Converter return molten steel processing method

A molten steel and converter technology, applied in the manufacture of converters and other directions, can solve the problems of high labor intensity, furnace lining erosion, splash accidents, etc., and achieve the effect of avoiding difficult rhythm, controlling process splash, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for treating molten steel from a converter, including the following steps:

[0027] 1. Prepare slag-making materials, based on the amount of molten steel per ton: active lime, dolomite and sinter;

[0028] The added amount of active lime is 16kg / t;

[0029] The dolomite addition amount is 6kg / t;

[0030] The added amount of the sintered ore (carbon content≤0.20%, sulfur content and phosphorus content≤0.030%) is 5kg / t.

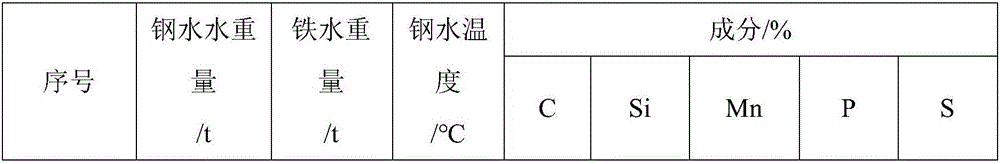

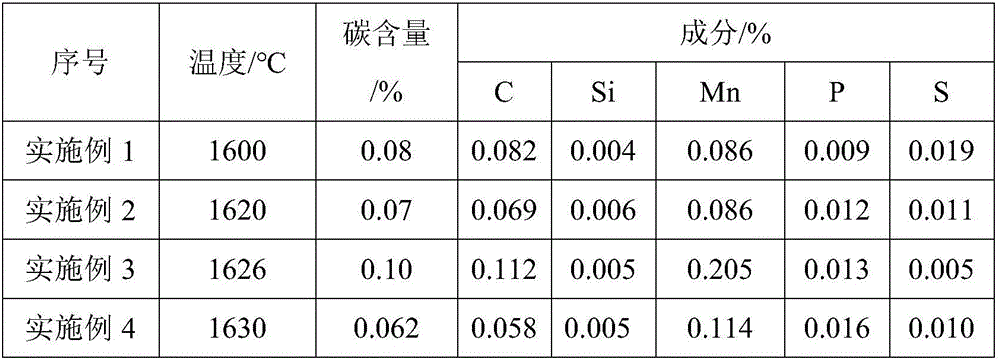

[0031] 2. Prepare the whole package of 130t molten steel and 10t molten iron.

[0032] 3. The treatment is carried out according to the method for treating molten steel in the converter, and the specific steps are as follows:

[0033] a. After deoxidizing the returned molten steel, the whole package of 130t of returned molten steel is converted into the converter, and then 10t of molten iron is added.

[0034] b. The blowing gun position adopts the gun position: 1520mm (the gun position refers to the distance between the nozzle of the oxygen lance and the li...

Embodiment 2

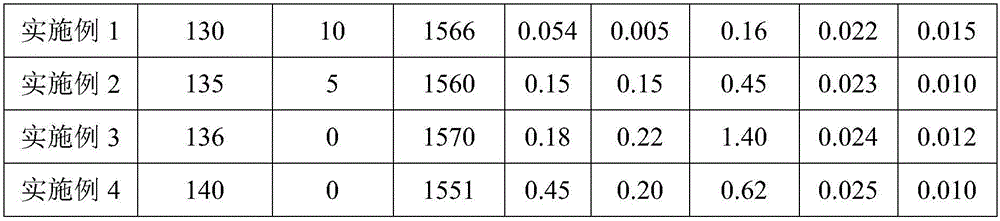

[0040] According to a method for treating molten steel in a converter according to embodiment 1, the difference is that in step a, 135t of molten steel is added to the furnace, and 5t of molten iron is added; in step b, the blowing lance position is 1600mm, and the initial oxygen pressure is started. Control at 0.30Mpa. After the gun position is constant at 1550mm, the oxygen pressure will be raised to 0.83Mpa at a rate of 0.015~0.020Mpa per second and then constant. When the oxygen pressure is raised to 0.55Mpa, 15kg / t of lime and 5kg / t of dolomite are added. , Sintered ore 3kg / t; in step d, the measured temperature is 1620℃ and the carbon content is 0.070%; in step f, oxygen is blown to 300m 3 Raise the gun.

Embodiment 3

[0042] 1. Prepare slag-making materials, based on the amount of molten steel per ton: active lime, dolomite and sinter;

[0043] The added amount of active lime is 18kg / t;

[0044] The dolomite addition amount is 5kg / t;

[0045] The added amount of the sintered ore (carbon content≤0.20%, sulfur content and phosphorus content≤0.030%) is 13kg / t.

[0046] 2. Prepare the whole package of 136t molten steel.

[0047] 3. The treatment is carried out according to the method for treating molten steel in the converter, and the specific steps are as follows:

[0048] a. After deoxidizing the reheated molten steel, the 136t reheated molten steel is transferred into the converter.

[0049] b. The blowing gun position adopts the gun position: 1650mm (the gun position refers to the distance between the nozzle of the oxygen lance and the liquid level of the molten pool). The initial oxygen pressure for blowing is controlled at 0.35Mpa. After the gun position is constant at 1650mm, it will be 0.015~0.020 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com