Production method of microalgae grease based on low-carbon emission recycling of domestic sewage

A technology for domestic sewage and microalgae oil, which is applied in the production of fat oil/fat, chemical instruments and methods, and fat production. It can solve the problems of low carbon recovery rate and high cost of microalgae oil, reduce pollution, reduce production costs, The effect of high shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

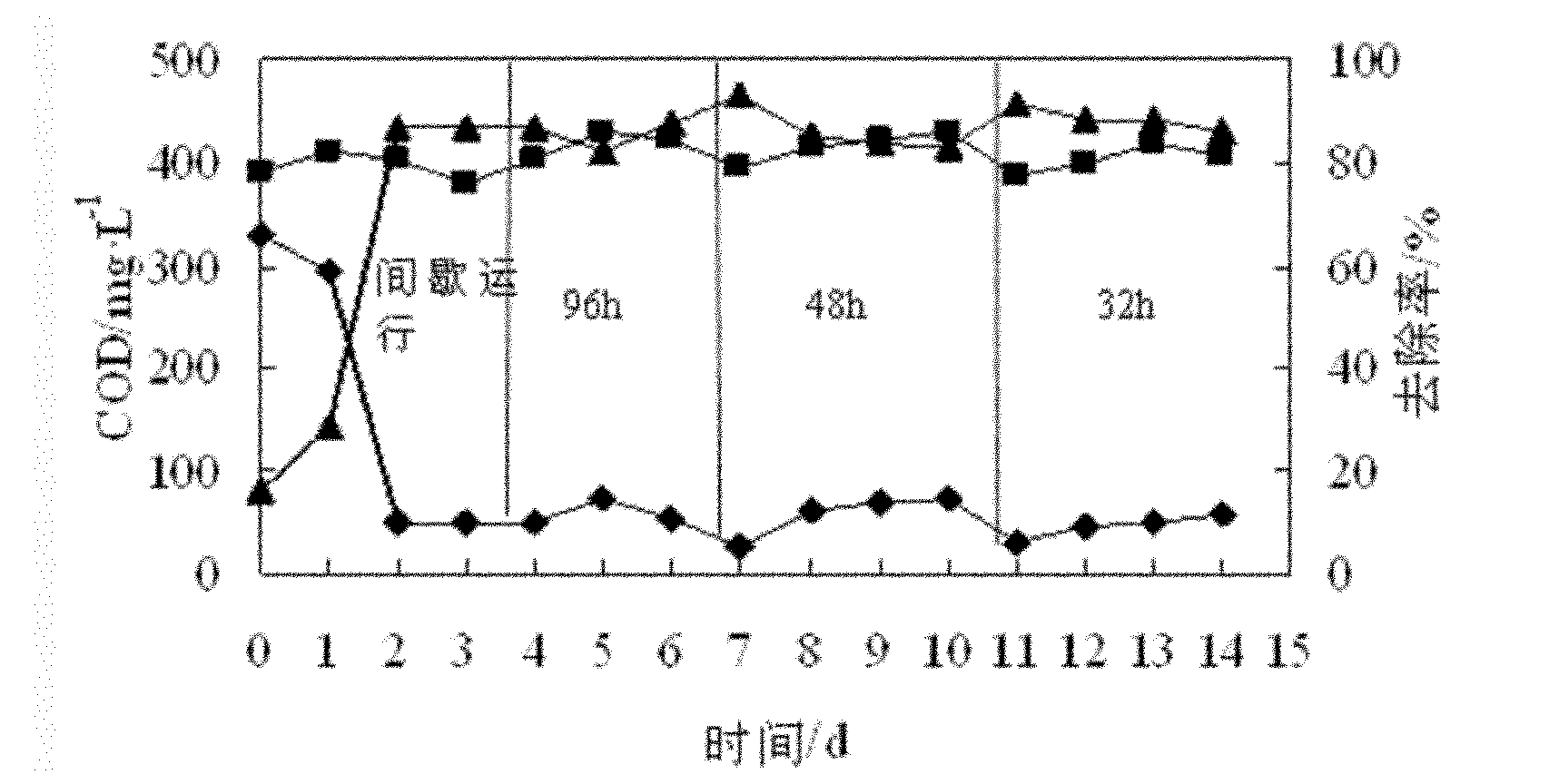

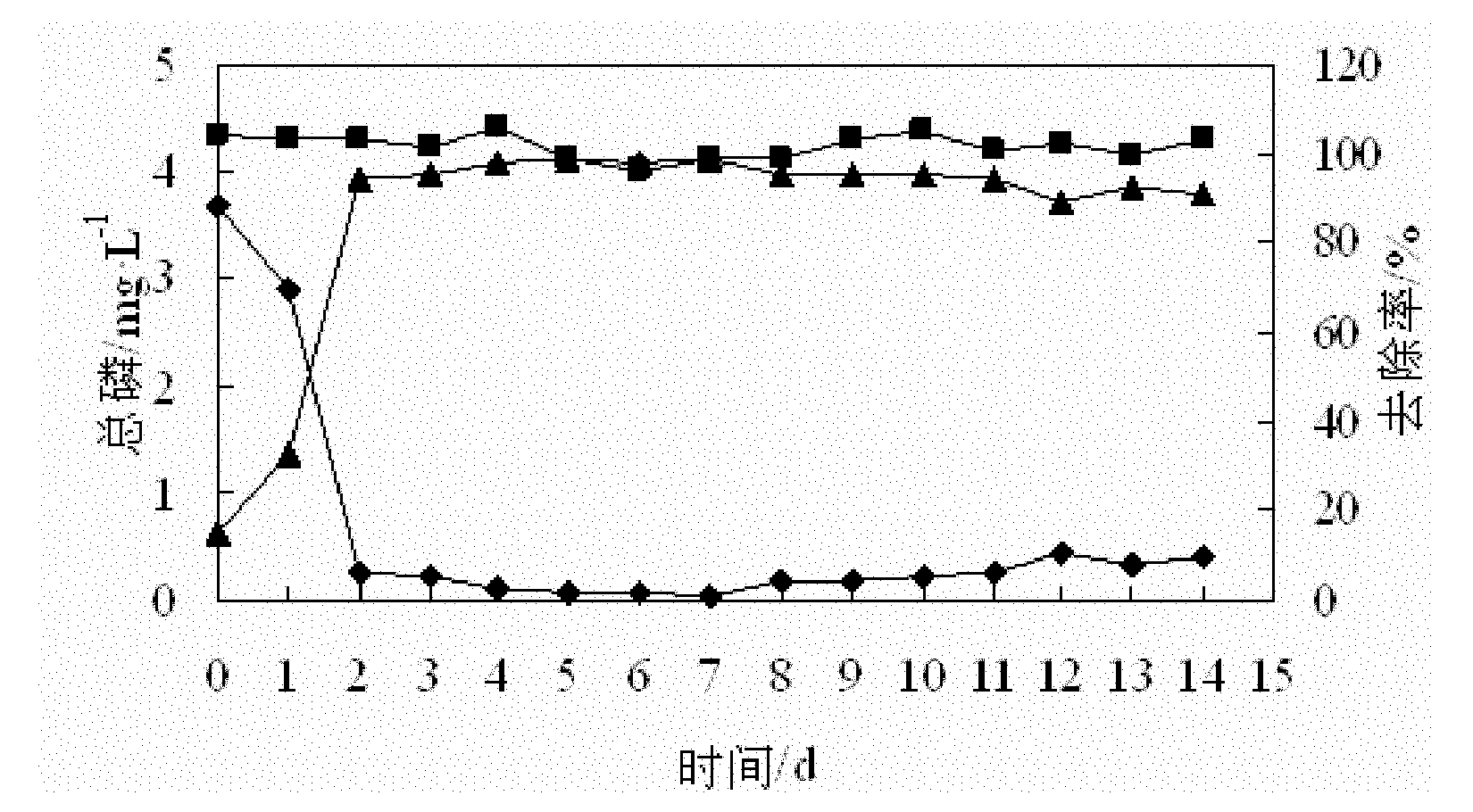

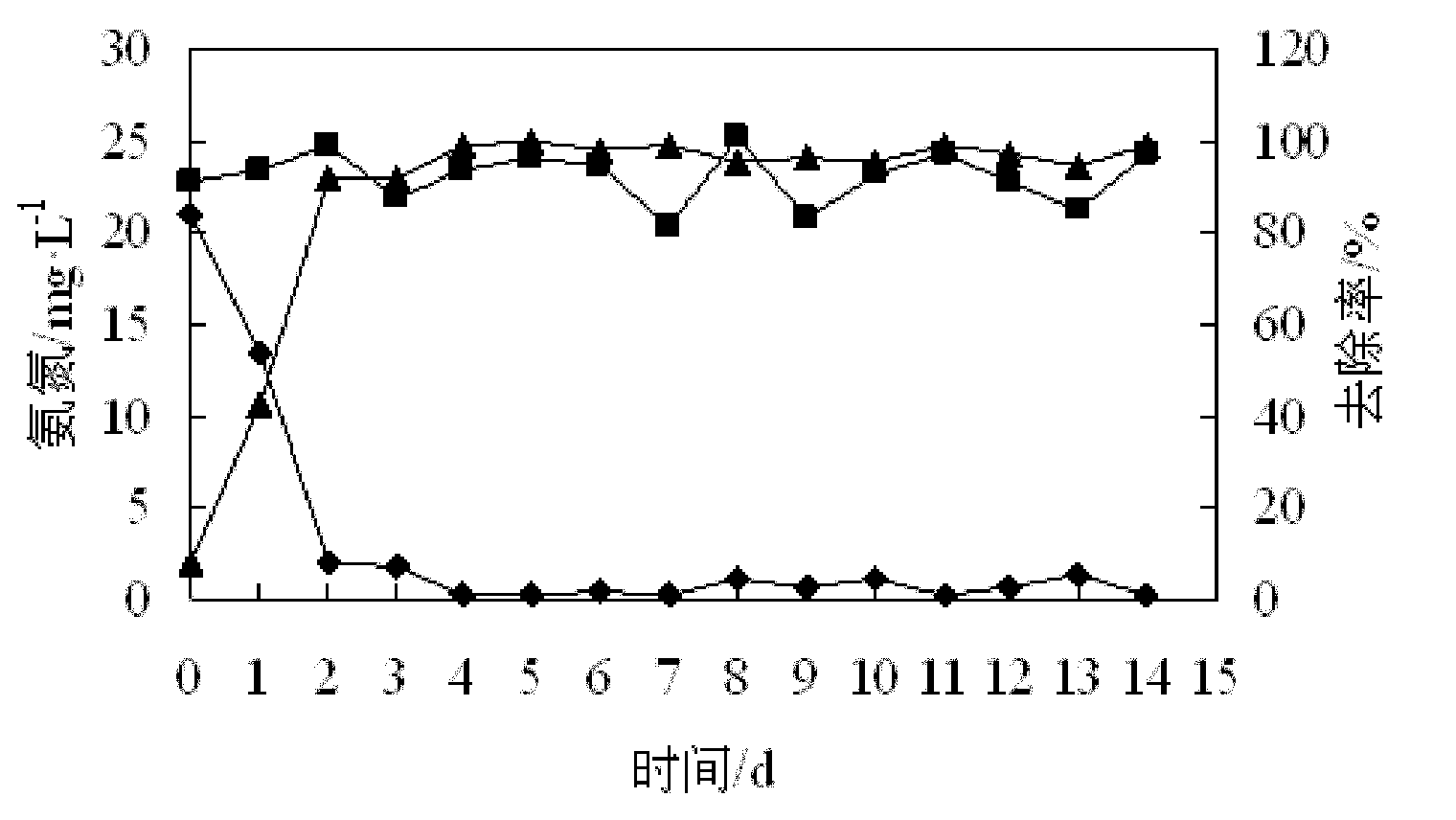

[0009] Embodiment 1: In this embodiment, the microalgae oil production method based on low-carbon emission of domestic sewage is carried out according to the following steps: sterilize the waste water that has undergone primary treatment, and then introduce it into a photobioreactor; Microalgae were then inoculated into the photobioreactor with CO 2 As an aeration gas source for cultivation, the cultivation process runs intermittently until the microalgae grows logarithmically and the density reaches above 0.2g / L, and then changes to continuous water inflow. During the continuous water inflow, the pH is always kept at 5-10, and the collected The microalgae in the water are dehydrated and then the oil is extracted to obtain the microalgae oil.

specific Embodiment approach 2

[0010] Embodiment 2: This embodiment differs from Embodiment 1 in that: the wastewater is domestic sewage, beer wastewater or molasses wastewater. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the sterilization pretreatment adopts high temperature and high pressure, calcium hypochlorite, ozone, Cl 2 , chlorine dioxide or ultraviolet sterilization. Other steps and parameters are the same as those in the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com