Method and device for low-carbon emission energy regeneration by coupling waste gas and waste water

An energy and wastewater technology, applied in the field of energy, can solve the problems of high cost of microalgae oil, low carbon recovery rate, low fixation rate, etc., and achieve the effect of reducing CO2 emissions, high impact load resistance, and promoting growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

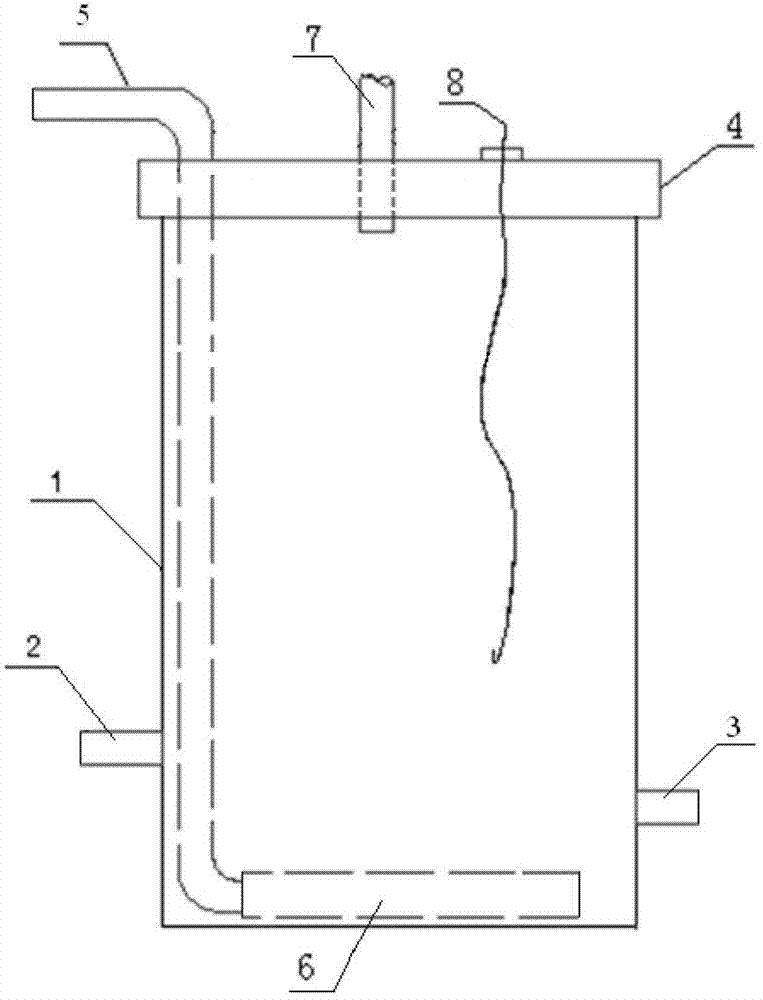

[0024] Specific implementation mode 1: In this implementation mode, a method for coupling waste gas and waste water to low-carbon emission energy is realized according to the following steps:

[0025] 1. Take the waste water after the primary treatment of the sewage treatment plant for sterilization pretreatment, and then import it into the reactor, and inoculate the microalgae in the waste water in the reactor with a volume ratio of 10%~50%. liquid;

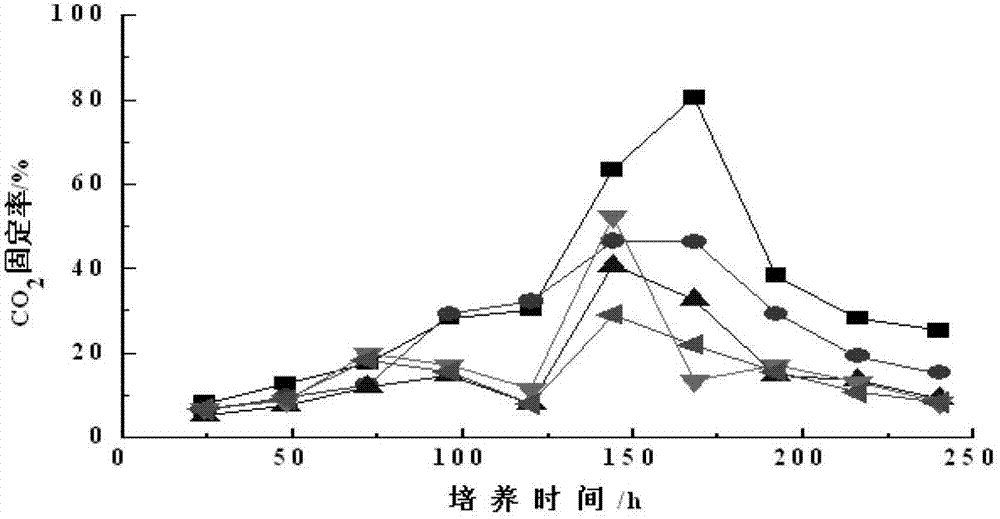

[0026] 2. Pass the exhaust gas into the mixed solution to cultivate microalgae, and at the same time discharge and collect the residual gas in the process of cultivating microalgae in the reactor;

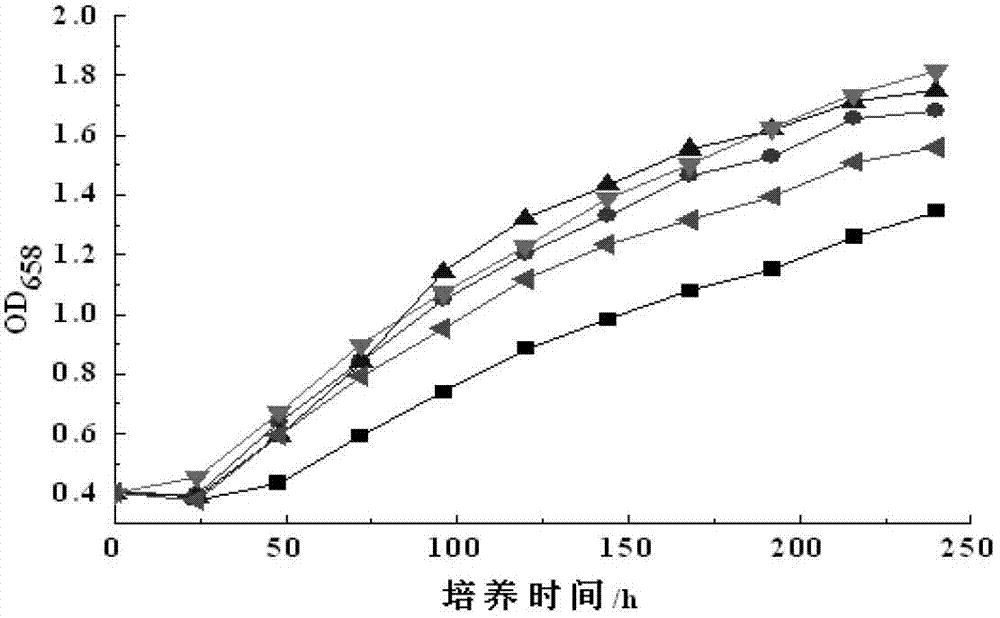

[0027] 3. Mix the residual gas collected in step 2 with the intake air and re-introduce it into the mixed solution in the reactor. When the microalgae are cultivated to OD 658 The value is basically stable, that is, after entering the stable period, the mixed solution is discharged, and the microalgae in the mixed solution are colle...

specific Embodiment approach 2

[0032] Embodiment 2: This embodiment differs from Embodiment 1 in that the waste water described in step 1 is domestic sewage, beer waste water, molasses waste water or industrial waste water. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the sterilization treatment described in step one is high-pressure steam sterilization, calcium hypochlorite sterilization, Cl 2 Sterilization, chlorine dioxide sterilization, ozone sterilization or ultraviolet sterilization. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com