Low-concentration gas power generation treatment method

A technology of low-concentration gas and treatment method, applied in the field of low-concentration gas power generation treatment, to achieve the effect of reducing pollution, huge economic and social benefits, and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

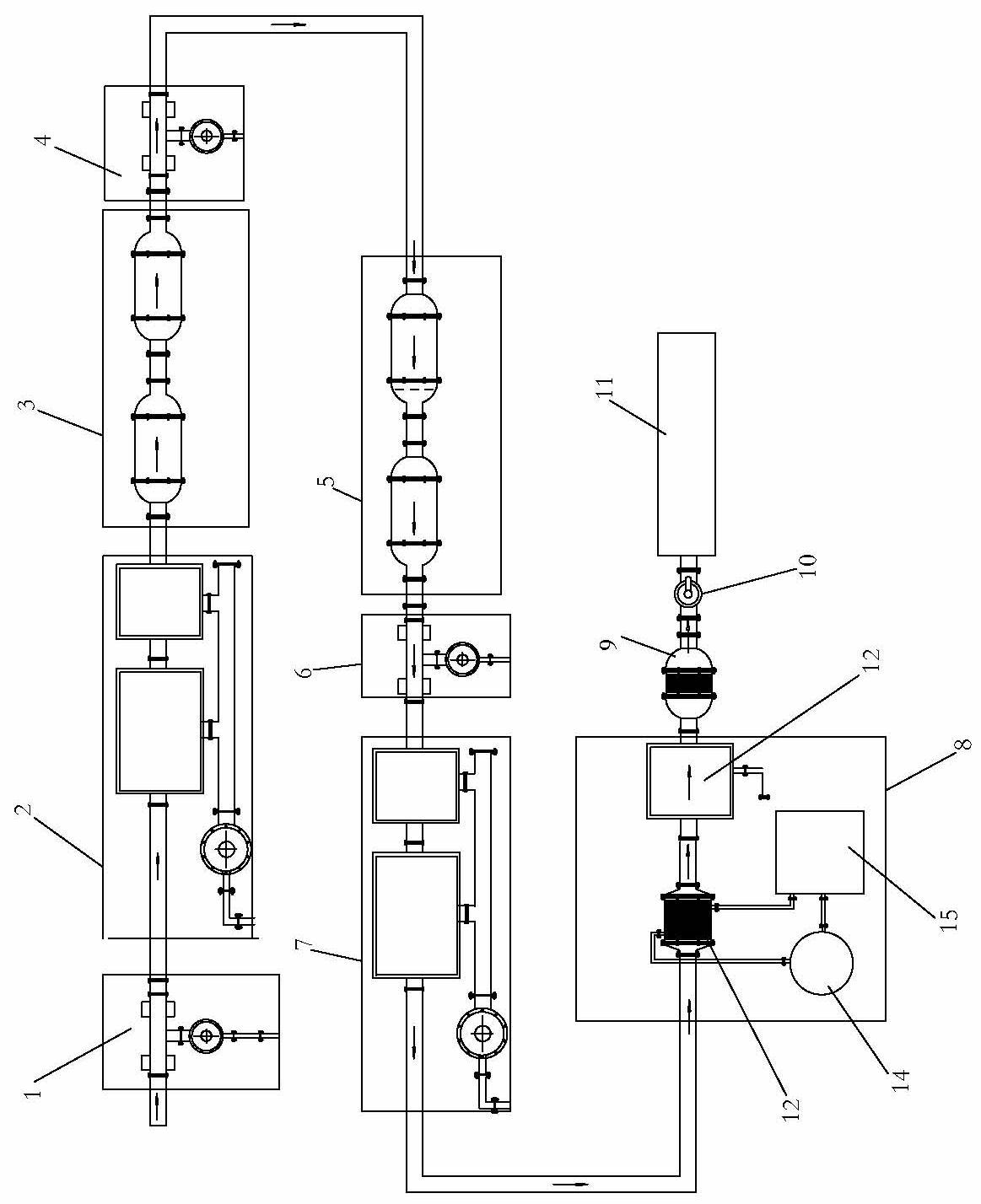

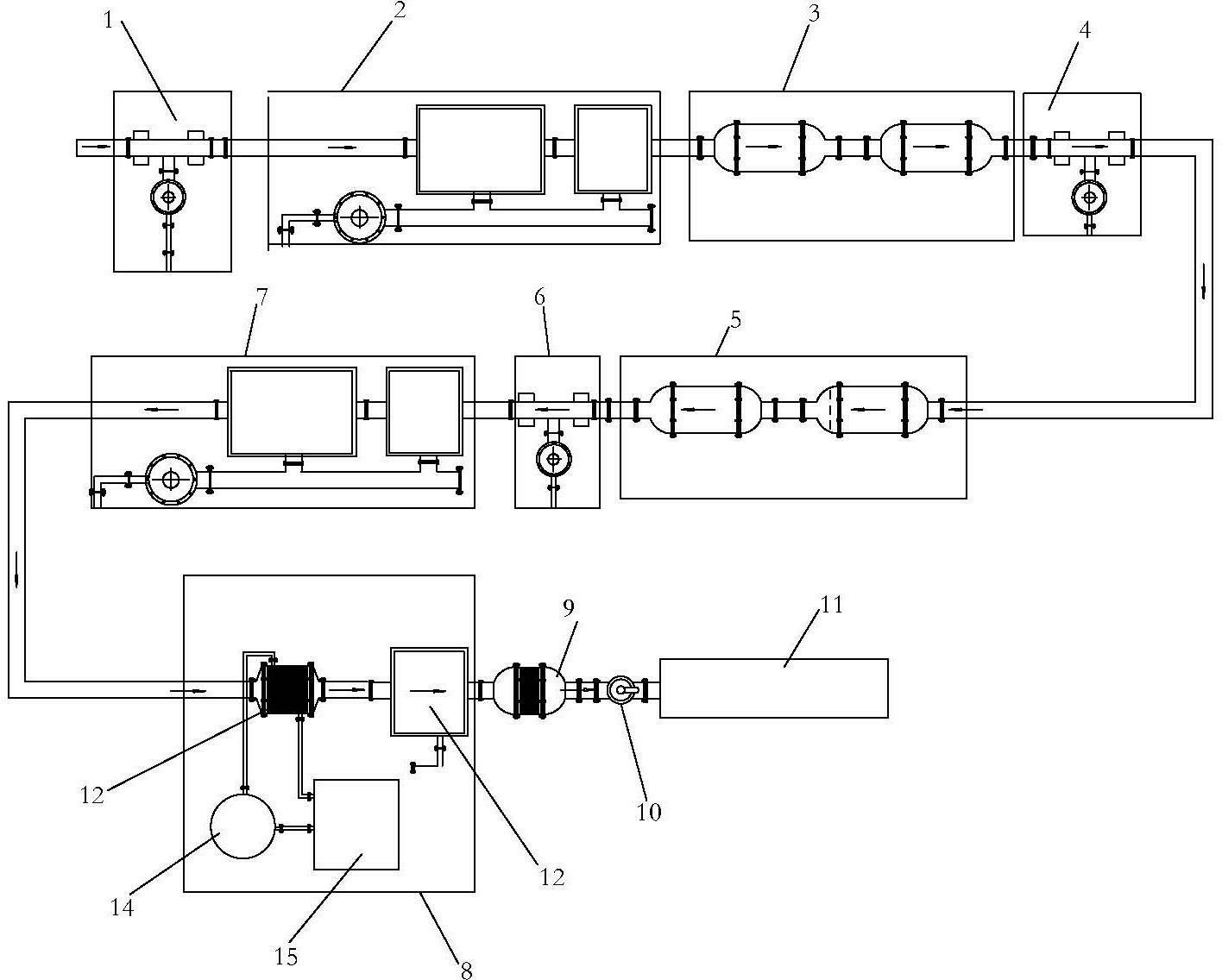

[0007] The specific embodiment of the present invention will be described in detail below in conjunction with the process flow diagram.

[0008] Depend on figure 1 Shown, the present invention is realized by the following methods in concrete implementation:

[0009] Low-concentration gas refers to by volume: methane 3%-25%, oxygen 11%-15%, nitrogen 54%-72%, carbon dioxide 0.1%-4%, combustible impurity gas 0-2%, non-combustible impurity gas 4%-7%, the total content is 100%, relative humidity ≥ 70%, temperature ≤ 57 ℃ gas, the gas is sent from the pumping pump station (pump station outlet pressure 30KPa-50KPa) into the water submerged relief valve 1. Adjust the pressure, and then send it to the first water-sealed flame arrester 2 to filter the large particles of solid impurities in the gas, and keep the pressure of the gas below 30KPa to eliminate the flame and ensure safety, and then enter the second A pipeline gas cooling displacer 3, the first pipeline gas cooling displacer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com