Device for preparing hot molten iron and byproducts by using red mud

A technology for by-products and molten iron, applied in the field of metal smelting, can solve the problems of inability to spit out slag and the inability to select magnetic separation methods, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

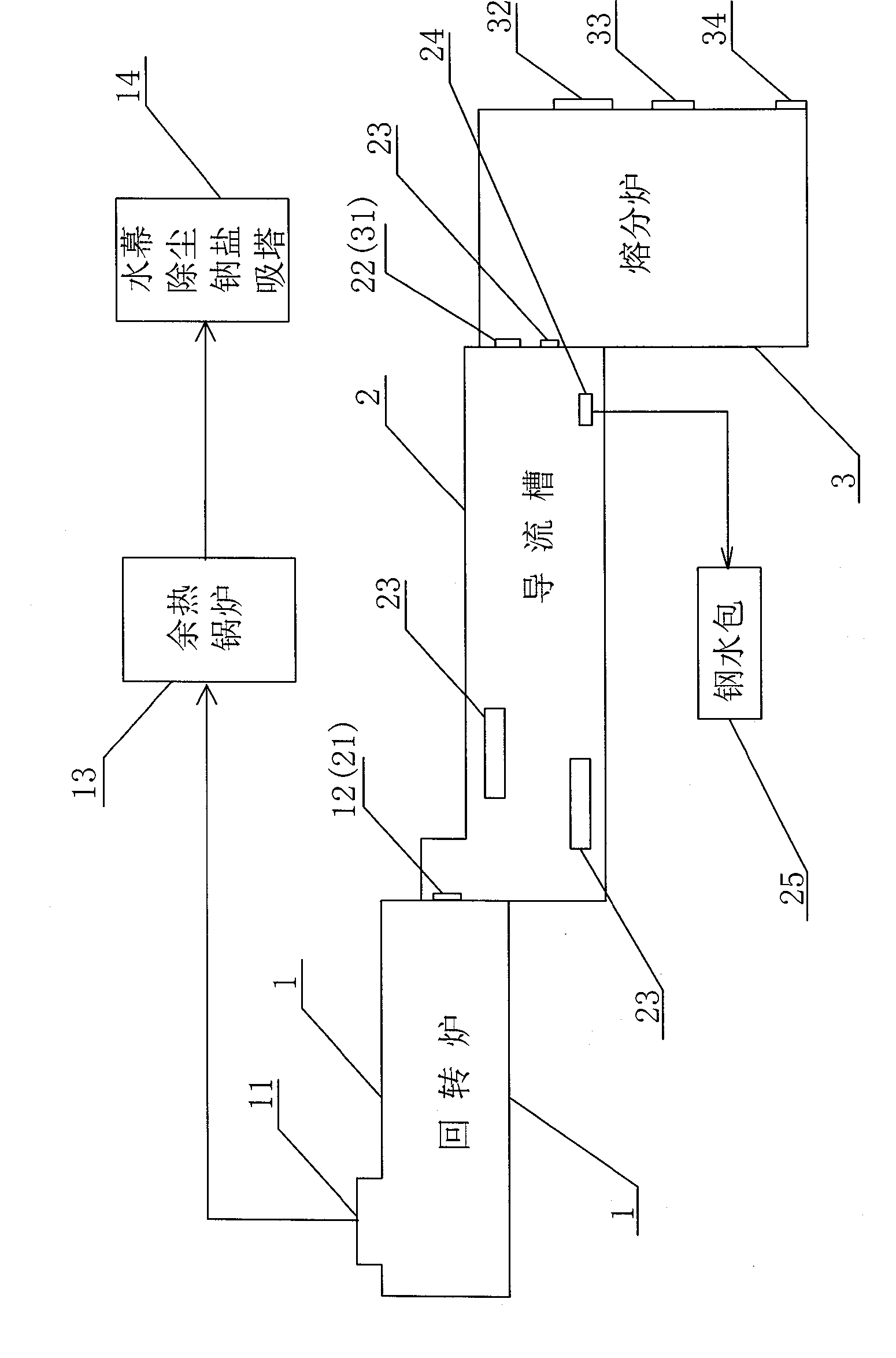

[0020] Such as figure 1 As shown, during installation, the positions of the rotary furnace 1, the diversion tank 2, and the melting furnace 3 are successively lowered, and the heights of their heads or lower parts are lower than their tails or upper parts. That is: the head of rotary furnace 1 is slightly lower than its tail; the tail of diversion tank 2 is lower than the head of rotary furnace 1, but higher than the head of diversion tank 2; the upper part of melting furnace 3 is lower than the guide The head of launder 2, but higher than the lower part of melting furnace 3.

[0021] A device for producing hot molten iron and by-products from red mud, comprising a rotary furnace 1, a diversion tank 2, and a melting furnace 3, the tail of the rotary furnace 1 is provided with a flue gas outlet 11, and the head is provided with a discharge port 12 , the flue gas outlet 11 of the rotary furnace 1 communicates with a water curtain dedusting sodium salt suction tower 14 through t...

Embodiment 2

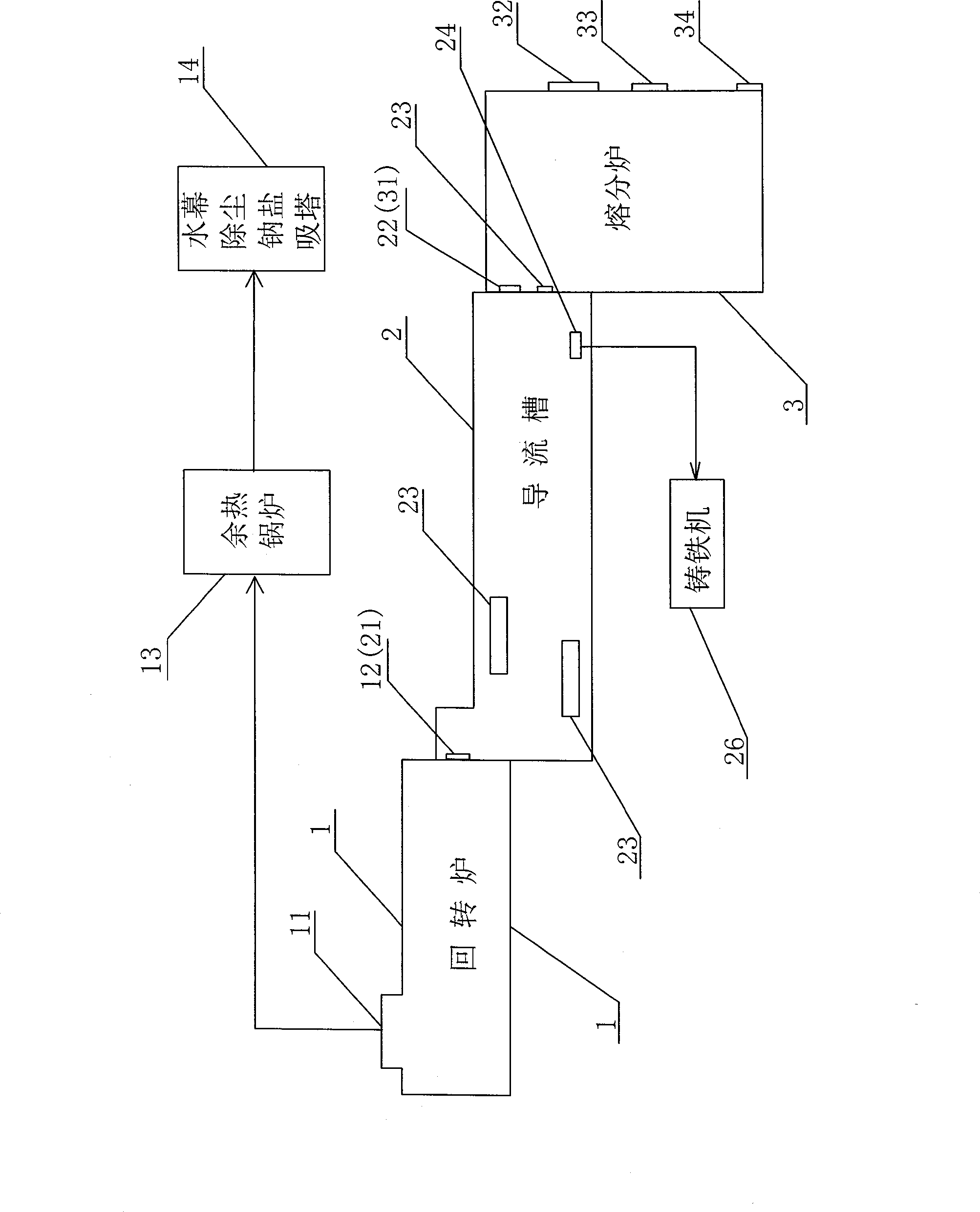

[0027] Such as figure 2 As shown, the hot metal outlet 24 on the lower side of the head of the diversion tank 2 is connected to the cast iron machine 26; the others are the same as those in the first embodiment.

[0028] Working process of the present invention is as follows:

[0029] Such as figure 1 , 2 As shown, according to the ratio of 1:0.05-0.35:0.2-0.5 by weight percentage, take red mud, lime, coal, and mix them evenly to make mixed raw meal and add it to the rotary kiln 1. The temperature in the rotary kiln 1 is 800-1460 degrees Celsius; the mixed raw material is dried and pre-reduced in the rotary kiln 1 for 2-10 hours, and the reduced material in a semi-molten state is generated; the temperature from the tail to the head in the rotary kiln 1 ranges from 800 degrees gradually rises to 1460 degrees; the above-mentioned reducing material enters the diversion tank 2 from the discharge port 12 of the rotary kiln 1 through the feed port 21 of the diversion tank 2; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com