A large-scale converter injection process method

A technology of large-scale converters and process methods, applied in the manufacture of converters, lime production, etc., can solve the problems of not considering the influence of stirring intensity on the smelting process, the single converter smelting process, and not considering the energy-saving and efficiency-enhancing issues, etc., to achieve the suppression of explosive Effects of splashing, reducing splashing, and shortening smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] In this embodiment, the main chemical composition of the smelted steel is as follows in weight percentage figure 1 Shown:

[0066] Table 1

[0067]

[0068] In this embodiment, when molten steel is smelted, solid particles are sprayed into the converter, and the requirements for solid particles are shown in Table 2:

[0069] Table 2

[0070] Types of solid particles Diameter before passivation diameter after passivation tolerance scope CaO particles 20nm--180nm ≤2mm ±5%

[0071] When CaO solid particles are sprayed into the converter, the medium gas is used as the carrier. The specific process steps are as follows:

[0072] 1) The tonnage of the converter project is 180t, which is suitable for converter smelting with a large scrap ratio.

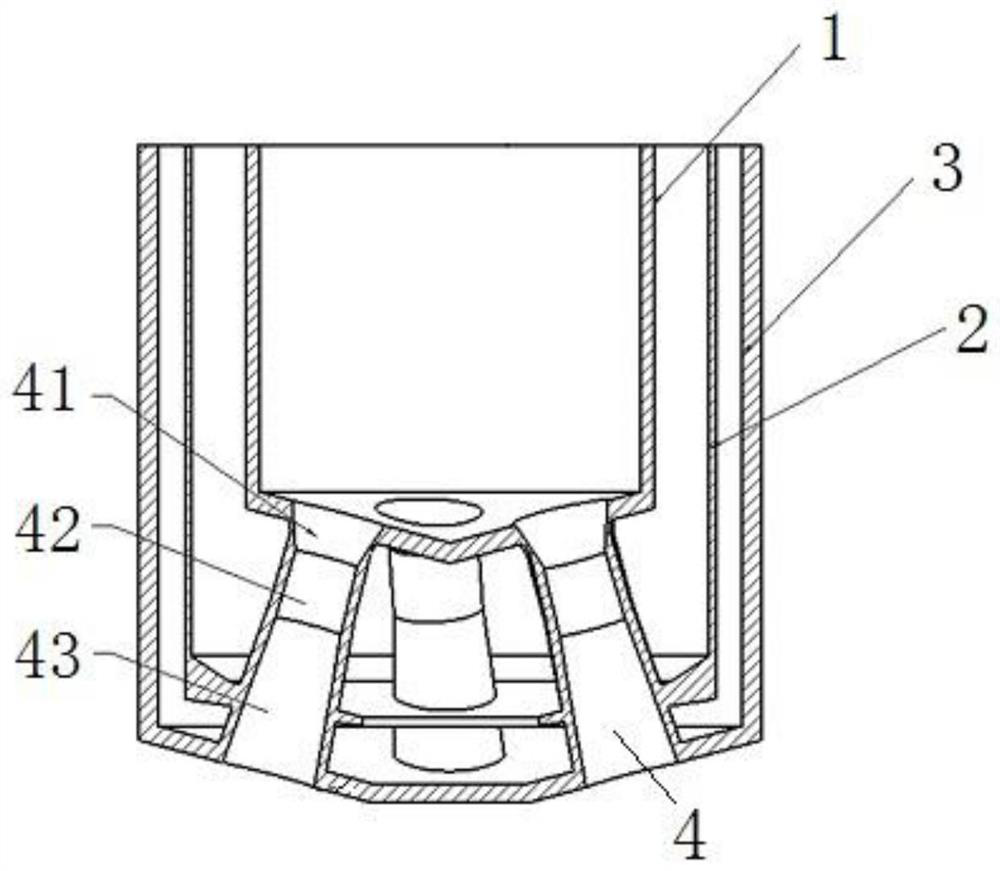

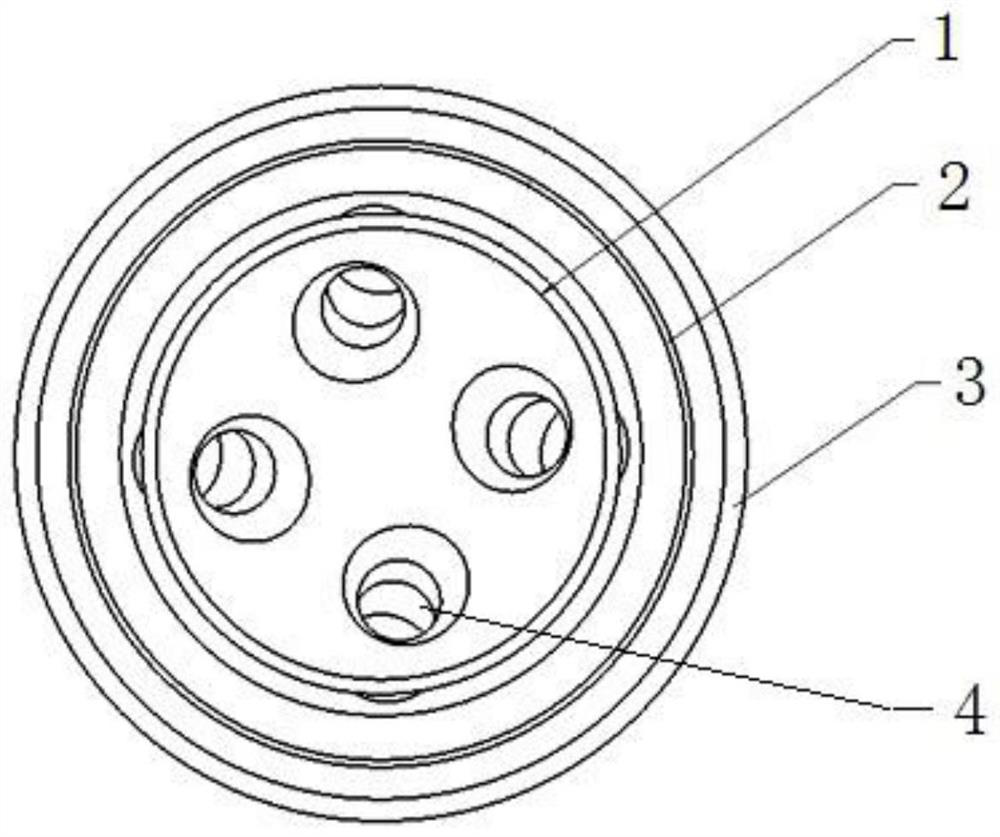

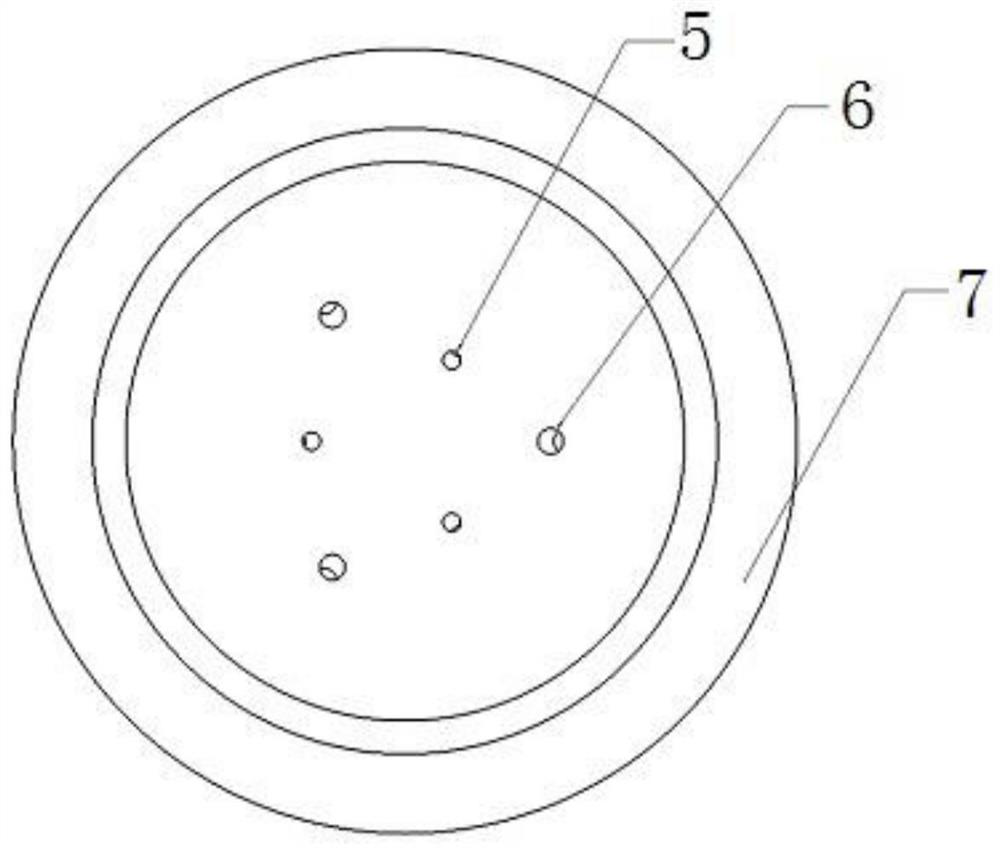

[0073] 2) Simultaneously spray CaO solid particles through the swirl oxygen lance and the horizontal slot-type bottom blowing element, or use the horizontal slot-type bottom blowing element to blow...

Embodiment 2

[0083] In this embodiment, gas is blown into the converter through a swirl oxygen lance and a horizontal slot bottom blowing element.

[0084] The gas flow rate of the horizontal slot bottom blowing element is 710m 3 / h, bottom blowing intensity 0.06m 3 / min. t, the average carbon-oxygen product is 0.0021.

[0085] The inclination angle of the nozzle hole of the swirl oxygen lance is 7.5°, the swirl angle is 11°, and the inlet pressure of the oxygen lance is 1.0MPa. The diameter of the entrance of the nozzle shrinkage section is 80mm, the diameter of the throat is 40mm, and the impact area is increased by more than 4%.

[0086] After the oxygen blowing finishes, the swirl oxygen lance lifts the lance operation, stops blowing, calculates the amount of injecting rare earth element solid particles according to formula 2 (k=ay+bW), in the formula: injecting amount is y=6.93 tons, a =0.091, b=43%, w=0.03, k=0.64 tons. The solid particles of rare earth elements are sprayed thro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com