Systems and methods for capturing natural gas liquids from oil tank vapors

a technology of oil tank vapor and natural gas, which is applied in the direction of liquid hydrocarbon mixture recovery, lighting and heating apparatus, solidification, etc., can solve the problems of little or no financial return and considerable environmental pollution, and achieve the effect of avoiding ice formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

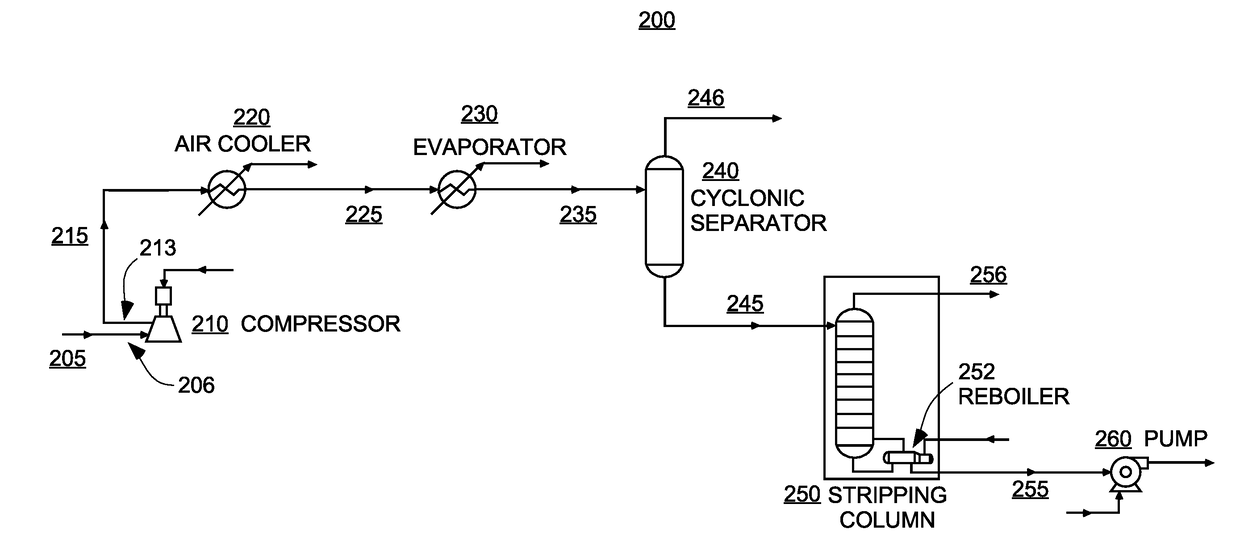

[0051]Commonly overlooked, tank vapors can be a big environmental problem. Some oil producers vent or combust oil vapors, ignoring environmental regulations while trying to minimize operating cost. Some use Vapor Recover Units (VRUs) to compress oil vapors into sales lines.

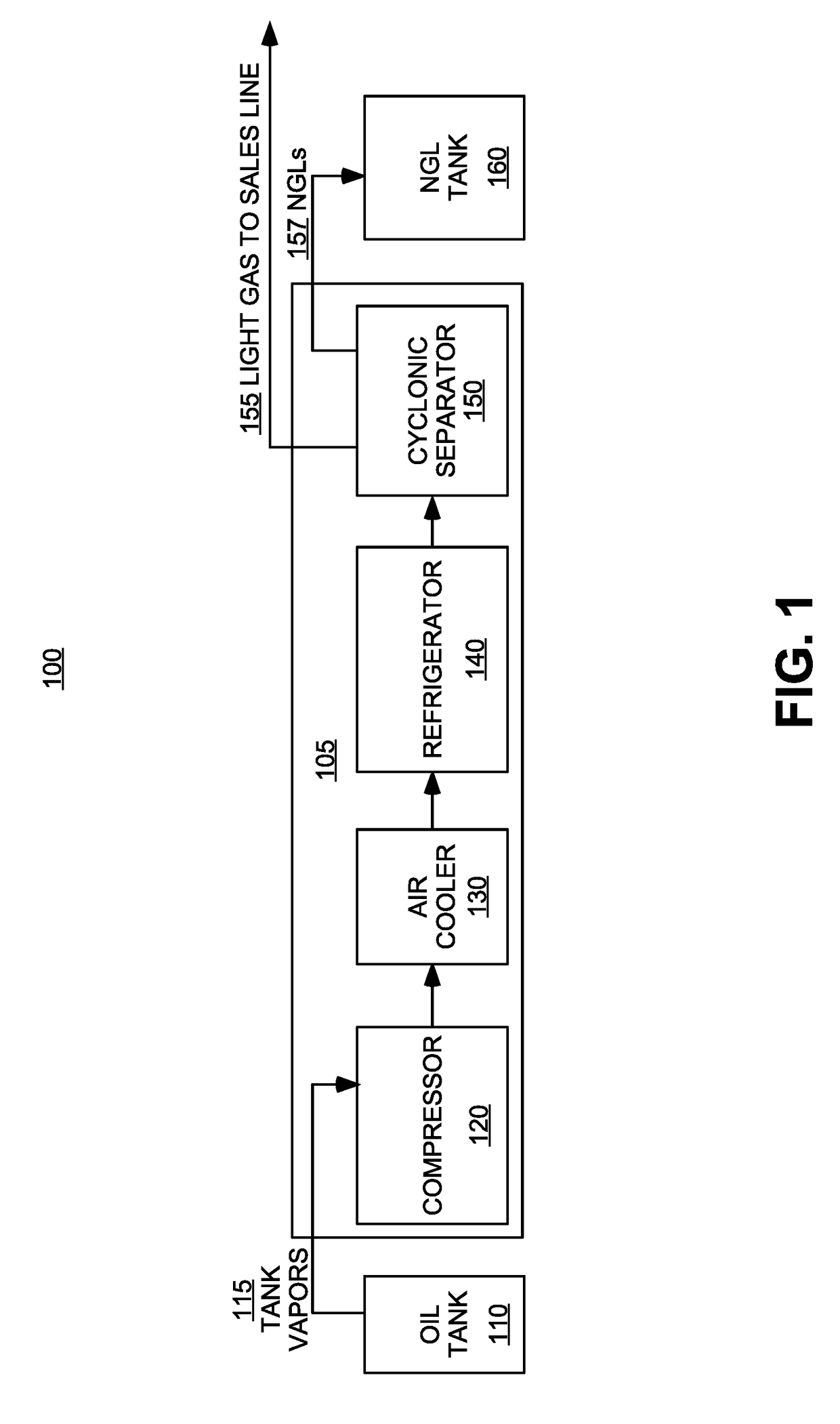

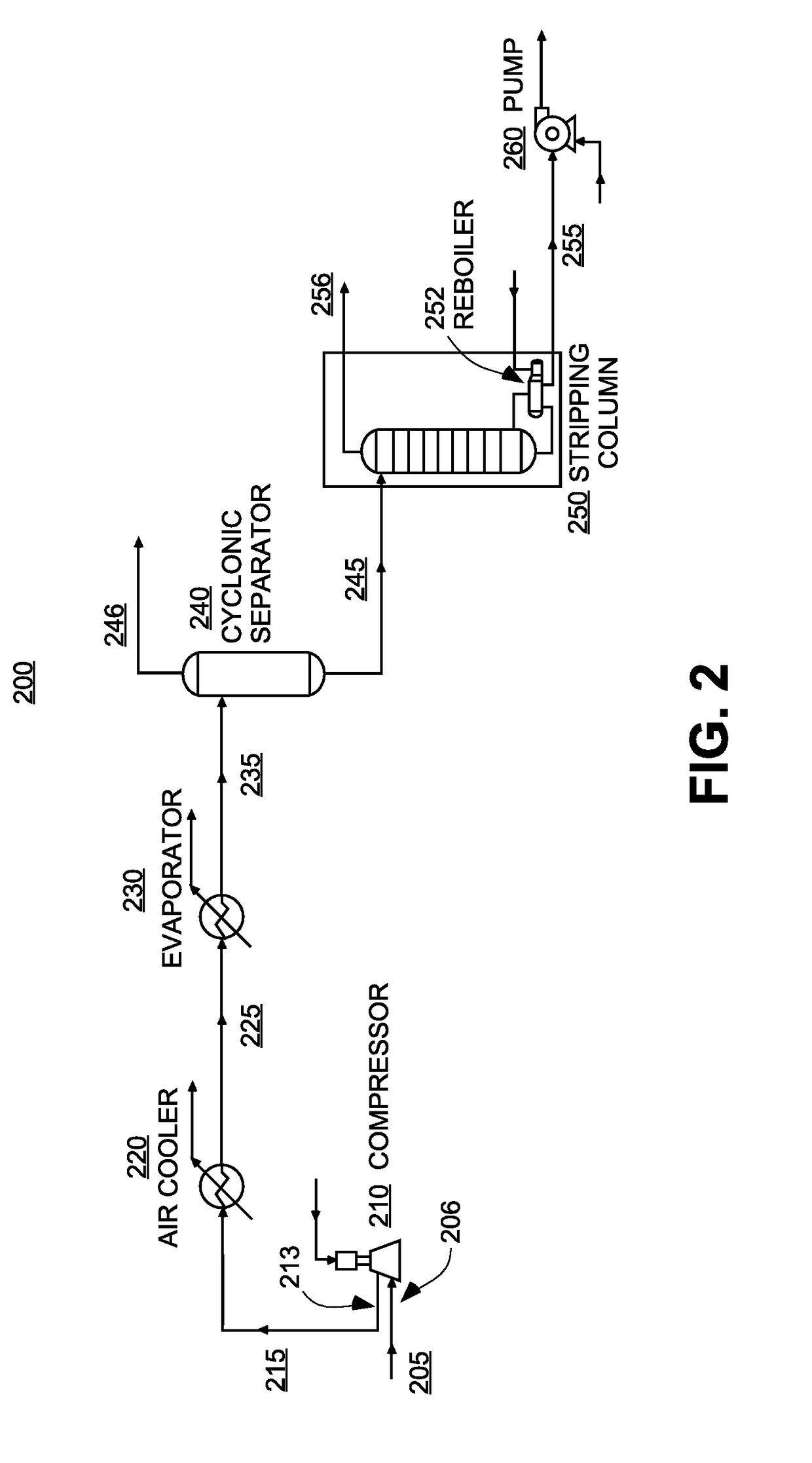

[0052]To cut oil vapor emission and carbon emission, reduce operating expenses, while capitalizing on natural gas liquids (NGLs) present in tank vapors, embodiments of the present invention capture and liquefy tank hydrocarbon vapors, and actively reject oxygen from the liquid hydrocarbon product, so that instead of being flared or disposed of at minimal return as sales-line gas, they can be shipped off to the market and sold as high-quality, valuable liquid fuels. In addition to drastically cutting environmental impacts, low pressure NGL-rich vapors from oil tank batteries can thus be monetized, providing a much better economic return than using a Vapor Recovery Unit (VRU) alone. Oil vapor or gas processing units...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com