Patents

Literature

36results about How to "Control splash" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supercharger

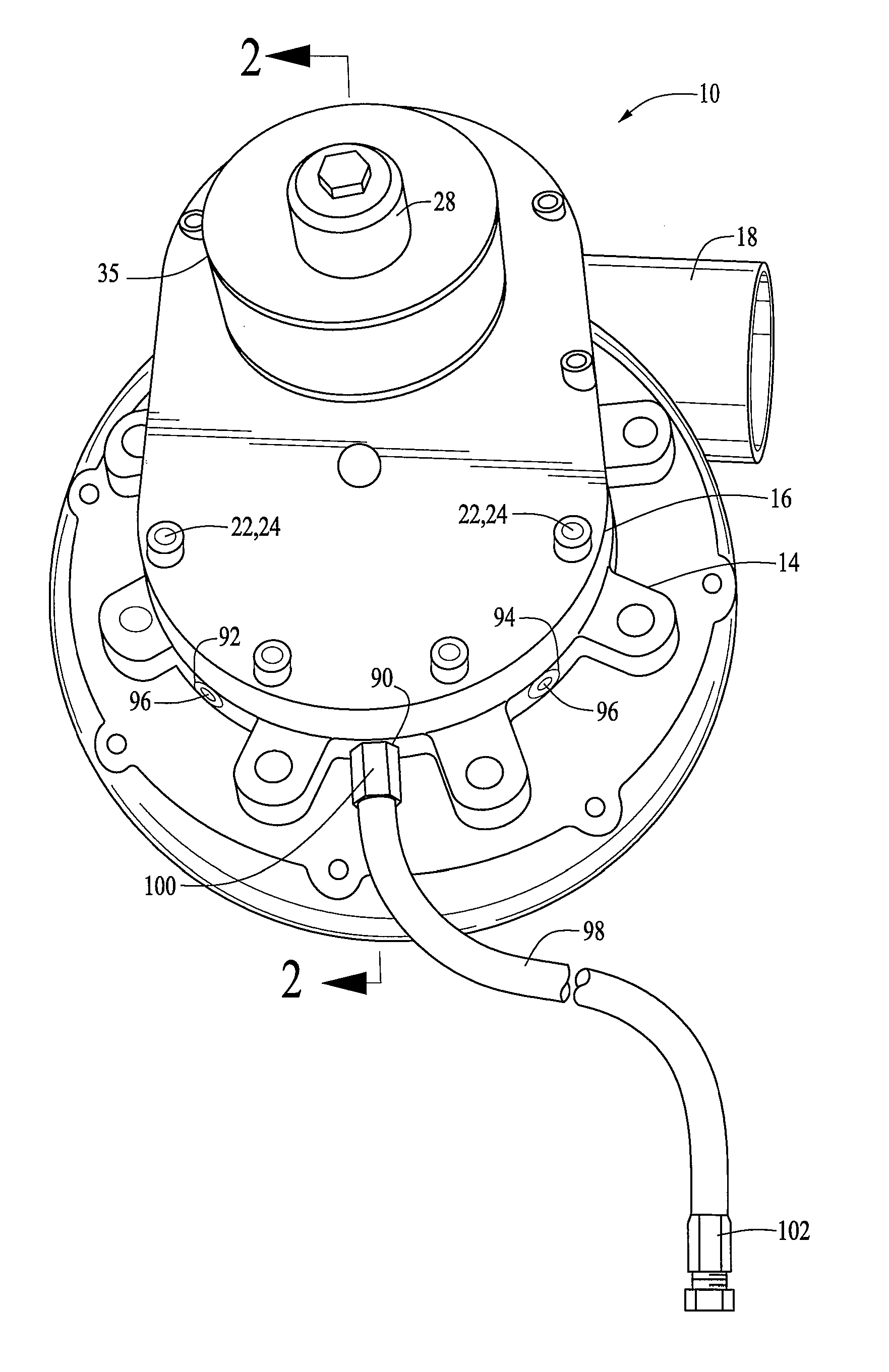

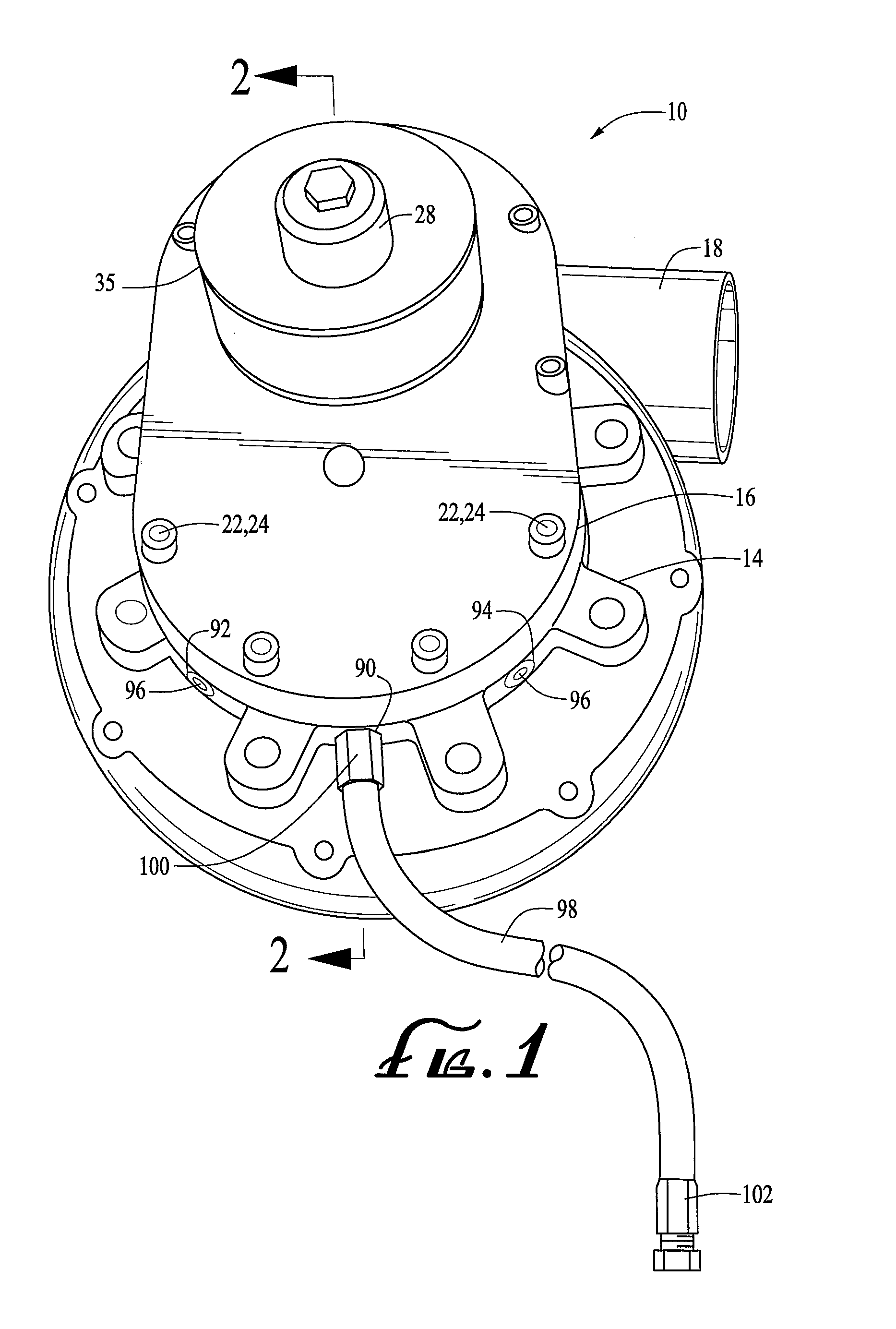

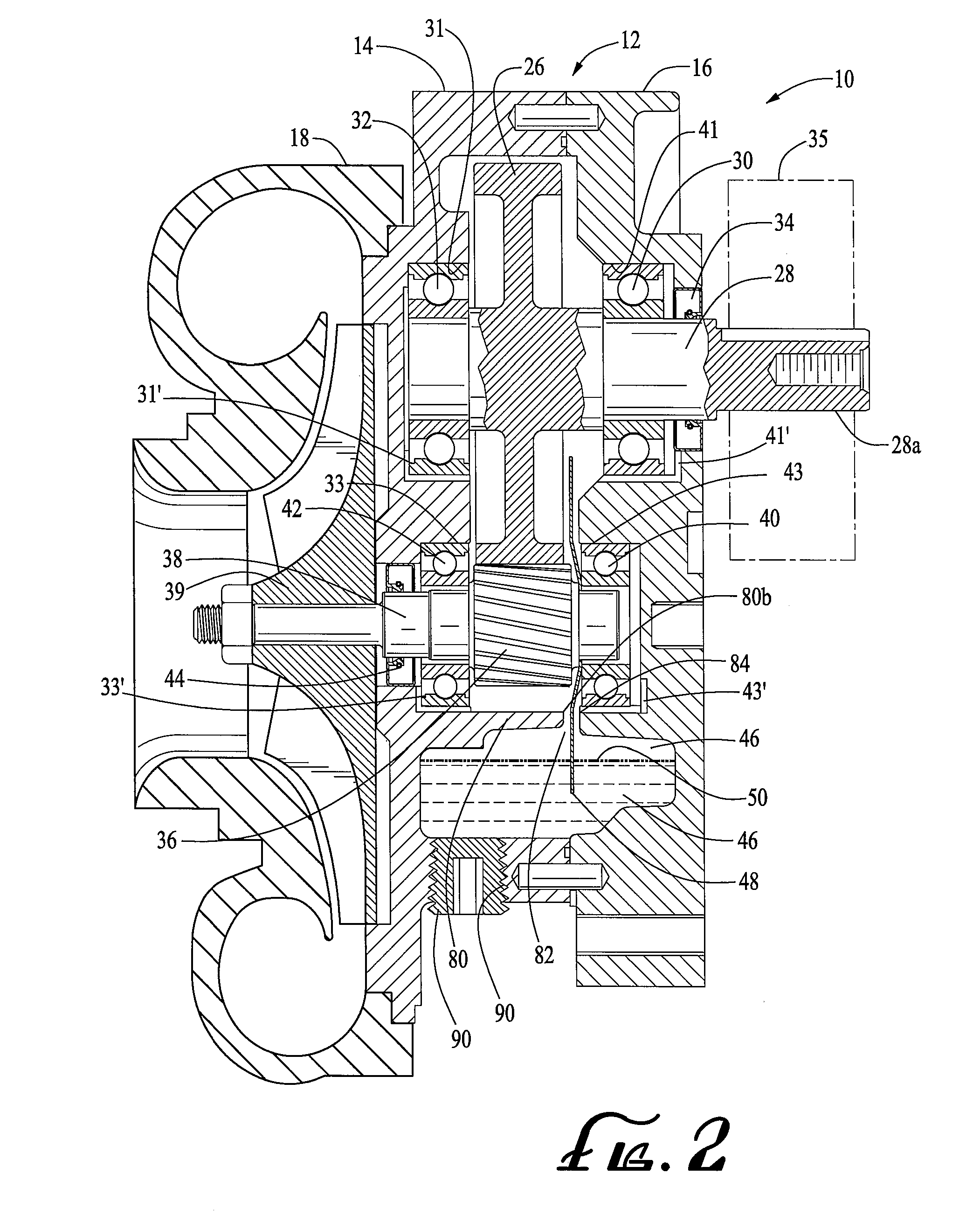

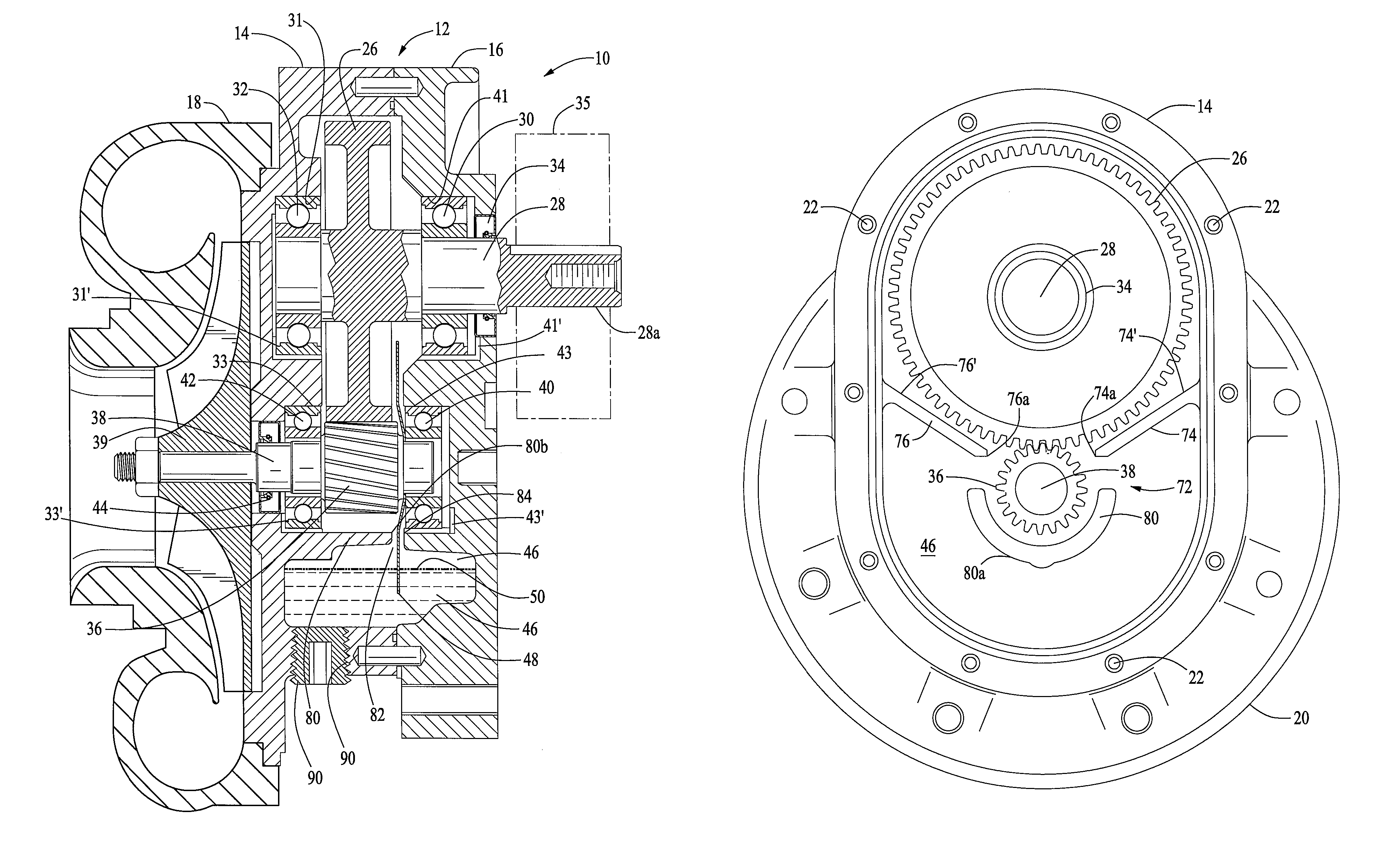

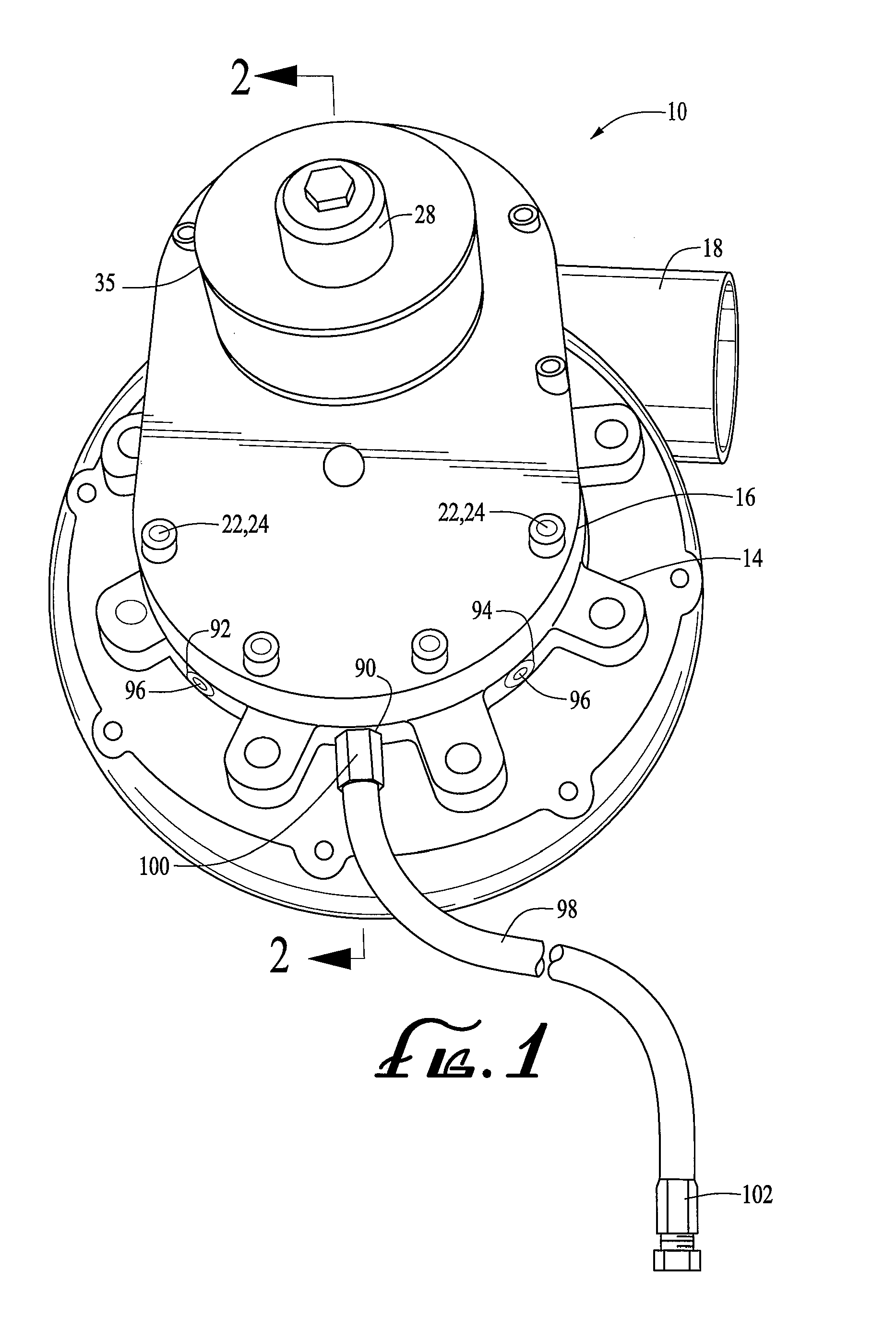

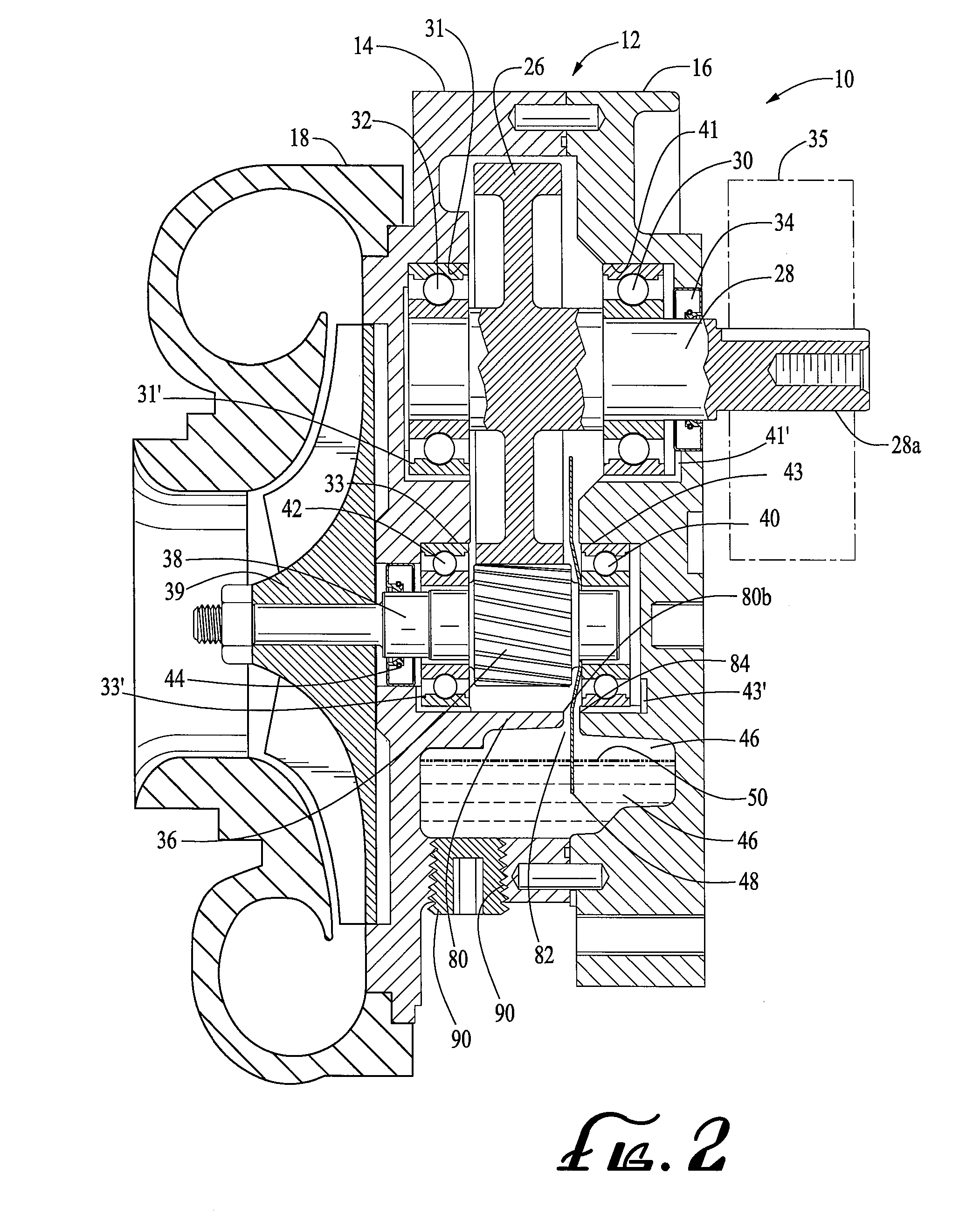

ActiveUS20100000498A1Fully lubricatedControl splashCombustion enginesEngine sealsImpellerEngineering

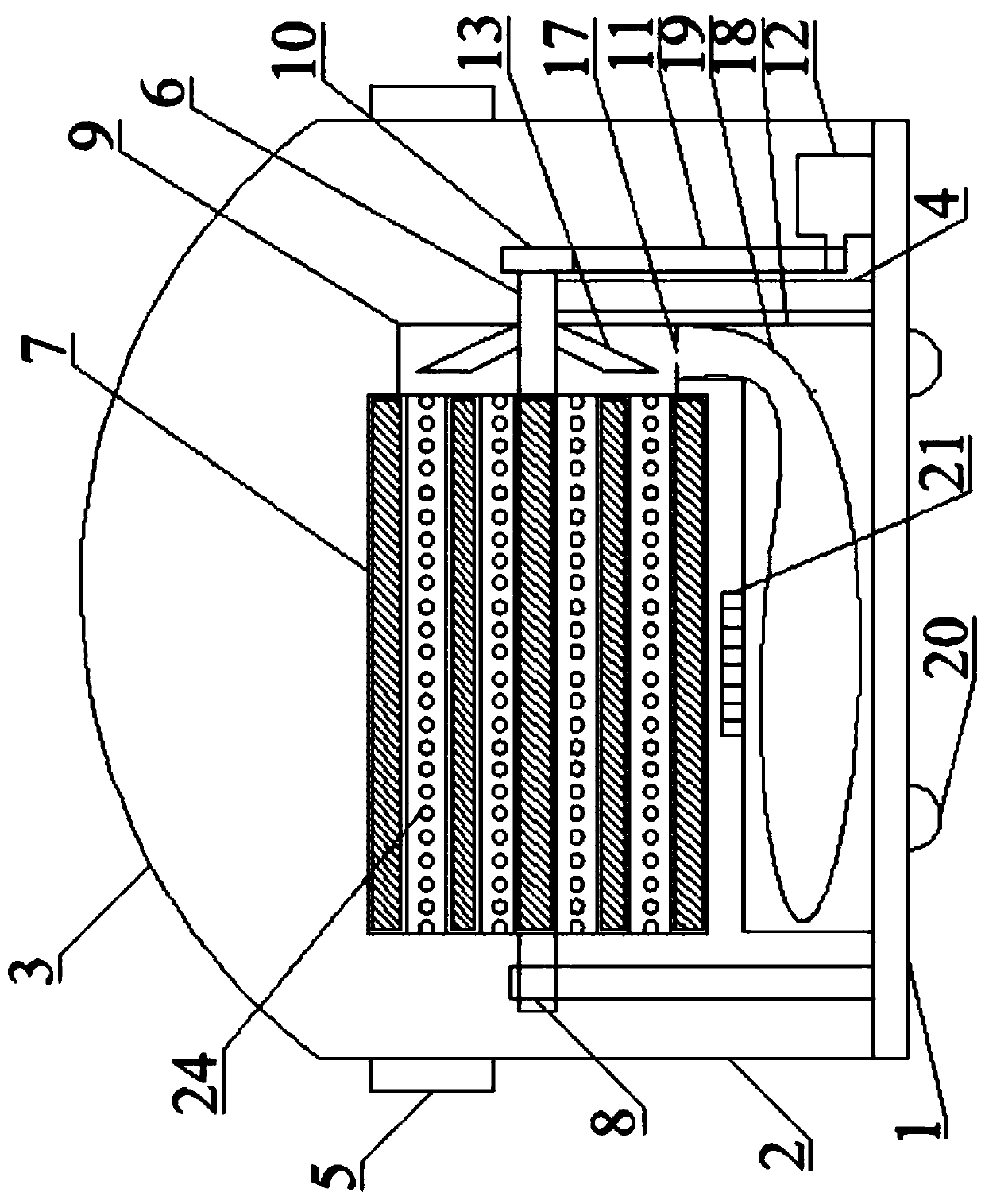

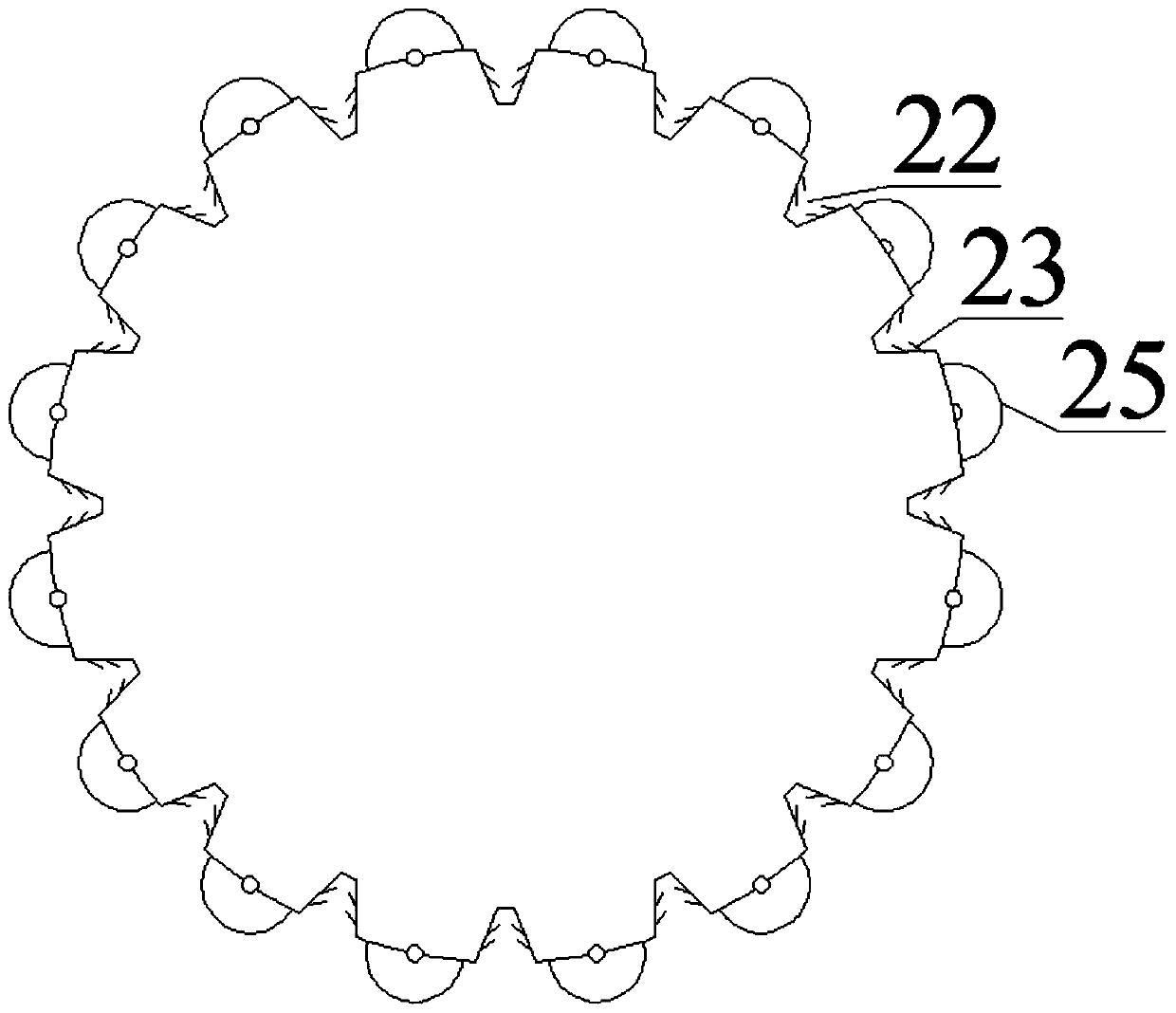

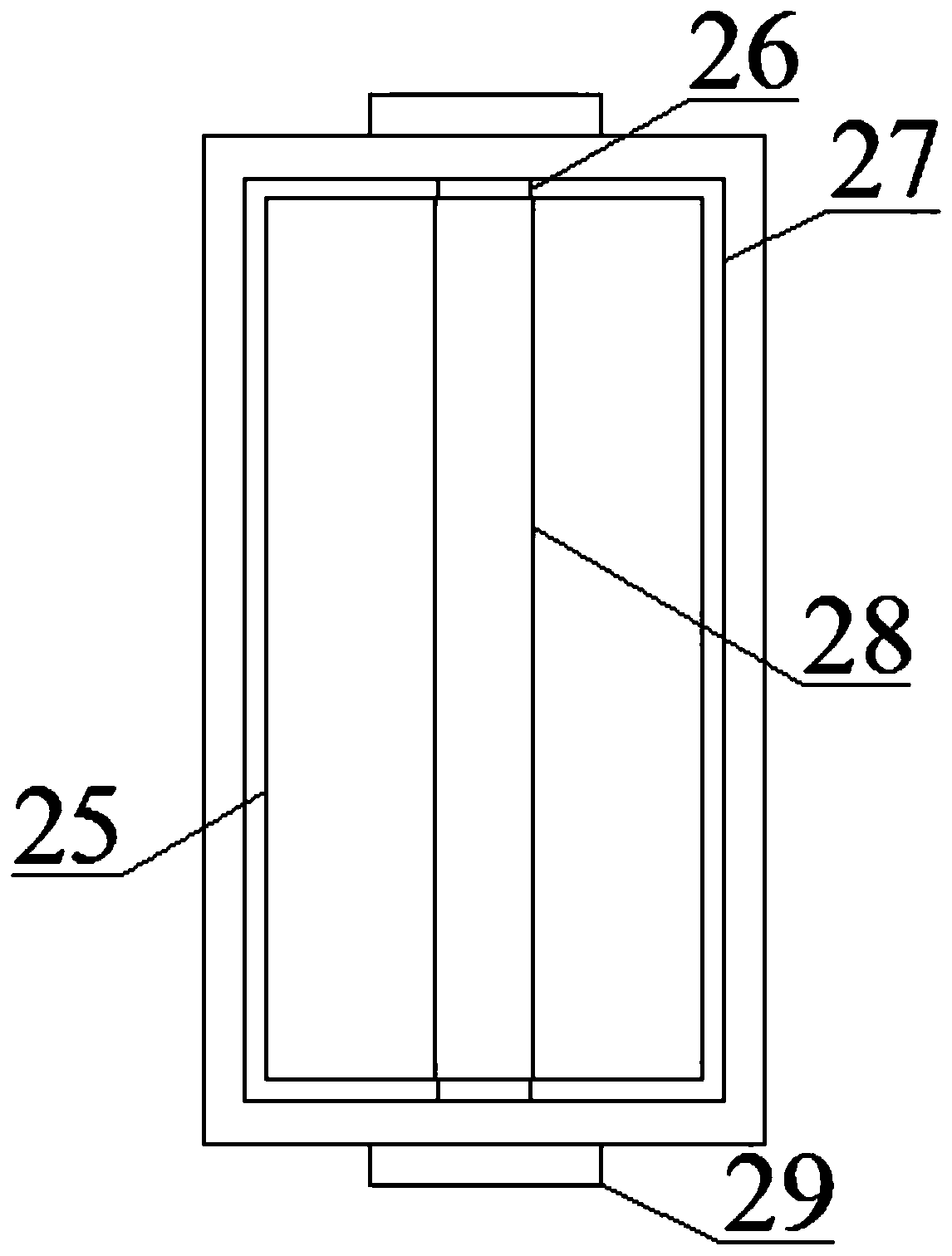

A supercharger for an internal combustion engine having an internal reservoir adapted to receive a supply of lubricating oil. An oil slinger is mounted on the impeller shaft for rotation therewith that extends into the reservoir for collecting and slinging lubricating oil onto the supercharger bearings, shafts and the drive and impeller gears. A baffle assembly is carried by the interior of the supercharger housing for controlling the volume and flow of lubricating oil onto said gears and bearings and directing oil flow therefrom back into said reservoir to prevent excessive lubrication buildup on the gears and the deleterious effects that result therefrom.

Owner:VORTECH ENG

Supercharger with oil slinger and baffles

ActiveUS8028524B2Fully lubricatedReduce total powerCombustion enginesEngine sealsImpellerEngineering

A supercharger for an internal combustion engine having an internal reservoir adapted to receive a supply of lubricating oil. An oil slinger is mounted on the impeller shaft for rotation therewith that extends into the reservoir for collecting and slinging lubricating oil onto the supercharger bearings, shafts and the drive and impeller gears. A baffle assembly is carried by the interior of the supercharger housing for controlling the volume and flow of lubricating oil onto said gears and bearings and directing oil flow therefrom back into said reservoir to prevent excessive lubrication buildup on the gears and the deleterious effects that result therefrom.

Owner:VORTECH ENG

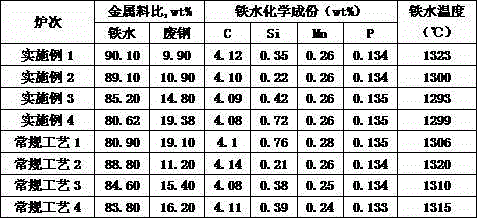

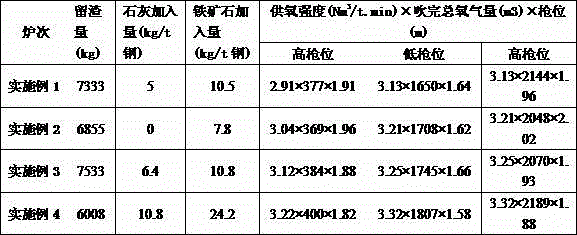

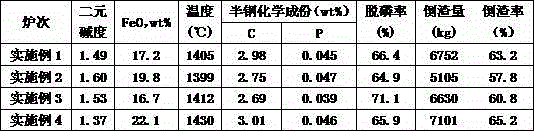

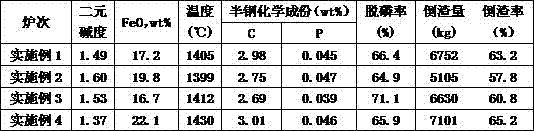

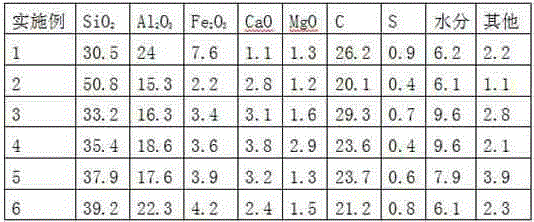

Method for controlling splashing in less slag smelting decarbonization period of converter

ActiveCN105525055AReduce consumptionImprove stabilityManufacturing convertersProcess efficiency improvementSlagUltimate tensile strength

The invention discloses a method for controlling splashing in the less slag smelting decarbonization period of a converter. The technical problem that splashing is likely to happen in the decarbonization period of the double slag and remaining slag smelting technology of a converter in the prior art is mainly solved. The method for controlling splashing in the less slag smelting decarbonization period of the converter comprises the following steps of steel scrap adding, molten iron charging, converter blowing desilicication and dephosphorization, pre-slag pouring, converter blowing decarbonization, converter tapping and slag remaining. By means of control over adding of limestone or dolomite in the converter blowing decarbonization period, the oxygen supply strength is controlled to be increased step by step during lance feeding blowing, and the problems of explosive splashing during lance feeding blowing and returning dry splashing in the blowing process in the decarbonization period are well controlled through adjustment on the lance height and the oxygen supply strength in the blowing process.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

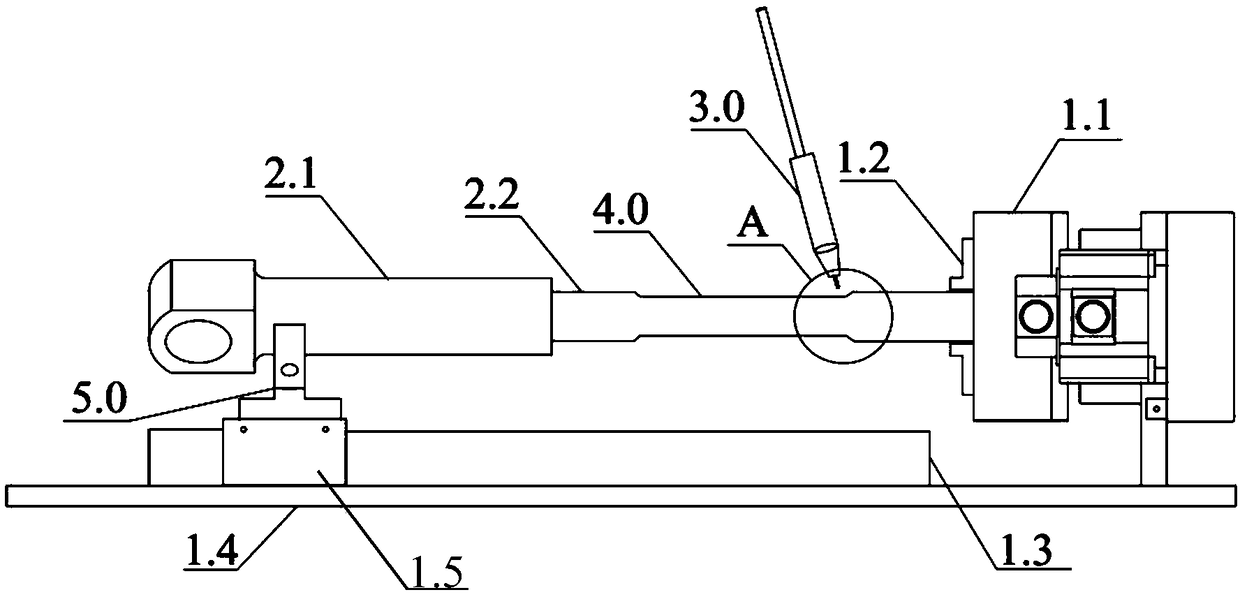

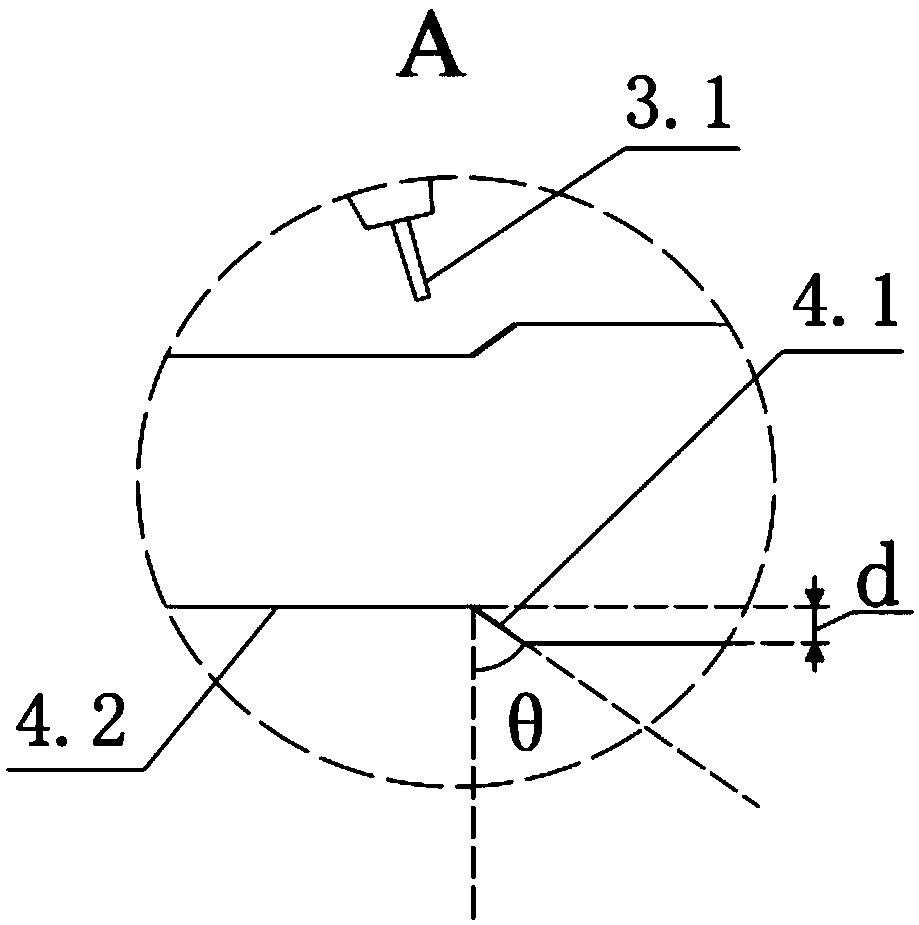

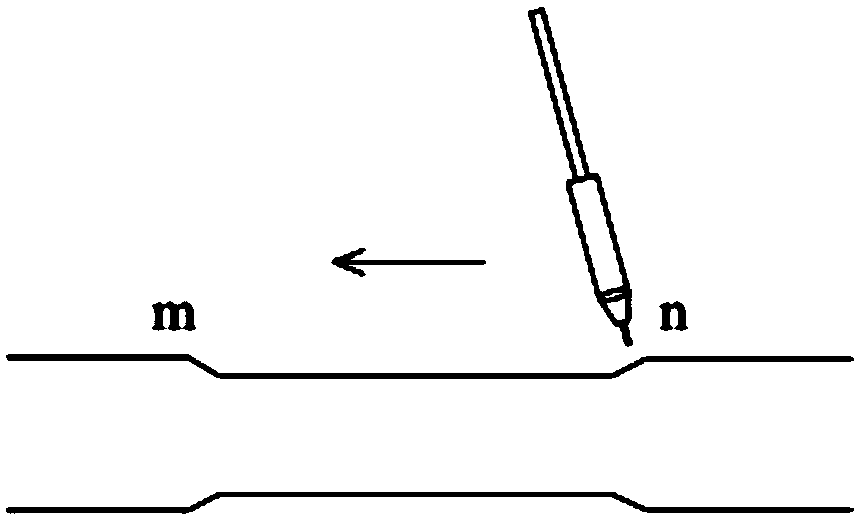

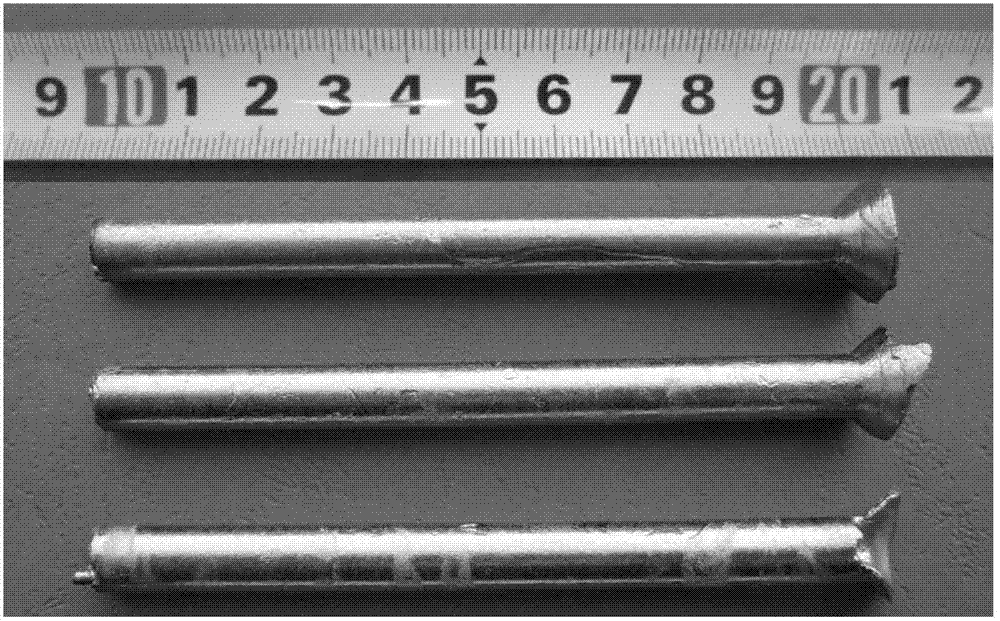

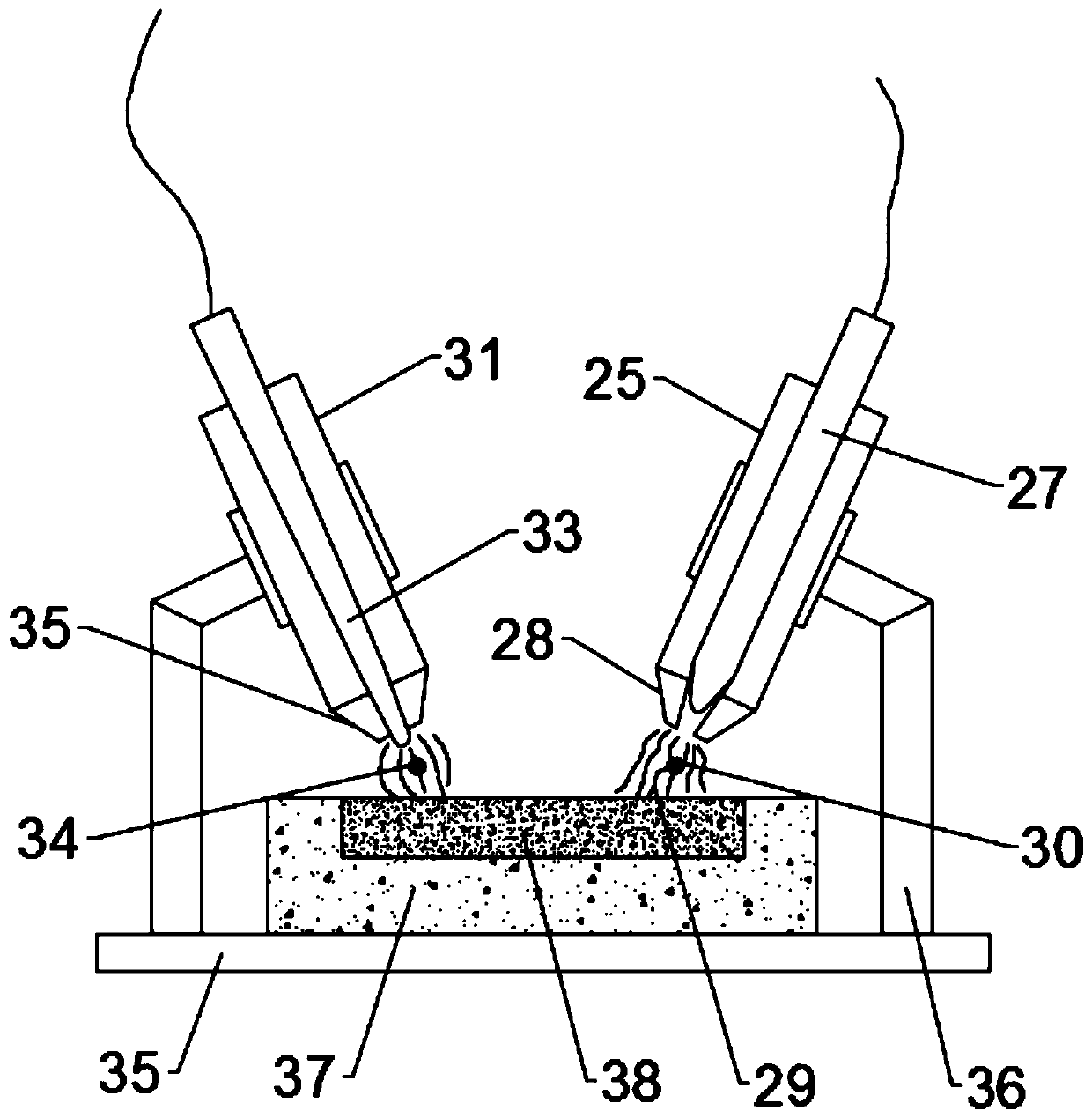

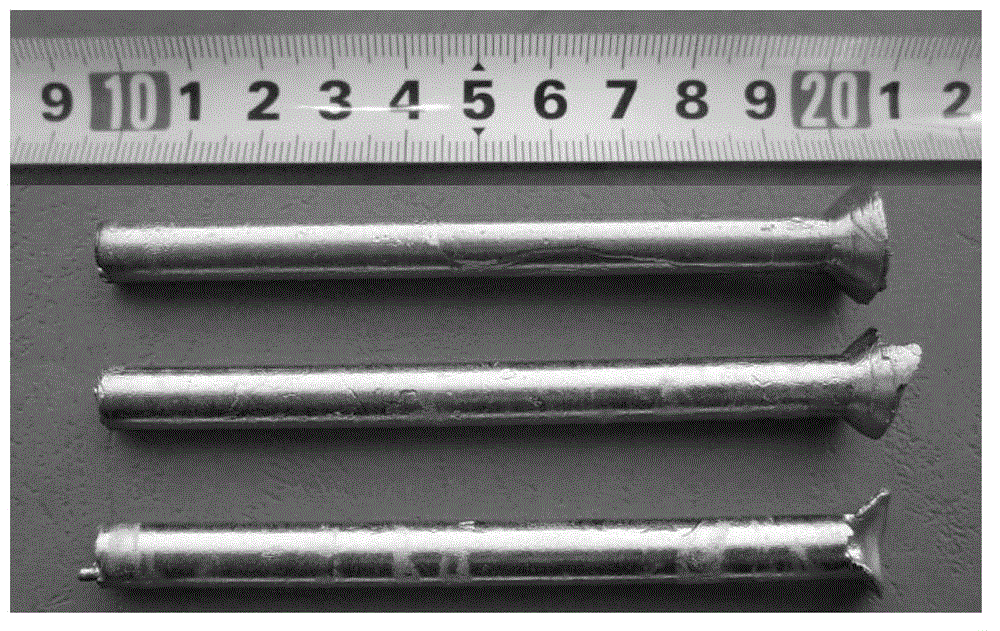

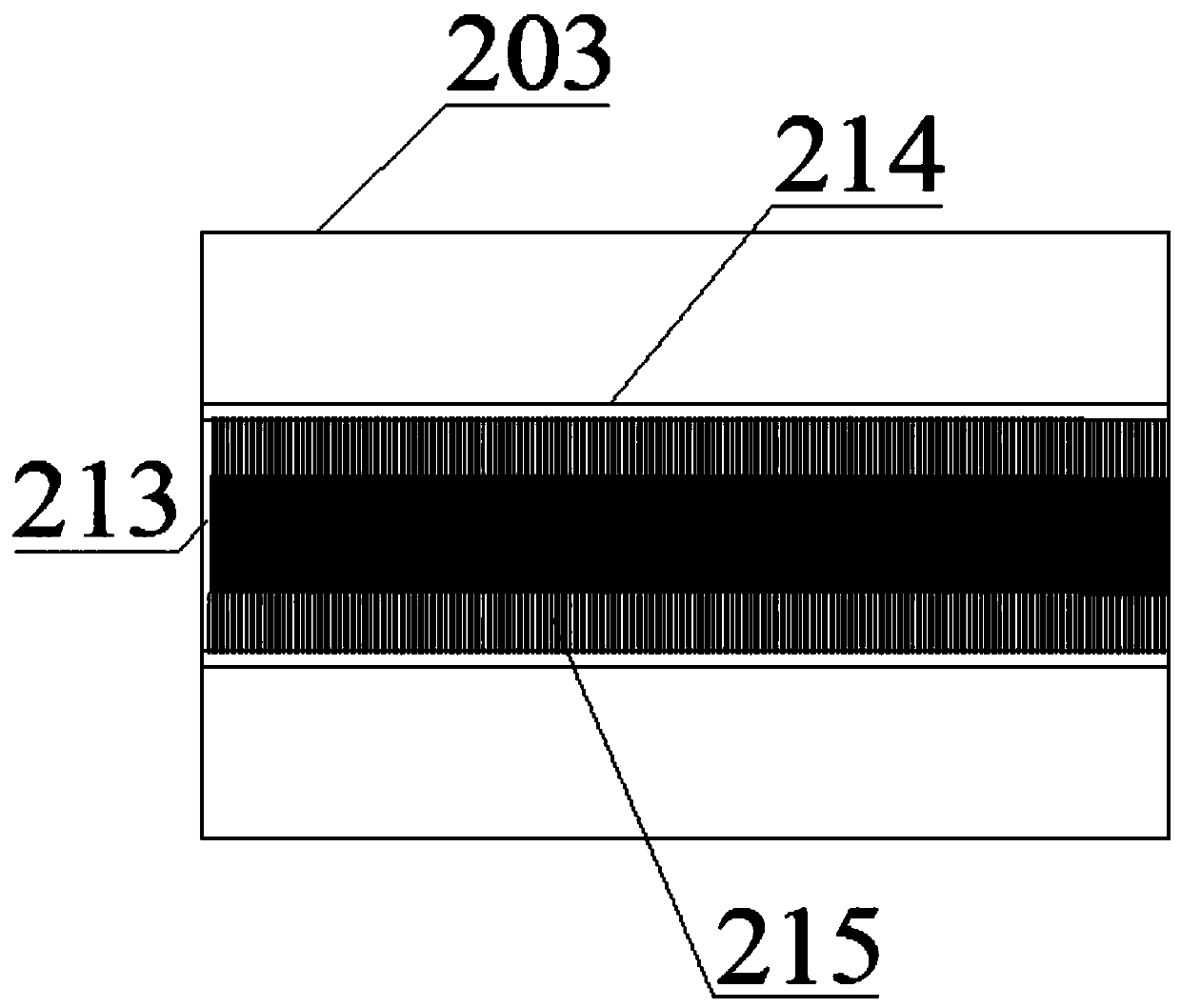

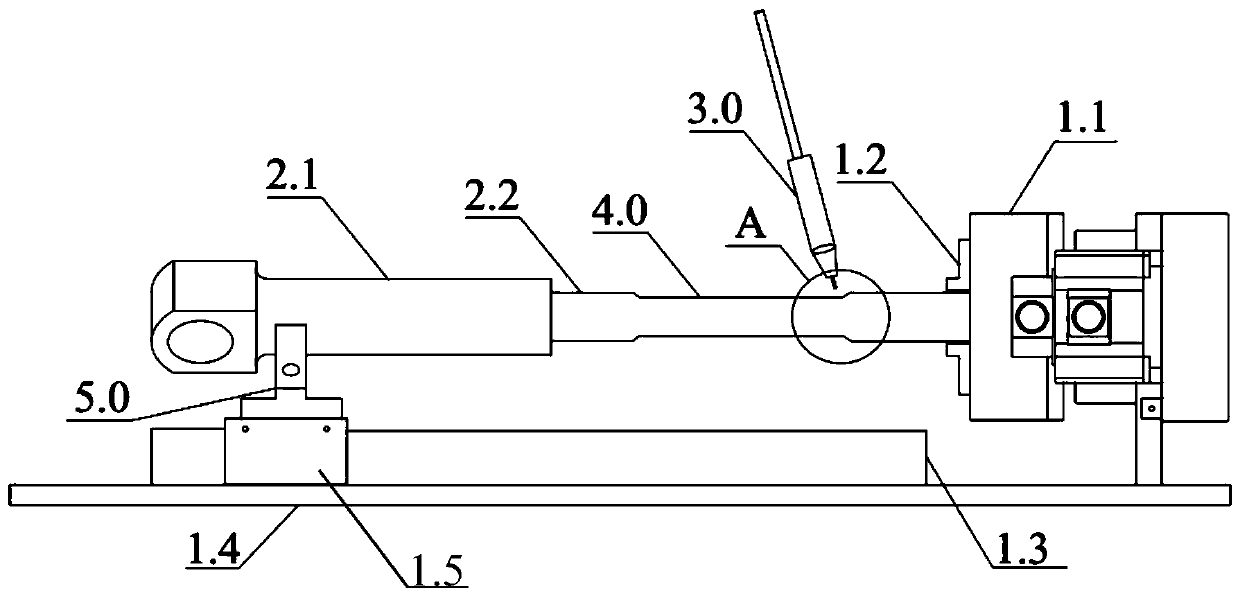

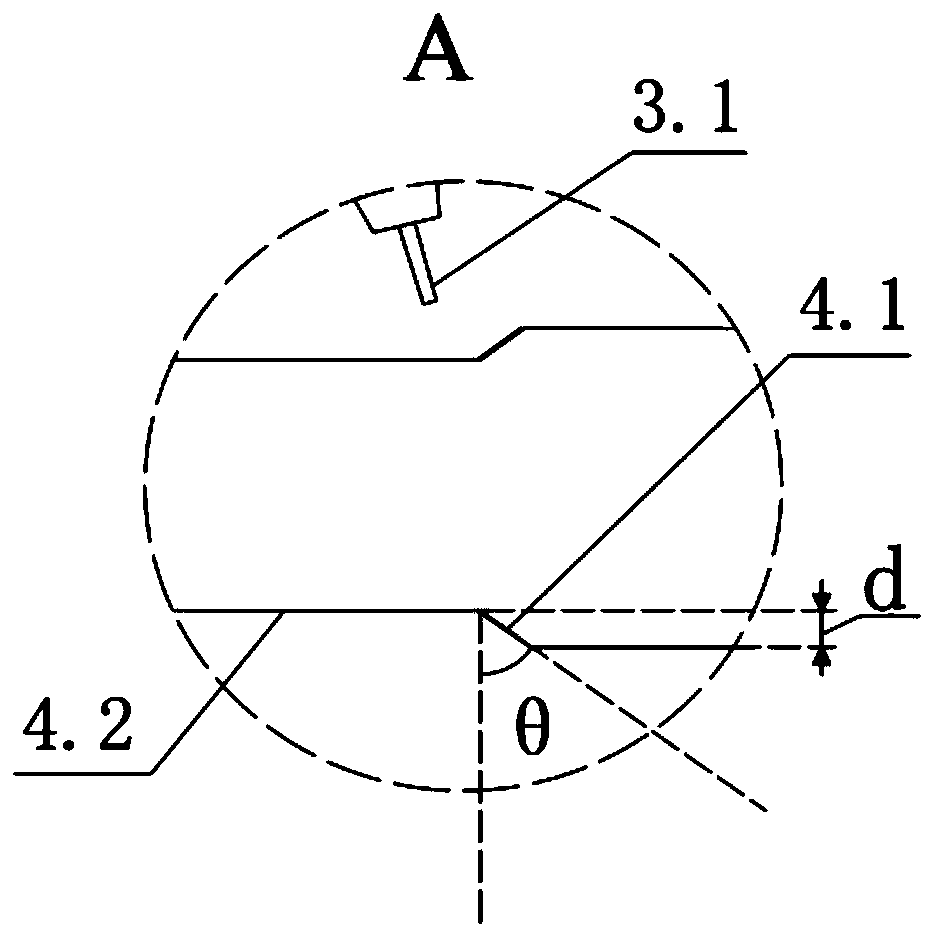

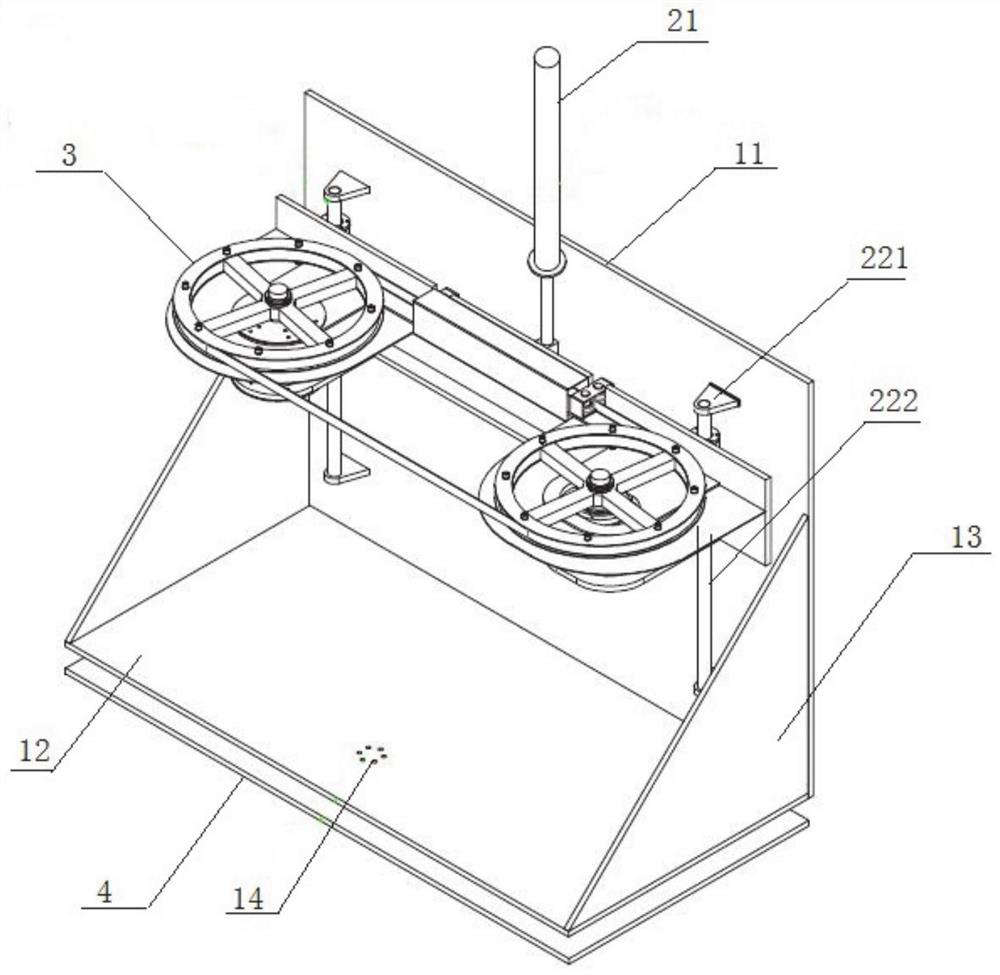

Locomotive-buffer-bar surface repairing and remanufacturing method

ActiveCN109079421AGuaranteed stabilityReduce welding heat inputWelding apparatusSand blastingEngineering

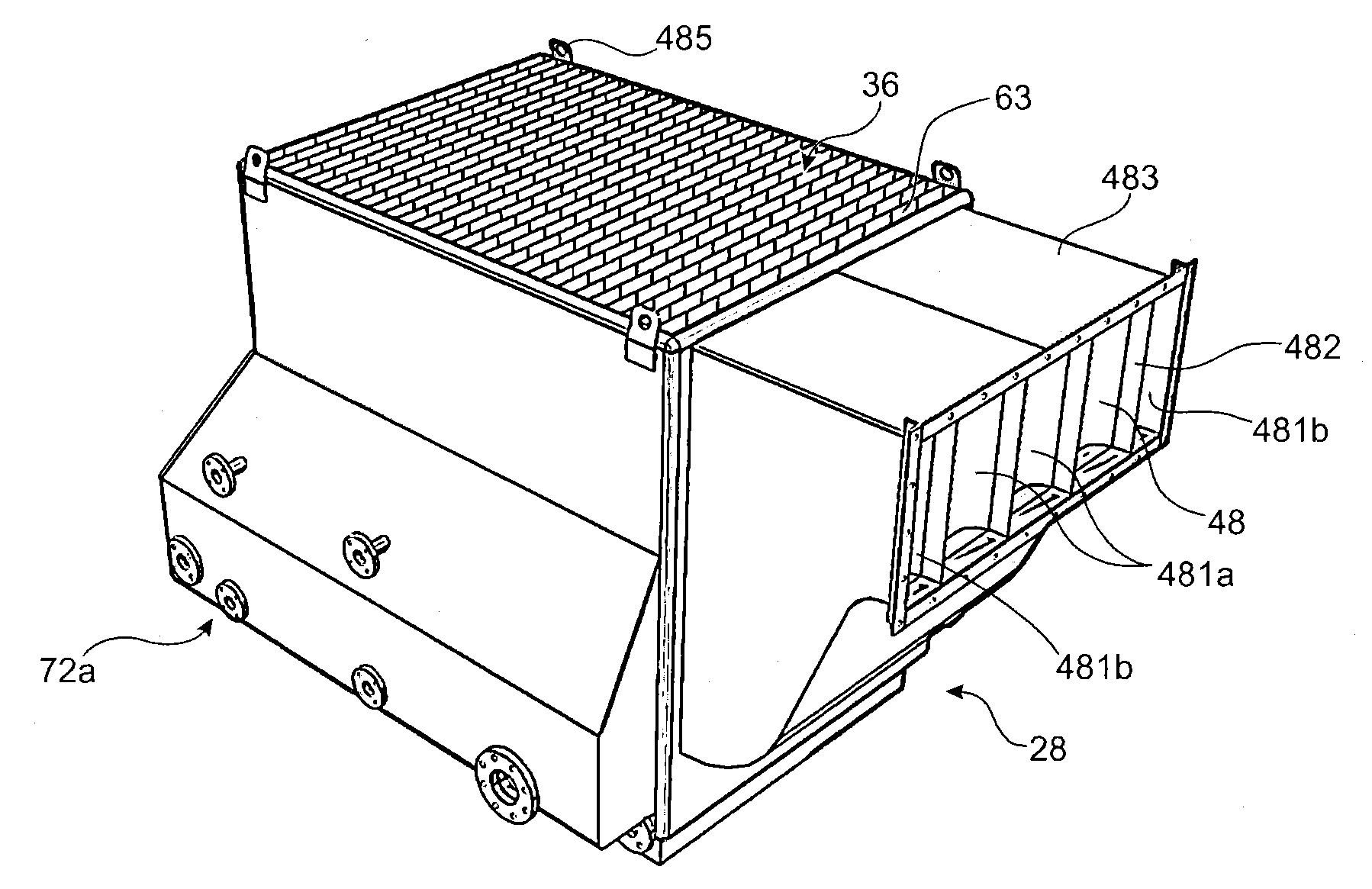

The invention discloses a locomotive-buffer-bar surface repairing and remanufacturing method. The locomotive-buffer-bar surface repairing and remanufacturing method includes the following steps that S1, repairable to-be-repaired buffer bars are screened out; S2, the abrasion loss of the to-be-repaired buffer bars is checked, to-be-repaired areas are determined on different-radius shaft segments ofthe buffer bars according to the size of the abrasion loss respectively, and to-be-repaired grooves are processed in the to-be-repaired areas; S3, the to-be-repaired buffer bars are sequentially subjected to sand blasting, cleaned and preheated; S4, one ends of the to-be-repaired buffer bars are fixed on a displacement device, and the to-be-repaired grooves are subjected to continuous annular welding through a CMT automatic welding system to complete repairing of the to-be-repaired buffer bars; S5, the repaired buffer bars obtained in the step S4 are welded to be subjected to slow cooling treatment; S6, the repaired areas of the repaired buffer bars are machined according to the size of an original-buffer-bar drawing, and then whole sand blasting is carried out. The locomotive-buffer-barsurface repairing and remanufacturing method is low in cost, high in efficiency and high in repairing quality, and the buffer bars after being repaired and remanufactured with the method can reach thequality standard of a new buffer bar.

Owner:SOUTHWEST JIAOTONG UNIV

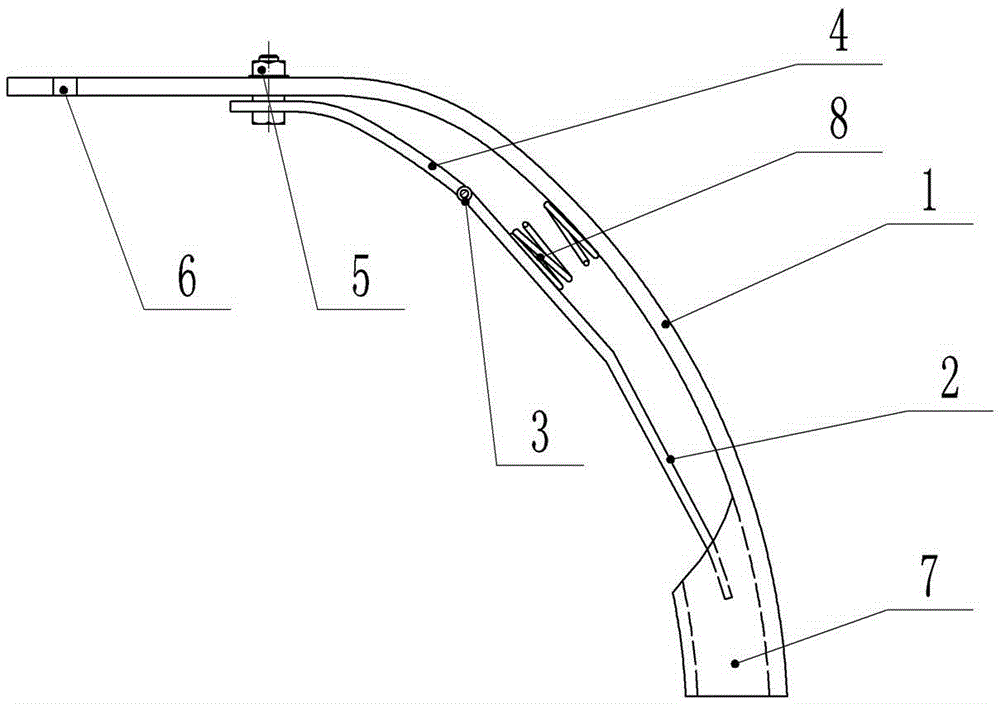

Double-layer automobile fender

The invention belongs to the technical field of automobile spare parts, and particularly discloses a double-layer automobile fender. The double-layer automobile fender comprises an arc outer plate, an inner plate and a movable plate; multiple installing holes are formed in one end of the outer plate, and a through opening is formed in the other end of the outer plate; one end of the inner plate is fixedly connected with the upper portion of the outer plate, and the other end of the inner plate is hinged to the movable plate so that the movable plate can rotate around the edge hinged to the inner plate; the movable plate is arranged at the lower end of the inner plate, and an elastic device is arranged between the movable plate and the outer plate. The fender is capable of preventing muddy water from splashing to solve the problem that muddy water rebounded by the fender splashes. Compared with an existing platy fender, the flow direction of the muddy water rolled up by wheels is guided, most of the muddy water is limited from splashing all over, and an automobile and the environment outside the automobile are protected better.

Owner:NINGBO JOYSONQUIN AUTOMOTIVE SYST HLDG CO LTD

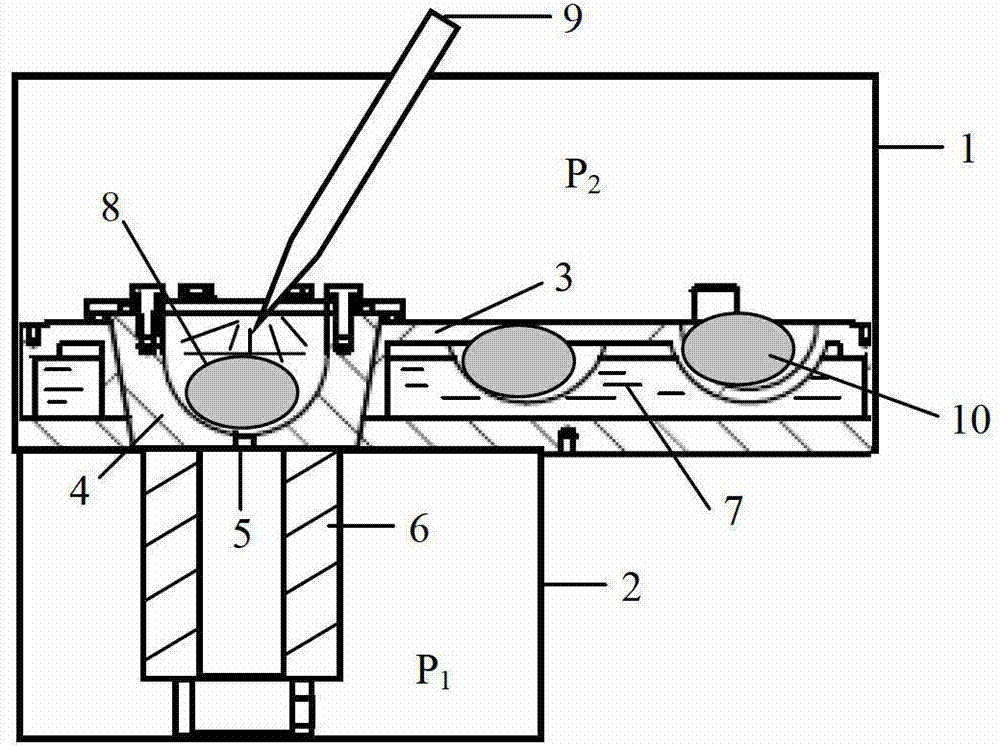

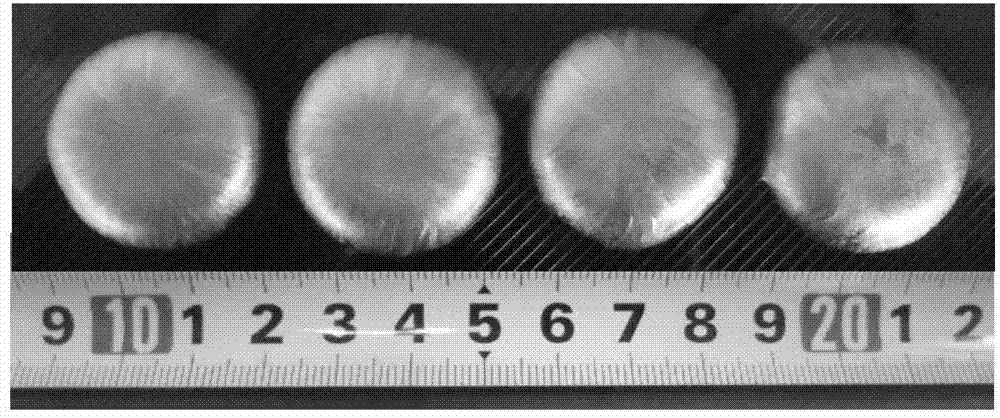

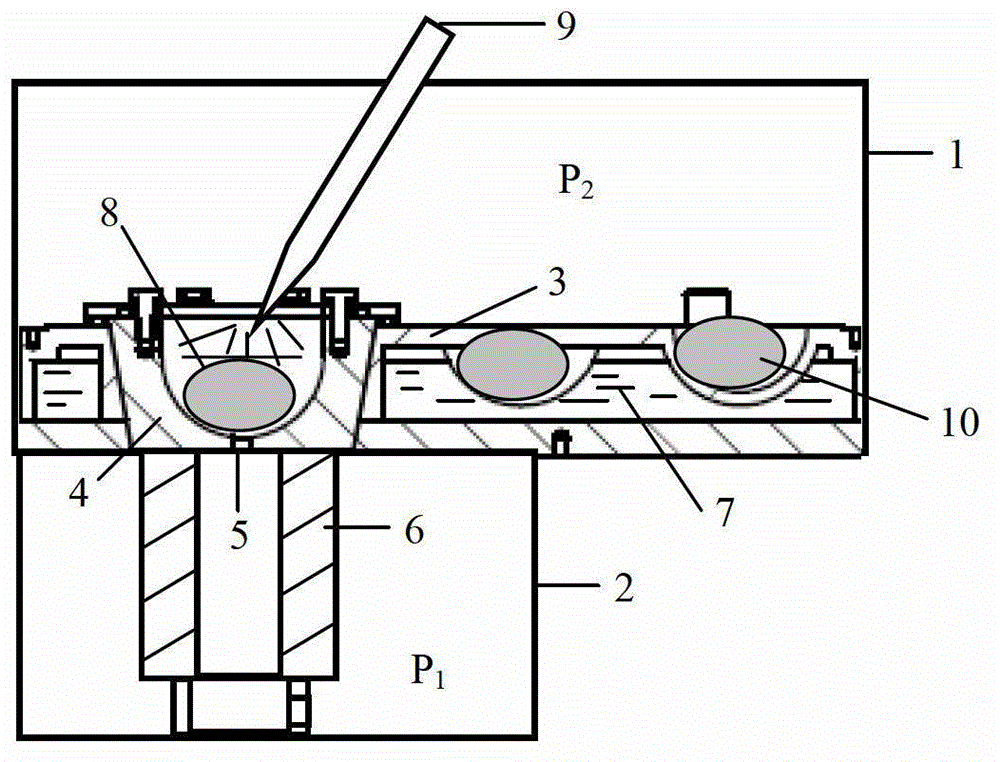

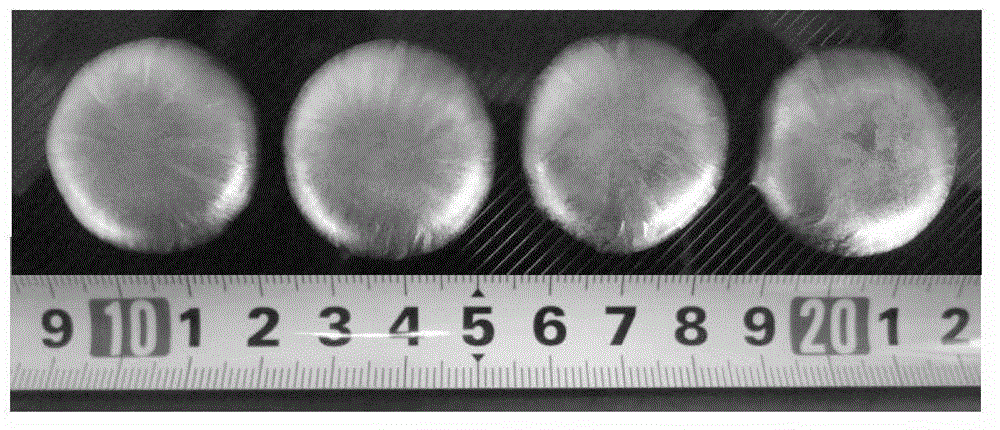

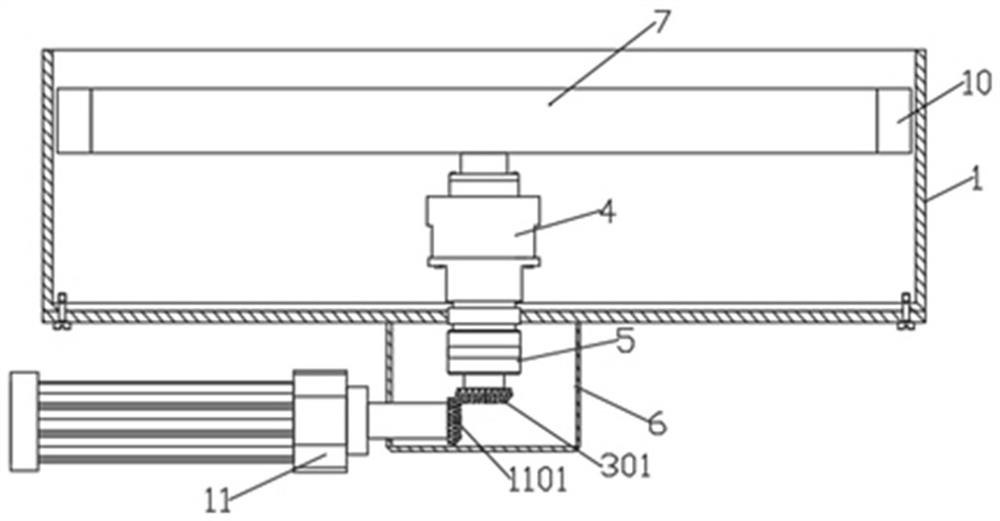

Preparation method for metal alloy test rod

InactiveCN102901659AAvoid pollutionImprove uniformityPreparing sample for investigationDifferential pressureVacuum chamber

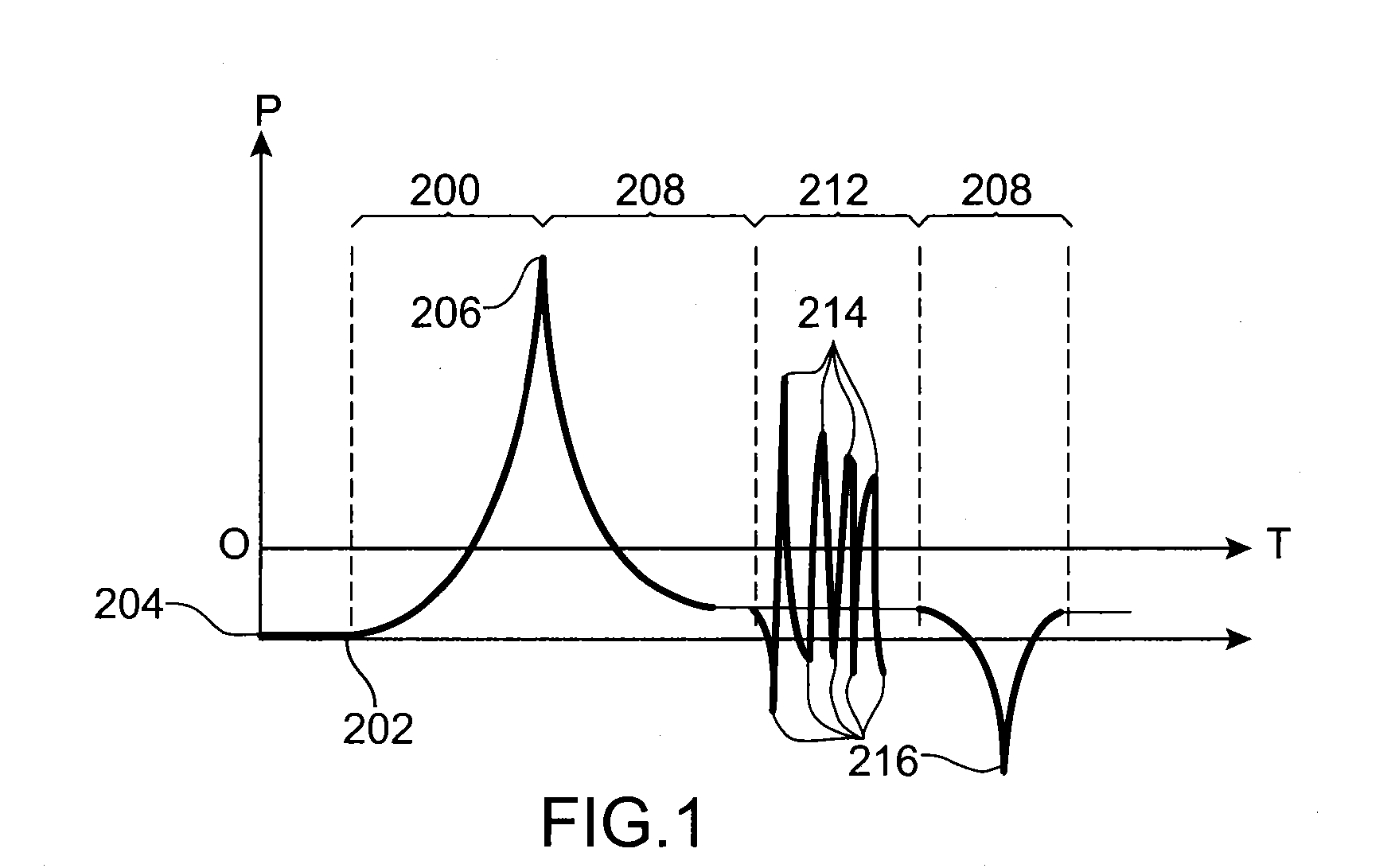

The present invention relates to the field of metal alloy test rod production, and provides a metal alloy test rod preparation method. According to the method, a vacuum suction casting device is adopted, wherein a vacuum chamber is filled with high purity argon to achieve pressure P1 of 0.02-0.06 MPa; when a button ingot surface layer is completely melted and a through hole on the bottom of an alloy ingot crucible is sealed through a liquid sealing manner, the vacuum chamber is continuously filled with high purity argon to increase pressure to P2, wherein pressure difference between the P2 and the P1 is 0.01-0.1 MPa; and pressure difference suction casting molding is adopted. The preparation method has the following characteristics that: high cleaning and high efficiency are provided; high uniformity and high accuracy of the components can be achieved; a size of the test rod can be phi 12 mm*120 mm; disadvantages of uniform component, difficult oxygen content control, long period or complex process, and the like of powder metallurgy, mold melting casting, extrusion molding, ingot processing and other test rod preparation methods are overcome; and strict requirements on the ideal alloy test rod by standard sample preparation, alloy design, performance testing, material feeding rod preparation and other processes can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

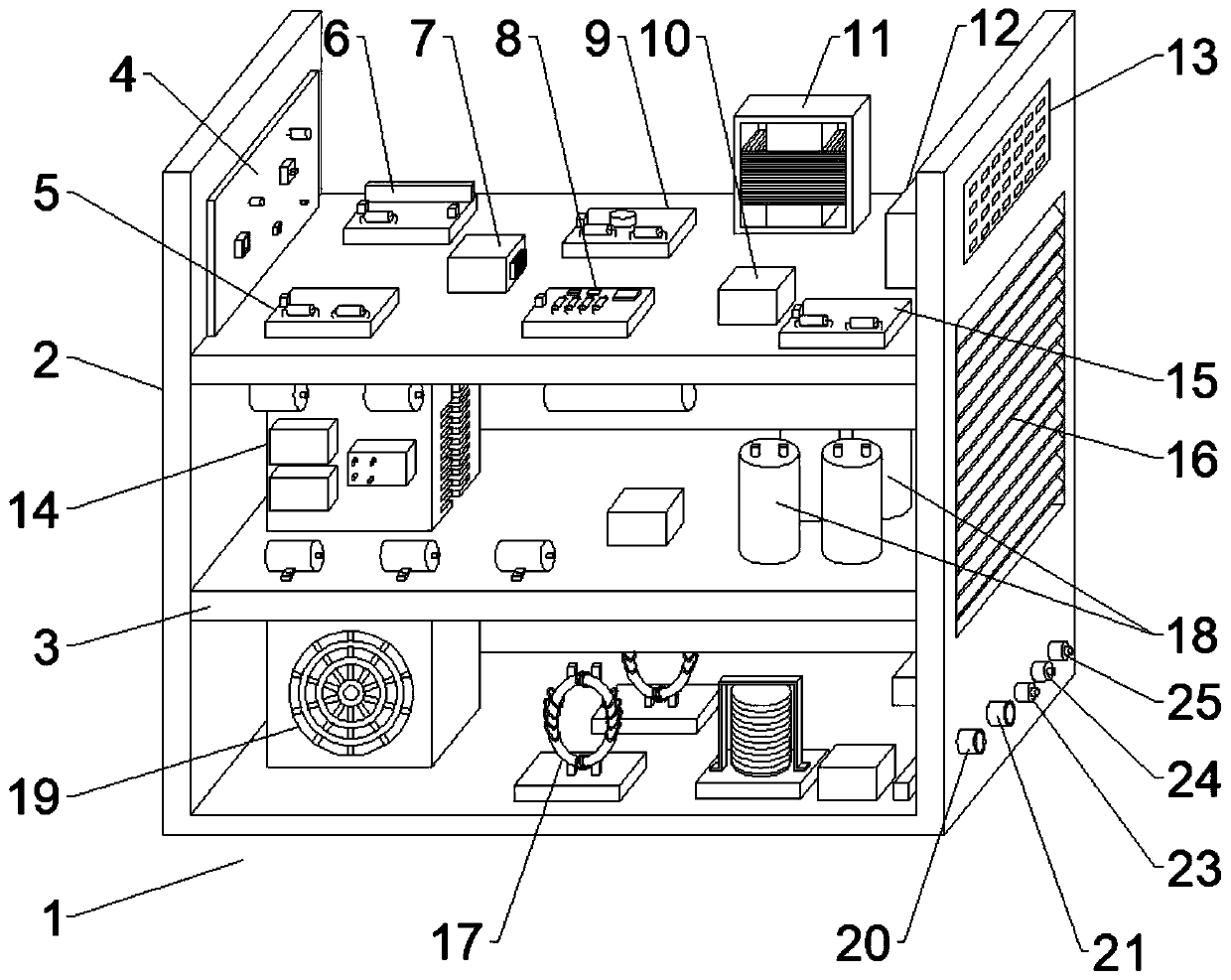

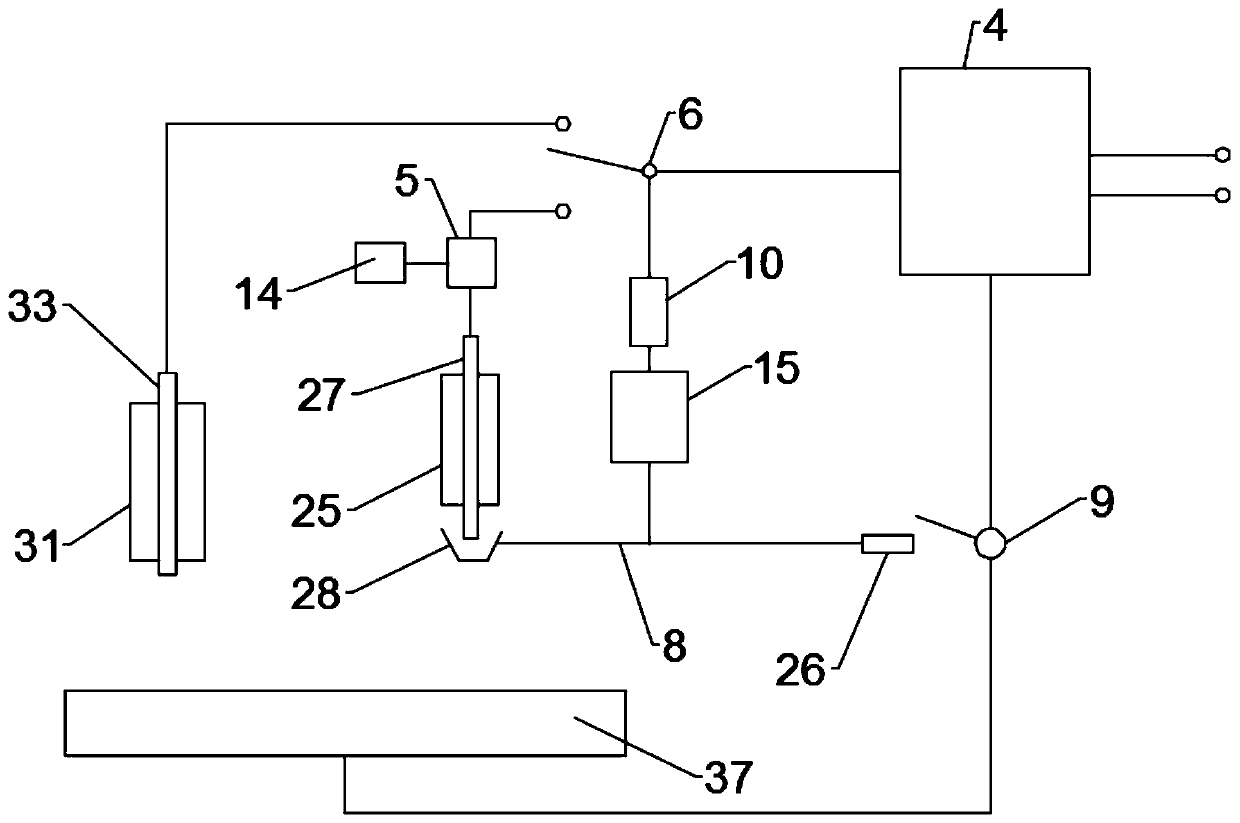

Plasma arc technology based digital multifunctional power supply

PendingCN110026665AReasonable useStable structureArc welding apparatusPlasma welding apparatusEngineeringMolten metal

A plasma arc technology based digital multifunctional power supply comprises a plasma arc welding power supply, wherein the plasma arc welding power supply comprises a rack, and a separating plate which is arranged in the rack; the separating plate is divided into an upper separating plate layer and a lower separating plate layer; the inner part of the plasma arc welding power supply is divided into a power supply control assembly, a welding output control assembly and a display operation assembly. The plasma arc technology based digital multifunctional power supply is stable in structure, andreasonable in space utilization; a workpiece is arranged between a plasma welding gun and an argon arc welding gun; the electric arc of argon arc welding and plasma welding can be changed; welding wires are heated and smelted through plasma arc and argon arc during being welded, and molten melt droplets are formed and enter a molten melt smelting pool on the workpiece, so that the welding smelting depth and the welding speed can be greatly increased, and the splashing is controlled; a main control board for controlling realizes power supply control; and the plasma arc technology based digitalmultifunctional power supply has the characteristics of being high in efficiency, small in loss, and wide in applicable scope.

Owner:吴忠市黄河电焊机有限公司

Preparation method for metal alloy test rod

InactiveCN102901659BAvoid pollutionImprove uniformityPreparing sample for investigationDifferential pressureVacuum chamber

The present invention relates to the field of metal alloy test rod production, and provides a metal alloy test rod preparation method. According to the method, a vacuum suction casting device is adopted, wherein a vacuum chamber is filled with high purity argon to achieve pressure P1 of 0.02-0.06 MPa; when a button ingot surface layer is completely melted and a through hole on the bottom of an alloy ingot crucible is sealed through a liquid sealing manner, the vacuum chamber is continuously filled with high purity argon to increase pressure to P2, wherein pressure difference between the P2 and the P1 is 0.01-0.1 MPa; and pressure difference suction casting molding is adopted. The preparation method has the following characteristics that: high cleaning and high efficiency are provided; high uniformity and high accuracy of the components can be achieved; a size of the test rod can be phi 12 mm*120 mm; disadvantages of uniform component, difficult oxygen content control, long period or complex process, and the like of powder metallurgy, mold melting casting, extrusion molding, ingot processing and other test rod preparation methods are overcome; and strict requirements on the ideal alloy test rod by standard sample preparation, alloy design, performance testing, material feeding rod preparation and other processes can be met.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

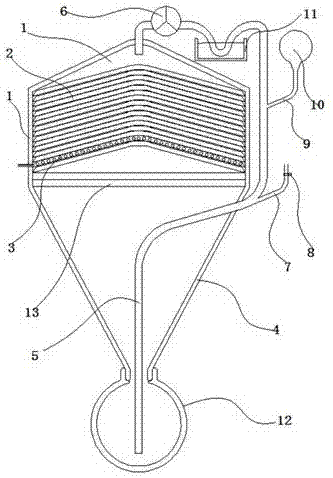

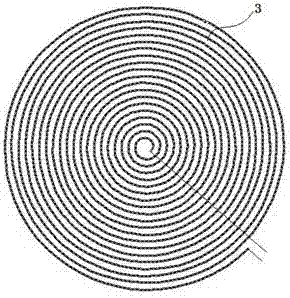

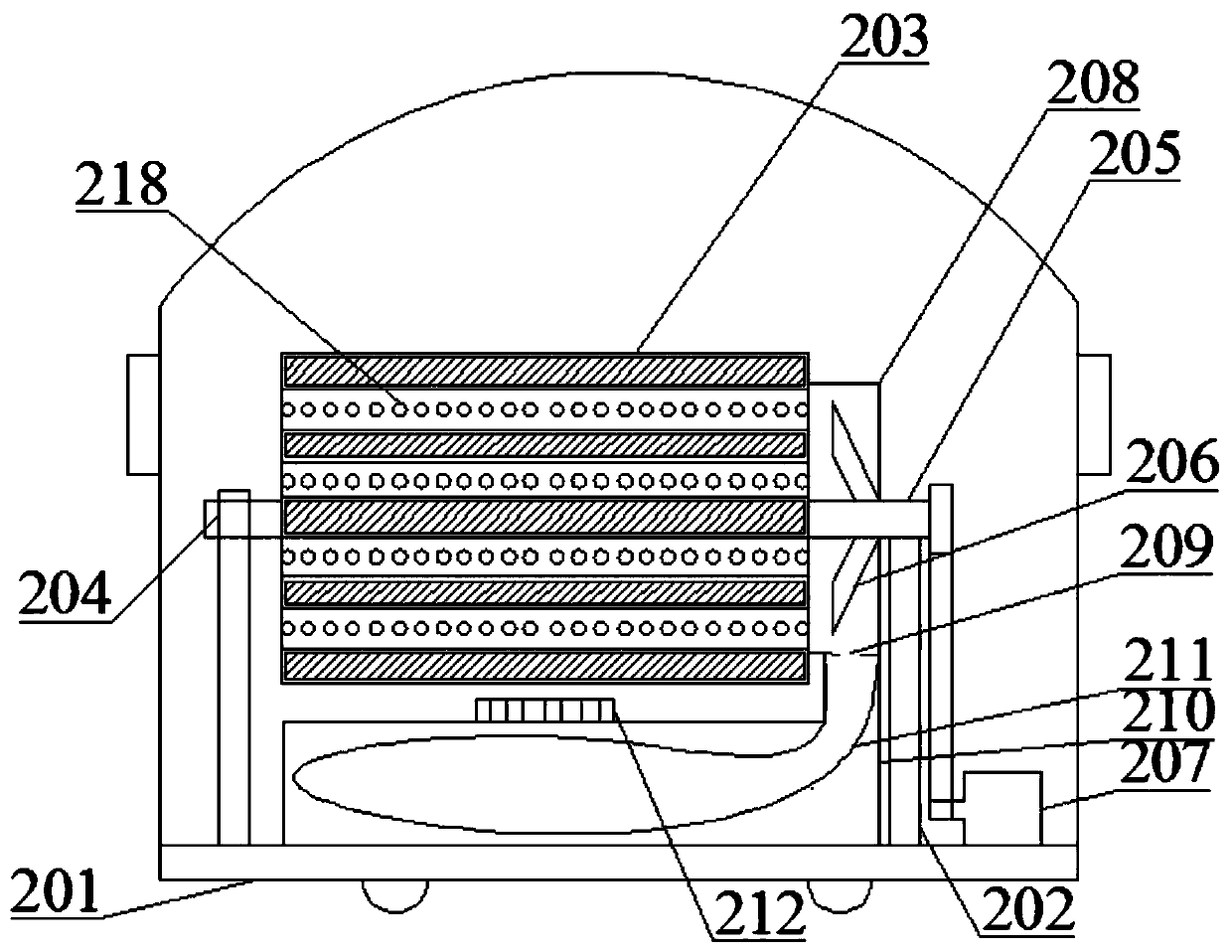

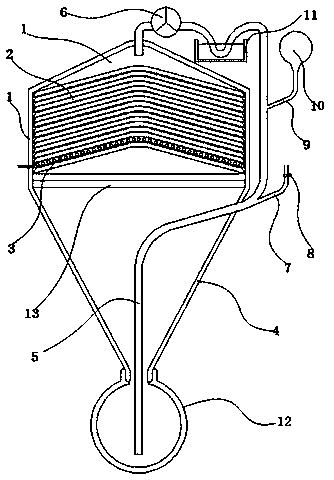

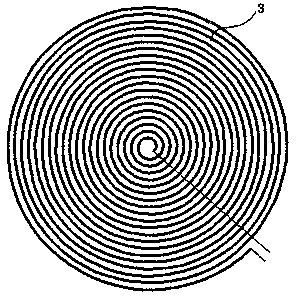

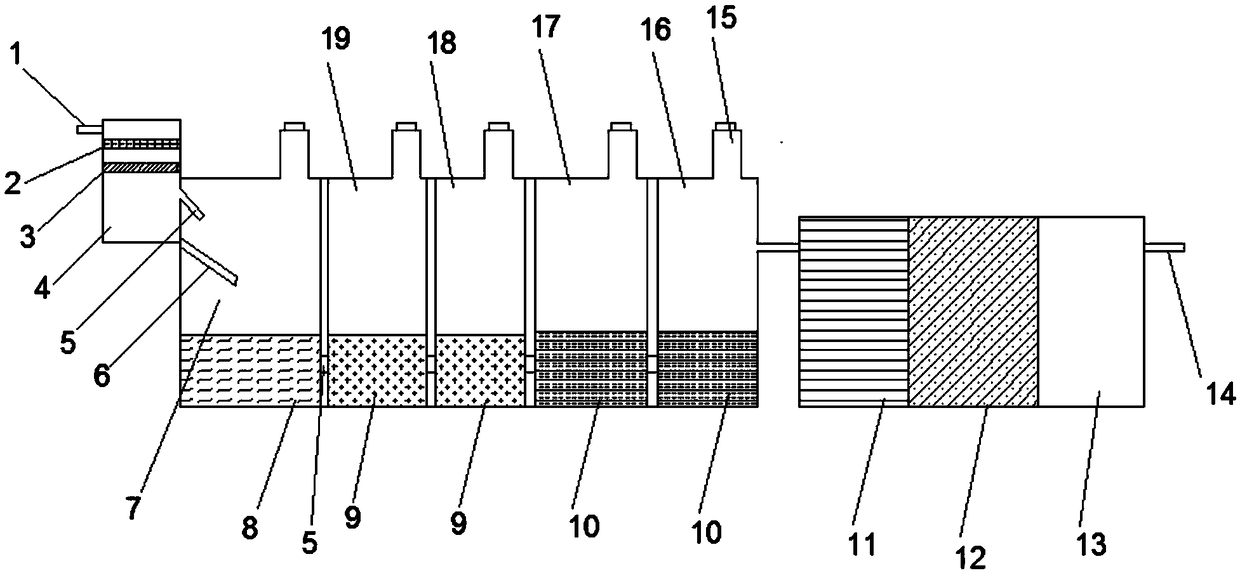

Waste gas treatment system for detecting heavy metals in food

ActiveCN107497242AGood adsorption effectLow costGas treatmentPreparing sample for investigationChemistryWaste treatment

The invention discloses a waste gas treatment system for detecting heavy metals in food. The system comprises a waste gas cavity, wherein an adsorption chamber is formed in the upper part of the waste gas cavity, the bottom of the waste gas cavity is connected with a reaction ball chamber, a plurality of calcium oxide adsorption layers are arranged in the adsorption chamber, each calcium oxide adsorption layer comprises a fiber skeleton and calcium oxide applied to the fiber skeleton, and the fiber skeletons are wound into a spiral line structure by a fiber bundle; a conical chamber is formed in the lower part of the waste gas cavity, and the bottom tip end of the conical chamber is in sealed communication with the reaction ball chamber; the system further comprises an air circulation device which comprises a pipe, one end of the pipe is communicated with the upper part of the adsorption chamber, the other end extends into the reaction ball chamber, an air pump is arranged on the pipe, and the pipe is further connected with a first branch pipe and a second branch pipe. Adsorption and digestion are performed in a closed environment in a fully sealed form, so that the waste gas cannot leak, and little harm is caused to the environment and human bodies. The reaction digestion condition can be clearly observed through the waste gas chamber and the reaction ball chamber which are made of transparent glass.

Owner:衣维贤

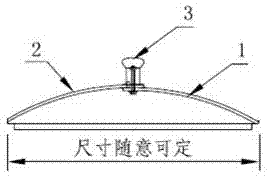

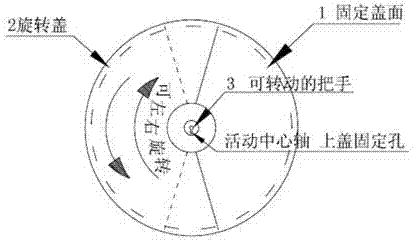

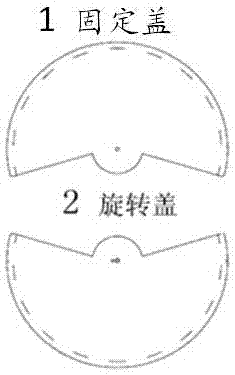

Combined rotary oil-splashing-preventing pot cover

InactiveCN107319949ASimple structureSolve the problem of splashing cooking fumes polluting the kitchenCooking-vessel lids/coversEngineeringPollution

The invention relates to a combined rotary oil-splashing-preventing pot cover. The pot cover comprises a fixed cover (1), a rotary cover (2) and a rotatable handle (3), wherein the rotary cover (2) can regulate the size of an opening according to actual use conditions of an operator. The combined rotary oil-splashing-preventing pot cover has the advantages that design simplification is achieved, food can be added and stir-fried by using the rotatable handle (3) to regulate a food inlet, and the cooking degree of food can be observed during stir-frying; the pot cover is simple and convenient in actual use, capable of effectively preventing hot oil splashing, capable of reducing the scalding of the operator, capable of controlling splashing hot oil in the minimum range, capable of reducing the pollution of a cooking bench, a stove and a wall face and capable of solving the problem that a kitchen is polluted by splashing hot oil.

Owner:韩忠

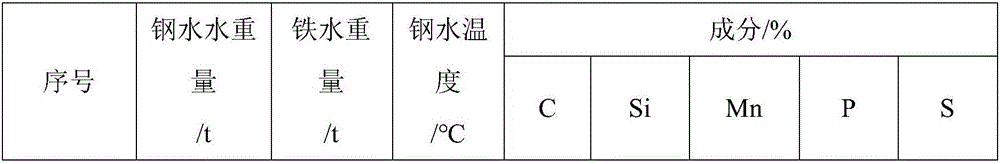

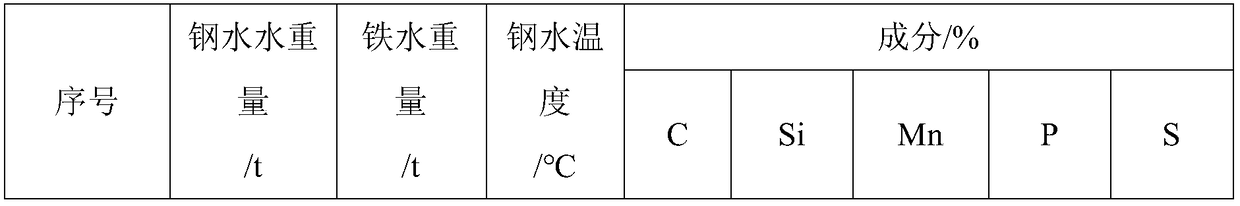

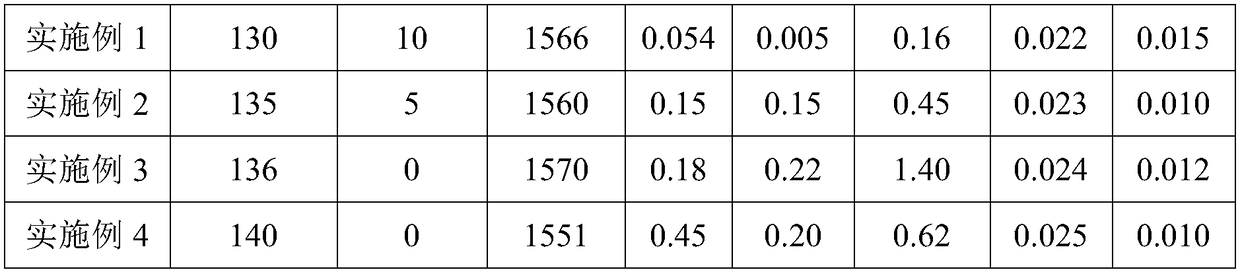

Converter return molten steel processing method

ActiveCN106834592AShort processing timeAvoid Rhythm DifficultyManufacturing convertersMolten steelDolomite

The invention discloses a converter return molten steel processing method. The converter return molten steel processing method comprises the following steps that (1) return molten steel is deoxidized and then smelted through a converter, a whole ladle of molten steel is completely added into the converter to be processed, if the charging amount of the molten steel is not enough, molten iron is added into the steel ladle till reaching the preset amount, and then the molten steel and the molten iron are added into the converter; (2) a blow gun is started at 1500-1650 mm, the initial oxygen pressure while blowing is started is controlled to be 0.30-0.35 Mpa, after the gun position is constant at 1500-1650 mm, the oxygen pressure is increased to 0.80-0.85 Mpa at the speed of 0.015-0.020 Mpa / s, and in the pressure increasing process, after the oxygen pressure is increased to 0.5 Mpa, 15-20 kg / t of lime, 5-8 kg / t of dolomite and 0-13 kg / t of sintered ore are added; (3) after blowing is conducted for 1-2 min, the oxygen gun position is declined to 1300-1400 mm; (4) TSC is measured through a sublance after blowing is conducted for 3-4 min, and the oxygen blowing amount and the adding amount of the sintered ore are dynamically controlled according to TSC measuring data; and (5) after a target component of the molten steel is obtained through blowing, the gun is lifted, and tapping is conducted. The converter return molten steel processing method is short in processing cycle and high in efficiency.

Owner:SHANDONG IRON & STEEL CO LTD

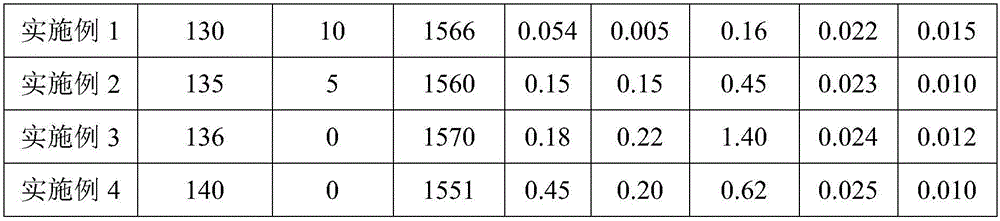

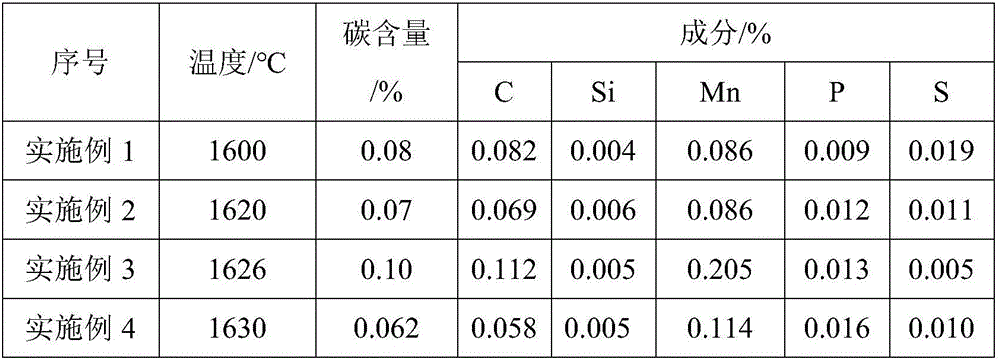

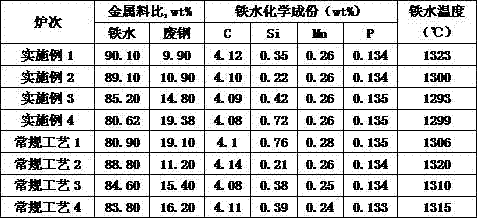

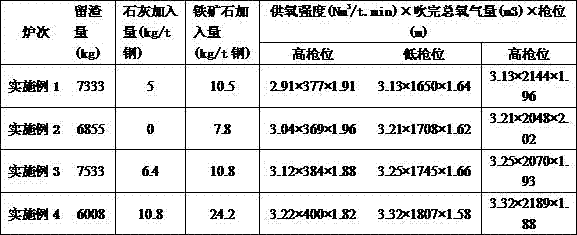

A control method for splashing during decarburization period of converter less slag smelting

ActiveCN105525055BReduce consumptionImprove stabilityManufacturing convertersProcess efficiency improvementSlagWell control

The invention discloses a method for controlling splashing in the less slag smelting decarbonization period of a converter. The technical problem that splashing is likely to happen in the decarbonization period of the double slag and remaining slag smelting technology of a converter in the prior art is mainly solved. The method for controlling splashing in the less slag smelting decarbonization period of the converter comprises the following steps of steel scrap adding, molten iron charging, converter blowing desilicication and dephosphorization, pre-slag pouring, converter blowing decarbonization, converter tapping and slag remaining. By means of control over adding of limestone or dolomite in the converter blowing decarbonization period, the oxygen supply strength is controlled to be increased step by step during lance feeding blowing, and the problems of explosive splashing during lance feeding blowing and returning dry splashing in the blowing process in the decarbonization period are well controlled through adjustment on the lance height and the oxygen supply strength in the blowing process.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

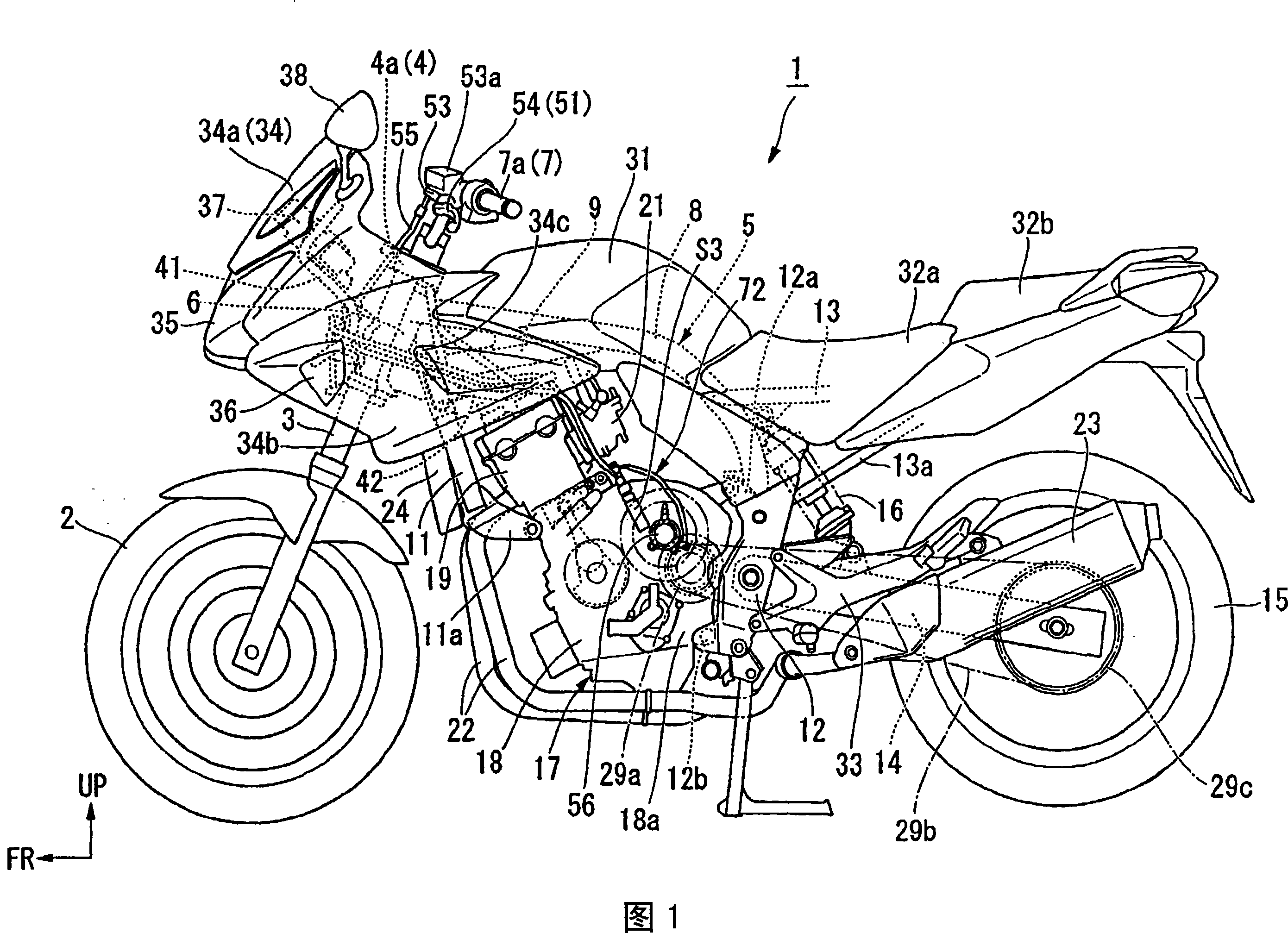

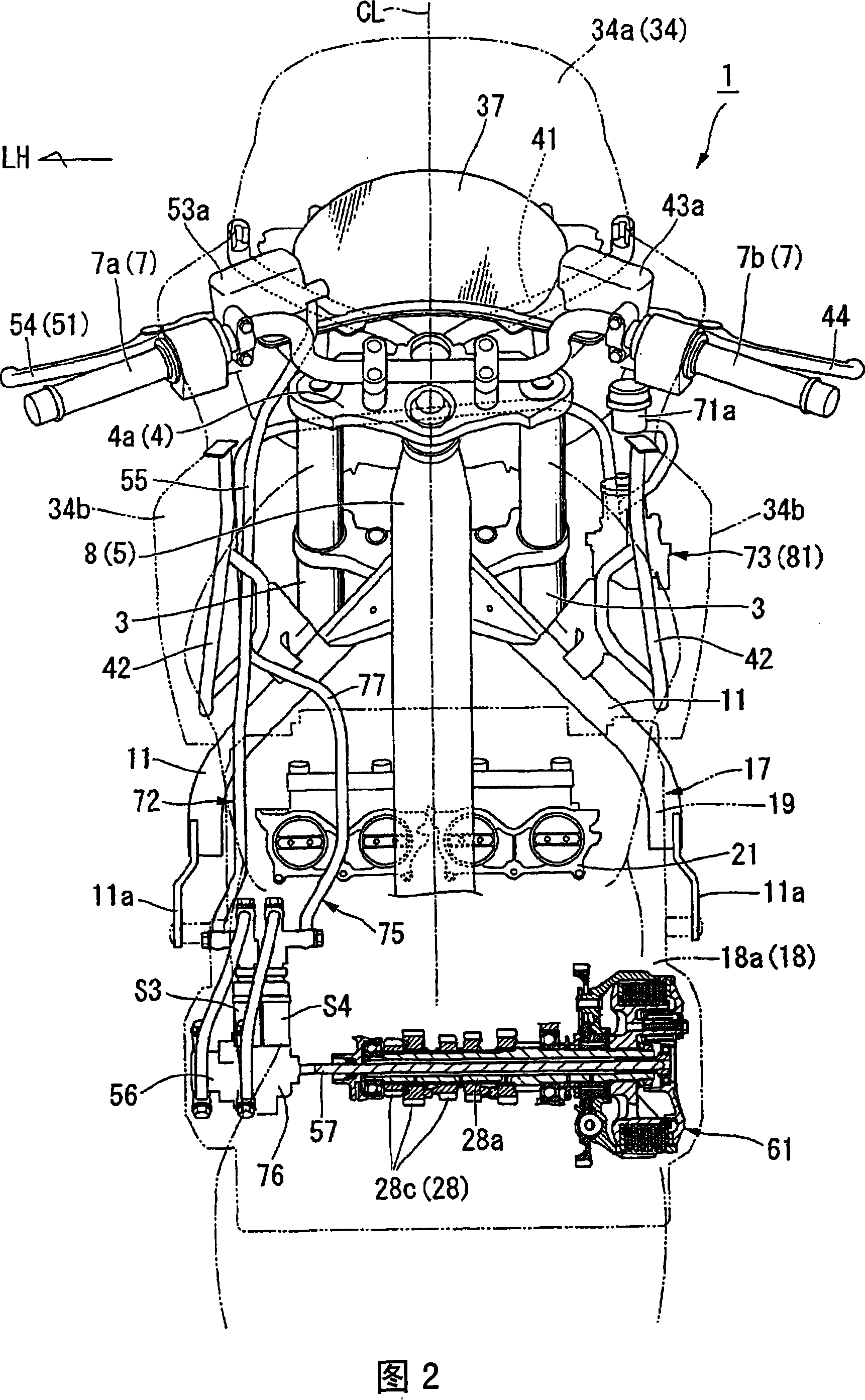

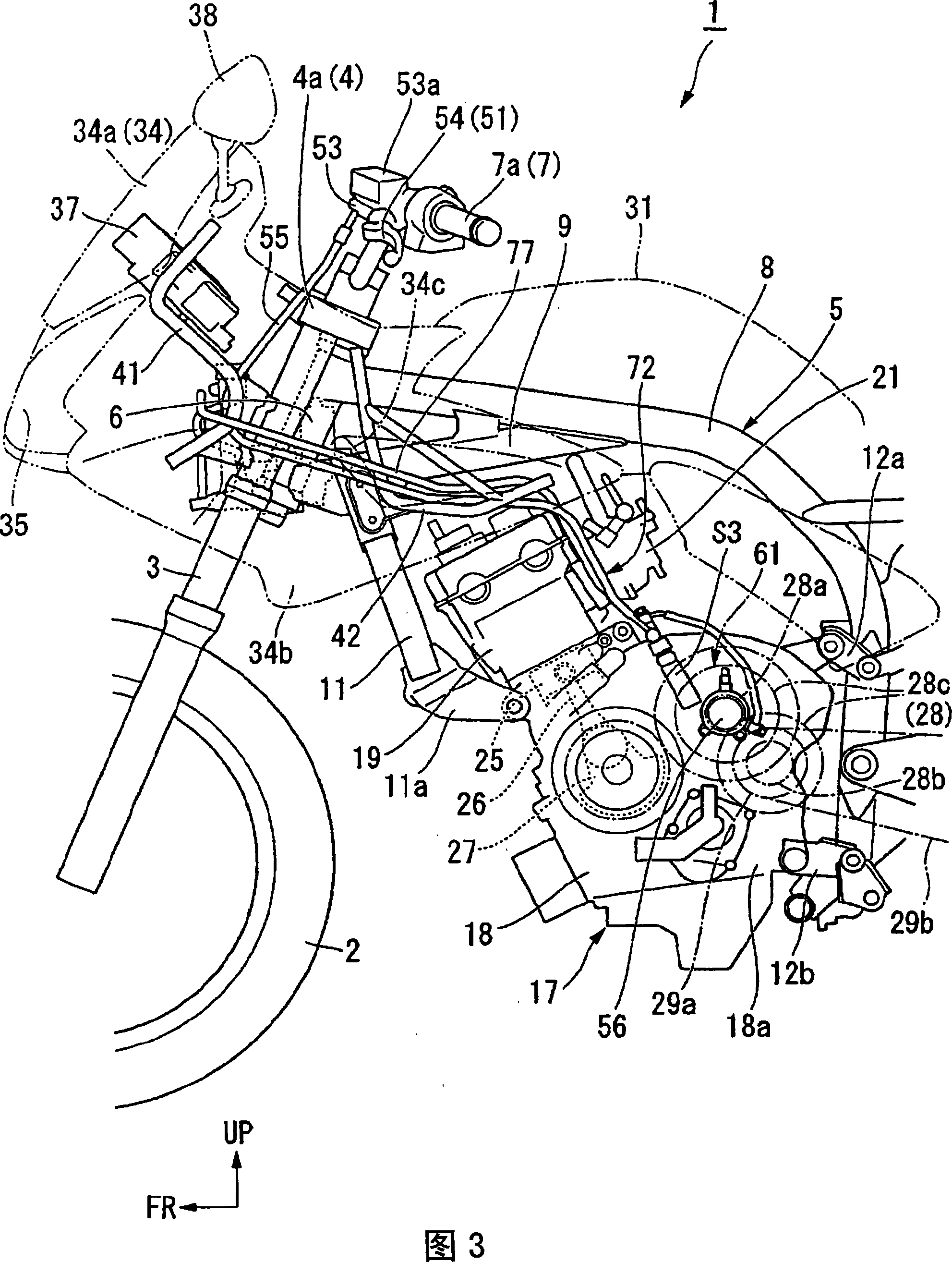

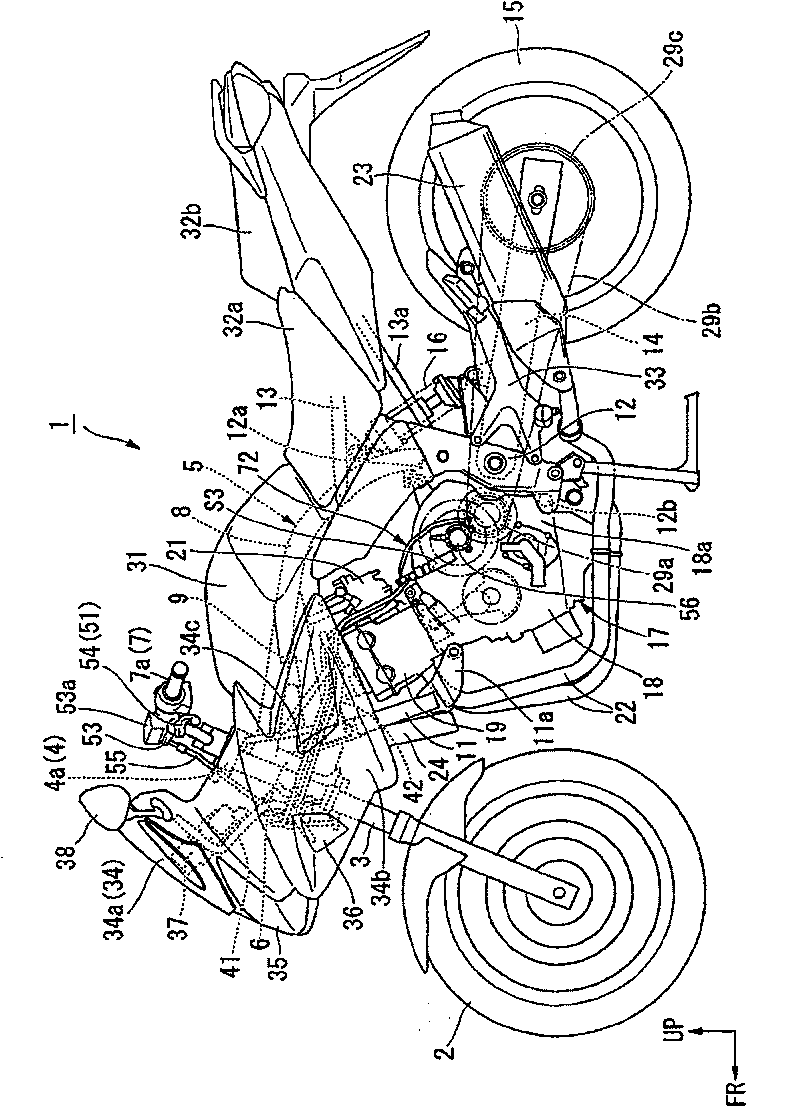

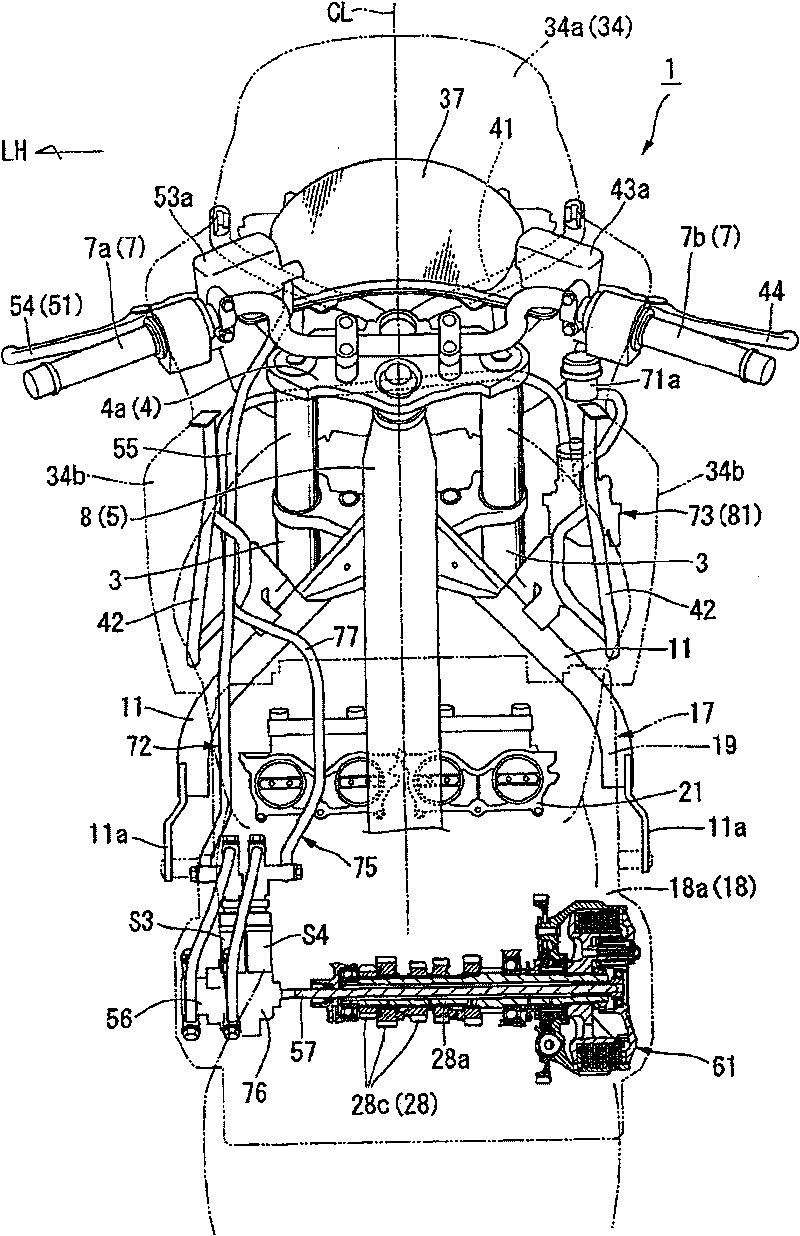

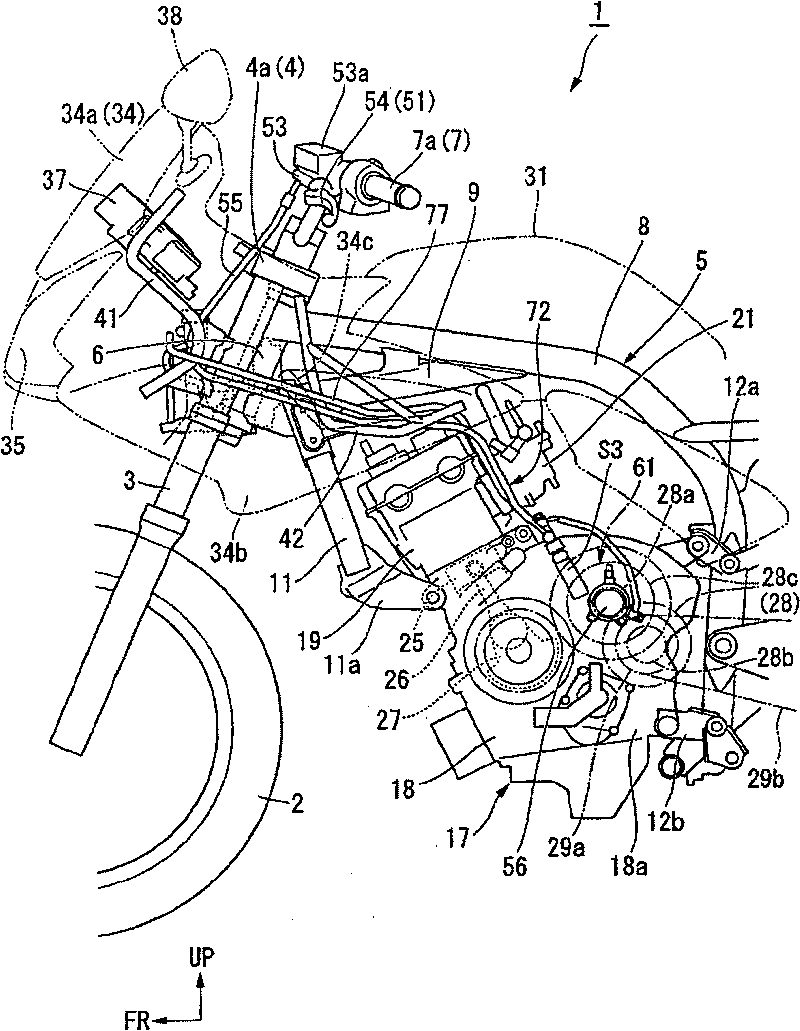

Clutch-manipulation assist device

InactiveCN101173698AImprove cooling effectControl splashFluid actuated clutchesControl devicesEngineeringActuator

The present invention provides a clutch manipulation assist device, which includes a clutch assist actuator, the actuator is arranged at a position where it is possible to suppress the influence of heat from an engine on the actuator without requiring the heat insulation structure or the like. The clutch manipulation assist device includes a clutch mechanism (61) which is arranged in a power transmission path for transmitting a rotational driving force of an engine (17) to a wheel, a clutch-manipulation mechanism in which a clutch manipulation force is inputted, and an actuator (73) which generates a clutch assist force in response to a manipulation of the clutch manipulation mechanism, the actuator is arranged in front of the engine (17) and outside a main frame (8).

Owner:HONDA MOTOR CO LTD

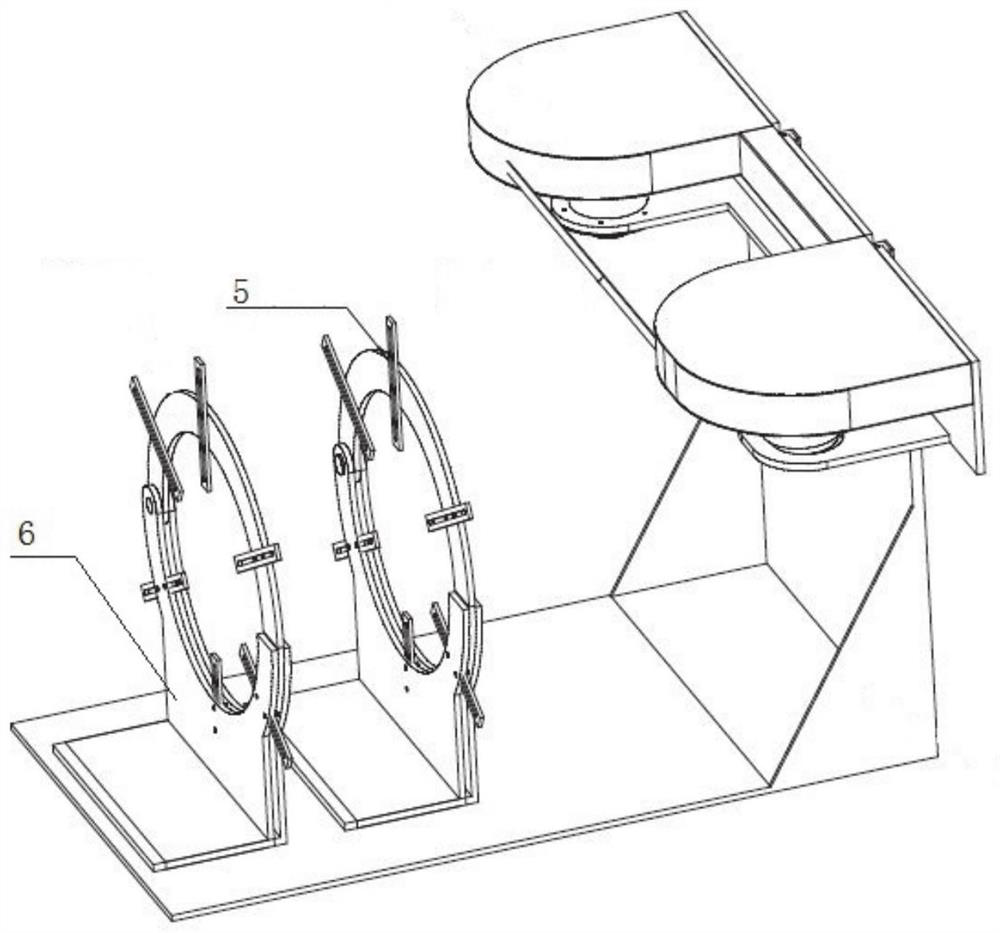

Polishing and derusting device for carrier roller production

InactiveCN110480488AEasy accessEasy to collectGrinding machinesGrinding/polishing safety devicesDual actionDrive shaft

The invention discloses a polishing and derusting device for carrier roller production. The polishing and derusting device for carrier roller production comprises a base and an outer cover. The outercover is arranged on the base; the outer cover comprises two oppositely arranged side walls and an arc-shaped top wall connected between the two side walls; observation ports are formed in the two side walls; a bracket is arranged on the base; a bearing pedestal is arranged on the bracket; a transmission shaft is arranged on the bearing pedestal in a sleeving manner; a belt wheel is mounted at oneend of the transmission shaft and is connected to a motor through a belt; the motor is mounted on the base; a roller is arranged on the transmission shaft; the roller is of an inner hollow structure;the roller is fixedly connected to the transmission shaft; and a wheel set is mounted below the base. Under electromagnetic action and dust collecting action, splatter of scrap iron can be controlledeffectively, so that the personal safety of staff is guaranteed. The scrap iron can be prevented from being adsorbed to the surface of a carrier roller, so that the polishing quality of the carrier roller is improved.

Owner:湖南创威科技有限公司

Device for limiting the consequences of a widespread fire in premises

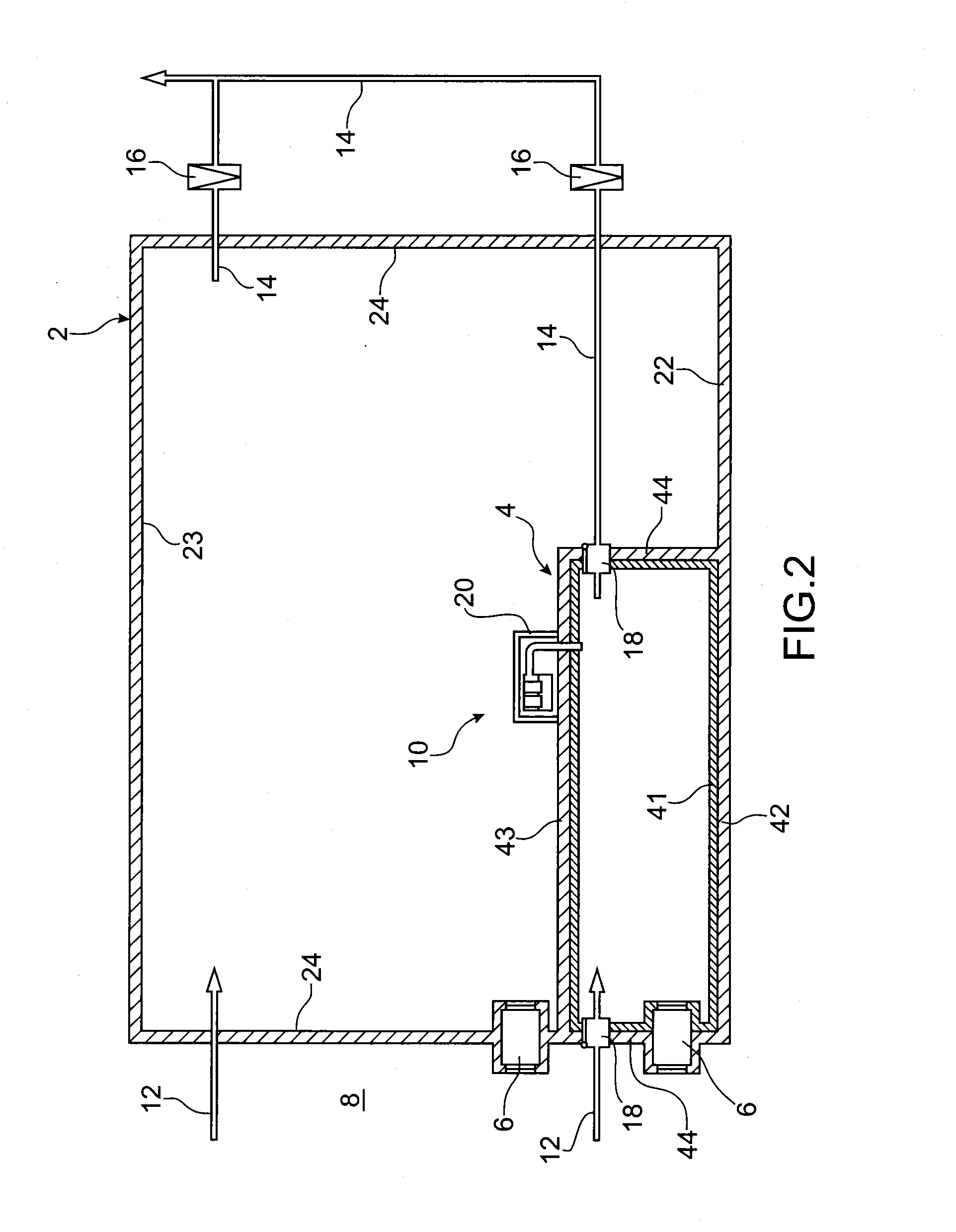

InactiveUS20130126195A1Simplify liquid-supply circuitMore passiveDispersed particle filtrationFire rescueEngineeringStorage cell

A device for limiting consequences of a fire, in a room, including a reservoir including a vessel containing a liquid, the reservoir including one or more chambers in communication with a storage cell and one or more other chambers. The reservoir also includes at least a first overflow tank and at least a second overflow tank, both integral, placed on either side of the reservoir, each tank configured to receive the liquid when the liquid exceeds a predetermined given height in the vessel.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

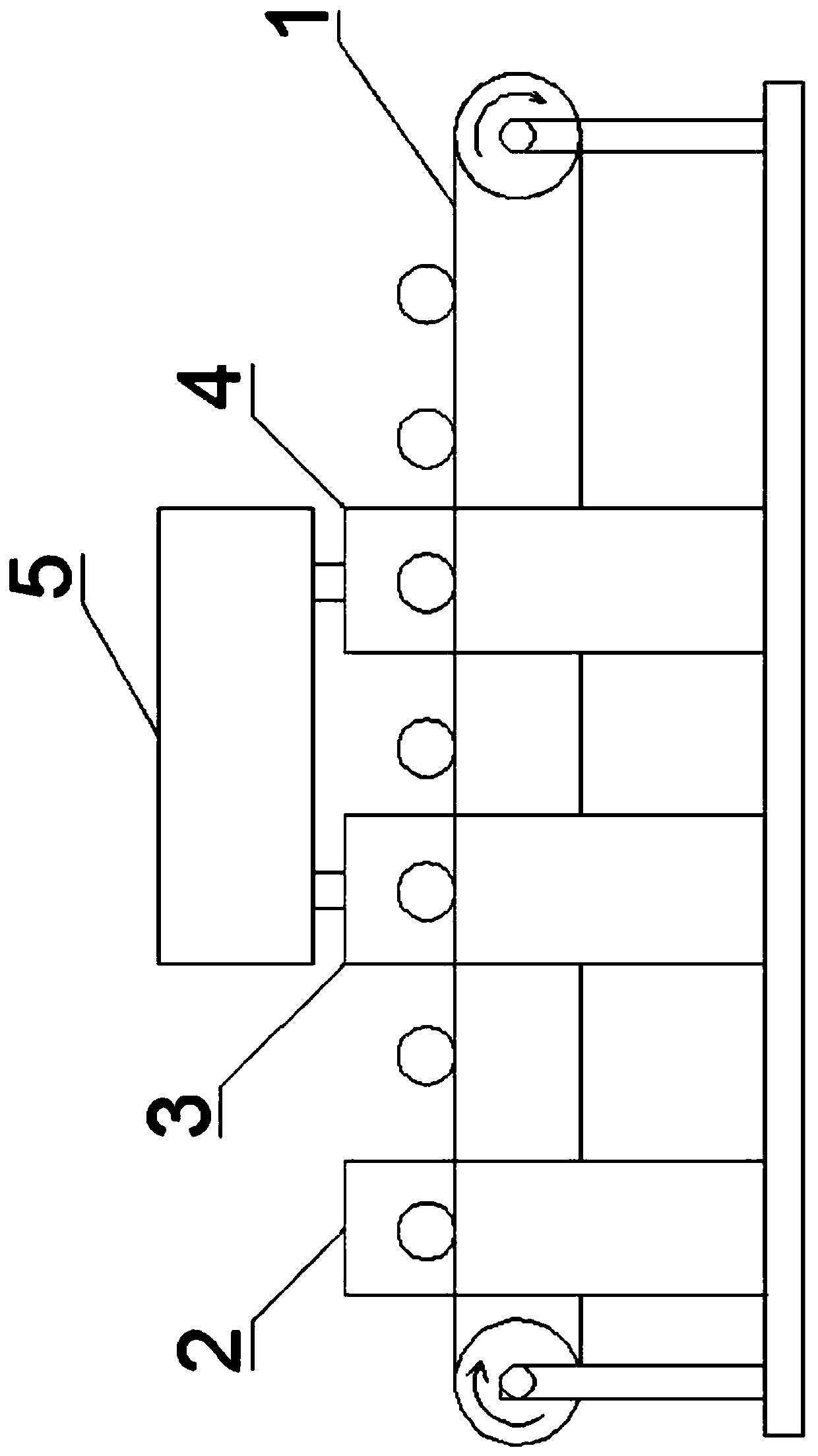

Paint spraying production system of carrier roller

InactiveCN110314802AGuaranteed grinding qualityImprove sanding qualityRevolution surface grinding machinesPretreated surfacesLacquerElectric machinery

The invention discloses a paint spraying production system of a carrier roller. The paint spraying production system comprises a carrier roller conveying device, a grinding device, a paint spraying device and a drying device, wherein the grinding device, the paint spraying device and the drying device are sequentially arranged in the conveying direction of the carrier roller; the carrier roller conveying device comprises a support and the two sides of the support are respectively provided with a first belt and a second belt; the outer sides of the peripheral rings of the first belt and the second belt are respectively provided with a first shaft seat and a second shaft seat and the tail ends of the first shaft seat and the second shaft seat are respectively provided with a connecting shaft; the end part of each connecting shaft is provided with a groove; each groove is matched with the corresponding shaft core of the carrier roller; the first belt and the second belt rotate through a first motor and a second motor below the support respectively; and the first motor and the second motor are electrically connected with a controller. According to the paint spraying production system,the carrier roller is sequentially polished, painted and dried through the form that the carrier roller is conveyed by a conveying belt, time and labor are saved, space is saved, production efficiencyis high, metal powder and paint mist can be effectively prevented from entering a working environment, and the advantages of environmental protection and energy saving are achieved.

Owner:湖南创威科技有限公司

Exhaust gas treatment system for food heavy metal detection

ActiveCN107497242BNo harmObserve the reaction digestionGas treatmentPreparing sample for investigationFiber bundleAir pump

Owner:衣维贤

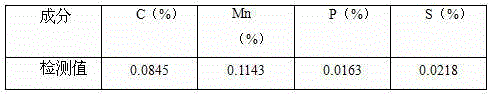

Oxygen converter steelmaking method

InactiveCN105950817AControl splashIncrease consumptionManufacturing convertersProcess efficiency improvementProcess systemsSludge

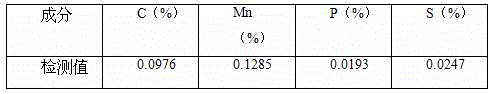

The invention relates to an oxygen converter steelmaking method. The process system of the method comprises: a loading system: 90-94% by weight of molten iron and 6-10% by weight of steel scrap are quantitatively loaded; an oxygen supply system: the lance position (H / mm) of an oxygen lance is 1100-1800mm far from a metal level; a slagging system: the added slagging material comprises 14-17% by weight of limestones, 28-34% by weight of lime, 21-25% by weight of unfired dolomite, 14-17% by weight of sludge balls and 14-17% by weight of iron ores by virtue of a single-slag operation; a temperature system: a tapping temperature Ttapping=Tliquid phase+deltaTdegree of superheat+deltaTprocess, wherein Ttapping is the tapping temperature, Tliquid phae is a liquid phase line temperature, deltaTdegree of superheat is a degree of superheat, and deltaTprocess is a process temperature drop from tapping to starting pouring; and a terminal point system: the steel comprises terminal point chemical components in percentages by mass: 0.06-0.20% of C, 0.05-0.35% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S and the balance of Fe and trace elements.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

A method for repairing and remanufacturing the surface of a locomotive buffer bar

ActiveCN109079421BGuaranteed stabilityReduce welding heat inputWelding apparatusSand blastingEngineering

A method for repairing and remanufacturing the surface of a buffer rod of a locomotive, the steps of which are as follows: S1, screening out repairable buffer rods to be repaired; S2, inspecting the wear amount of the buffer rod to be repaired, respectively in the shaft sections of the buffer rods with different radii, Determine the area to be repaired according to the size of the wear amount, and process the groove to be repaired in the area to be repaired; S3, perform sandblasting, cleaning and preheating treatment on the buffer bar to be repaired in sequence; S4, fix one end of the buffer bar to be repaired on the variable On the positioner, continuous annular welding is performed on the groove to be repaired by the CMT automatic welding system to complete the repair of the buffer bar to be repaired; S5, post-weld slow cooling treatment is performed on the repair buffer bar obtained in step S4; S6, the repair area of the repair buffer bar is Machined to original drawing size and then sandblasted as a whole. The method of the invention has low cost, high efficiency and high repairing quality, and the quality standard of new parts can be reached after repairing and remanufacturing through the method of the invention.

Owner:SOUTHWEST JIAOTONG UNIV

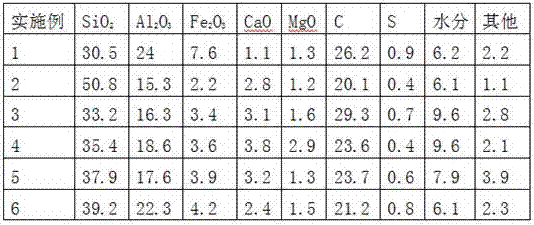

Application of coal gangue used as converter slag inhibiting agent, and converter slag inhibiting method

ActiveCN105132613AGood slag suppression effectControl splashManufacturing convertersIron oxideCoal gangue

The invention discloses the application of coal gangue used as a converter slag inhibiting agent, and a converter slag inhibiting method. According to the method, coal gangue is used as slag inhibiting agent base materials; when slag inhibition is performed during blowing, steel of 1-2kg / ton is added every time; when slag inhibition is performed during furnace inversion and steel tapping, steel of 0.2-0.5kg / ton is added every time. A good slag inhibiting effect can be reached by a small quantity of the slag inhibiting agent, and the splash during converter blowing can be effectively controlled. Because the price of raw materials is low, and a processing technology is simple, the cost of the slag inhibiting agent only accounts for 10-30% of that of a conventional technology; the waste of raw coal or magnesium resources is effectively avoided. Aiming at the problems of over-high soft blowing of iron oxides during blowing, difficult converter inversion at a blowing end, and slag overflow in steel tapping after reblowing, according to the method, the slag inhibiting agent is added, so that slag iron oxides can be effectively reduced, and the purposes for controlling splash and quickly tapping steel are reached. The method does not have bad influences on the environment, and besides, resources are saved, and cost is reduced, so that the method has a popularization and application value in steelmaking production plants.

Owner:TANGSHAN STAINLESS STEEL +1

Method of controlling green environment-friendly smelting of converter

ActiveCN109913612AControl splashEliminate the phenomenon of spill pollutionManufacturing convertersGreen environmentSlag

The invention relates to a method of controlling green environment-friendly smelting of a converter. The method concretely comprises the following steps of (1) performing double-slag operation when Si+ Ti is not less than 0.7%; (2) performing converter rocking for more than two times altogether after the double-slag operation is ended, wherein the converter rocking angle is 30 degrees to -30 degrees, and performing lance sinking for oxygen blowing after waiting for 1 min to 2 min at a zero position; (3) manually adjusting an oxygen pressure valve to 30% to 35% during secondary lance sinking,wherein oxygen flow is 35000 m<3> / h to 38000 m<3> / h, and the lance height is 3.0 m to 3.2 m; (4) performing oxygen blowing for 30 s to 40 s, and after the flow is stabilized, manually adjusting the pressure valve to return to 85% to 88% of the initial state, and adjusting the oxygen flow to 51000 m<3> / h to 53000 m<3> / h; and (5) pressing slag by using a slag pressing material at the early stage andintermediate stage of blowing, wherein the addition amount of the slag pressing material is 200 to 300 kg per batch; and at the later stage of blowing, only allowing to add an iron-contained material, wherein the addition amount of the iron-contained material is not greater than 300 kg per batch. According to the method disclosed by the invention, through technology optimization, metal splashingliable to occur during secondary lance sinking is effectively controlled; the phenomenon that smoke dust overflows to cause pollution during secondary lance sinking is eliminated; stable control oversmelting of the converter is realized; environmental pollution is reduced; and meanwhile, the metal charge consumption is reduced.

Owner:ANGANG STEEL CO LTD

Special dustproof polymethyl methacrylate polishing machine

InactiveCN113400178APrevent splashControl splashPolishing machinesGrinding drivesPolishingPolymethyl methacrylate

The invention discloses a special dustproof polymethyl methacrylate polishing machine which comprises a shell. The shell comprises a protective shell and a top plate, the top plate is arranged at the top of the protective shell and fixedly installed at the top of the protective shell through fixing bolts, a fixing hole is formed in the center of the top plate, a polishing disc is arranged in the protective shell, a rotating assembly is arranged on the polishing disc and comprises a fixing sleeve, a fixing groove is formed in the fixing sleeve, a knuckle bearing is fixedly installed in the fixing groove, the knuckle bearing is arranged on a rotating shaft in a sleeving mode, and the end, away from the fixing groove, of the rotating shaft is fixedly installed at the top of the polishing disc. According to the special dustproof polymethyl methacrylate polishing machine provided by the invention, the protective shell is arranged on the periphery of the polishing disc, so that splashing of polishing liquid in the polishing process is prevented, and splashing of dust and the polishing liquid is effectively controlled; meanwhile, protective cotton is additionally arranged on an outer ring of the polishing disc, so that scratching is avoided when the protective cotton makes contact with the inner face of the protective shell; and the technical problem that in the prior art, during polishing, the dust and the polishing liquid splash to cause harm to a human body is solved.

Owner:JIANGSU TOMSON NEW MATERIAL TECH CO LTD

Clutch-manipulation assist device

InactiveCN101173698BControl impactControlled coolingFluid actuated clutchesControl devicesActuatorClutch

The present invention provides a clutch manipulation assist device, which includes a clutch assist actuator, the actuator is arranged at a position where it is possible to suppress the influence of heat from an engine on the actuator without requiring the heat insulation structure or the like. The clutch manipulation assist device includes a clutch mechanism (61) which is arranged in a power transmission path for transmitting a rotational driving force of an engine (17) to a wheel, a clutch-manipulation mechanism in which a clutch manipulation force is inputted, and an actuator (73) which generates a clutch assist force in response to a manipulation of the clutch manipulation mechanism, the actuator is arranged in front of the engine (17) and outside a main frame (8).

Owner:HONDA MOTOR CO LTD

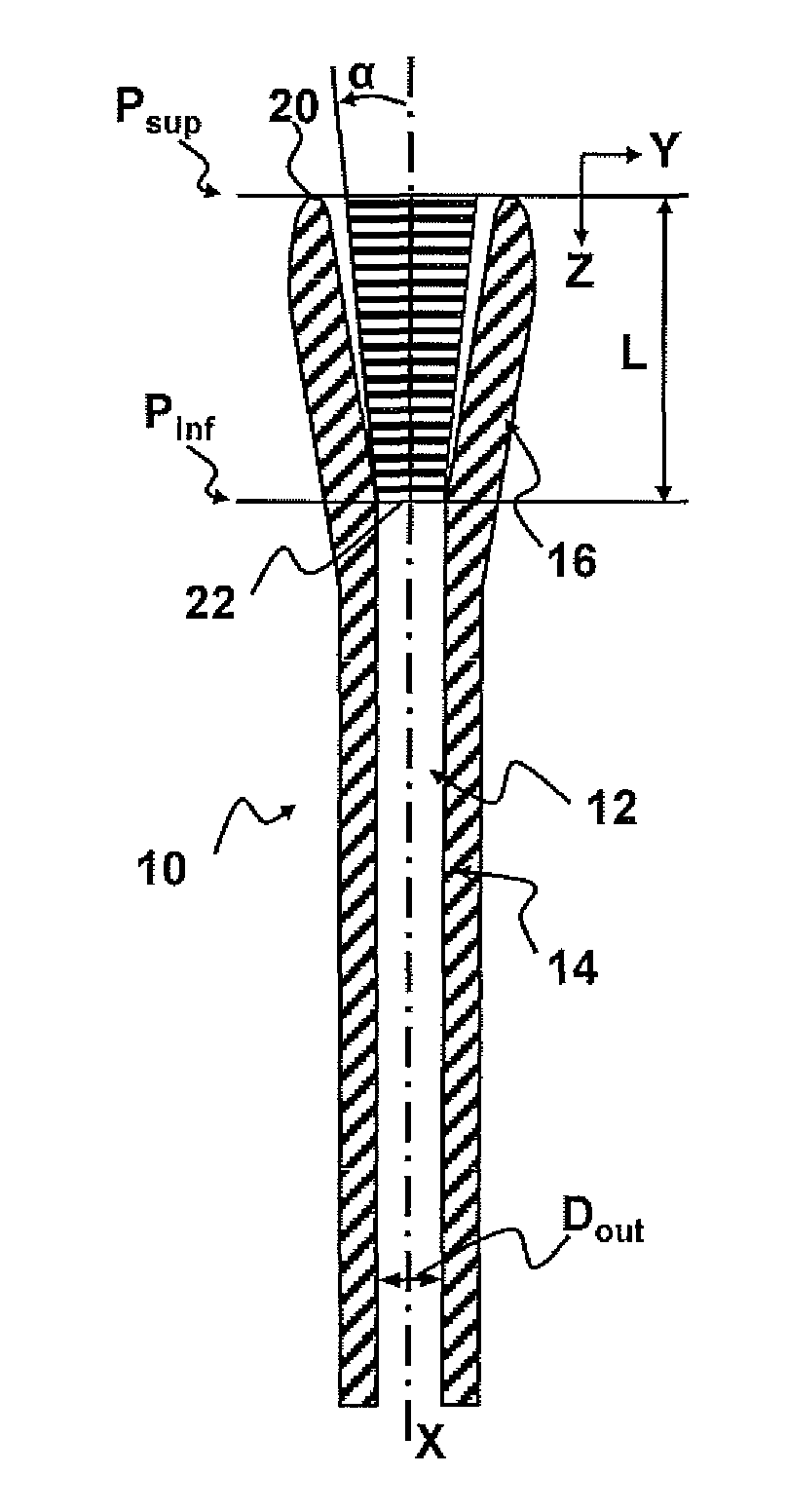

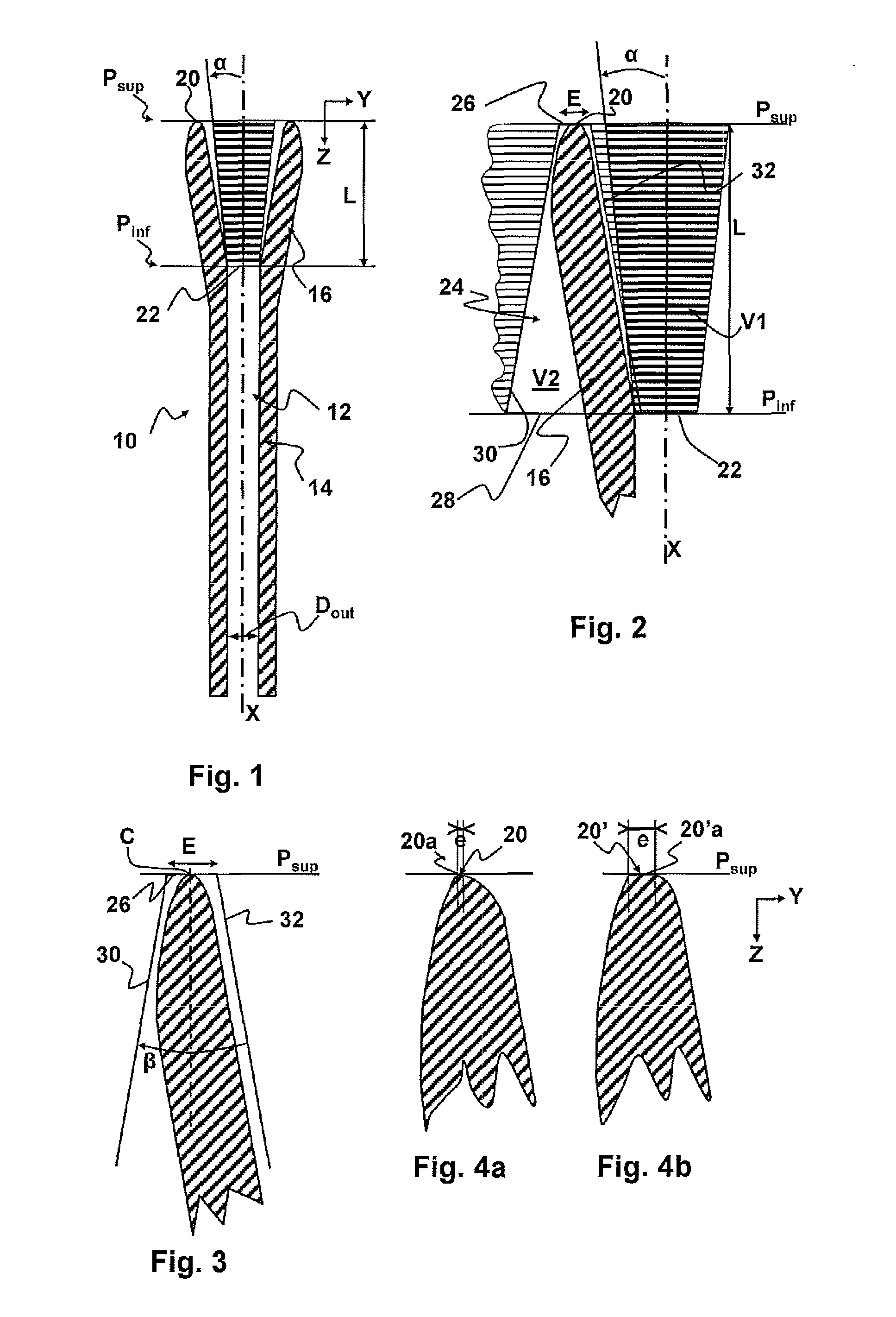

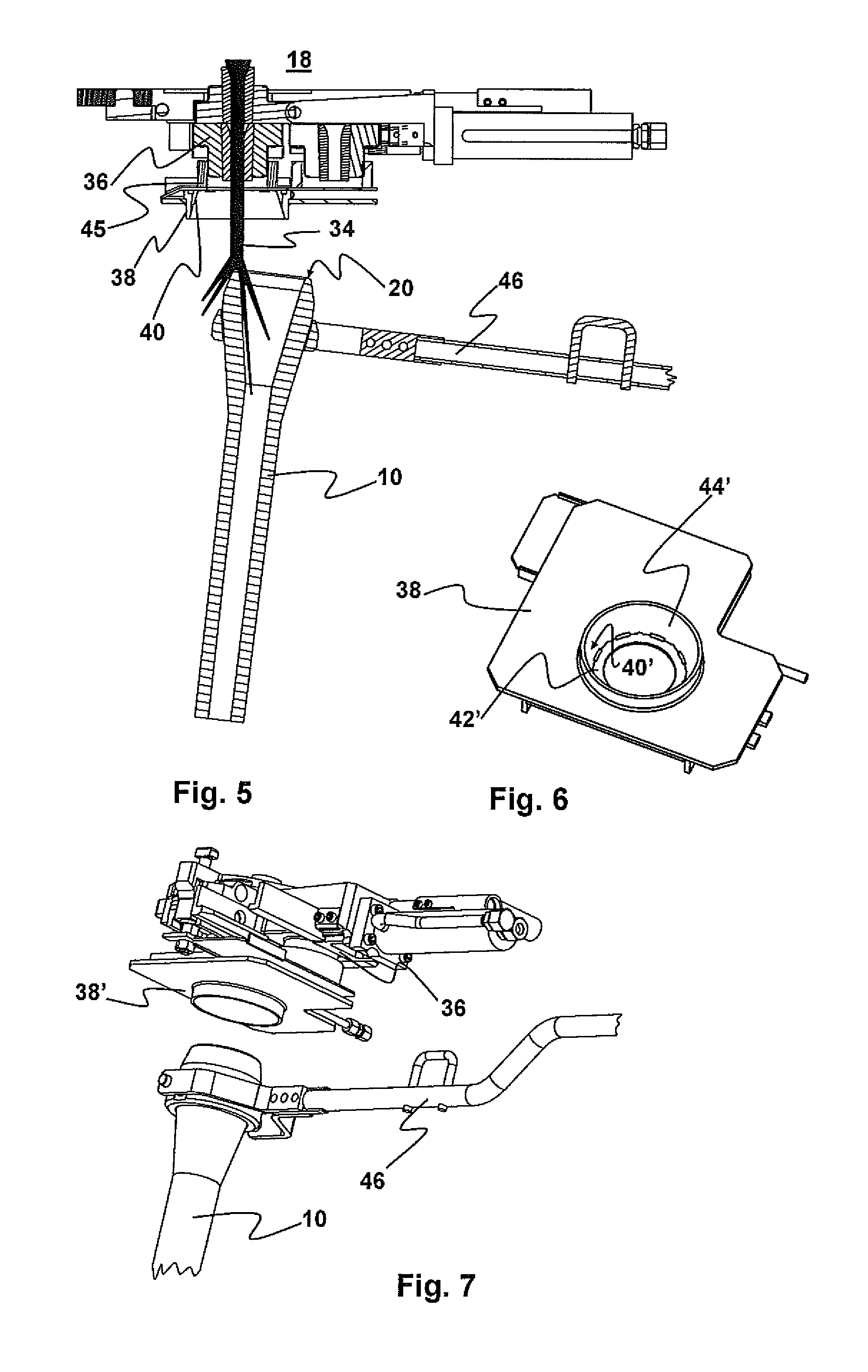

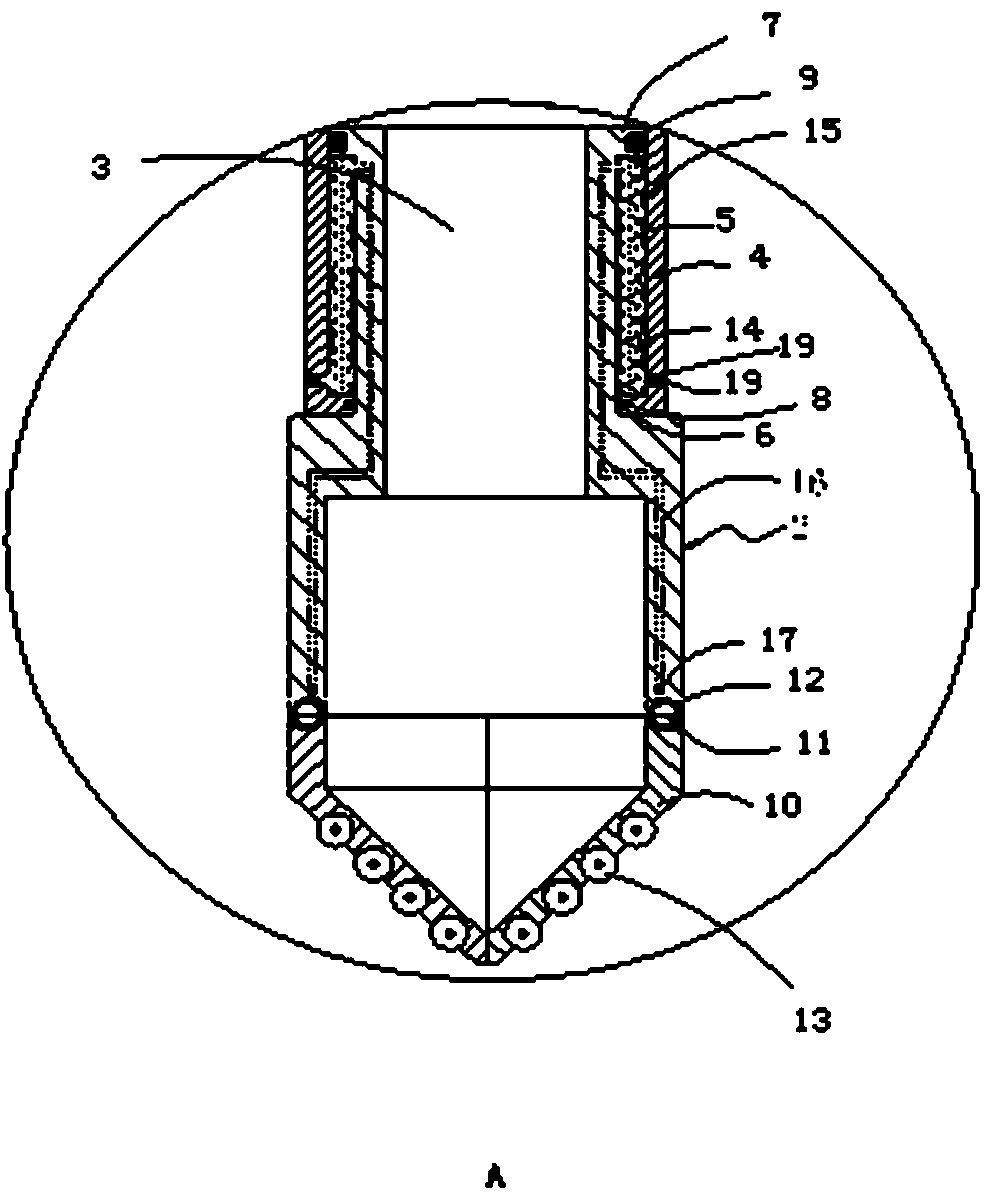

Tube for pouring liquid metal, assembly of a tube and a metal frame and metal frame

ActiveUS9517505B2Reduce riskControl splashMelt-holding vesselsPipe supportsMetal frameworkCircular cone

Owner:VESUVIUS GRP SA

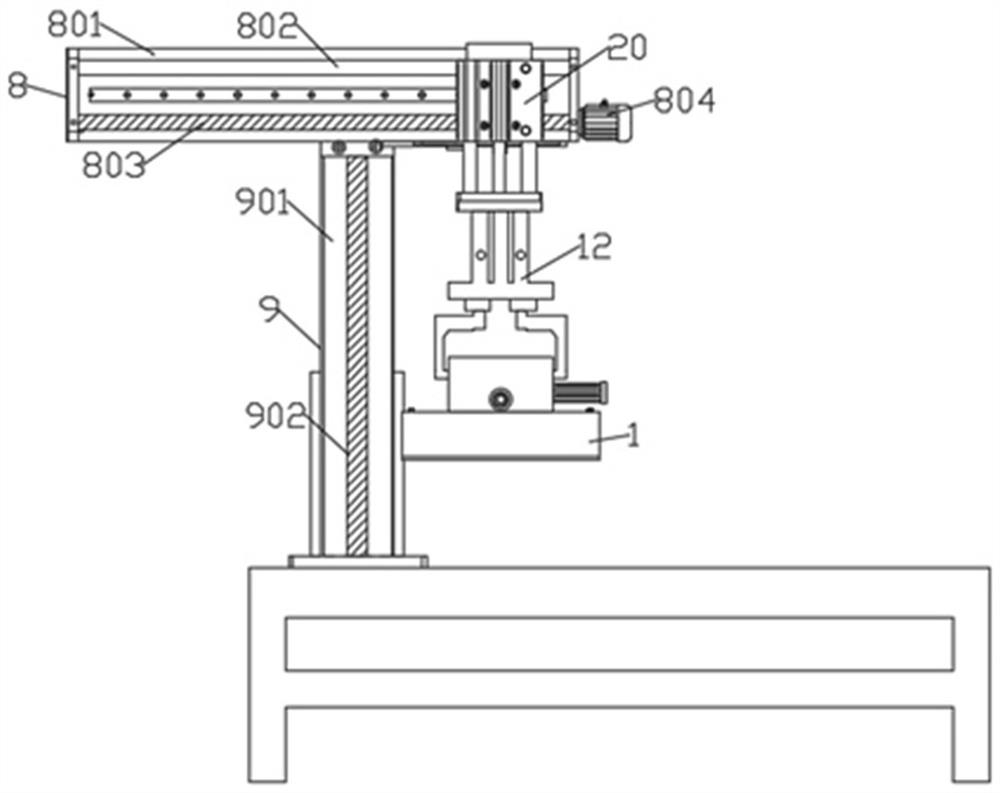

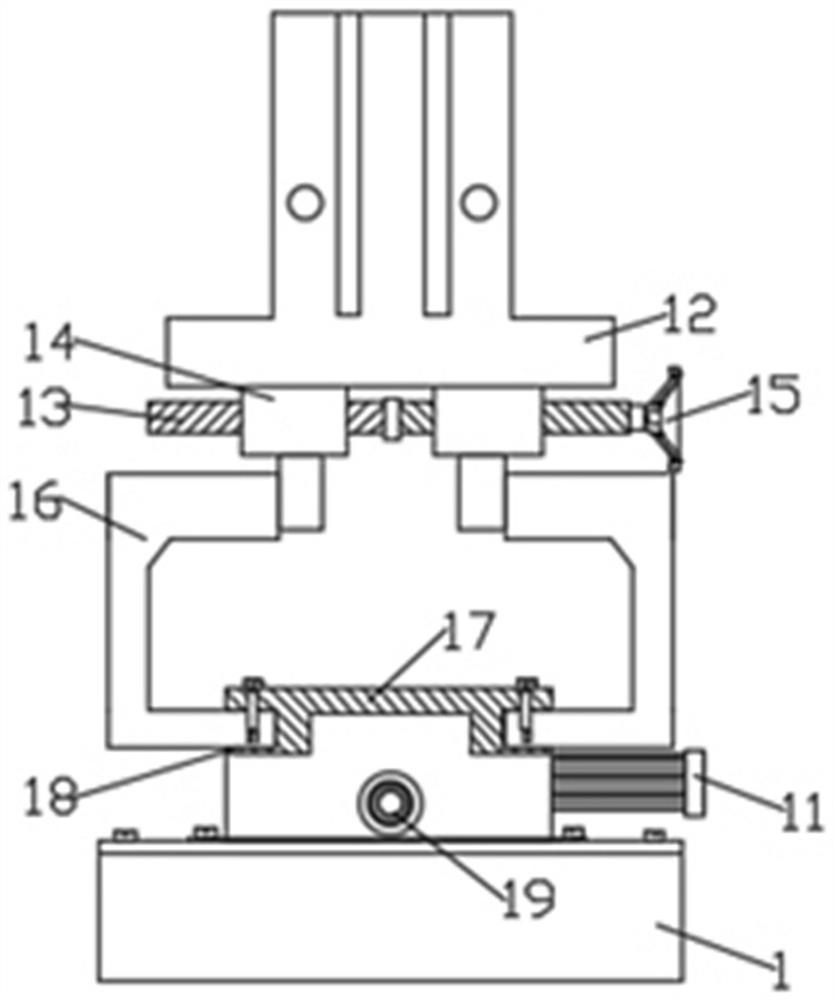

Multi-angle PE pipe cutting system

PendingCN112356115AEasy to adjustSimple wayMetal working apparatusClassical mechanicsStructural engineering

The invention particularly relates to a multi-angle PE pipe cutting system. For changing the current situation that an existing PE pipe machining device is monotonous in cutting effect, the PE pipe cutting system capable of achieving multi-angle cutting and multiple functions is provided. The PE pipe cutting system comprises a shell, a moving device, a cutting device and a base. The moving devicecomprises a lifting mechanism arranged on a back plate of the shell, the cutting device is fixed to the moving device, and movement in the vertical direction is achieved through the lifting mechanism;and besides, the shell and the base can move relatively through a rotating shaft, so that the movement of the whole shell in the horizontal direction is realized. According to the cutting system, flexible adjustment of the cutting device in multiple horizontal and vertical directions is realized through simple device improvement, and the cutting system has important significance when applied to PE pipe machining.

Owner:山东茂盛管业有限公司

A method for treating molten steel in a converter

ActiveCN106834592BShort processing timeAvoid Rhythm DifficultyManufacturing convertersMolten steelDolomite

The invention discloses a converter return molten steel processing method. The converter return molten steel processing method comprises the following steps that (1) return molten steel is deoxidized and then smelted through a converter, a whole ladle of molten steel is completely added into the converter to be processed, if the charging amount of the molten steel is not enough, molten iron is added into the steel ladle till reaching the preset amount, and then the molten steel and the molten iron are added into the converter; (2) a blow gun is started at 1500-1650 mm, the initial oxygen pressure while blowing is started is controlled to be 0.30-0.35 Mpa, after the gun position is constant at 1500-1650 mm, the oxygen pressure is increased to 0.80-0.85 Mpa at the speed of 0.015-0.020 Mpa / s, and in the pressure increasing process, after the oxygen pressure is increased to 0.5 Mpa, 15-20 kg / t of lime, 5-8 kg / t of dolomite and 0-13 kg / t of sintered ore are added; (3) after blowing is conducted for 1-2 min, the oxygen gun position is declined to 1300-1400 mm; (4) TSC is measured through a sublance after blowing is conducted for 3-4 min, and the oxygen blowing amount and the adding amount of the sintered ore are dynamically controlled according to TSC measuring data; and (5) after a target component of the molten steel is obtained through blowing, the gun is lifted, and tapping is conducted. The converter return molten steel processing method is short in processing cycle and high in efficiency.

Owner:SHANDONG IRON & STEEL CO LTD

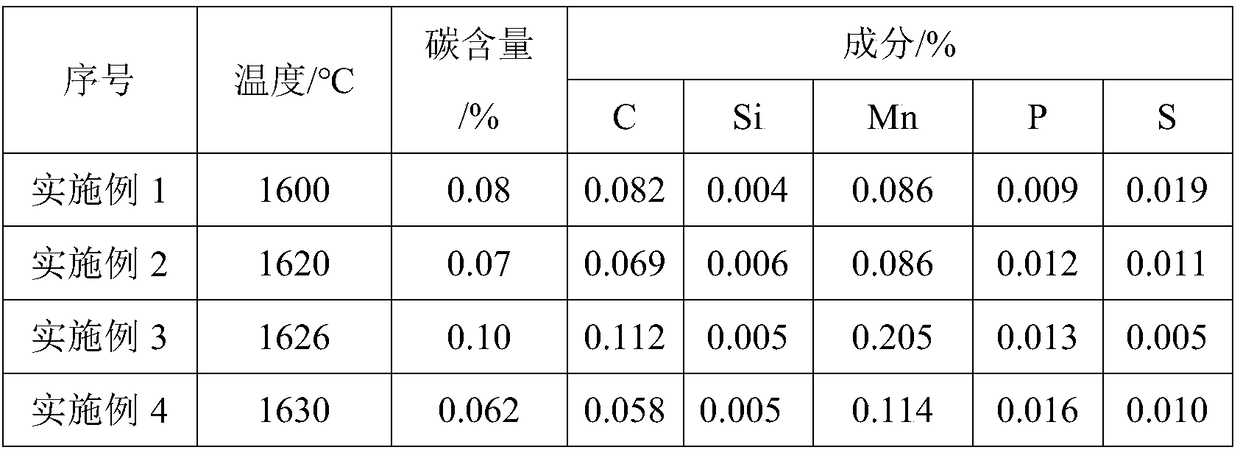

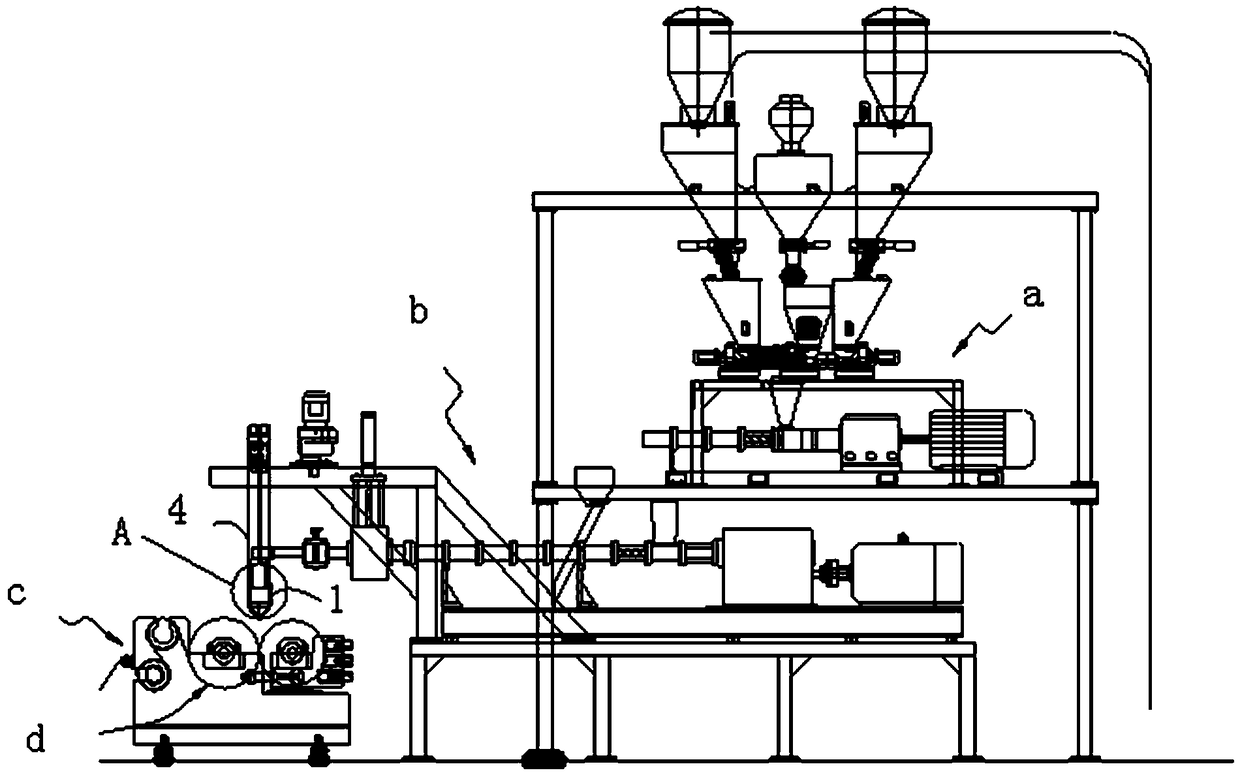

One-time-molding synthetic film production line and connection structure thereof

The invention discloses a one-time-molding synthetic film production line and a connection structure for the one-time-molding synthetic film production line. The one-time-molding synthetic film production line and the connection structure for the one-time-molding synthetic film production line are characterized by comprising a closed refining machine, a casting film machine, a primary thickness detection machine, a stretcher, a secondary thickness detection machine, a point pressing machine, a corona machine and a winder, wherein primary thickness detection machine is butted to the material outlet of the casting film machine and used for performing primary thickness detection on a synthetic film, the stretcher is butted to the material outlet of the primary thickness detection machine andused for performing stretching operations on the synthetic film, the point pressing machine is butted to the material outlet of the stretcher and used for performing point pressing operations on the synthetic film, the corona machine is butted to the material outlet of the point pressing machine and used for performing corona treatment on the synthetic film, and the winder is butted to the material outlet of the corona machine and used for winding the synthetic film. By means of the production line, production-line one-time-molding operations are combined, multiple intermediate links are omitted, the synthetic film molding smoothness is extremely high, the production efficiency is improved by a large margin, and the finished product quality of the synthetic film is high.

Owner:福建玮晟机械有限公司

A control method for green environmental protection smelting of converter

ActiveCN109913612BControl splashEliminate the phenomenon of spill pollutionManufacturing convertersGreen environmentSlag

The invention relates to a method of controlling green environment-friendly smelting of a converter. The method concretely comprises the following steps of (1) performing double-slag operation when Si+ Ti is not less than 0.7%; (2) performing converter rocking for more than two times altogether after the double-slag operation is ended, wherein the converter rocking angle is 30 degrees to -30 degrees, and performing lance sinking for oxygen blowing after waiting for 1 min to 2 min at a zero position; (3) manually adjusting an oxygen pressure valve to 30% to 35% during secondary lance sinking,wherein oxygen flow is 35000 m<3> / h to 38000 m<3> / h, and the lance height is 3.0 m to 3.2 m; (4) performing oxygen blowing for 30 s to 40 s, and after the flow is stabilized, manually adjusting the pressure valve to return to 85% to 88% of the initial state, and adjusting the oxygen flow to 51000 m<3> / h to 53000 m<3> / h; and (5) pressing slag by using a slag pressing material at the early stage andintermediate stage of blowing, wherein the addition amount of the slag pressing material is 200 to 300 kg per batch; and at the later stage of blowing, only allowing to add an iron-contained material, wherein the addition amount of the iron-contained material is not greater than 300 kg per batch. According to the method disclosed by the invention, through technology optimization, metal splashingliable to occur during secondary lance sinking is effectively controlled; the phenomenon that smoke dust overflows to cause pollution during secondary lance sinking is eliminated; stable control oversmelting of the converter is realized; environmental pollution is reduced; and meanwhile, the metal charge consumption is reduced.

Owner:ANGANG STEEL CO LTD

Application of coal gangue as converter slagging inhibitor and methods for converter slag suppression

Owner:TANGSHAN STAINLESS STEEL +1

Domestic sewage treatment system

InactiveCN109293132AEasy to cleanSimple processTreatment involving filtrationMultistage water/sewage treatmentConstructed wetlandActivated carbon

The invention discloses a domestic sewage treatment system, which comprises a manual grid pool, a sedimentation tank, a primary treatment tank, a secondary treatment tank, a tertiary treatment tank, afourth treatment tank, a horizontal subsurface constructed wetland, a vertical subsurface constructed wetland, and a discharge pool, the artificial grid pool is connected with an inlet pipe, and thedischarge pool is connected with an outlet pipe, and water outlet channels are arranged among the sedimentation tank, the primary treatment tank, the secondary treatment tank, the tertiary treatment tank, and the fourth treatment tank, the tops of the sedimentation tank, the primary treatment tank, the secondary treatment tank, the tertiary treatment tank and the fourth treatment tank are all provided with a clearing mouth, the sedimentation tank is provided with crushed straw, the primary treatment tank and the secondary treatment tank are all provided with an activated carbon adsorbent, andthe tertiary treatment tank and the fourth treatment tank are all provided with a biological filler. The domestic sewage treatment system has the advantages of fully automatic operation, simple process, no energy consumption, and high decontamination efficiency, and is suitable for the treatment of decentralized domestic sewage.

Owner:华蓥市职业教育培训中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com