Plasma arc technology based digital multifunctional power supply

A plasma arc, multi-functional technology, applied in the field of ion arc, can solve the problems such as the pulsation characteristics of the plasma arc cannot be effectively adjusted, the welding penetration and welding speed cannot meet the requirements, and the welding quality and efficiency are affected, and the loss is low. , Wide range of application, the effect of improving welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

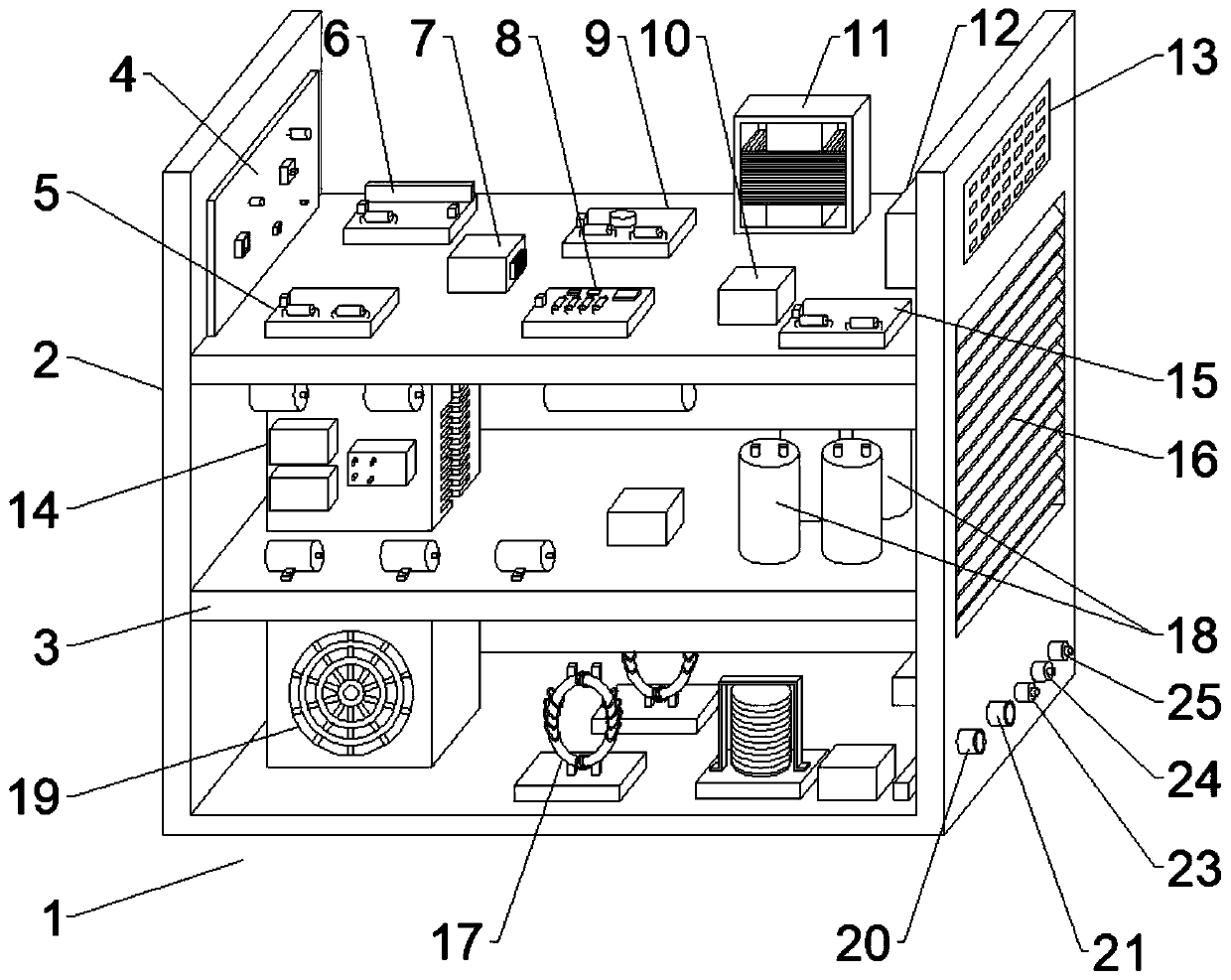

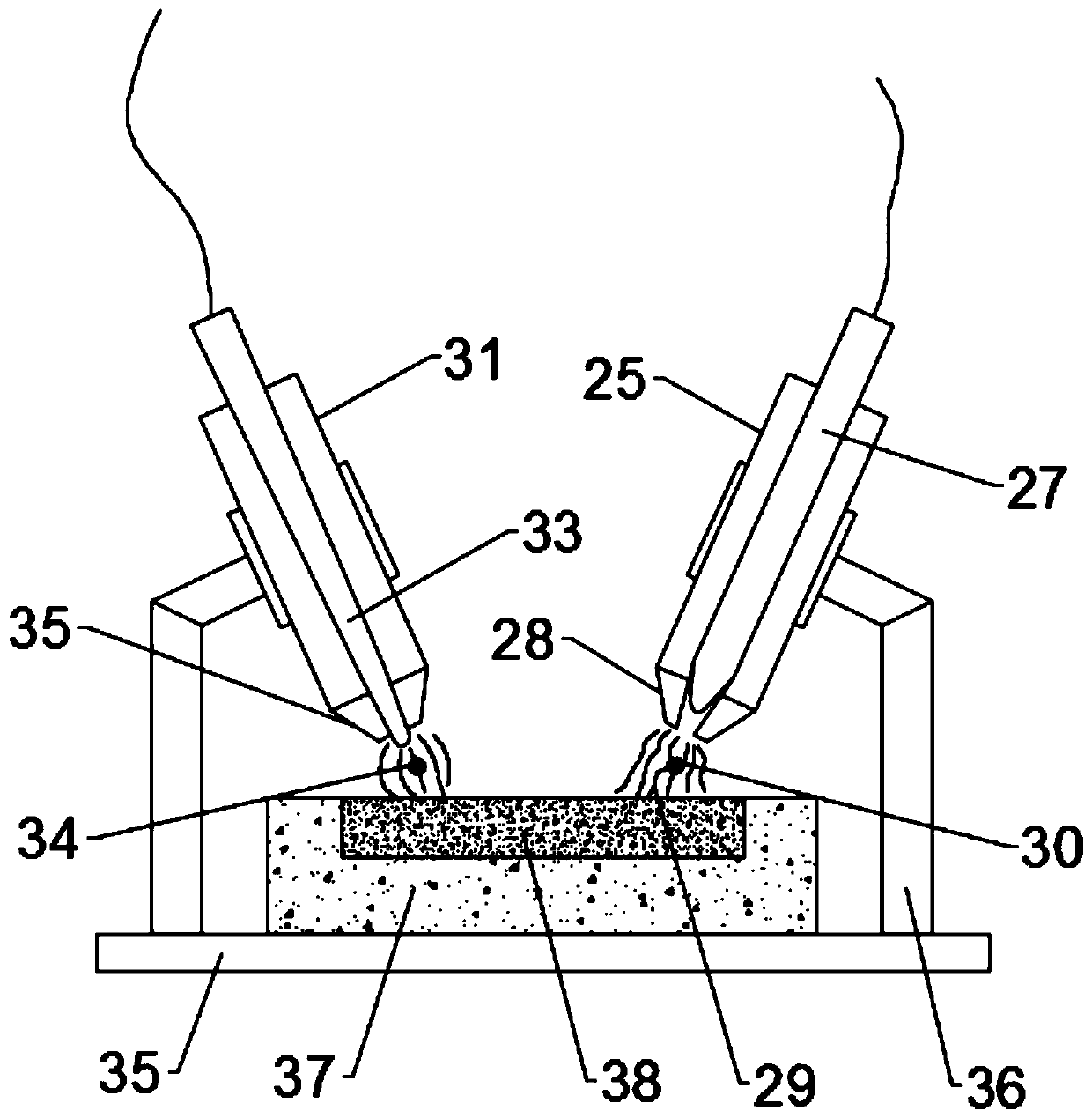

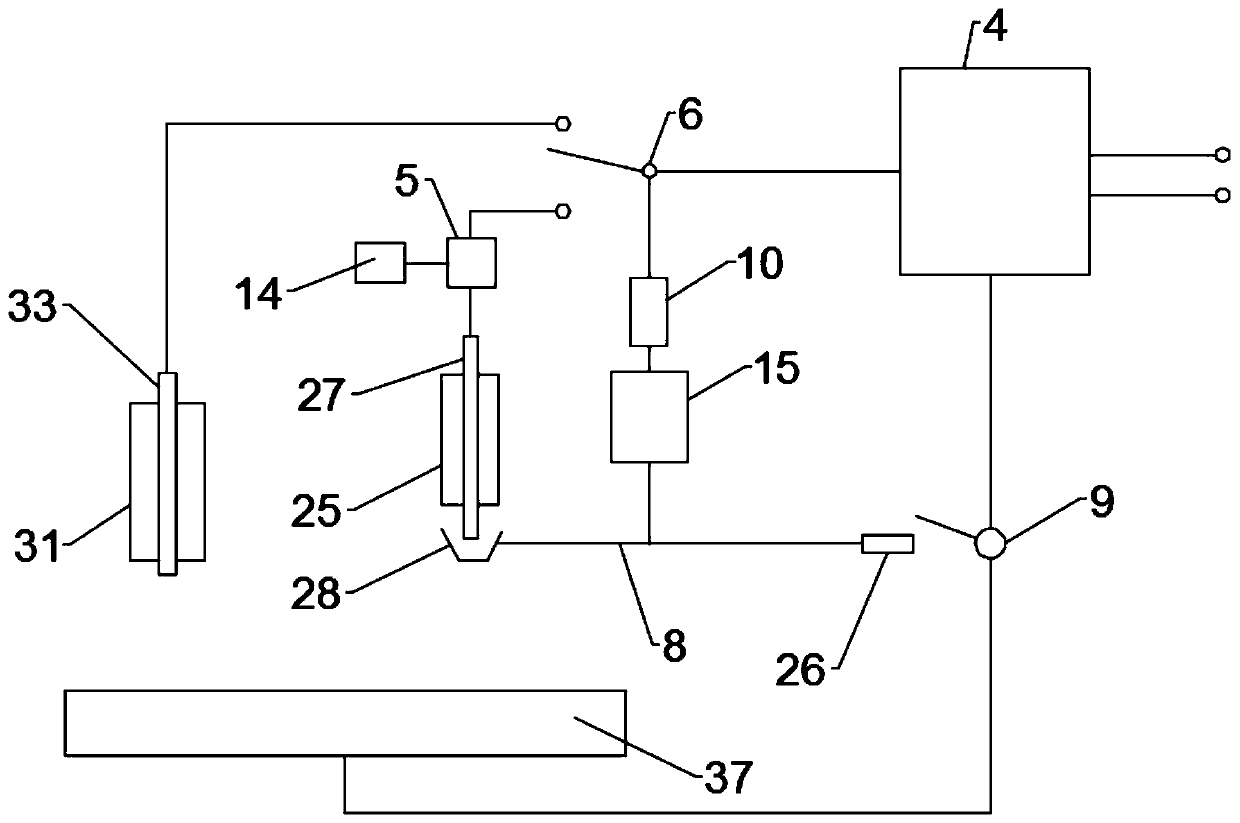

[0029] as attached Figure 1-3 As shown, a digital multifunctional power supply based on plasma arc technology includes a plasma arc welding power supply 1. The plasma arc welding power supply 1 is composed of a frame 2 and a partition 3 arranged inside it. The partition 3 is divided into an upper partition And the lower partition, the partition 3 divides the interior of the plasma arc welding power supply 1 into a multi-layer chamber for the installation of components, and rationally utilizes the space;

[0030] The plasma arc welding power supply 1 is internally divided into a power control component, a welding output control component, and a display operation component; wherein, the power control component includes a main control board 4, a PLC controller 7, a main transformer 17, a storage tank 18, a fan 19, Plasma welding torch interface 20, argon arc welding torch interface 21, air inlet interface 22, water inlet interface 23 and return water interface 24;

[0031] Spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com