Application of coal gangue as converter slagging inhibitor and methods for converter slag suppression

A coal gangue and converter technology, applied in the field of slag suppression, can solve problems such as economic impact, cost increase, and complicated process, and achieve the effects of low price, avoiding waste, and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

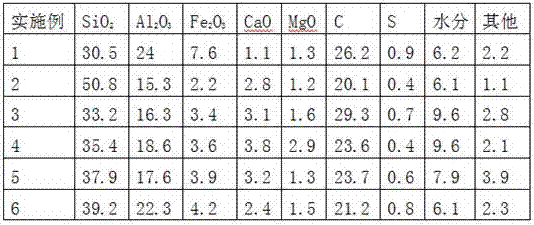

Examples

Embodiment 1

[0028] Embodiment 1: The method for suppressing slag in the converter adopts the following specific process steps.

[0029] Conventional smelting in a 100-ton converter; the molten iron entering the furnace has a C content of 4.23wt%, a Si content of 0.66wt%, a P content of 0.0133wt%, and a Ti content of 0.008wt%. The temperature of the molten iron is 1320°C. The weight of molten iron is 105.3 tons, and the weight of scrap steel is 15.2 tons.

[0030] Due to the high content of silicon in molten iron, when the amount of oxygen blown into the converter reaches 25%, the flue gas detection system shows that the CO content rises faster, indicating that there is a risk of splashing; add 100kg of slagging agent through the high-level silo, and other processes continue to follow The model setting was automatically executed, the CO content curve returned to normal, and no slag splashing occurred in the early stage. End point: End point C is 0.054wt%, P is 0.013wt%, and temperature is...

Embodiment 2

[0031] Embodiment 2: The method for suppressing slag in the converter adopts the following specific process steps.

[0032] Conventional smelting in a 100-ton converter; the C content of molten iron entering the furnace is 4.33%, the content of Si is 0.42%, the content of P is 0.0130%, and the content of Ti is 0.008%, and the temperature of molten iron is 1240°C. The weight of molten iron is 105.8 tons, and the weight of scrap steel is 15.9 tons.

[0033] Due to the low temperature of molten iron entering the furnace, when the amount of oxygen blown into the converter reaches 30%, the flue gas detection system shows that CO is always lower than 30%. Due to the low temperature of the molten pool, a large amount of FeO accumulates, indicating the risk of splashing; The slag agent was 150kg, and other processes continued to be automatically executed according to the model settings, the CO content curve returned to normal, and no slag splashing occurred in the early stage. End po...

Embodiment 3

[0034] Embodiment 3: The method for suppressing slag in the converter adopts the following specific process steps.

[0035] Conventional smelting in a 100-ton converter; the C content of molten iron entering the furnace is 4.25%, the Si content is 0.50%, the P content is 0.0125%, and the Ti content is 0.028%, and the temperature of the molten iron is 1335°C. The weight of molten iron is 104.3 tons, and the weight of scrap steel is 16.2 tons.

[0036] Due to the high content of Ti content in the molten iron, the heating rate of the molten pool is too fast. When the oxygen blowing amount of the converter reaches 25%, the flue gas detection system shows that the CO content rises faster, which indicates that there is a risk of splashing; Other processes continued to be automatically executed according to the model settings, the CO content curve returned to normal, and no slag splashing occurred in the early stage. End point: End point C is 0.044%, P is 0.015%, and temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com