Garbage microwave pyrolysis comprehensive treatment system and method and equipment used by same

A technology of comprehensive treatment and treatment methods, applied in the field of garbage treatment, can solve the problem of the complexity of garbage components over time and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

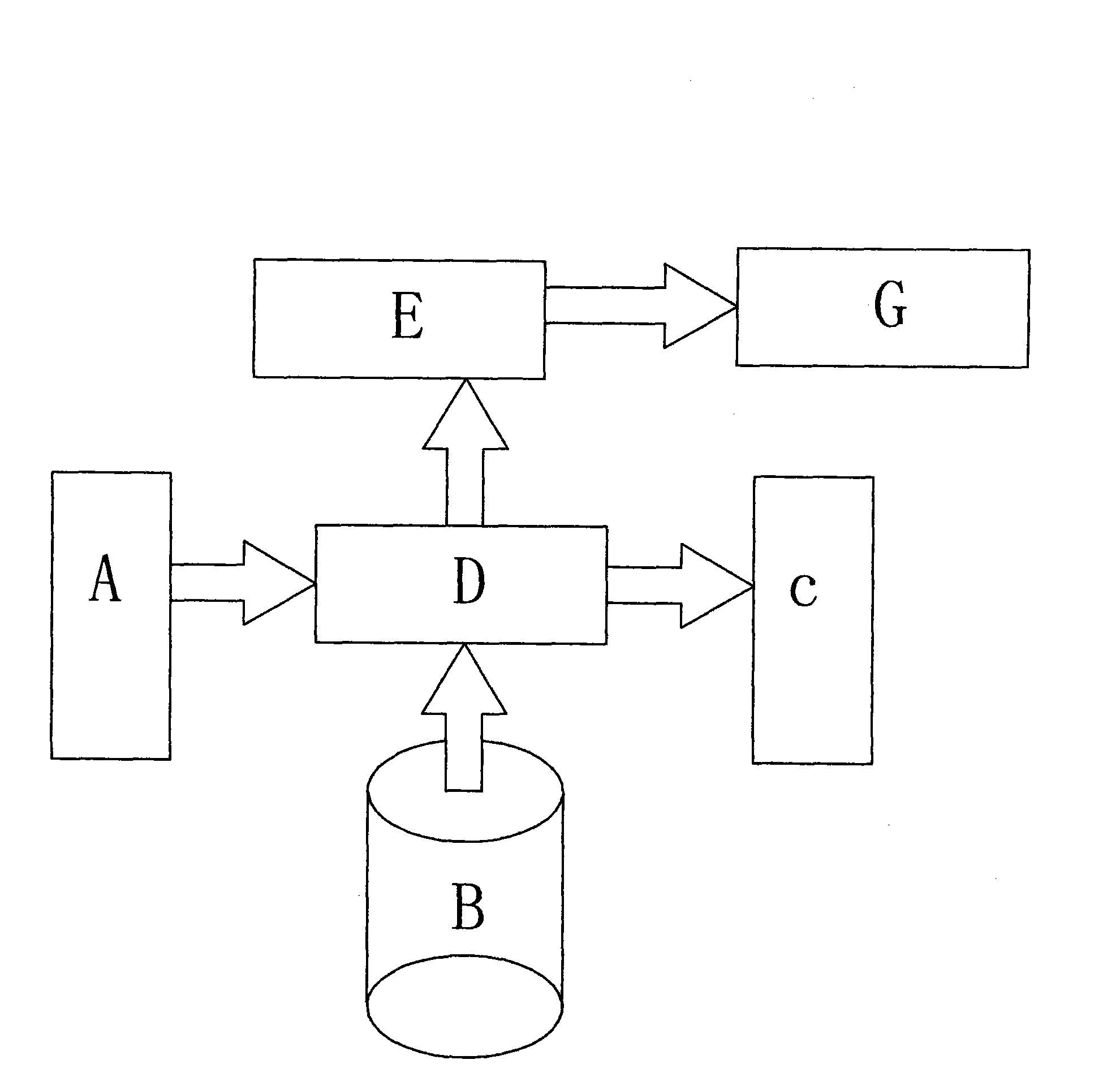

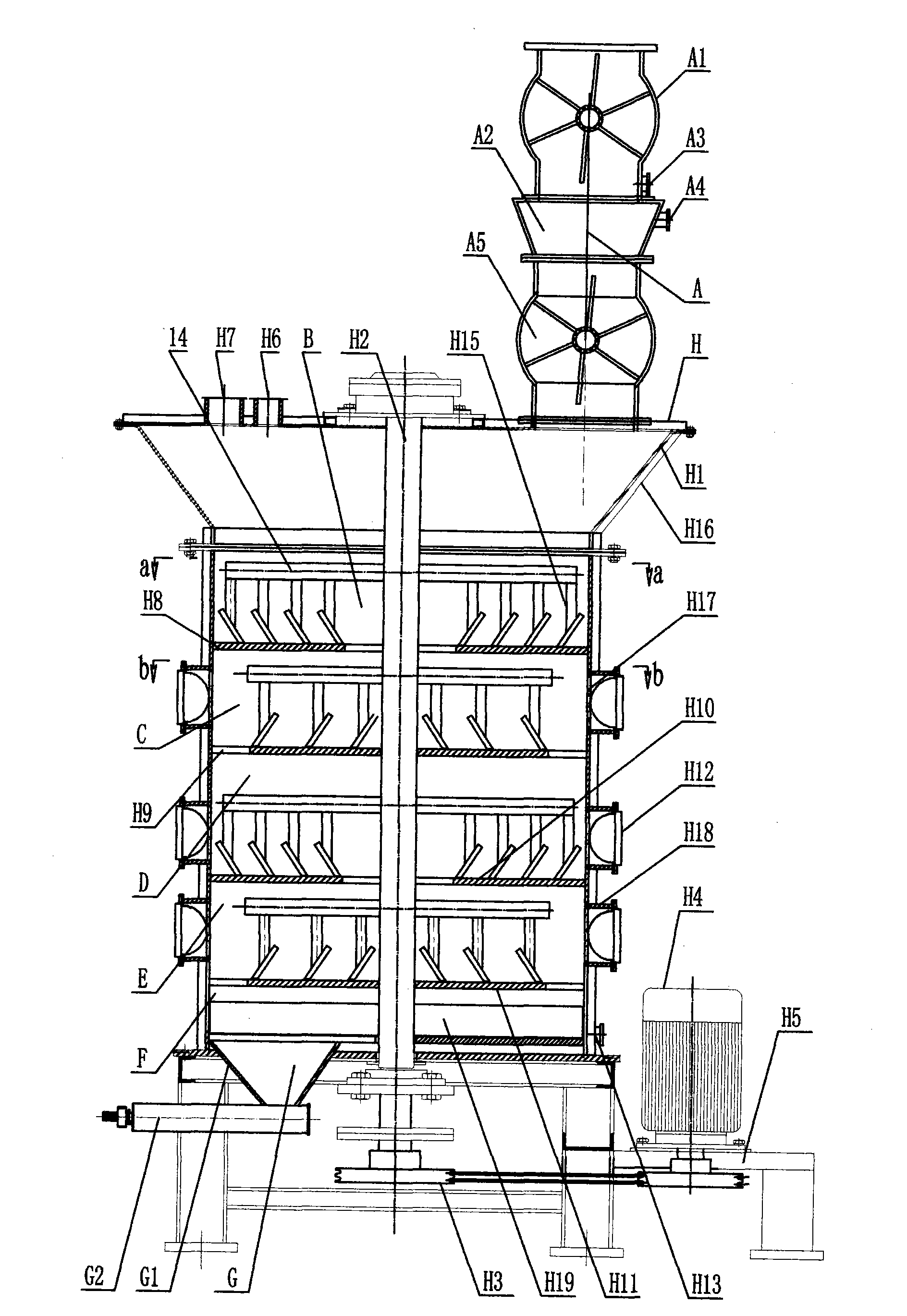

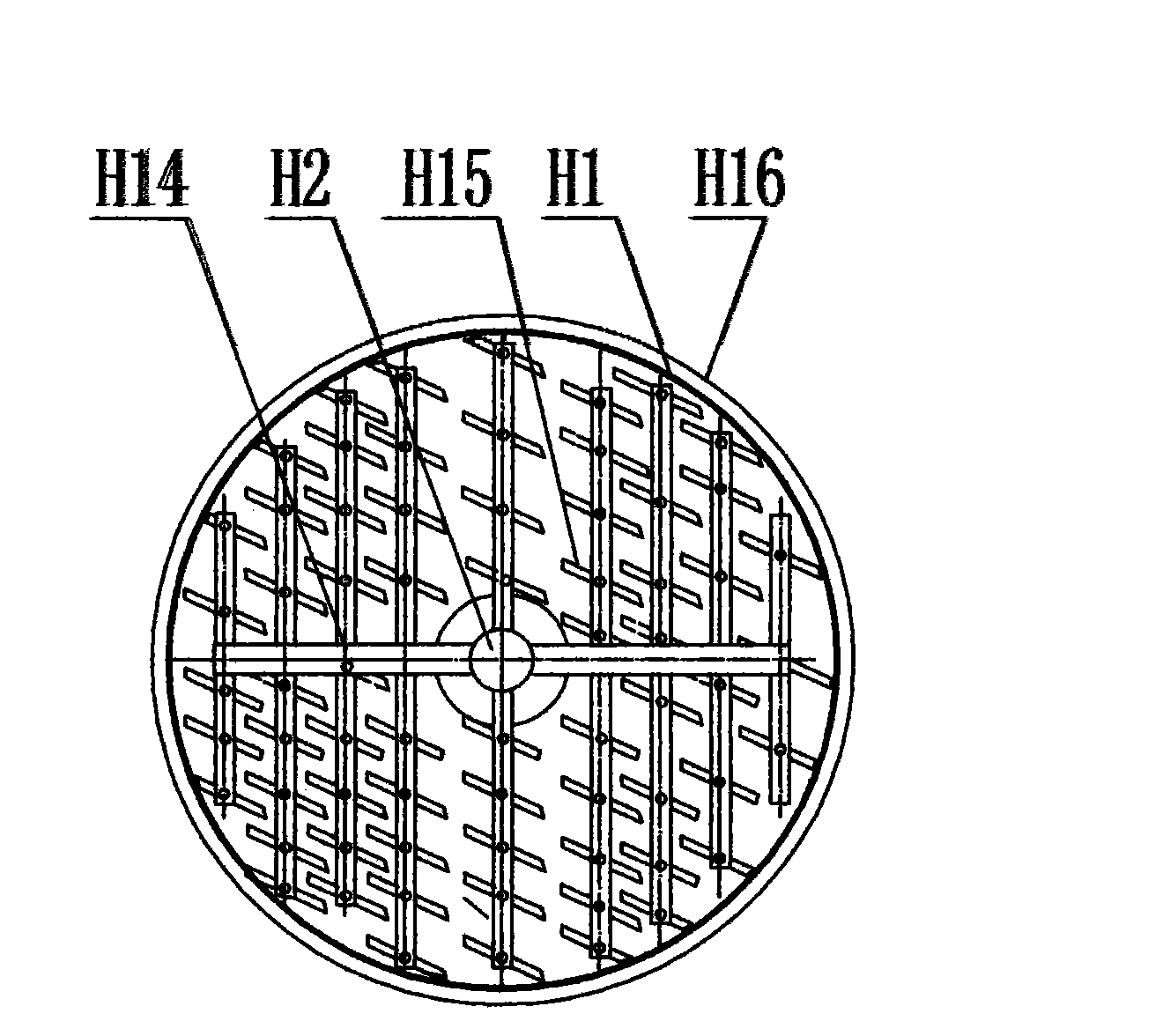

[0133] See attached figure 1 , Waste microwave cracking comprehensive treatment system, the comprehensive treatment system consists of: municipal solid waste pre-treatment system A, vertical waste continuous microwave heating low-temperature cracking furnace B, solid product production activated carbon system C, cracking steam preparation fuel steam system D, liquid product Distillation and extraction of light oil and fuel oil system F and supporting sewage treatment system G are composed of municipal solid waste pre-treatment system A, solid product production activated carbon system C and pyrolysis steam preparation fuel steam system D respectively combined with vertical waste continuous microwave heating low-temperature pyrolysis The primary feeder (BA1), discharger (BG 2) and pyrolysis steam outlet (BH6) of furnace B are connected, and the liquid product is distilled to extract light oil and fuel oil. Oil line connection.

[0134] During the garbage treatment process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com