Process for preparing hot molten iron and byproducts by utilizing red mud

A process method and by-product technology, which are applied in the field of producing hot molten iron and by-products, can solve the problems of inability to select magnetic separation methods, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

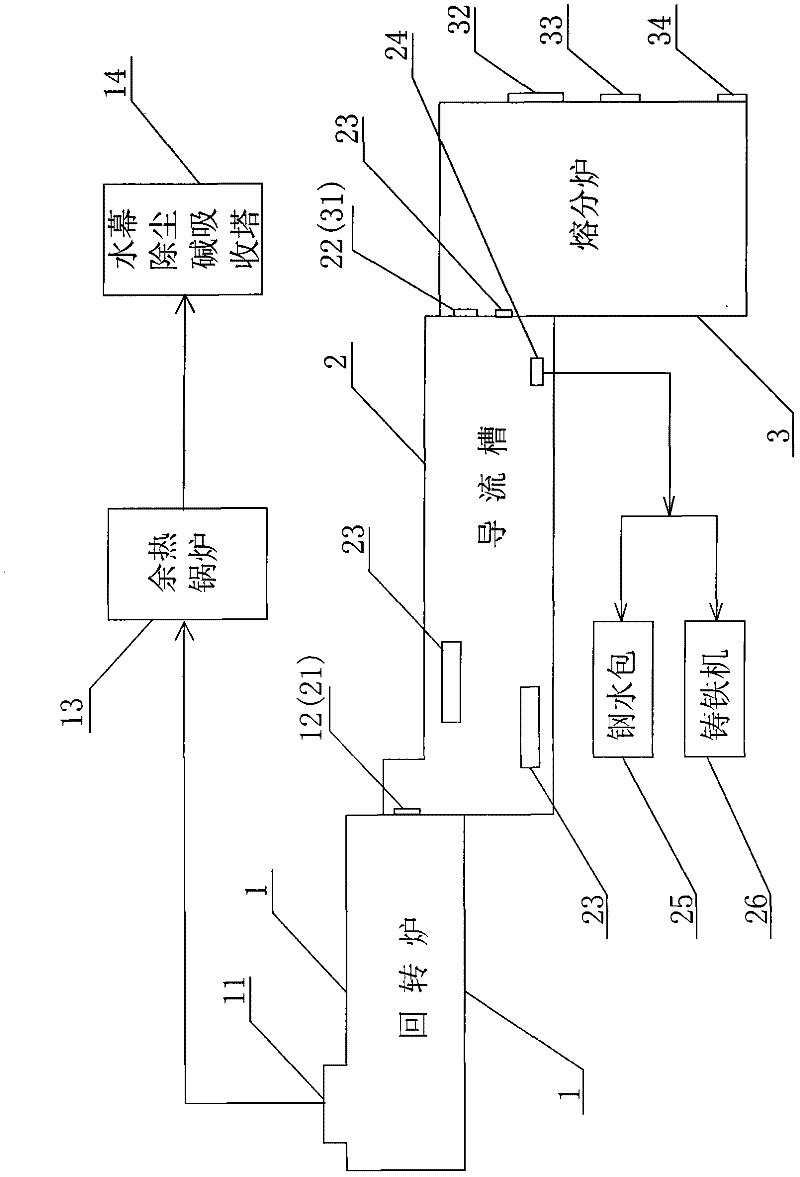

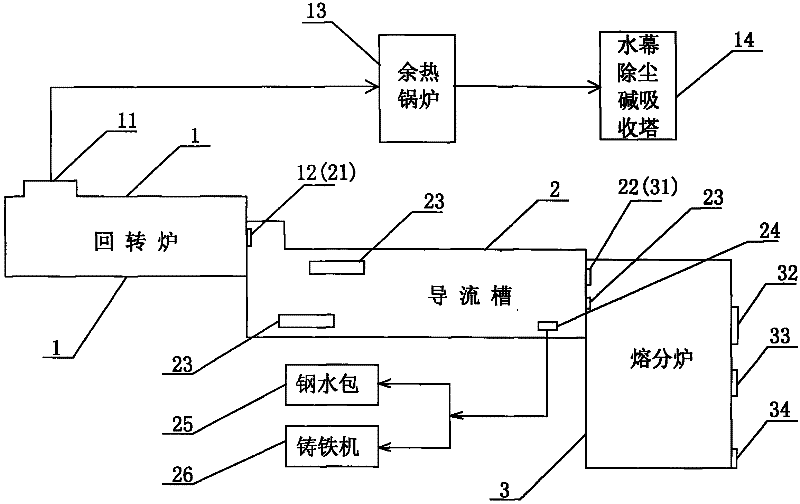

[0031] see figure 1 , describe in detail the process for implementing the first embodiment of the present invention. (If the content of titanium and aluminum in the red mud used is relatively high, the following method is adopted)

[0032] A process for preparing hot molten iron and by-products from red mud, comprising the following steps:

[0033] a) According to the ratio of 1:0.1:0.3 by weight, take red mud, lime, coal, and mix them uniformly to make mixed raw meal;

[0034] b) Add the above-mentioned mixed raw meal into the rotary kiln 1, the temperature in the rotary kiln 1 is 800-1460 degrees Celsius; the mixed raw meal is dried and pre-reduced in the rotary kiln for 2-10 hours, and the semi-molten The reduced raw material in the state; the temperature in the rotary kiln 1 from the tail to the head gradually rises from 800 degrees Celsius to 1460 degrees Celsius;

[0035]c) Enter the above-mentioned reducing material into the diversion groove 2 from the discharge port...

Embodiment 2

[0039] see figure 1 , describe in detail the process for implementing the second embodiment of the present invention. (If the content of titanium and aluminum in the red mud used is relatively high, the following method is adopted)

[0040] A process for preparing hot molten iron and by-products from red mud, comprising the following steps:

[0041] a) According to the ratio of 1:0.2:0.4 by weight, take red mud, lime, coal, and mix them uniformly to make mixed raw meal;

[0042] b) Add the above-mentioned mixed raw meal into the rotary kiln 1, and the temperature in the rotary kiln 1 is 800-1460 degrees Celsius; the mixed raw meal is dried and pre-reduced in the rotary kiln 1 for 2-10 hours, and the resulting half The reducing material in the molten state; the temperature in the rotary kiln 1 from the tail to the head gradually rises from 800 degrees Celsius to 1460 degrees Celsius;

[0043] c) The above-mentioned reducing material is entered into the diversion groove 2 thr...

Embodiment 3

[0047] see figure 1 , describe in detail the process for implementing the third embodiment of the present invention. (If the content of titanium and aluminum in the red mud used is relatively high, the following method is adopted)

[0048] A process for preparing hot molten iron and by-products from red mud, comprising the following steps:

[0049] a) According to the ratio of 1:0.1:0.3 by weight, take red mud, lime, coal, and mix them uniformly to make mixed raw meal;

[0050] b) Add the above-mentioned mixed raw meal into the rotary kiln 1, the temperature in the rotary kiln 1 is 900-1360 degrees Celsius; the mixed raw meal is dried and pre-reduced in the rotary kiln for 3-8 hours, and the resulting semi-molten The reduced raw material in the state; the temperature in the rotary kiln 1 from the tail to the head gradually rises from 900 degrees Celsius to 1360 degrees Celsius;

[0051] c) Enter the above-mentioned reducing material into the diversion groove 2 from the disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com