Oxygen converter steelmaking method

A technology of oxygen converter and oxygen lance, which is applied in the field of steelmaking to achieve the effects of increasing consumption, reducing oxygen consumption and reducing CO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A kind of oxygen converter steelmaking method

[0022] Loading system: Quantitative loading is adopted, with 91.7t of molten iron and 8.2t of scrap steel.

[0023] Oxygen supply system: The oxygen lance position (H / mm) is 1170-1680mm away from the metal liquid surface.

[0024] Slagging system: Single slag operation is adopted, and the quality of slagging materials added is: limestone 804kg, lime 1650kg, raw burnt dolomite 1253kg, sludge ball 817kg, iron ore 797kg. The slag-making material conforms to the second grade or above of the ferrous metallurgical industry standard of the People's Republic of China.

[0025] Temperature system: the smelted steel type is HPB300, the temperature in the smelting process is stable, and the tapping temperature is 1668°C.

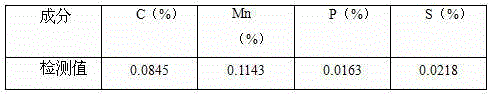

[0026] End point system: See Table 1 for the mass percentages of the chemical composition of carbon, manganese, phosphorus, sulfur and other end points.

[0027] Table 1 Example 1 endpoint chemical...

Embodiment 2

[0029] Embodiment 2: A kind of oxygen converter steelmaking method

[0030] Loading system: Quantitative loading is adopted, with 91.1t of molten iron and 8.1t of scrap steel.

[0031] Oxygen supply system: The oxygen lance position (H / mm) is 1150-1660mm away from the metal liquid surface.

[0032] Slagging system: single slag operation is adopted, and the quality of slagging materials added is: limestone 796kg, lime 1626kg, raw burnt dolomite 1233kg, sludge ball 806kg, iron ore 806kg. The slag-making material conforms to the second grade or above of the ferrous metallurgical industry standard of the People's Republic of China.

[0033] Temperature system: the smelted steel type is HPB300, the temperature in the smelting process is stable, and the tapping temperature is 1668°C.

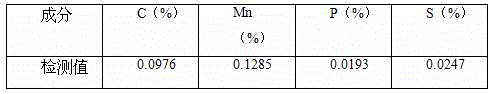

[0034] End point system: carbon, manganese, phosphorus, sulfur content End point chemical composition mass percentage is shown in Table 2.

[0035] Table 2 The chemical composition of the end point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com