Method for smelting low-carbon stainless steel by utilizing GOR converter

A converter smelting and stainless steel technology, applied in the manufacture of converters, etc., can solve problems such as high cost, reduced smelting effect, and difficult production, and achieve the effects of reducing oxidation, improving the mixing efficiency of the molten pool, and improving the decarbonization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

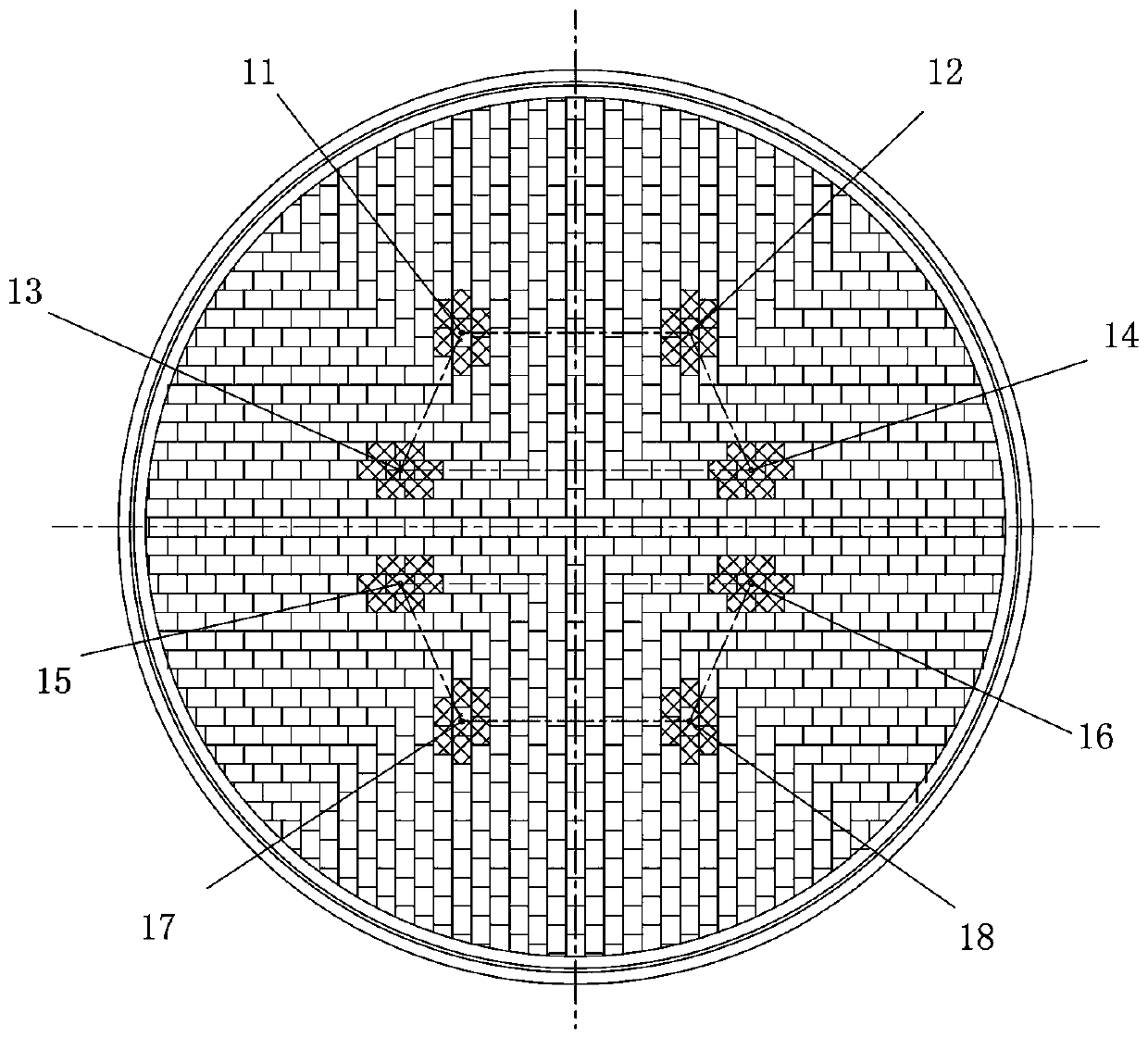

Method used

Image

Examples

Embodiment 1

[0028] Heat number: 1907-147

[0029] Steel type: 304L

[0030] Example 1 The weight of molten steel for rough refining of stainless steel in the furnace: 93.2 tons, and the composition (%) of molten steel for rough refining of stainless steel in the furnace is shown in the following table:

[0031] C Si mn P S Cr Ni Cu N 2.652 0.04 0.11 0.036 0.254 17.71 6.45 0.04 0.03

[0032] The decarburization process of GOR converter smelting described in this embodiment is as follows:

[0033] S1: Add the stainless steel rough-smelting molten steel with a temperature of 1500°C into the GOR furnace;

[0034] S2: The first stage of main decarburization: top lance oxygen blowing flow rate: 90Nm 3 / min; bottom blowing flow: oxygen 80Nm 3 / min, nitrogen 5Nm 3 / min; blowing time: 16min, until the carbon content in the molten pool is reduced to 1.0%, enter the second stage of main decarburization;

[0035] S3: The second stage of main decarburization:...

Embodiment 2

[0044] Heat number: 1907-148

[0045] Steel type: 304L

[0046] Example 2 The weight of molten steel for rough refining of stainless steel in the furnace: 91.6 tons, and the composition (%) of molten steel for rough refining of stainless steel in the furnace is shown in the table below:

[0047] C Si mn P S Cr Ni Cu N 3.00 0.23 0.14 0.034 0.257 17.55 6.47 0.04 0.023

[0048] The tapping composition (%) of embodiment 2

[0049] C Si mn P S Cr Ni Cu N 0.023 0.51 1.45 0.033 0.003 18.28 7.96 0.05 0.047

Embodiment 3

[0051] Heat number: 1907-186

[0052] Steel type: 316L

[0053] Example 3 The weight of molten steel for rough refining of stainless steel in the furnace is 92.2 tons, and the composition (%) of molten steel for rough refining of stainless steel in the furnace is shown in the following table:

[0054] C Si mn P S Cr Ni Cu N 1.70 0.37 0.16 0.033 0.277 16.23 6.70 0.05 0.027

[0055] The tapping composition (%) of embodiment 3 is shown in the table below:

[0056] C Si mn P S Cr Ni Cu N Mo 0.021 0.52 1.43 0.034 0.004 16.23 10.15 0.07 0.030 2.038

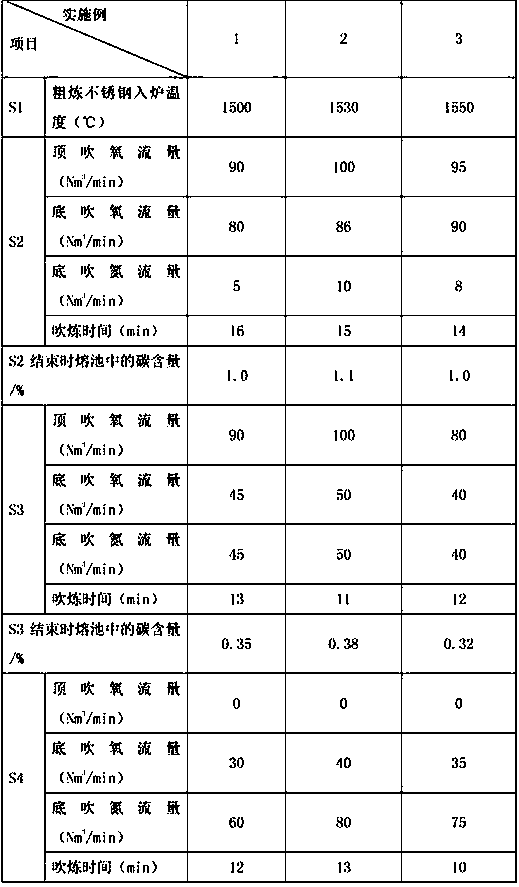

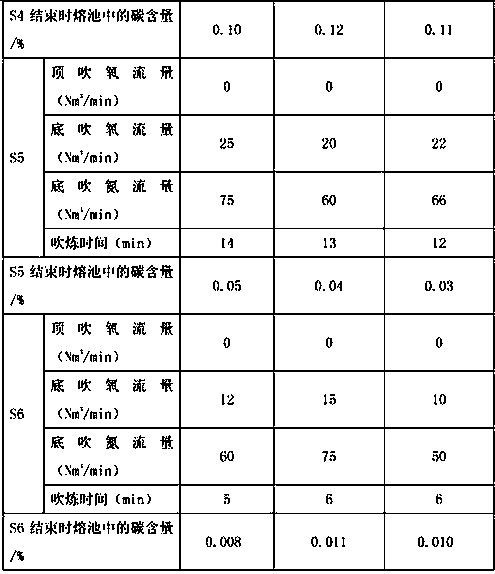

[0057] The difference between the GOR converter smelting decarburization process described in Examples 2-3 and Example 1 is that the parameters of each step are different, and the specific parameters are shown in Table 1.

[0058] Table 1:

[0059]

[0060]

[0061] The oxygen supply amount in the decarburization process of the present invention is ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com