One-time-molding synthetic film production line and connection structure thereof

A technology of connecting structures and synthetic membranes, which is applied in the field of synthetic membrane manufacturing, can solve problems such as raw material splashing, and achieve the effect of controlling raw material splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

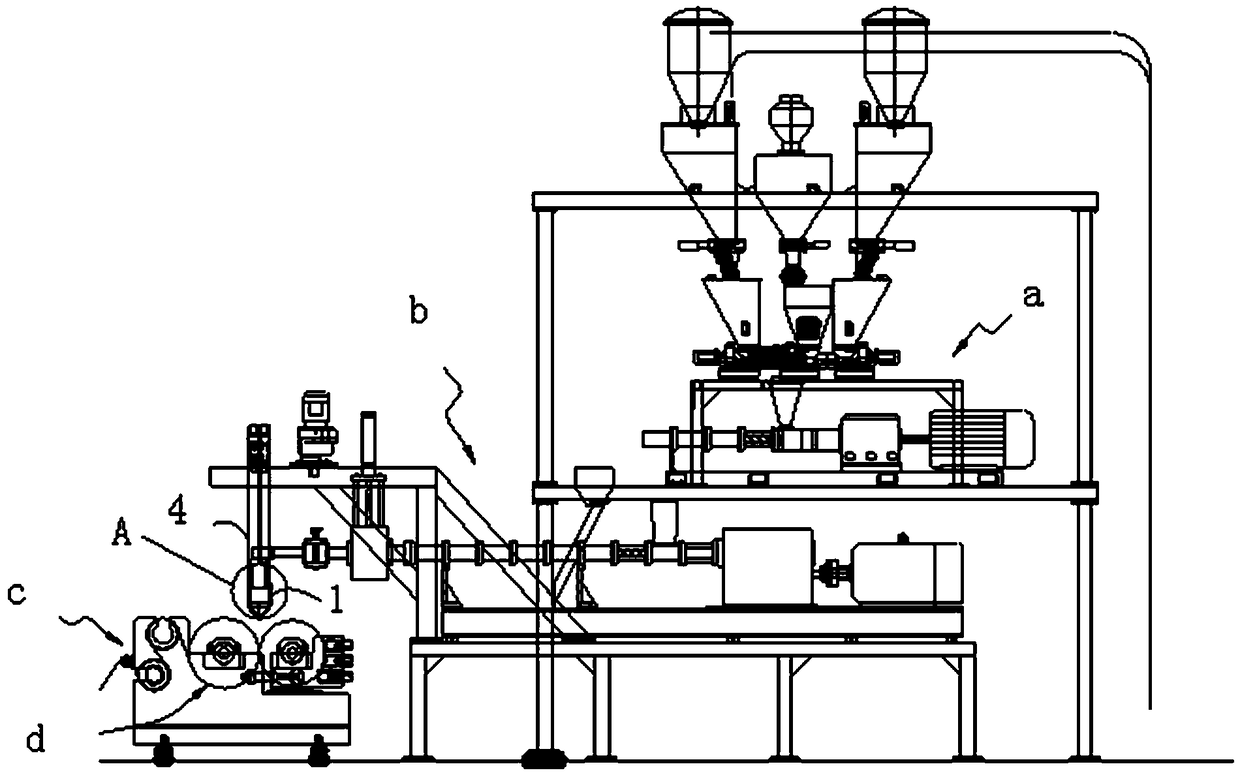

[0048] A production line for one-time forming synthetic film, the connection device is installed between the internal mixer a and the casting machine c.

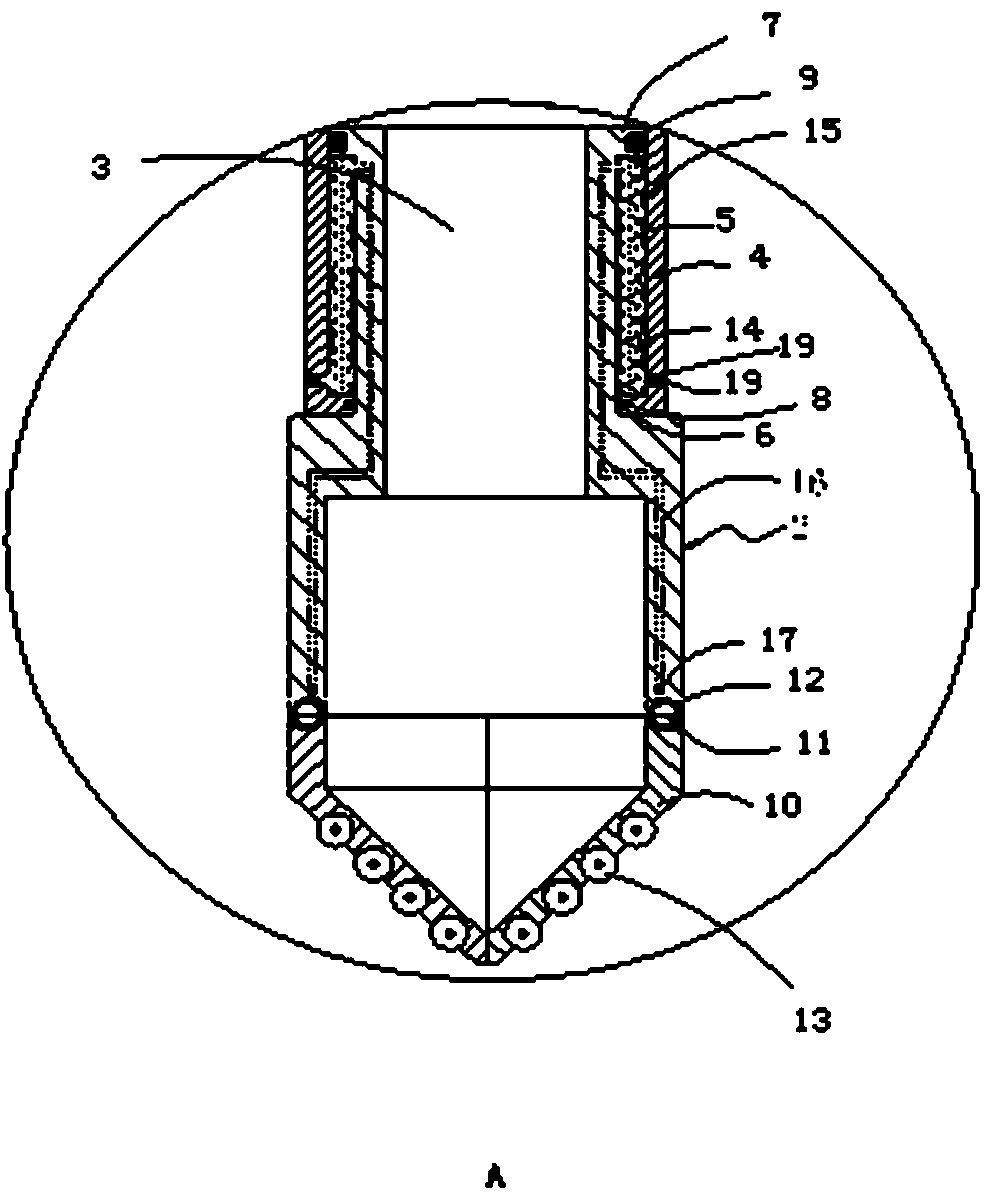

[0049] The connection device includes a connecting pipe 4 which is vertically arranged as a whole, the upper end of the connecting pipe 4 is connected to the discharge port 20 of the twin-screw extruder b, and the lower end of the movable head 2 is connected with a discharge part 1. The discharge part 1 includes The movable head 2, the upper end of the movable head 2 is vertically slidably connected in the discharge port 20, the movable head 2 is provided with a feeding channel 3, the upper end of the discharging channel 3 communicates with the discharge port 20, and the other end communicates with the discharge port 20. It runs through the lower end of the movable head 2.

[0050] An elastic part 5 is arranged inside the discharge port 20. In this embodiment, the elastic part 5 is a spring, and the elastic part 5 is located...

Embodiment 2

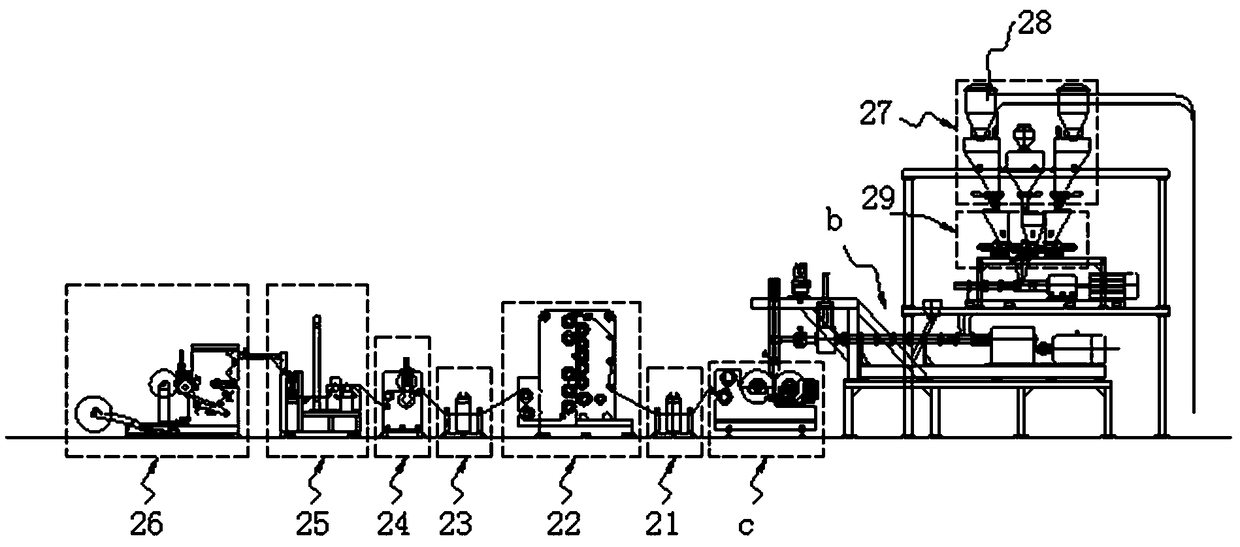

[0060] A production line for one-time forming synthetic film, including the connecting structure in Embodiment 1;

[0061] It also includes a primary thickness measuring machine 21, a stretching machine 22, a secondary thickness measuring machine 23, a pressure point machine 24, a corona machine 25, and a winding machine 26 arranged in sequence on the side away from the casting machine c;

[0062] A thickness measuring machine 21 is connected to the discharge port 20 of the casting machine c and used for the first thickness detection of the synthetic film;

[0063] Stretching machine 22, docked at the outlet 20 of primary thickness measuring machine 21 and used for stretching the synthetic film;

[0064] A pressure point machine 24 is connected to the discharge port 20 of the stretching machine 22 and is used to perform a pressure point operation on the synthetic film;

[0065] The corona machine 25 is connected to the discharge port 20 of the pressure point machine 24 and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com