Device and method for removing CO2 in power plant exhaust gas by means of ash slurry

A technology for ash and flue gas, which is applied to chemical instruments and methods, separation methods, gas treatment, etc. It can solve the problems of large pressure drop in the tower, low decarbonization efficiency, and limited flow rate, and achieves low equipment corrosion and degassing. High carbon efficiency and the effect of reducing decarbonization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

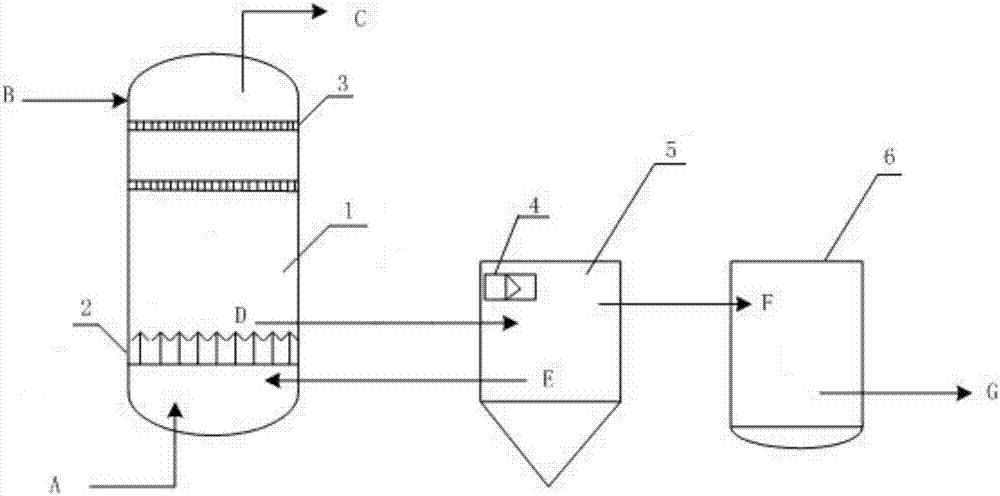

[0033] Such as figure 1Shown, the present invention provides a kind of utilizing ash slurry to remove CO in power plant flue gas 2 The device includes: a reactor 1, a sedimentation tank 5 and a clarifier 6; the upper input end of the reactor 1 is fed into the ash slurry, the lower input end is fed into the desulfurized flue gas from the power plant, and the upper output end is discharged from the decarbonized The output end of the lower end of the flue gas is connected to the sedimentation tank 5; the output end of the sedimentation tank 5 is connected to the clarification tank 6; the output end of the clarification tank 6 is connected to the atmosphere.

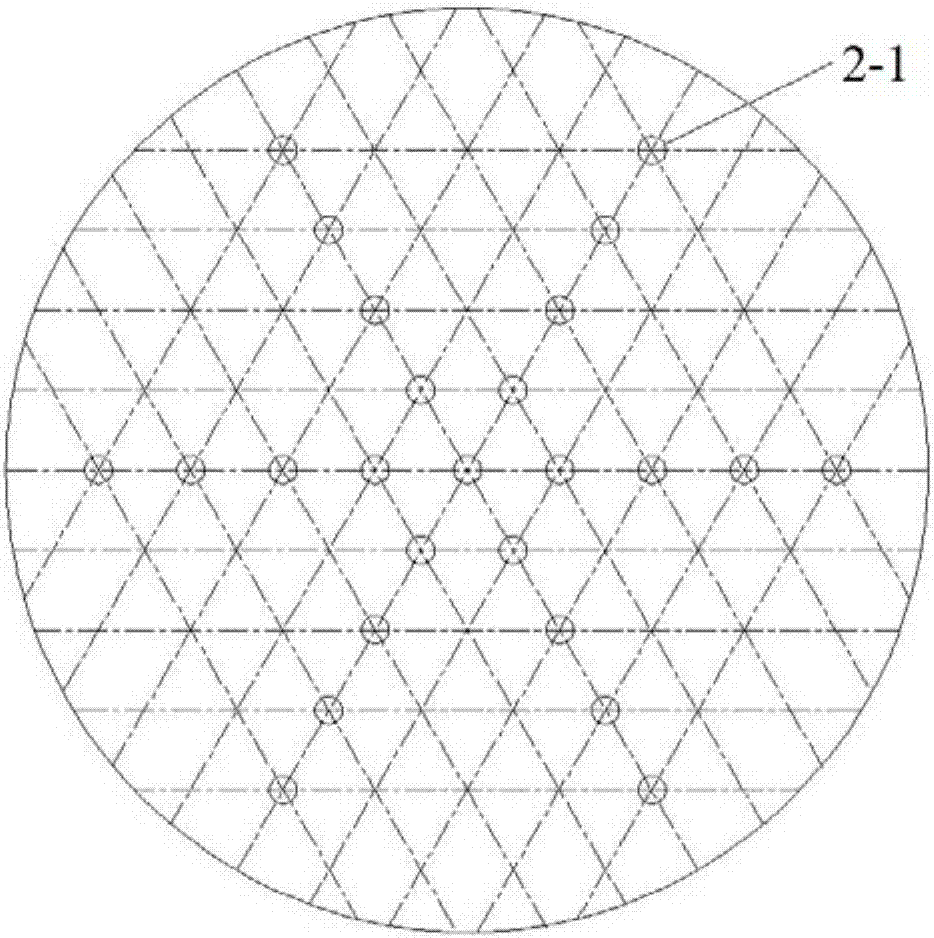

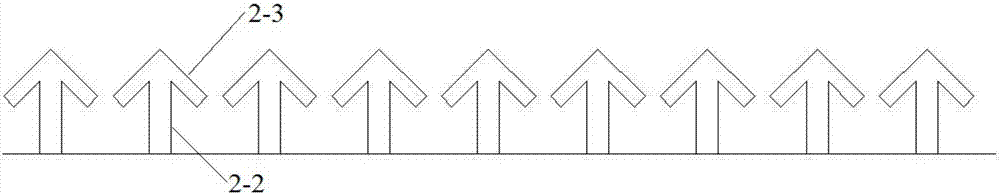

[0034] More specifically, a gas distributor 2 is provided in the reactor 1 . The gas distributor 2 is a circular plate-shaped structure, such as figure 2 As shown, the board is provided with a small hole 2-1 through the board body, and the diameter of the small hole is 30-50mm; image 3 As shown, branch pipes 2-2 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com