Construction method for heat-insulating wall body of building

A construction method and building thermal insulation technology, applied in the processing of building materials, thermal insulation, construction, etc., can solve the problems of limiting the application range of organic thermal insulation materials, small thermal conductivity, high thermal conductivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

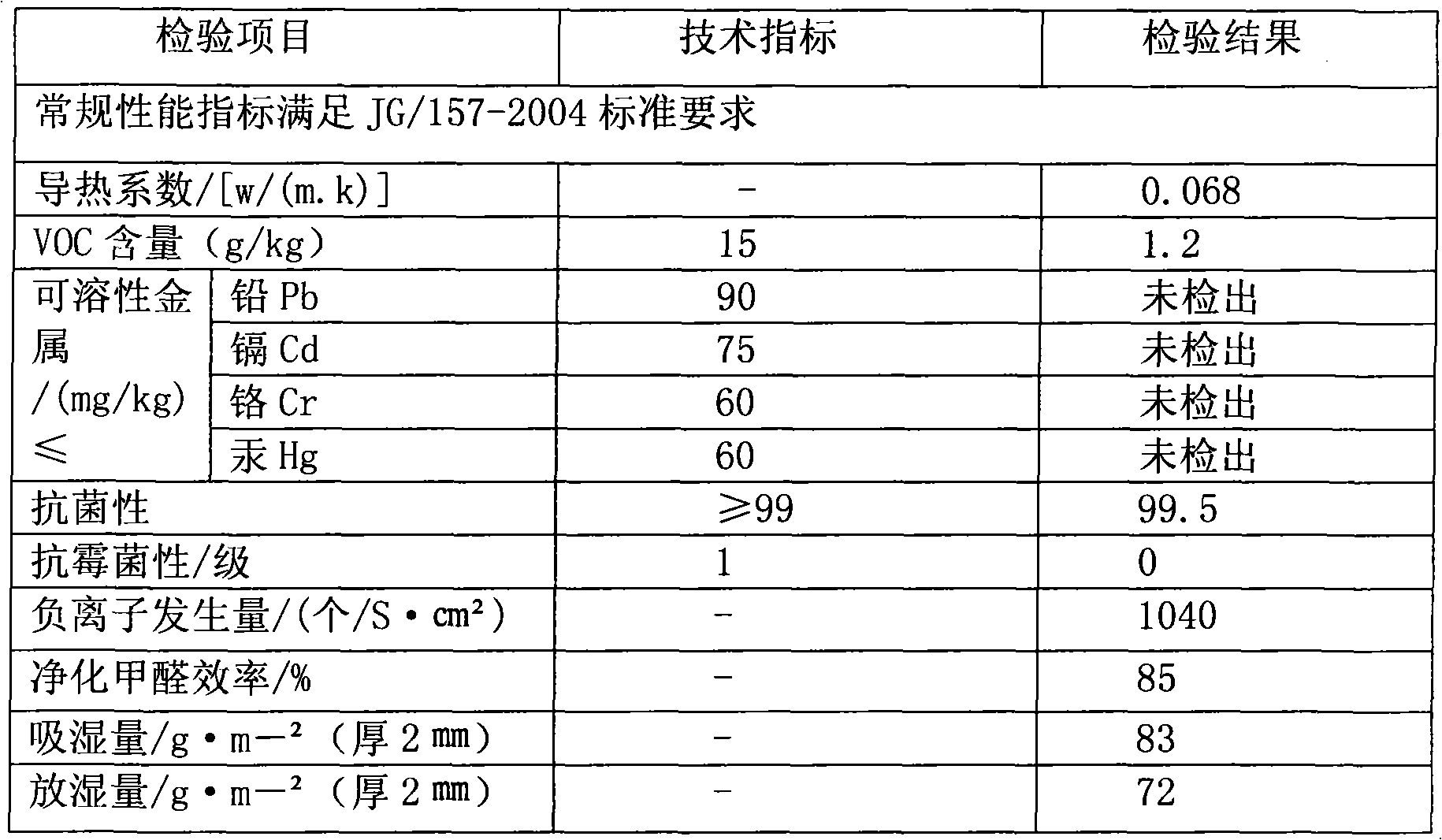

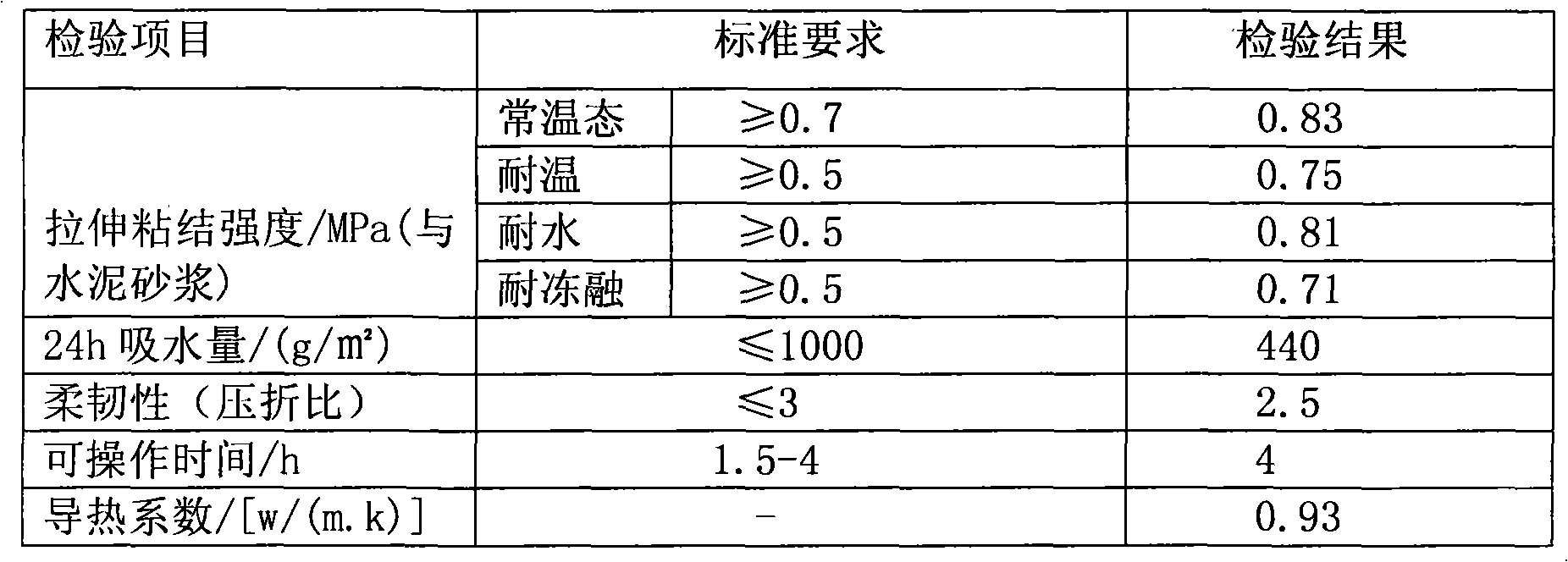

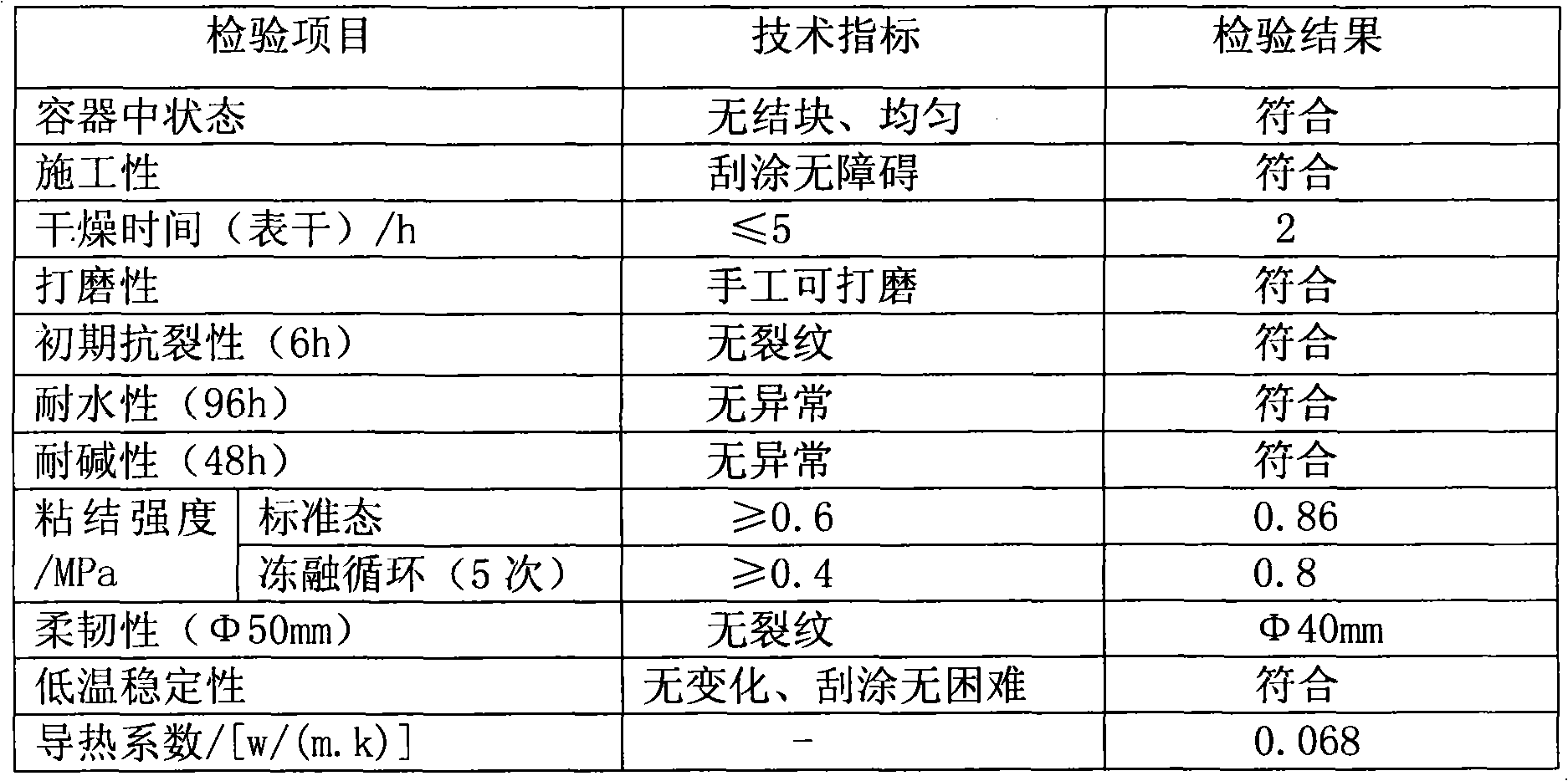

[0045] The present invention is further described in detail below in conjunction with specific embodiments: a construction method for building thermal insulation walls, using a combination system of thermal insulation and decoration materials for internal and external walls of building walls, including phase-change energy storage inorganic / organic thermal insulation mortar for external walls, Phase change energy storage plastering mortar + grid cloth, phase change energy storage flexible water-resistant putty, permeable elastic primer and solar heat reflection heat insulation exterior wall coating; phase change energy storage desulfurization gypsum insulation mortar for interior walls, temperature adjustment Wet antibacterial flexible putty and temperature and humidity adjustment antibacterial interior wall paint, the specific construction steps are as follows:

[0046] Construction of interior wall insulation and decoration system:

[0047] a. Directly apply phase-change ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com