Polylactic acid blended non-woven fabric having improved flexibility and method for preparing same

A technology of polylactic acid and non-woven fabrics, applied in textiles, papermaking, non-woven fabrics, etc., can solve the problems of not paying attention to the improvement of the mechanical or physical properties of mixed textile fabrics, and the lack of research, so as to reduce friction coefficient, increased flexibility, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] Next, the nonwoven fabric of the present invention will be specifically described by way of examples. This example is merely an example for describing the present invention more specifically, and it should be understood by those skilled in the art that the scope of the present invention is not limited to this example.

[0053] In addition, in the following examples and comparative examples, fibers were produced using various amounts of polylactic acid, polypropylene, dispersant, and softening agent. The polylactic acid polymer (PLA) was obtained from Minneapolis, Minnesota, U.S.A. Obtained by (Natureworks) where Liss is located, the melt flow index (MI: MeltIndex) is 15 to 30g / 10 points, the polypropylene polymer (PP) obtains the trade name SFR-171H from Hunan Petrochemical, and the melt flow index (MI : MeltIndex) is 35g / 10 minutes, has the melting temperature of about 160 ℃, and the dispersing agent obtains the trade name DYNARON8630P from JSR Corporation (JSR Corpora...

Embodiment 1

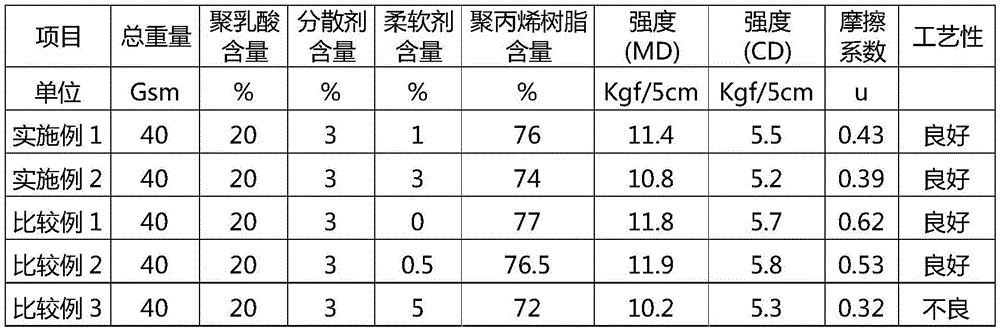

[0055] 20% by weight of polylactic acid, 3% by weight of dispersant, 1% by weight of softener, and 76% by weight of polypropylene resin were put in, melt-spun and fibrillated, stretched on a porous conveyor belt, and a 40gsm fiber was manufactured. Table 1 shows the physical properties of the polylactic acid / polypropylene nonwoven fabric and the produced nonwoven fabric measured.

Embodiment 2

[0057] A nonwoven fabric was manufactured in the same manner as in Example 1 except that 20% by weight of polylactic acid, 3% by weight of a dispersant, and 74% by weight of a softening agent 3% by weight of a polypropylene resin were added, and the manufactured nonwoven fabric was measured. properties and are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com