Well head accompanying gas on site recovery purification method

A technology for on-site recovery and associated gas, which is applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc., can solve the problems of difficult recovery of associated gas, and is beneficial to skid-mounted transportation, pollution reduction, replacement and The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further illustrated below through the embodiments in conjunction with the accompanying drawings.

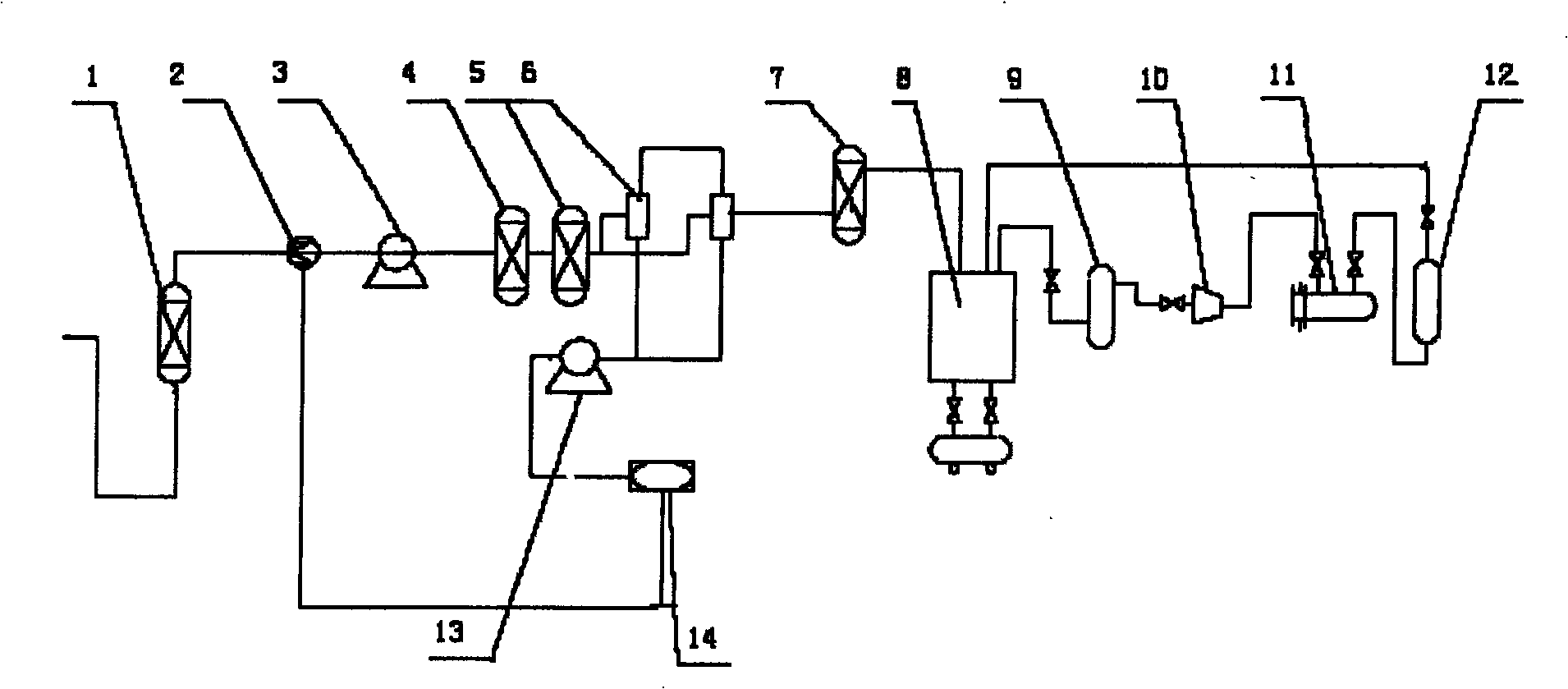

[0011] according to figure 1 Shown: The associated gas collected and stored in the wellhead storage tank is transported into the separator 1 at normal pressure and temperature, and the wellhead associated gas is collected in the separator 1 at an operating pressure of 3-6MPa and an operating temperature of 15-50°C. The gas phase, liquid phase, and solid phase in the filter are separated, and then enter the filter to recover condensate. Separator 1 consists of pre-filter + fine filter + adsorber. The device has a quick-opening structure and is easy to disassemble. While removing the associated gas-solid and liquid phase impurities at the wellhead, part of the heavy hydrocarbon components in the associated gas can also be separated and recovered to a certain extent. Then enter the gas preheater 2 to heat up to the temperature required for puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com