Flue gas decarburization system and method utilizing magnetized gas-liquid-solid three phase bed

A three-phase bed and flue gas technology, applied in the field of air pollutant control, can solve the problems of blocking packing, difficult to improve the removal rate, short gas-liquid contact time, etc. The effect of reducing operating costs and reducing energy consumption for regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

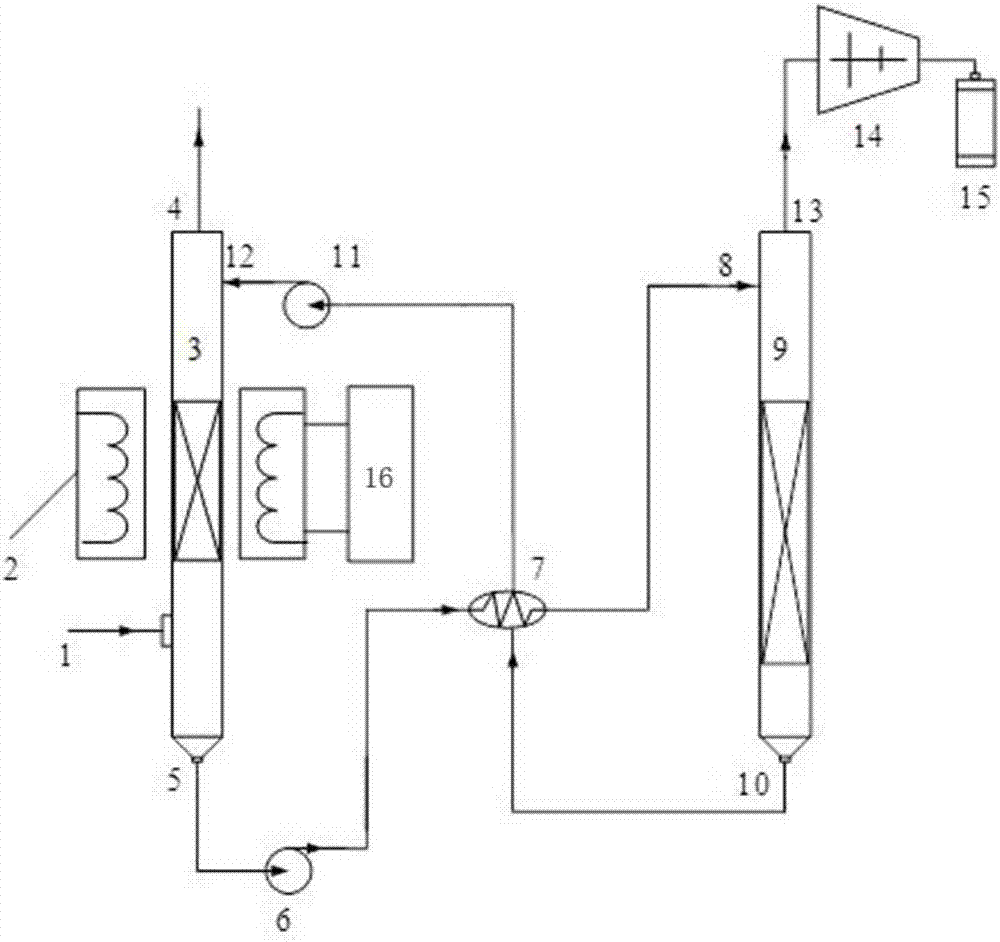

Method used

Image

Examples

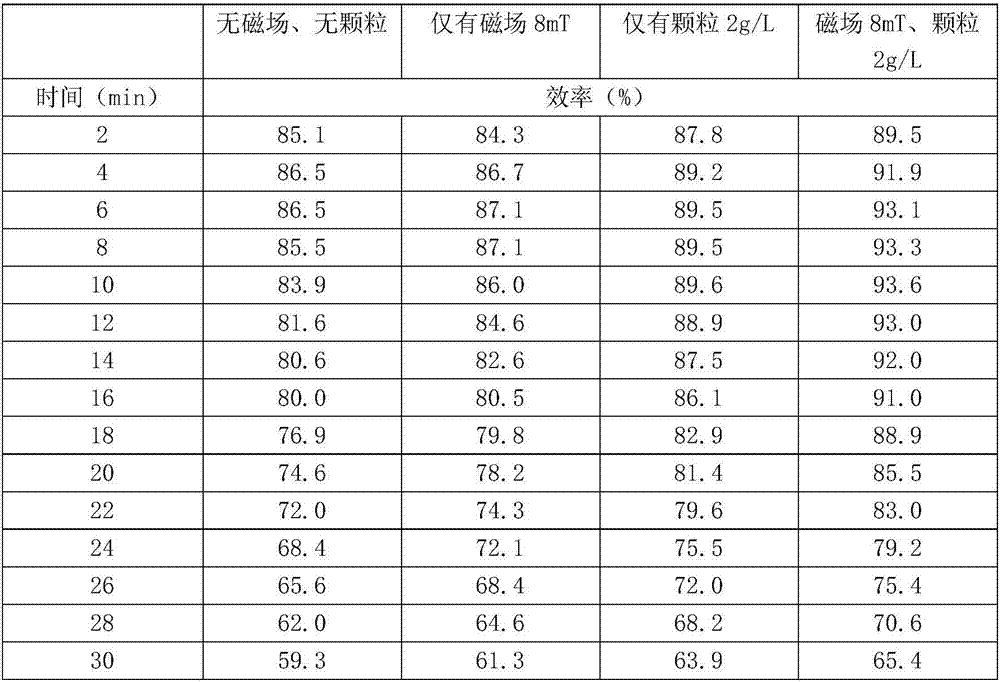

Embodiment 1

[0040] Use N 2 and CO 2 Gas mixing simulates flue gas, ammonia water absorbent, Fe 3 o 4 Nanoparticles and constant temperature vertical magnetic field, at a reaction temperature of 20°C, a simulated flue gas flow rate of 2.0L / min, a concentration of ammonia water of 5%, CO 2 Under the working condition of 20% concentration, four conditions of no magnetic field and no particles, only magnetic field, only particles, and synergistic effect of particles and magnetic field were selected to investigate the influence of magnetic field and magnetic particles in the absorption tower on the decarburization efficiency. The results are shown in Table 1.

[0041] Table 1: Decarbonization efficiency at different times

[0042]

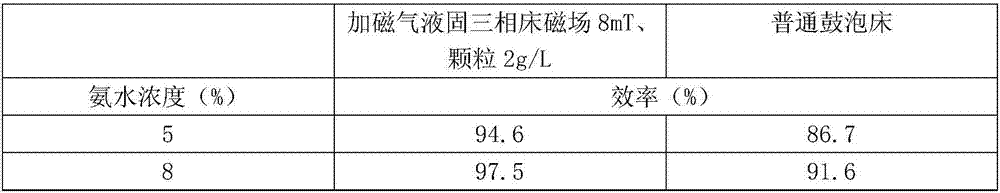

Embodiment 2

[0044] The implementation process is the same as in Example 1, and the difference in the influence of operating parameters such as ammonia concentration and flue gas flow rate on the decarburization efficiency is investigated by choosing a magnetic gas-liquid-solid three-phase bed and a common bubbling bed (without magnetic field and particles). The results are shown in Table 2 and Table 3.

[0045] Table 2: Decarburization Efficiency of Different Ammonia Concentrations

[0046]

[0047]

[0048] Table 3: Decarbonization efficiency of different flue gas flows

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com