Electric full-circle rotation inboard and outboard (double-motor) contra-rotating propeller propulsion unit

A propulsion device and full-turn technology, applied in the direction of outboard propulsion devices, propulsion device engines, mechanical gear transmissions, etc., can solve the problems of large transmission power loss, large bearing load, high cost, etc., and achieve protection from damage, Small size and high energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

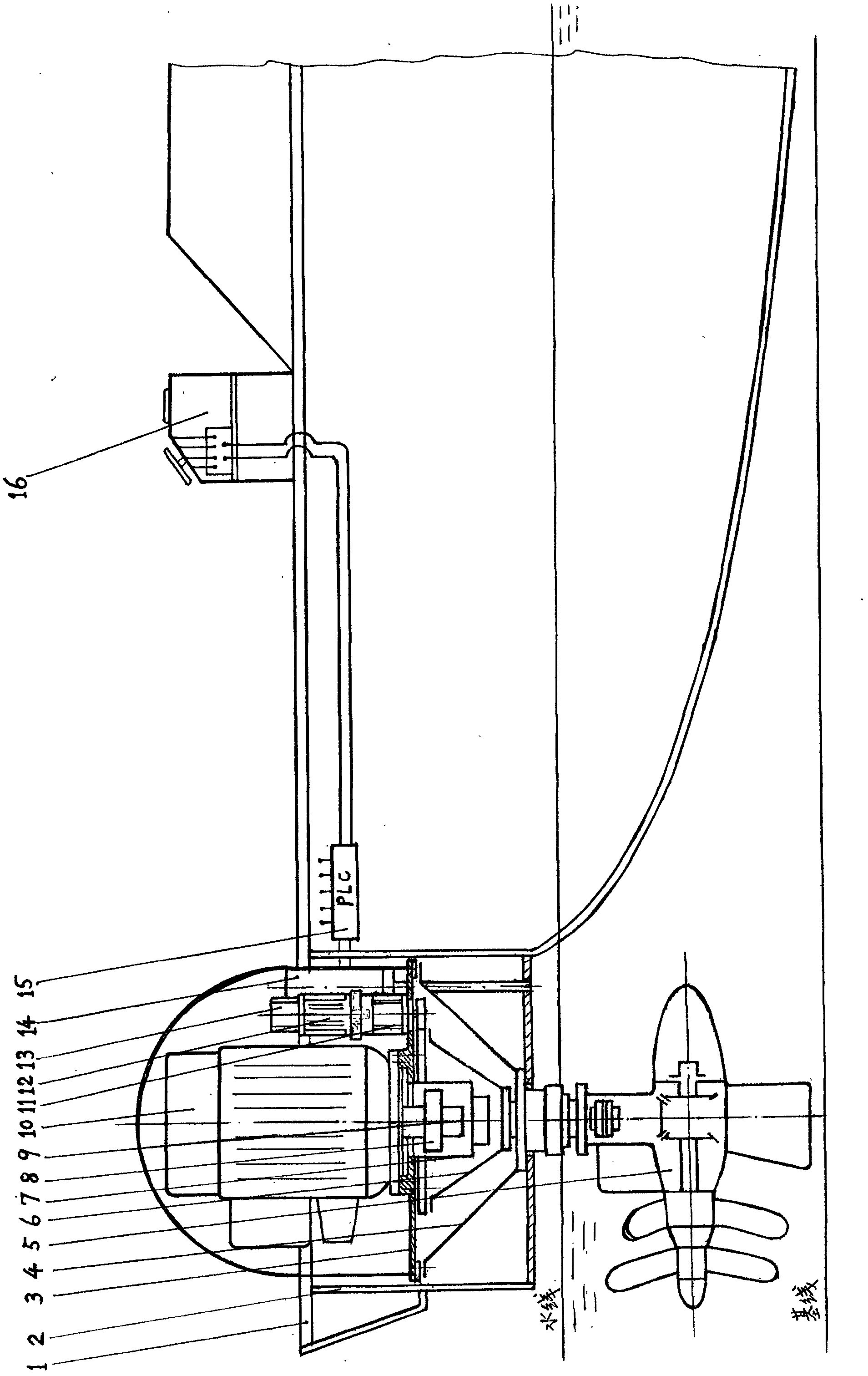

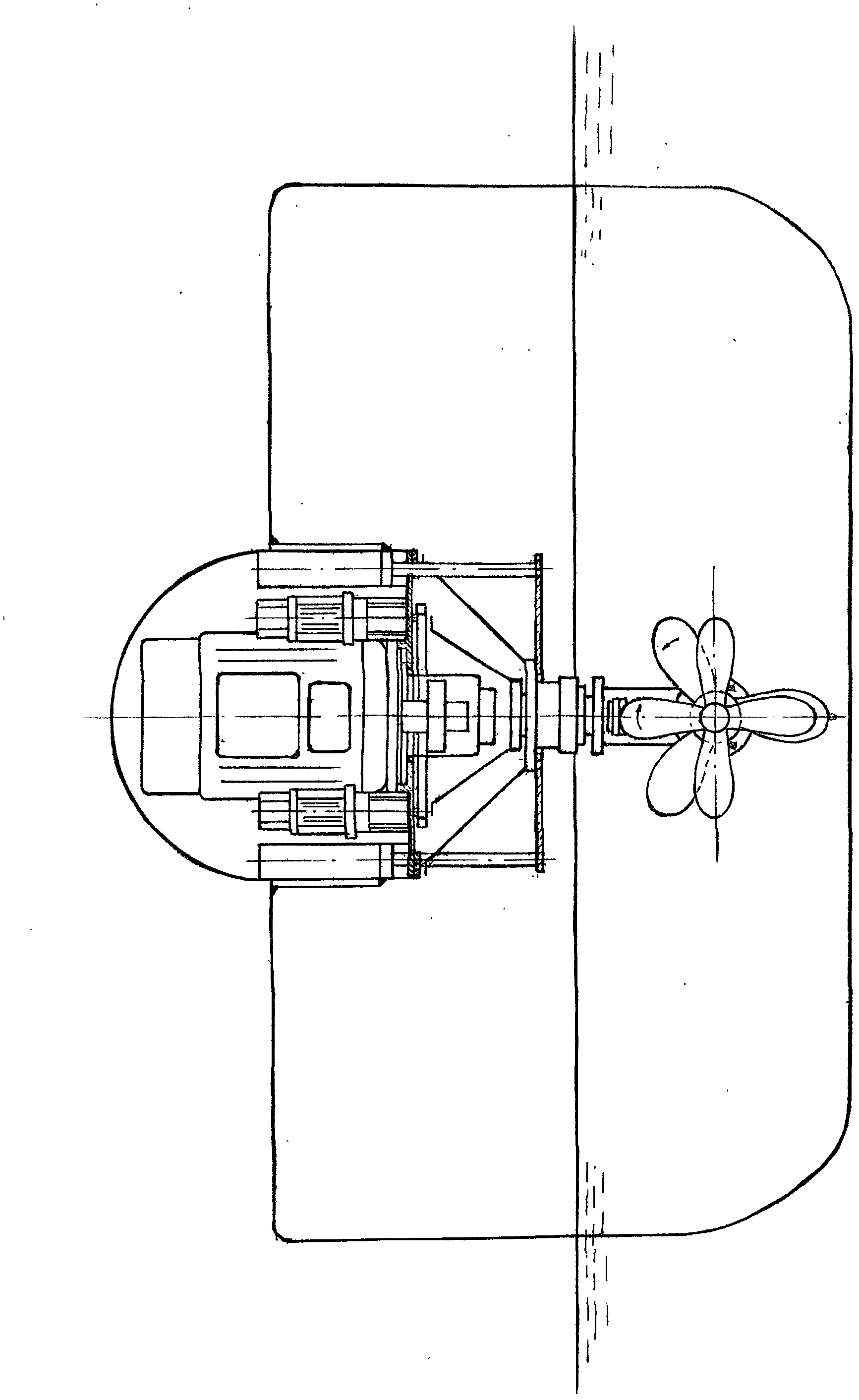

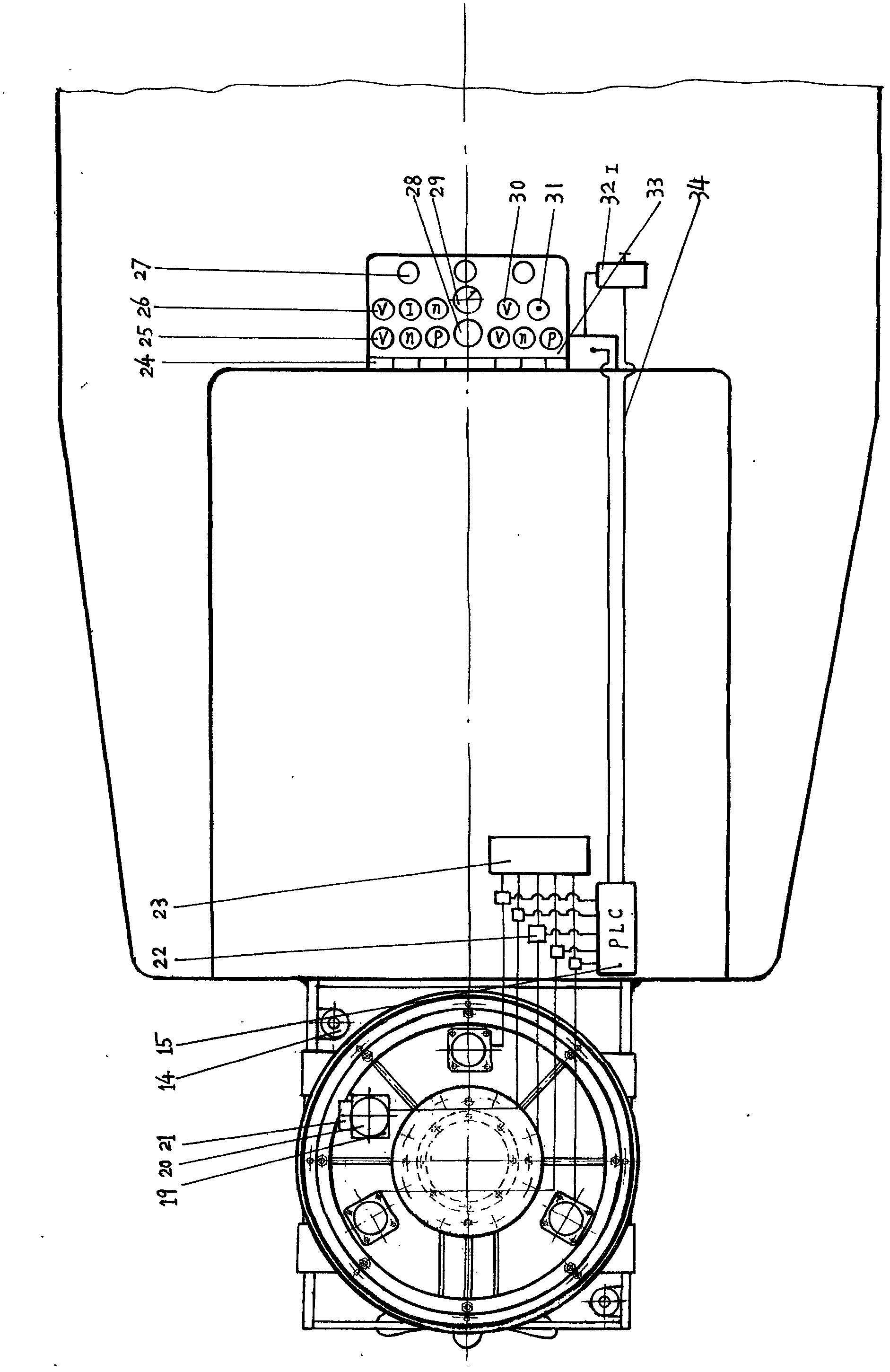

[0036] See figure 1 , 2 , The electric 360° full-rotation inboard and outboard (dual engine) counter-rotating propeller propulsion device of the present invention includes: a rudder revolving body 5 fixed on the stern 1; a protective propeller revolving body 5 fixed on the stern shell 2 Conical bracket 4; the conical bracket 4 is screwed to the upper circular plate base 3, and the main motor of AC permanent magnet variable frequency speed regulation or DC permanent magnet brushless speed regulation is installed on the circular plate base 3, 3 units 360 °The full-slewing motor includes an encoder 13, a servo motor 12 and a reducer 11; the first transmission chain that drives the intermediate transmission shaft 9 of the rudder revolving body 5, and the second transmission chain of the revolving part of the rudder revolving body 5, makes the The hydraulic lifting cylinder 14 of the propeller changing from two-dimensional motion to three-dimensional motion, 360° full rotation (doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com