Method for purifying natural gas

A technology for purification and treatment of natural gas, applied in the field of natural gas, which can solve problems such as environmental pollution, high production and use costs, and weak corrosion, and achieve the effects of reducing production costs and improving desulfurization and purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation of embodiment 1 desulfurizer

[0047] The natural graphite was treated twice with 5% HCl, filtered, then thoroughly washed with distilled water, dried at 110°C for 24 hours, and 10 g of the treated graphite was placed in 230 mL of concentrated H 2 SO 4 In, slowly add 30gKMn0 in ice-water bath 4 , Stir continuously so that the temperature of the solution does not exceed 20°C. At this time, the mixed solution was mechanically stirred at 35±3°C for 40 minutes, and then 460 mL of distilled water was slowly added to the mixed solution, and the temperature rose rapidly to 98°C. Keep the mixed solution at 35±3°C and continue stirring for 20min. After the reaction is completed, mix 1.4L distilled water and 100mLH 2 0 2 Add to solution. Stand still for 24 hours, and finally wash and filter with 5% HCl until no S0 can be detected in the filtrate 4 2- until. Finally, the filtered product was vacuum-dried at 50°C in a vacuum drying oven for use; the prepared...

Embodiment 2

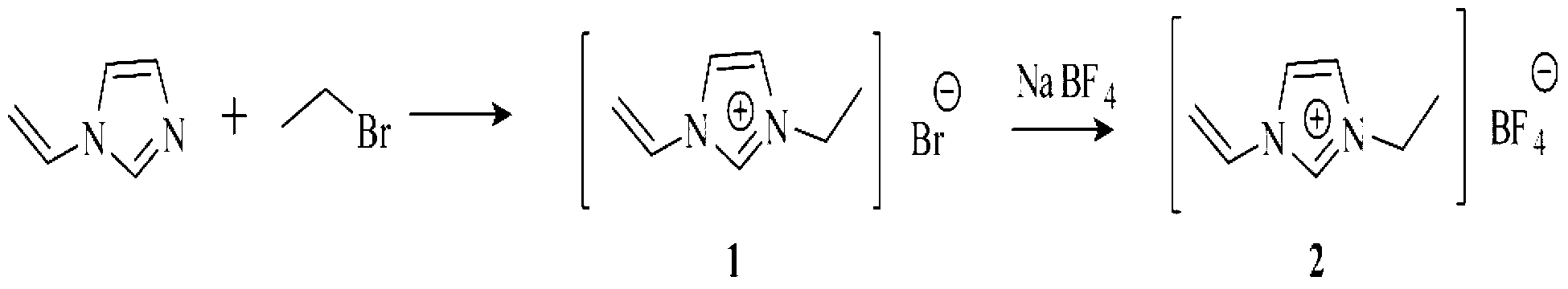

[0048] The preparation of embodiment 2 ionic liquid

[0049] Dissolve 1g of 1-vinylimidazole in 10ml of ethyl acetate solvent, put it in a 250ml three-neck flask, then add 1ml of bromoethane dropwise, after the dropwise addition, heat to 60°C to keep the temperature constant, and carry out stirring reaction for 12h. After the reaction is finished, the reaction system is suction-filtered, and the filtered cake is washed with ethyl acetate to obtain a light yellow solid intermediate, which is vacuum-dried to constant weight. Take 1g of the vacuum-dried solid intermediate and add 20ml of deionized water , put in a three-necked flask, take 2g of sodium tetrafluoroborate and add it into the three-necked flask, stir magnetically, heat to 60°C to keep the temperature constant, react for 24h, spin evaporate to remove water after the reaction, add acetone to the remaining liquid until Inorganic salt NaBr was precipitated, NaBr was removed by suction filtration, and finally acetone was ...

Embodiment 3

[0050] The preparation of embodiment 3 carbon dioxide absorbent

[0051] 120g ionic liquid 1-ethyl-3-vinylimidazole tetrafluoroborate, 200gN-methyldiethanolamine (MDEA), 410g monoethanolamine (MEA) and 270g deionized water prepared in Example 2 were prepared at normal temperature and pressure Mix and stir evenly in proportion to obtain a carbon dioxide absorber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com