Oxygen lance nozzle

An oxygen lance nozzle and nozzle technology, which is used in furnaces, manufacturing converters, lighting and heating equipment, etc., can solve the problems of high ambient temperature, easy erosion of the lower end surface, uneconomical steelmaking enterprises, etc. The effect of reducing splash phenomenon and reducing equipment consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

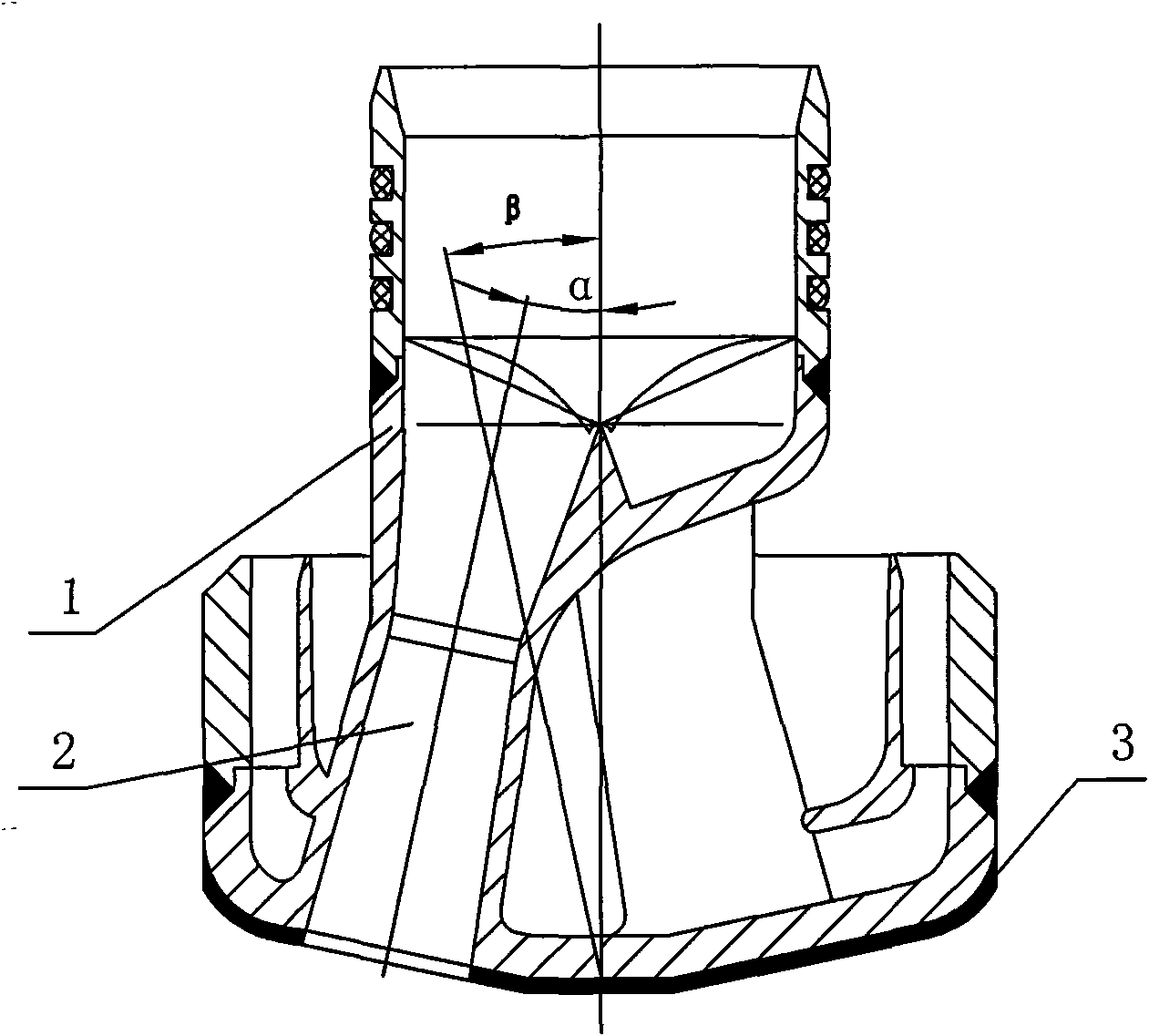

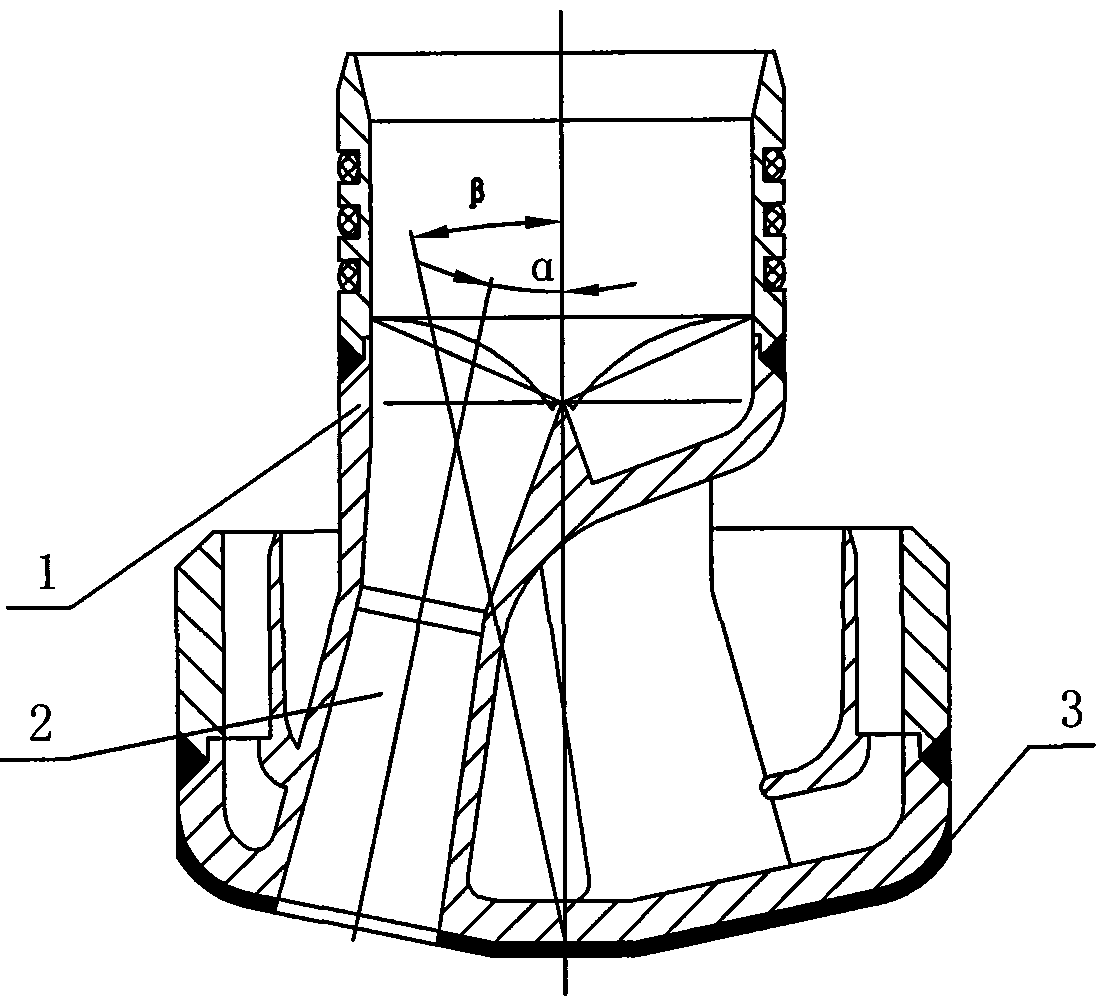

[0014] The lower part of the oxygen lance nozzle of the present invention is arranged in the molten pool, including the nozzle body 1 , the nozzle body 1 is provided with rako-open nozzle holes 2 in the circumferential direction, and the lower end surface of the nozzle is covered with a layer of nickel-chromium alloy layer 3 . The thickness of the nickel-chromium alloy layer 3 is 1.5-2mm. The axis of the nozzle hole 2 forms an included angle α with the nozzle axis, and α is between 5°-20°. The nozzle hole 2 and the axis plane of the nozzle body 1 form an included angle β, and β is between 5°-20°.

[0015] The preferred mode of the present invention is α=β=12°, and this angle is especially suitable for a nozzle with four nozzle holes 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com