Self-combustion biomass char production furnace

A biomass coke and self-ignition technology, applied in combustible gas heating coke ovens, coke ovens, biofuels, etc., can solve the problems of high energy costs, pollution of the atmospheric environment, and large external energy consumption, and achieve high comprehensive utilization. High heat utilization rate and effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

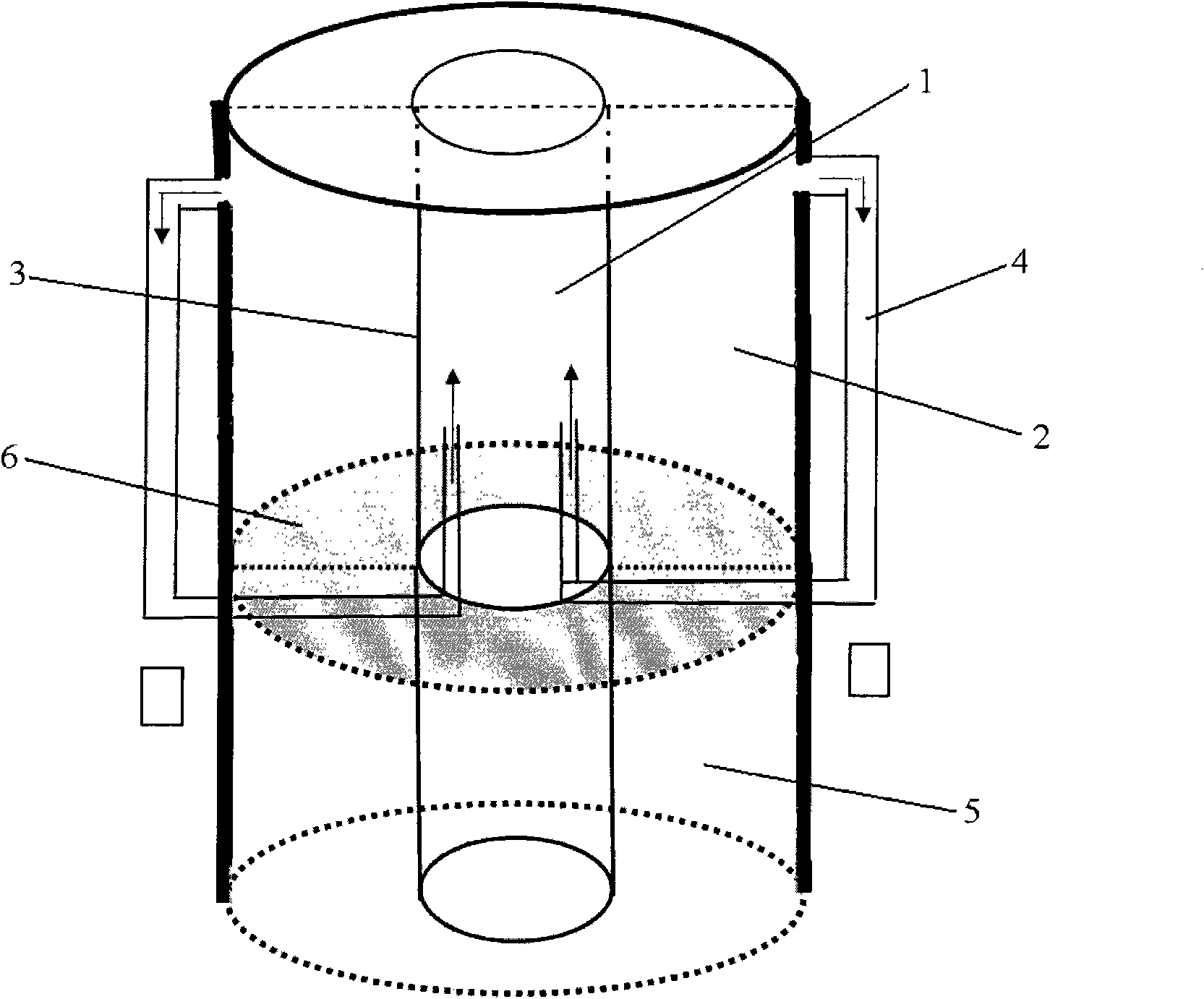

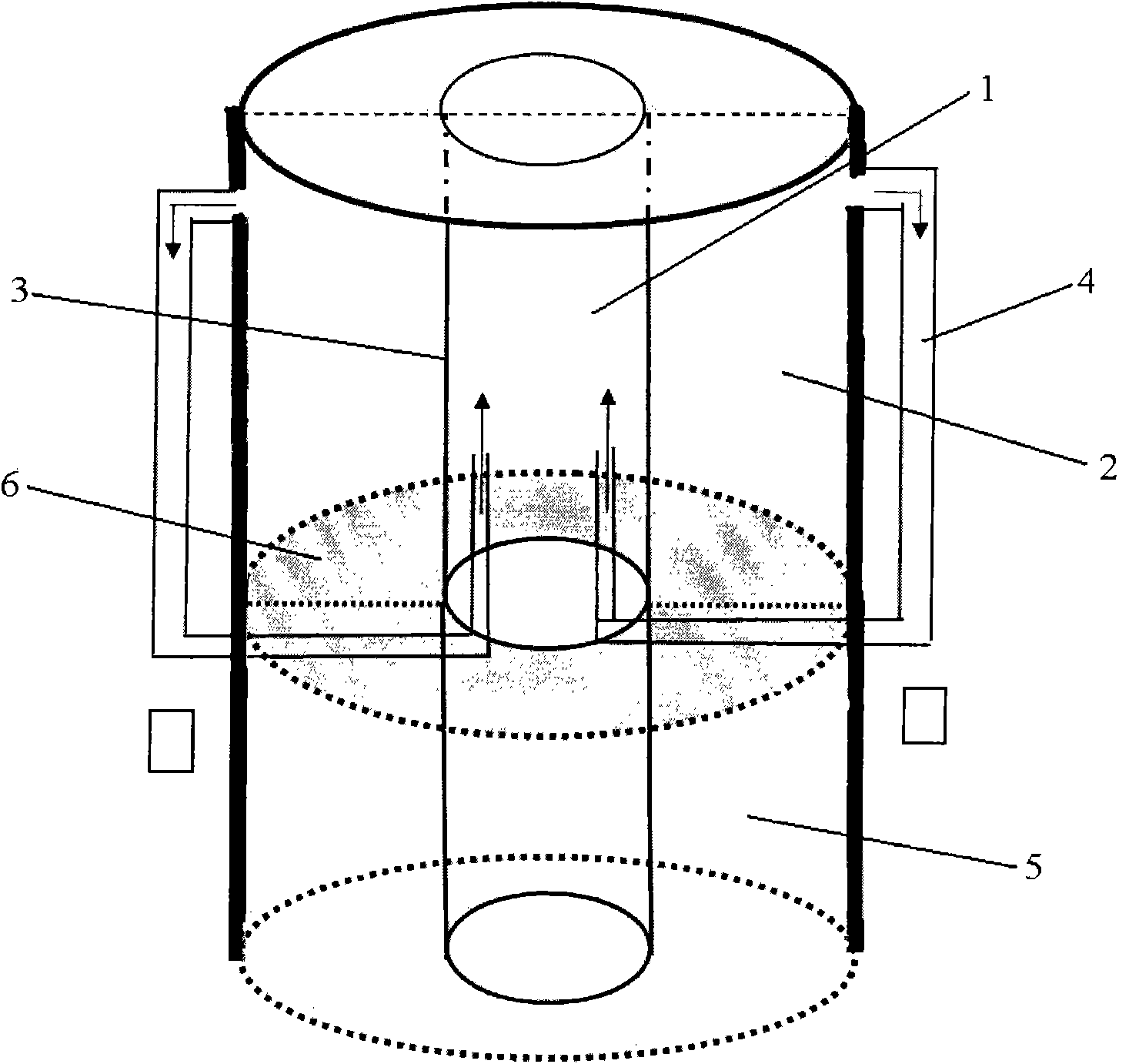

[0016] The present invention provides a self-igniting biomass coke production furnace. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

[0017] like figure 1 As shown, the production furnace is cylindrical with a height of 1800mm. In the production furnace, an inner wall 3 made of a steel plate with a thickness of 3mm is arranged concentrically with the production furnace, and the part inside the inner wall 3 is the combustion chamber 1; The plate 6 divides the annular area into the upper carbonization chamber 2 and the lower cooling chamber 5 . For increasing the strength of pumping plate 6, the steel bar of 2-4 diameter 10mm is lined below pumping plate. The heights of the combustion chamber and the carbonization chamber are both 1000 mm, the diameter of the combustion chamber is 150 mm, the diameter of the carbonization chamber is 250 mm, and the height of the cooling chamber is 500 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com