Comprehensive utilization process for low-carbon-emission Fischer-Tropsch synthesis tail gas

一种费托合成、碳排放的技术,应用在氢/合成气生产、碳氢化合物、碳氢化合物等方向,能够解决尿素合成装置建设成本高昂、尾气没有给予关注、设备投资高等问题,达到提高能源利用效率、解决氢源不足、降低能源成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

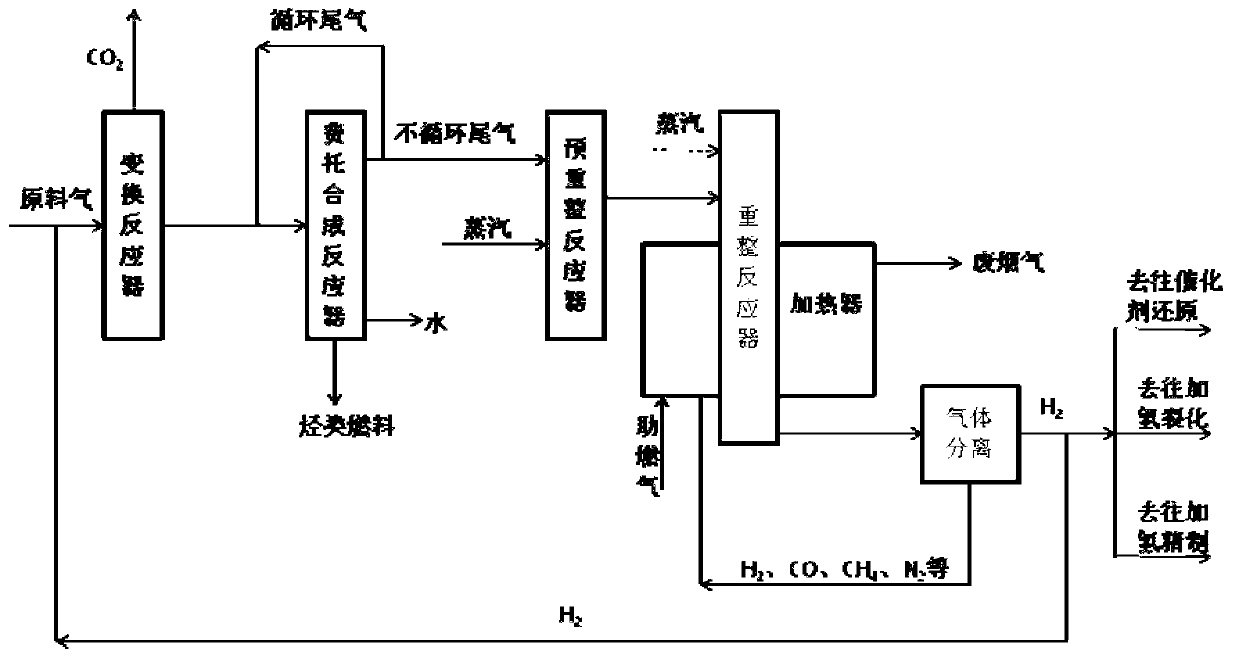

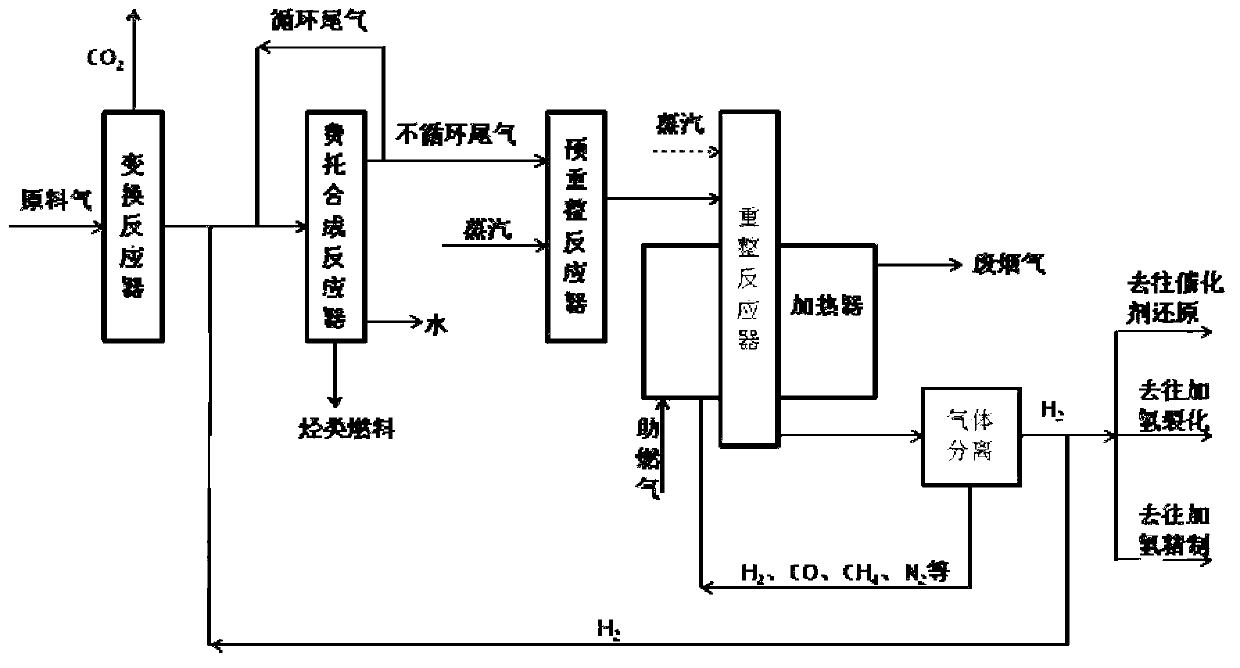

[0050] Embodiment one has used the raw material gas identical with comparative example, and according to figure 1 The process shown returns the produced hydrogen before the shift reactor.

[0051] 1) Raw gas refers to the gas containing carbon monoxide and hydrogen produced by gasification of coal or biomass, and the 5890NM 3 Raw material gas with a low hydrogen-to-carbon ratio per hour, wherein the molar ratio of hydrogen to carbon monoxide in the raw gas is 0.1, and it is transported to the shift reactor. Under the action of a catalyst, it is converted into hydrogen and carbon dioxide, and the 2120NM 3 / h of carbon monoxide is converted into carbon dioxide and the same volume of hydrogen is generated. After removing carbon dioxide, a shift gas of 4480 NM is produced for Fischer-Tropsch synthesis. 3 / h, wherein the molar ratio of hydrogen to carbon monoxide in the shift gas is 1.7, and the effective synthesis gas accounts for more than 88% of the total gas volume.

[0052]...

Embodiment 2

[0062] Adopt the tail gas treatment mode identical with embodiment one, still according to figure 1 The process shown returns the produced hydrogen before the shift reactor.

[0063] 1) Raw gas refers to the gas containing carbon monoxide and hydrogen produced by gasification of coal or biomass, and the 5950NM 3 Raw material gas with a low hydrogen-to-carbon ratio per hour, wherein the molar ratio of hydrogen to carbon monoxide in the raw gas is 1.1, and it is transported to the shift reactor. Under the action of a catalyst, it is converted into hydrogen and carbon dioxide, and the 256NM 3 / h of carbon monoxide is converted into carbon dioxide and the same volume of hydrogen is generated. After removing carbon dioxide, a shift gas of 4530NM is produced for Fischer-Tropsch synthesis. 3 / h, where the molar ratio of hydrogen to carbon monoxide in the shift gas is 1.43, and the effective synthesis gas accounts for more than 88% of the total gas volume.

[0064] 2) After mixing ...

Embodiment 3

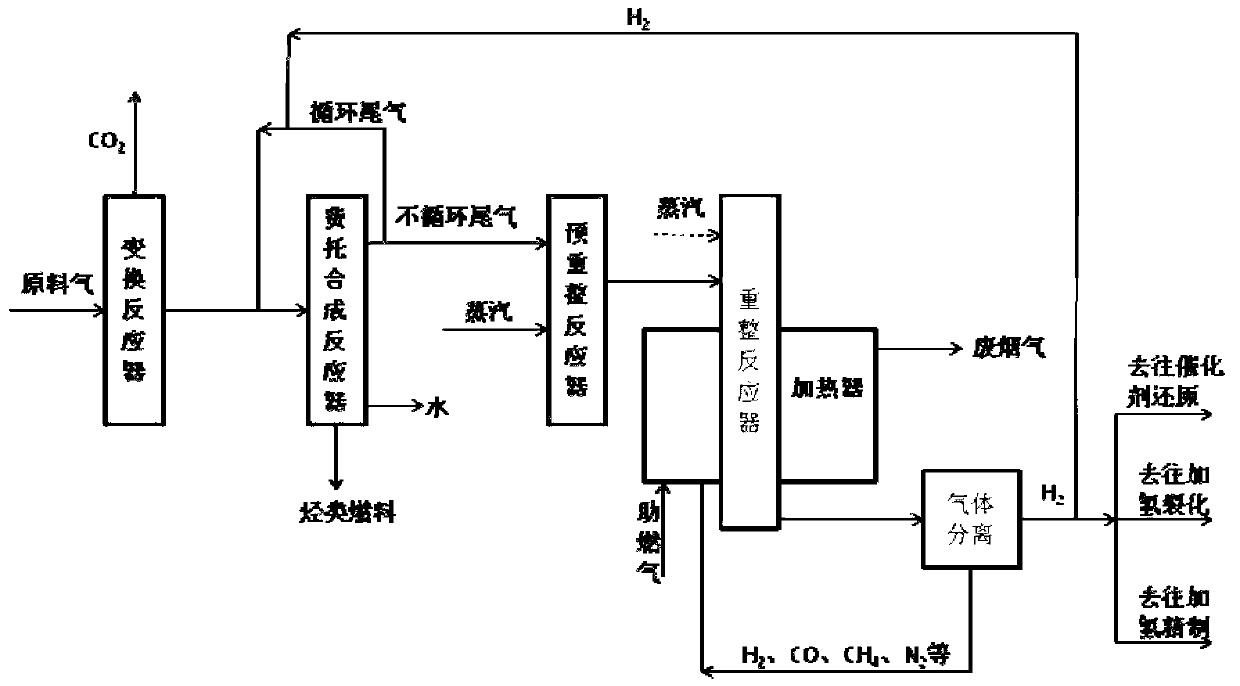

[0074] Embodiment three has used the change of gas composition and gas volume as shown in table 4 raw material gas, and according to figure 2 The process shown returns the produced hydrogen after the shift reactor.

[0075] 1) Raw gas refers to the gas containing carbon monoxide and hydrogen produced by gasification of coal or biomass, and the 5900NM 3 Raw material gas with a low hydrogen-to-carbon ratio per hour, wherein the molar ratio of hydrogen to carbon monoxide in the raw gas is 2.2, which is transported to the shift reactor. Under the action of a catalyst, it is converted into hydrogen and carbon dioxide, and the 300NM 3 / h of carbon monoxide is converted into carbon dioxide and the same volume of hydrogen is generated. After removing carbon dioxide, a shift gas of 5090NM is produced for Fischer-Tropsch synthesis. 3 / h, wherein the molar ratio of hydrogen to carbon monoxide in the shift gas is 3.0, and the effective synthesis gas accounts for more than 95% of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com