Multi-angle PE pipe cutting system

A cutting system, multi-angle technology, applied in metal processing and other directions, can solve problems such as single cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

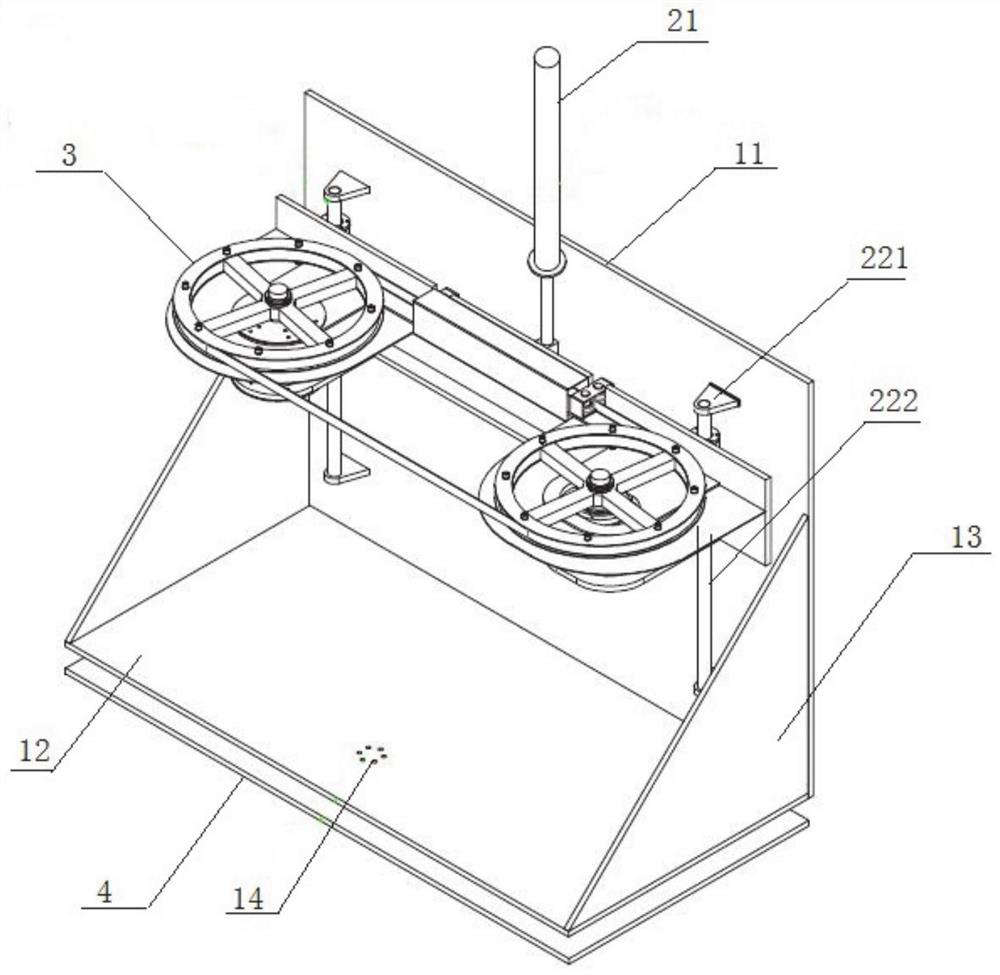

[0043] In this embodiment, a multi-angle PE pipe cutting system is provided, the structure of the cutting system is as attached figure 1 As shown, the cutting system includes a housing 1 , a moving device 2 , a cutting device 3 and a base 4 .

[0044] The housing 1 includes a back plate 11 , a bottom plate 12 and two triangular support plates 13 , the edges of the back plate 11 , bottom plate 12 and support plates 13 are connected to form an open space for accommodating a cutting device. Moreover, the backboard 11 is arranged vertically to the ground, while the bottom board 12 is arranged parallel to the ground. There is a through hole 14 at the center of the bottom plate 12, which is a flange fixing hole.

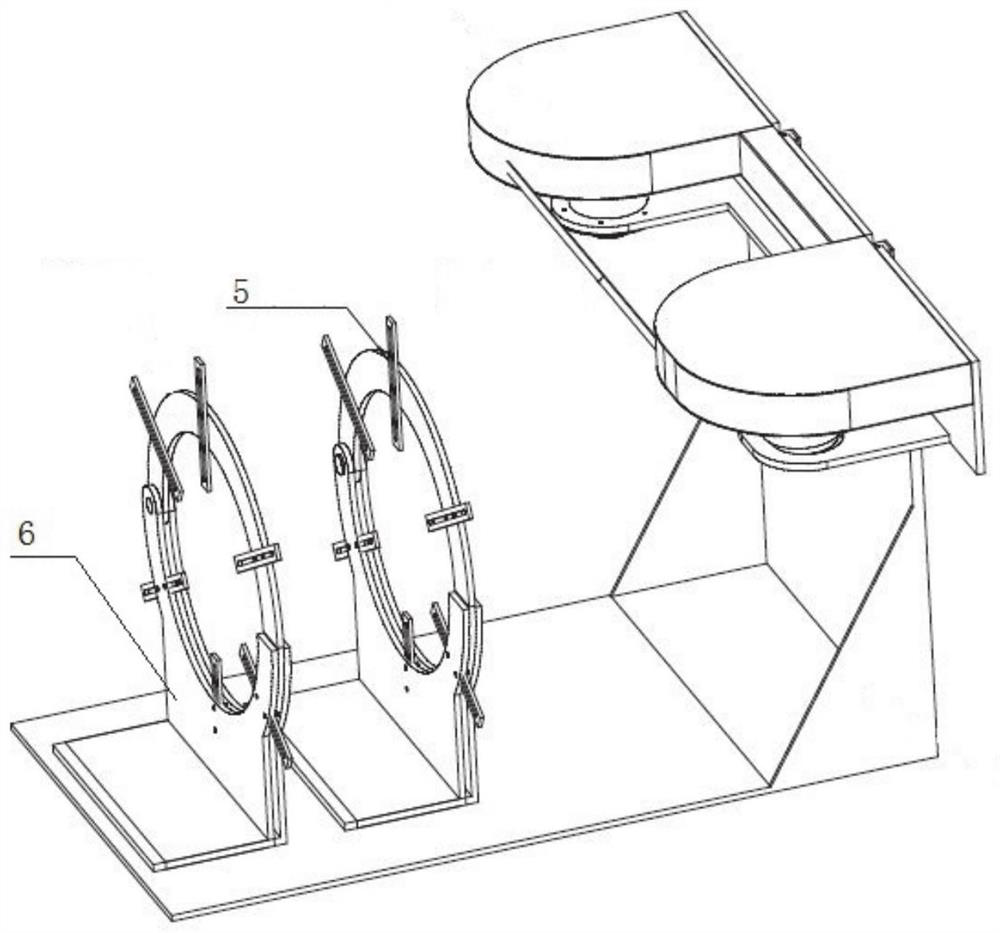

[0045] A rotating mechanism is arranged on the base 5 , and the rotating mechanism is a spiral rotating mechanism. The rotating shaft of the rotating mechanism passes through the flange fixing hole 14 on the bottom plate 12 and is fixed with the bottom plate 14 . The cas...

Embodiment 2

[0050] In this embodiment, another PE pipe cutting system is provided. In the PE pipe cutting system, the support plates 13 are square, and the free ends of the two support plates 13 are distorted inwardly. The shell of this structure has It is beneficial to further reduce the probability of waste chips splashing during the cutting process.

Embodiment 3

[0052] In this embodiment, a multi-angle PE pipe cutting system is provided, as attached figure 2 As shown, the cutting device includes the casing 1, the moving device 2, the cutting device 3 and the base 4 described in Embodiment 1, and also includes a clamping device 5 and a feeding device 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com