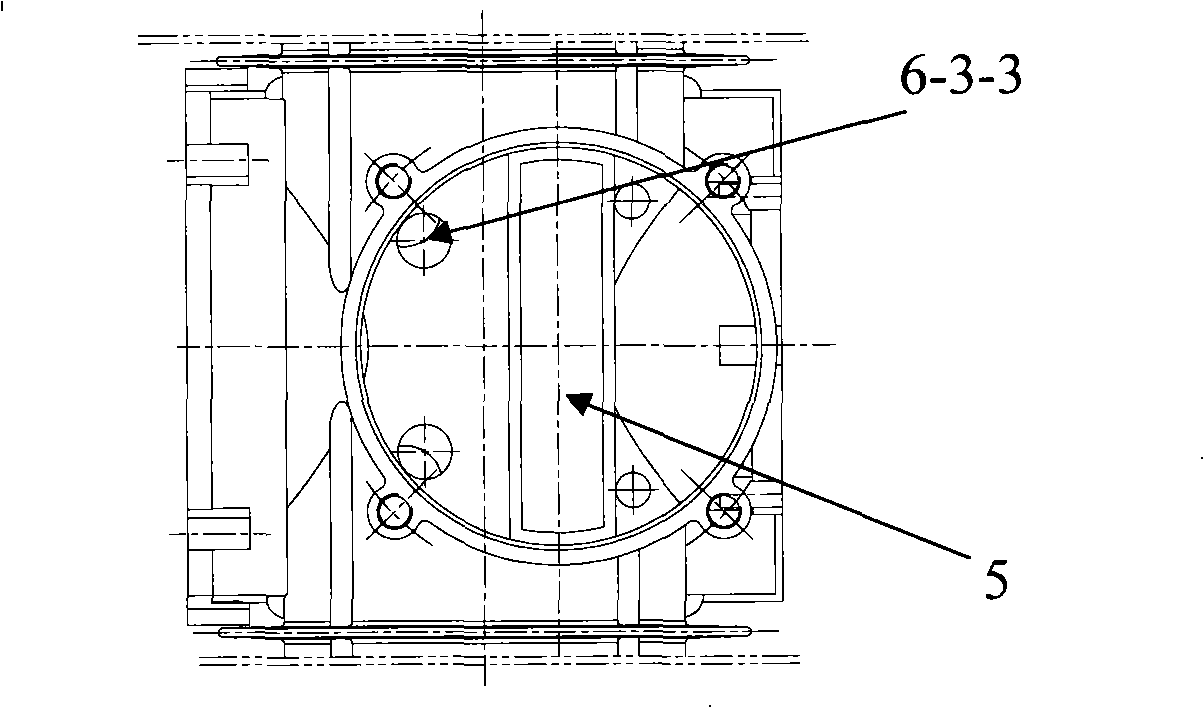

[0027] Please see figure 1 , The figure shows the axial view of the body, from which the basic structure of the body can be seen. The body includes a first cylinder liner 1, a second cylinder liner 2, a first main bearing hole 3, a second main bearing hole 4, a slideway 5, and the above-mentioned components are connected together by a base 6 with an intermediate position as a basic frame. Also, please see Figure 2-Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com