Carbonization reinforced regenerated aggregate, and preparation method and applications thereof

A technology of recycled aggregate and aggregate, applied in the field of building materials, can solve the problems of micro-cracks, limited application, weak interface, etc., to achieve the effect of enhancing strength, realizing permanent storage, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

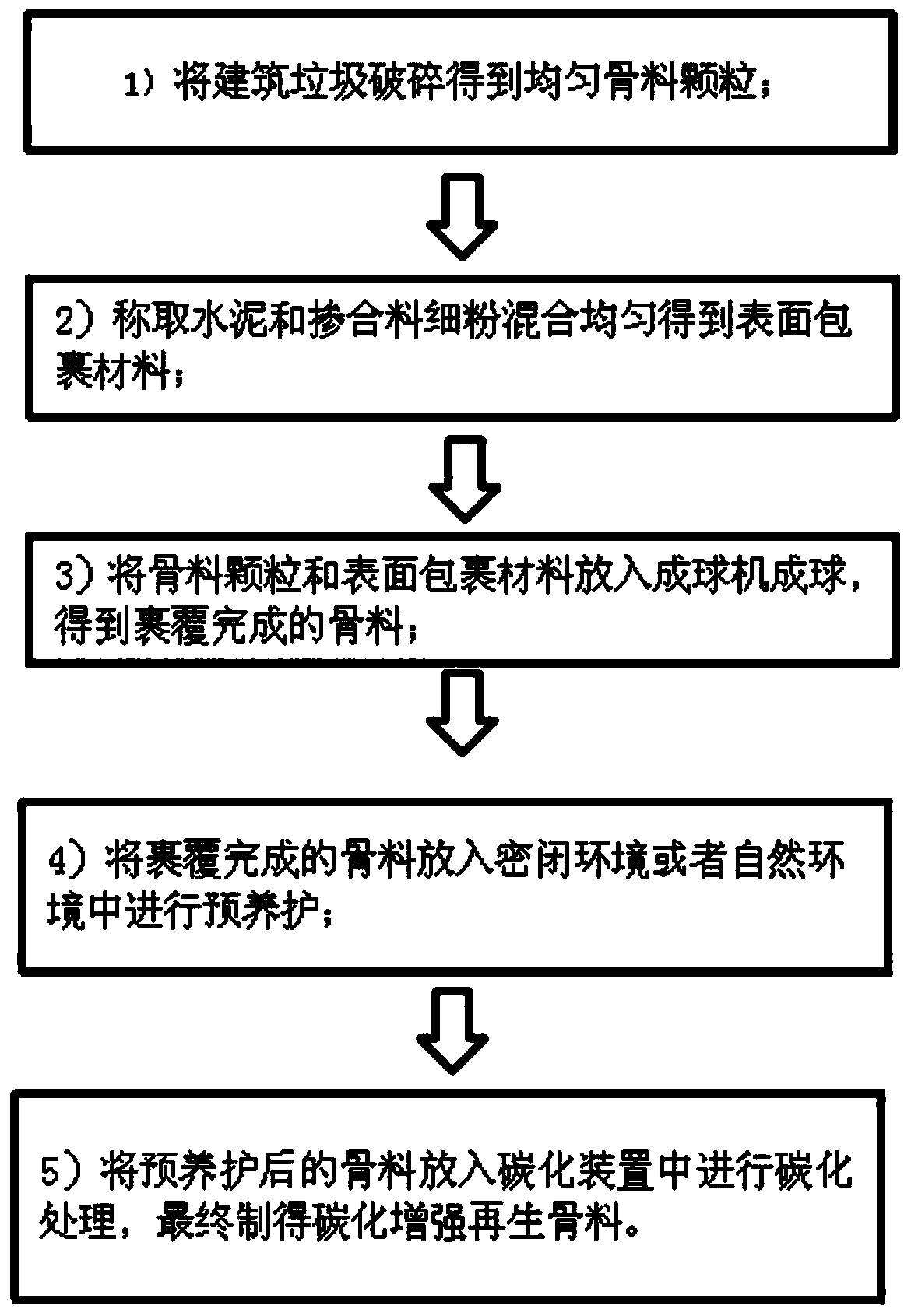

Method used

Image

Examples

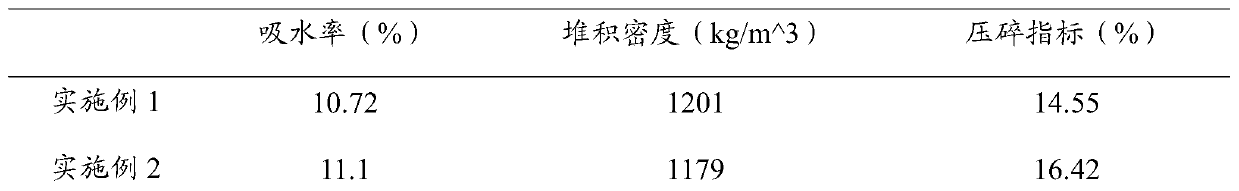

Embodiment 1

[0029] A method for preparing carbonization-enhanced recycled aggregates. In this embodiment, the construction waste is bricks, and the fine powder of the admixture is fine bricks. The specific preparation process is as follows: the bricks are crushed to obtain uniform brick aggregate particles with a particle size of 5-16 mm. Weigh 90 parts by mass of cement and 10 parts by mass of fine brick powder and mix evenly to obtain a surface wrapping material. Weigh 30 parts by mass of the surface wrapping material and 70 parts by mass of brick aggregate particles, mix them, and put them into the ball forming machine. Weigh water according to the water-cement ratio (mass ratio of water to surface wrapping material) of 0.20, spray water into the material pan of the ball forming machine, and obtain the finished brick aggregate after rolling. Put the wrapped brick aggregate into a sealed container for pre-curing, and the pre-curing time is 3 days. Then, the pre-cured brick aggregate is...

Embodiment 2

[0031] A method for preparing carbonization-enhanced recycled aggregates. In this embodiment, the construction waste is bricks, and the admixture fine powder is fly ash. The specific preparation process is as follows: the bricks are crushed to obtain uniform brick aggregate particles with a particle size of 5-16 mm. Weigh 80 parts by mass of cement and 20 parts by mass of fly ash and mix uniformly to obtain a surface coating material. Weigh 25 parts by mass of the surface wrapping material and 75 parts by mass of brick aggregate particles, mix them, and put them into the ball forming machine. Weigh water according to the water-cement ratio (mass ratio of water to surface wrapping material) of 0.20, spray water into the material pan of the ball forming machine, and obtain the finished brick aggregate after rolling. The wrapped brick aggregate is pre-cured in a sealed container, and the pre-curing time is 3 days. Then, the pre-cured brick aggregate is put into a carbonization d...

Embodiment 3

[0033] A method for preparing carbonization-enhanced recycled aggregates. In this embodiment, the construction waste is bricks, and the admixture fine powder is fly ash and muck. The specific preparation process is as follows: the bricks are crushed to obtain uniform brick aggregate particles with a particle size of 5-16 mm. Weigh 70 parts by mass of cement, 20 parts by mass of fly ash, and 10 parts by mass of muck to mix evenly to obtain a surface coating material. Weigh 25 parts by mass of the surface wrapping material and 75 parts by mass of brick aggregate particles, mix them, and put them into the ball forming machine. Weigh water according to the water-cement ratio (mass ratio of water to surface wrapping material) of 0.18, spray water into the material pan of the ball forming machine, and obtain the coated brick aggregate after rolling. The covered brick aggregate is pre-cured in a sealed container, and the pre-curing time is 7 days. Then put the pre-cured brick aggreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com