Low-carbon emission Fischer-Tropsch synthesis reaction process

A technology of Fischer-Tropsch synthesis and carbon emission, which is applied in the petroleum industry, producing hydrocarbons from carbon oxides, and the preparation of liquid hydrocarbon mixtures. It can solve the problems of lack of attention to tail gas, high construction costs of urea synthesis plants, etc., and achieve low cost , make full use of it, and realize the effect of low carbon emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Catalyst preparation

[0029] Cobalt-based Fischer-Tropsch synthesis catalyst. Cobalt-based catalysts were prepared with reference to Chinese patent CN1401736A. The zirconia carrier was prepared by using ammonia solution as precipitant and zirconium oxychloride as zirconium source. Then use cobalt nitrate as the cobalt precursor, and use the equal volume impregnation method to load cobalt on the obtained zirconia, and the obtained sample is dried and calcined to make a composition of Co 12wt% / ZrO 2 88% cobalt-based Fischer-Tropsch synthesis catalyst.

[0030] reforming catalyst. The reforming catalyst was prepared with reference to Chinese patent CN1248492A. According to the composition of Cu 40%, Zr 30%, Mn 20%, Ni 9.9%, Al 0.1% (mole percentage), configure the solution, in which zirconium oxychloride is the precursor of Zr, and the precursors of other elements are nitrates . Sodium carbonate is used as precipitating agent, and flow precipitation. The precip...

Embodiment 2

[0035] (1) Catalyst preparation

[0036] Cobalt-based Fischer-Tropsch synthesis catalyst. Cobalt-based catalysts were prepared with reference to Chinese patent CN 1398669A. By the content 10wt% of cobalt in the mixed solution, the zirconia content is 89.8wt%, and the content of manganese oxide is 0.2wt% to prepare the mixed solution (both percent by weight) of cobalt nitrate, zirconium oxychloride and manganese nitrate, with sodium carbonate As a precipitating agent, under continuous heating and stirring conditions, the mixed solution and precipitating agent are added dropwise, and the resulting precipitate is washed, dried and roasted to obtain a composition of Co 10wt% / ZrO 2 89.8wt% / MnO 2 0.2 wt% cobalt-based Fischer-Tropsch synthesis catalyst.

[0037] reforming catalyst. Carbon dioxide reforming catalyst was prepared according to Example 1.

[0038] (2) Implementation of process method

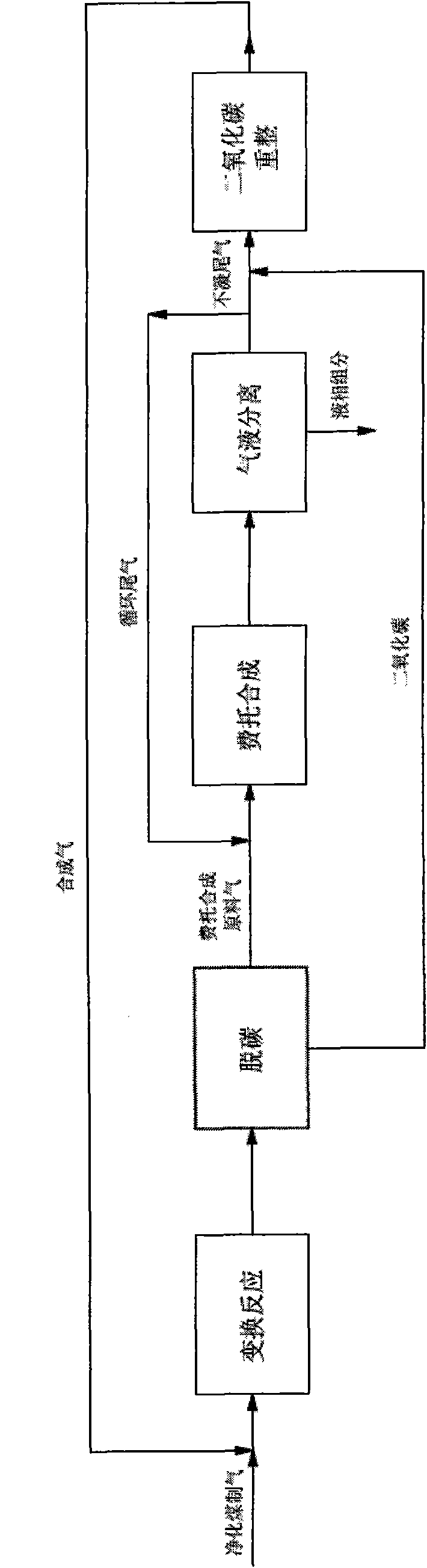

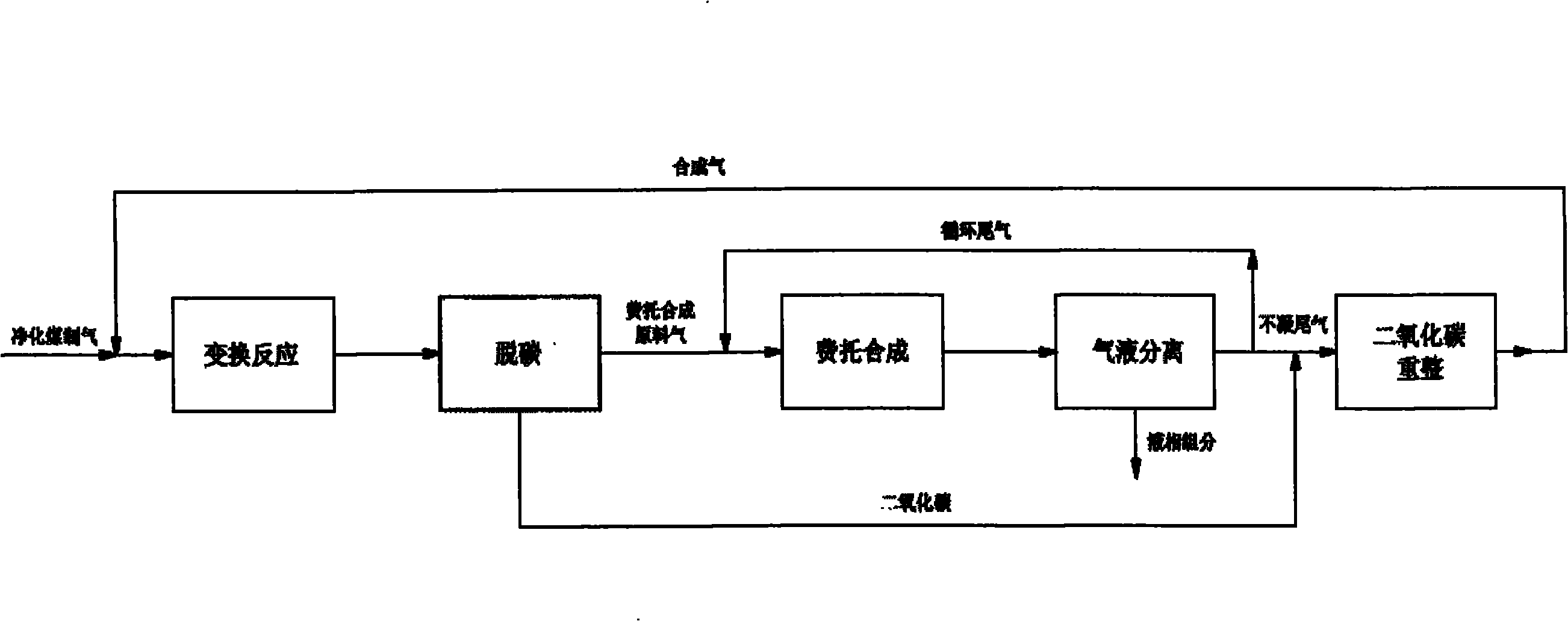

[0039] This embodiment adopts figure 1 The process flow shown. Coal-to-gas is ...

Embodiment 3

[0042] (1) Catalyst preparation

[0043] Cobalt-based Fischer-Tropsch synthesis catalyst. Cobalt-based catalysts were prepared with reference to Chinese patent CN1398951A. First pour tetrabutyl titanate (TBOT) into the dissolved C 12 h 30 (EO) 30 ethanol solution, stirred at room temperature for 1 h, and then added dropwise to water-ethanol solution to obtain a molar ratio of TBOT:C 12 h 30 (EO) 30 :H 2 O: EtOH = 1: 0.02: 4: 15 mixed solution, let stand for 72h, filter and then impregnate zirconium nitrate, after drying and roasting, 5wt% ZrO 2 / TiO 2 carrier. Cobalt was loaded on the obtained carrier by the equal volume impregnation method, and then dried and calcined to obtain 12wt% Co / ZrO 2 -TiO 2 catalyst.

[0044] reforming catalyst. Carbon dioxide reforming catalyst was prepared according to Example 1.

[0045] (2) Implementation of process method

[0046] This embodiment adopts figure 1 The process flow shown. Coal-to-gas and synthesis gas obtained by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com