Mineral precursor adsorbing agent and preparation method and application thereof

A precursor and adsorbent technology, which is applied in the field of mineral precursor adsorbent and its preparation, can solve the problem of unsatisfactory adsorption capacity and achieve excellent adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of mineral precursor adsorbent, its preparation method comprises the steps:

[0031] 1.38g magnesium hydroxide (Mg(OH) 2 ), 0.62g aluminum hydroxide (Al(OH) 3 ), (the molar ratio is 3:1), put it into a 50mL grinding jar, add 80g of zirconium balls with a diameter of 15mm, set the mill speed to 700rpm, and the grinding time to 180min. After the grinding is completed, the mineral precursor adsorbent is obtained.

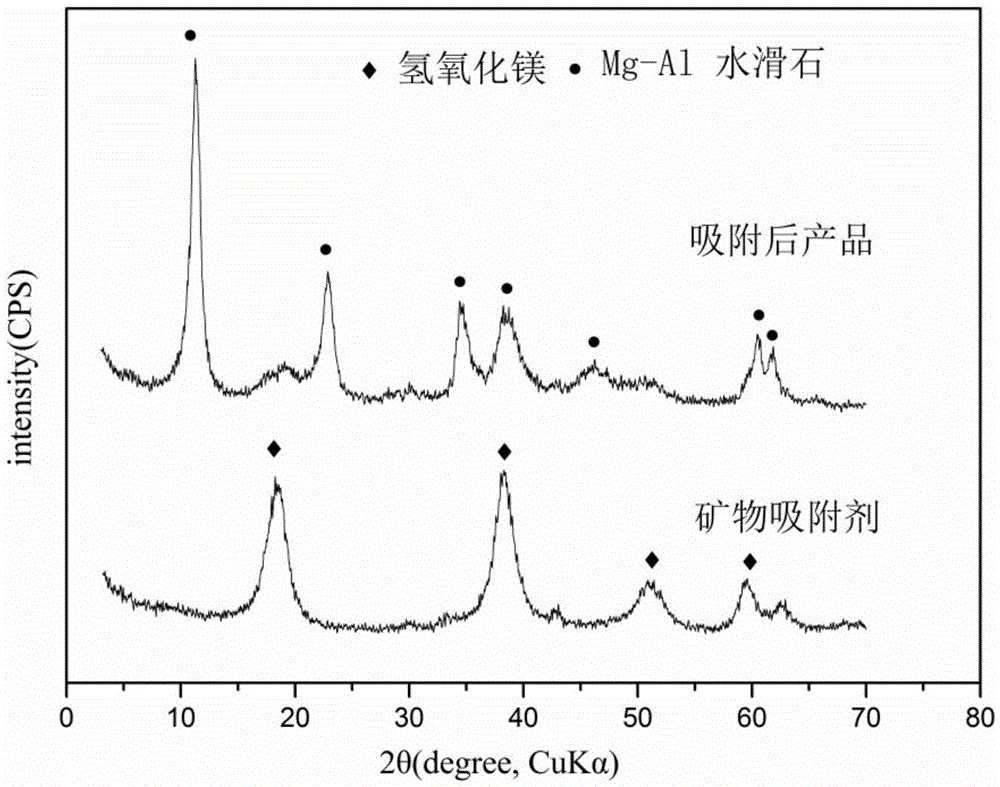

[0032] figure 1 The XRD patterns of the mineral precursor adsorbent obtained in this example are used to adsorb wastewater containing methyl orange before and after. Depend on figure 1 It can be seen that after the raw materials (magnesium hydroxide and aluminum hydroxide) are mechanically ground, the structure is destroyed, and a weak crystal structure substance near glass is formed. After absorbing methyl orange in the aqueous solution, the obtained mineral precursor adsorbent is transformed into Highly crystalline hydrotalcite.

[0033] Add the mi...

Embodiment 2

[0038] A kind of mineral precursor adsorbent, its preparation method comprises the steps:

[0039] Mix 0.5g calcium hydroxide, 1.15g calcium sulfate dihydrate and 0.35g aluminum hydroxide (molar ratio is 3:3:2), put them into a 50mL grinding jar, add 80g of zirconium balls with a diameter of 15mm, place Set the grinding speed in the mill to 500 rpm, and the grinding time to 120 min. After the grinding is completed, the mineral precursor adsorbent is obtained.

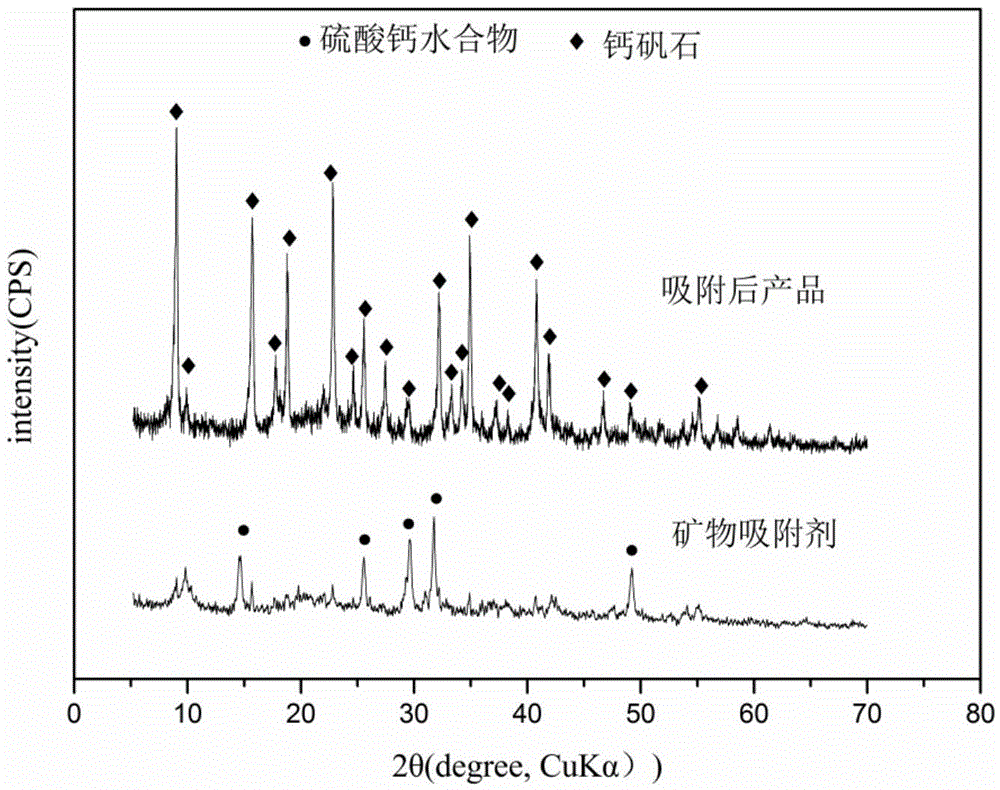

[0040] figure 2 It is the XRD patterns of the mineral precursor adsorbent obtained in this example before and after being used to adsorb phosphorus-containing wastewater. Depend on figure 2 It can be seen that after the raw materials (calcium hydroxide, calcium sulfate dihydrate, aluminum hydroxide) are mechanically ground, the structure is destroyed and a weakly crystalline substance is formed. After absorbing phosphorus in the aqueous solution, the mineral precursor compound is transformed into a highly crystallin...

Embodiment 3

[0046] A preparation method of a mineral precursor adsorbent, comprising the steps of:

[0047] Mix 0.85g of calcium hydroxide, 0.56g of calcium chloride dihydrate and 0.59g of aluminum hydroxide (the molar ratio is 3:1:2) into a 50mL grinding jar, add 80g of zirconium balls with a diameter of 15mm, and place in the grinding jar. The grinding speed is set to 500 rpm in the machine, and the grinding time is 120 min. After the grinding is completed, the mineral precursor adsorbent is obtained.

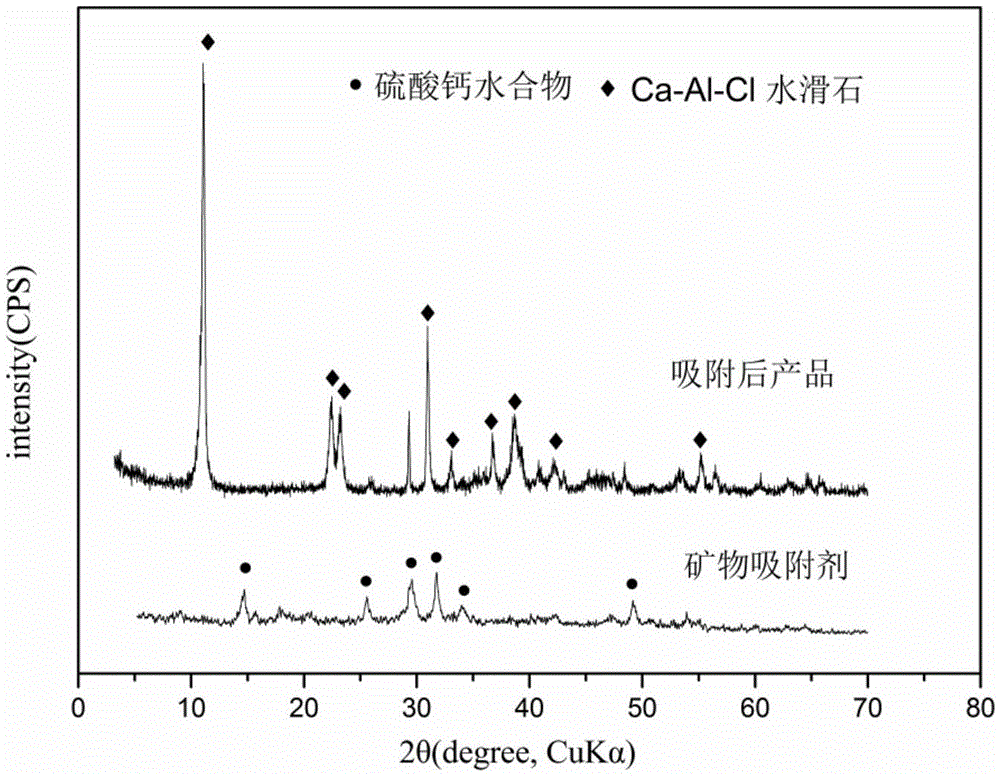

[0048] image 3 It is the XRD pattern of the products obtained after the mineral precursor adsorbent products obtained in this example are respectively used to adsorb chlorine-containing wastewater. Depend on image 3 It can be seen that after the raw material is mechanically ground, the structure is destroyed and a weakly crystalline substance is formed. After absorbing methyl orange in the aqueous solution, the mineral precursor compound is transformed into Ca-Al-Cl hydrotalcite. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com