Waste gas treatment system for detecting heavy metals in food

A technology for waste gas treatment and heavy metals, which is applied in gas treatment, preparation of test samples, measurement devices, etc., can solve problems such as corrosion, loss of heavy metals, and difficulty in extracting heavy metals, and achieves good adsorption effect, simple treatment, and environment-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

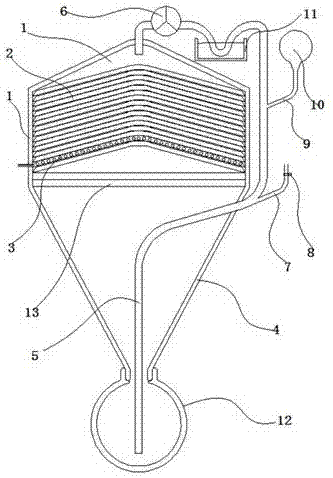

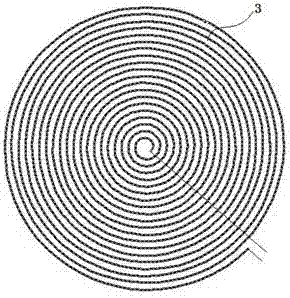

[0031] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0032] Such as figure 1 and figure 2 As shown, a waste gas treatment system for food heavy metal detection includes: waste gas chamber, the upper part of the waste gas chamber is an adsorption chamber 1, the bottom of the waste gas chamber is connected with a reaction ball chamber 12, and the adsorption and digestion are carried out in a closed form in a fully sealed form. It is carried out in the environment, the exhaust gas will not leak out, and it will hardly cause harm to the environment and the human body. The transparent glass waste gas chamber and the reaction ball chamber 12 can clearly observe the reaction and digestion situation....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com