System for simultaneously removing carbon dioxide and nitric oxide and method thereof

A carbon dioxide and nitrogen oxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high catalyst cost, deactivation, and easy poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

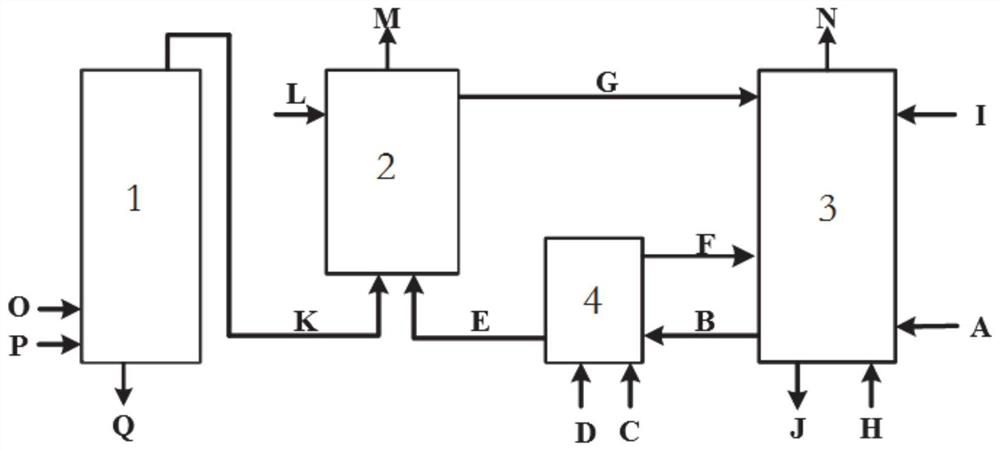

[0067] Such as figure 1 As shown, the system mainly includes the following equipment: coal-fired boiler 1, circulating fluidized bed decarburization and denitrification furnace 2, circulating fluidized bed calciner 3, and bubbling fluidized bed pyrolysis carbon deposition furnace 4. Calcium carbonate A first enters the circulating fluidized bed calciner 3 for calcination, and the generated high-temperature calcium oxide B is sent to the bubbling fluidized bed pyrolysis carbon deposition furnace 4 to provide heat for pyrolysis, and at the same time, biomass C enters the drum In the bubble fluidized bed pyrolysis carbon deposition furnace 2, it is pyrolyzed under the fluidization of a small amount of nitrogen D to generate carbon deposition calcium oxide / biomass char mixture E and pyrolysis gas F, and the pyrolysis gas F is sent to the calciner 3 The mixture E is fed into the circulating fluidized bed decarburization and denitrification furnace 2, and reacts with the carbon diox...

Embodiment 2

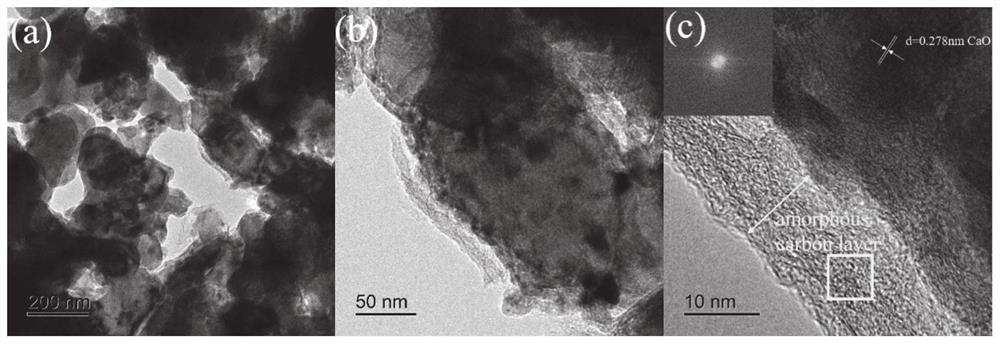

[0070] On the bubbling fluidized bed reactor mentioned in embodiment 1, adopt the calcium oxide and biomass identical with embodiment 1, have prepared carbon deposit calcium oxide, carry out TEM analysis to carbon deposit calcium oxide as follows image 3 shown. The preparation conditions of carbonized calcium oxide are: pyrolysis temperature 800°C, pyrolysis time 10min, mass ratio of pine wood / calcium oxide 20:100, fluidization number 2, pyrolysis atmosphere 100% nitrogen. Such as image 3 As shown in (a) and (b), after co-pyrolysis of calcium oxide and pine wood, carbon deposits are formed on the pores and surfaces of calcium oxide, and the calcium oxide grains are wrapped by a layer of amorphous carbon with a low degree of graphitization. Closely combined with carbon deposits. After further enlarging the carbon-deposited calcium oxide as image 3 As shown in (c), carbon-deposited calcium oxide is mainly composed of crystals and non-crystals. The interplanar spacing of cr...

Embodiment 3

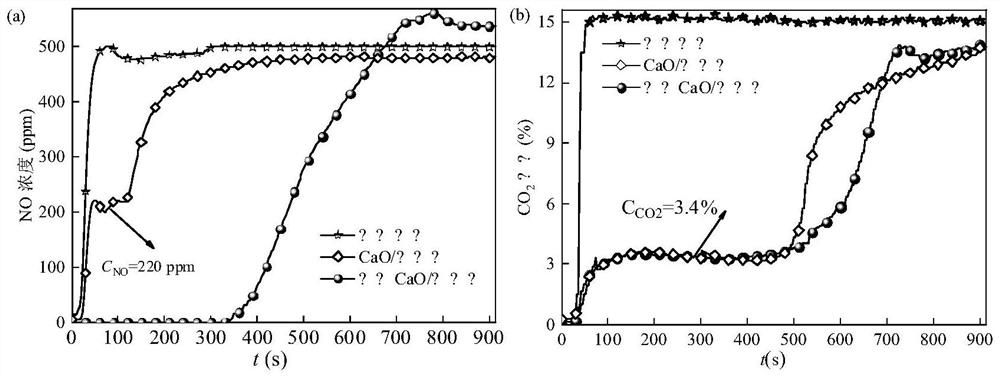

[0072] On the bubbling fluidized bed reactor mentioned in Example 1, the same calcium oxide and biomass as in Example 1 were used to study the effect of the mass ratio of biomass / calcium oxide on the simultaneous removal performance. The decarburization and denitrification reaction conditions are as follows: the mass of calcium oxide is 16g, the pyrolysis temperature of pine wood is 800°C, the pyrolysis time is 10min, the pyrolysis atmosphere is 100% nitrogen, and the removal reaction temperature is 650°C, and the fluidization number is 2. The inlet atmosphere is 15% carbon dioxide / 4% oxygen / 500×10 -4 % Nitric Oxide / Nitrogen Balance. Change the mass ratio of pine wood / calcium oxide, and use German Testo350 flue gas analyzer to test the nitric oxide and carbon dioxide in the outlet gas of the fluidized bed reactor. The results are as follows: Figure 4(a) and (b) shown. The denitrification performance of carbon-deposited calcium oxide increases with the increase of the mass r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com