Titanium extracting tailing-titanium gypsum based foam concrete and preparation method thereof

A technology of foam concrete and titanium tailings extraction, applied in ceramic products, other household appliances, applications, etc., can solve the problems of low density, pollute the environment, cannot achieve large consumption, etc., and achieve the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

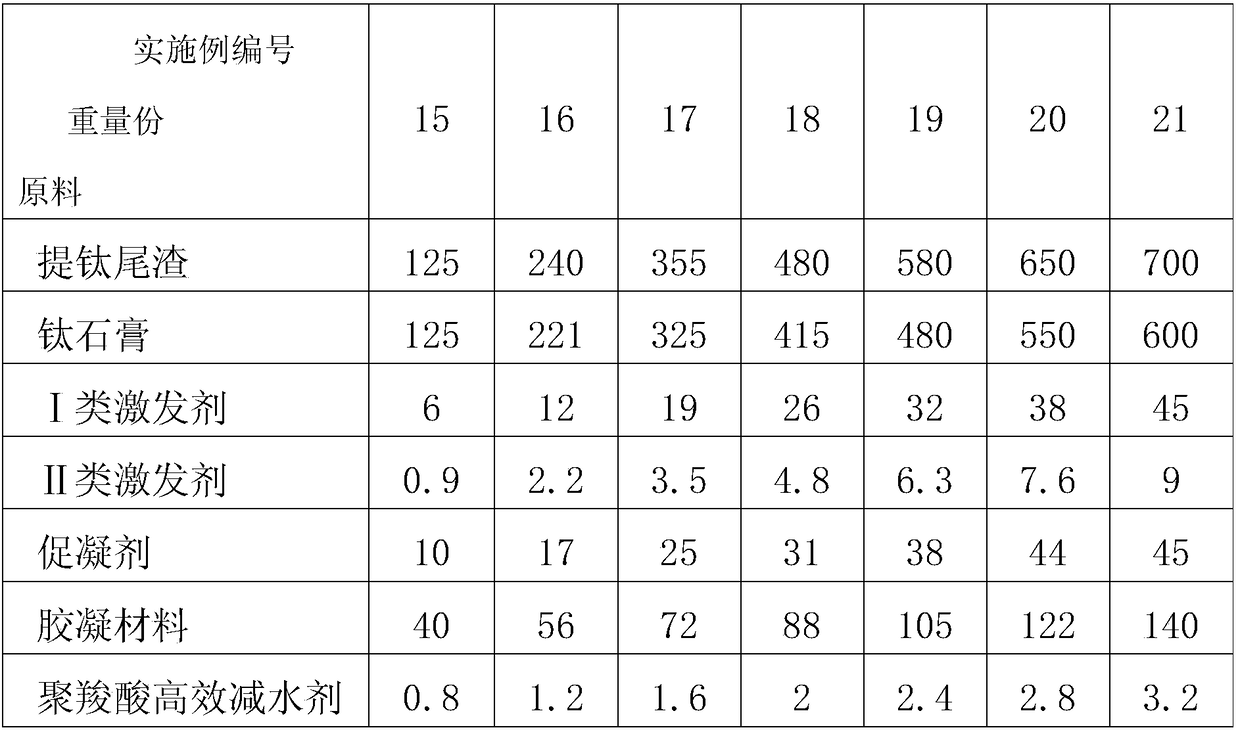

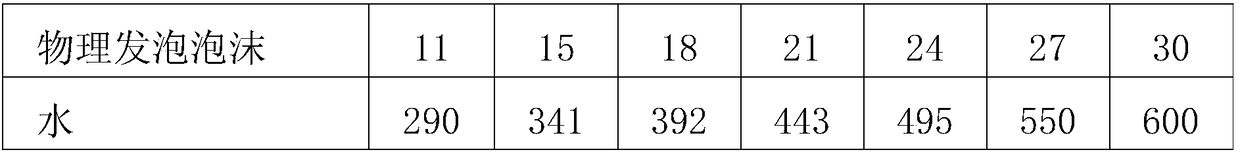

Examples

Embodiment 1

[0041] A method for preparing titanium tailings-titanium gypsum-based foam concrete, comprising the following steps:

[0042] a. Ingredients: 274.95g of titanium tailings, 274.95g of titanium gypsum, 13g of quicklime, 2.6g of sodium sulfate, 26g of sulphoaluminate cement, 61.1g of ordinary Portland cement, 1.3g of polycarboxylic acid superplasticizer, 30g of physical foaming foam and 390g of water are used to take the raw materials of each component;

[0043] b. Grinding: Grinding the titanium tailings (equipment in the prior art such as ball mill, vibrating mill, jet mill, etc. can be used for grinding) to a median particle size of 10-14 μm; grinding titanium gypsum (can be ground) Ordinary large ball mill or planetary ball mill) to a median particle size of 16-19 μm;

[0044] c. Mixing and stirring: mix titanium tailings, titanium gypsum, Class I activator, coagulant, and gelling materials (mixing equipment is the prior art equipment) into a mixture; water and polycarboxyli...

Embodiment 2

[0050] A method for preparing titanium tailings-titanium gypsum-based foam concrete, comprising the following steps:

[0051] a. Ingredients: 401.85g of titanium tailings, 401.85g of titanium gypsum, 19g of quicklime, 4.75g of sodium sulfate, 38g of sulphoaluminate cement, 89.3g of ordinary Portland cement, 0.95g of polycarboxylic acid superplasticizer, Physical foaming foam 24g, water 490g take each component raw material;

[0052] Others are the same as embodiment 1, omitted;

[0053] After testing, the strength of the titanium tailings-titanium gypsum-based foam concrete in this embodiment is 5.64MPa, and the bulk density is 837kg / m 3 .

Embodiment 3

[0055] A method for preparing titanium tailings-titanium gypsum-based foam concrete, comprising the following steps:

[0056] a. Ingredients: 367.2g of titanium tailings, 367.2g of titanium gypsum, 17g of quicklime, 2.5g of sodium sulfate, 17g of sulphoaluminate cement, 81.6g of ordinary Portland cement, 1.7g of polycarboxylic acid superplasticizer, Physical foaming foam 17g, water 467.5g take each component raw material;

[0057] Others are the same as embodiment 1, omitted;

[0058] After testing, the strength of the titanium tailings-titanium gypsum-based foam concrete in this embodiment is 7.54MPa, and the bulk density is 967kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com