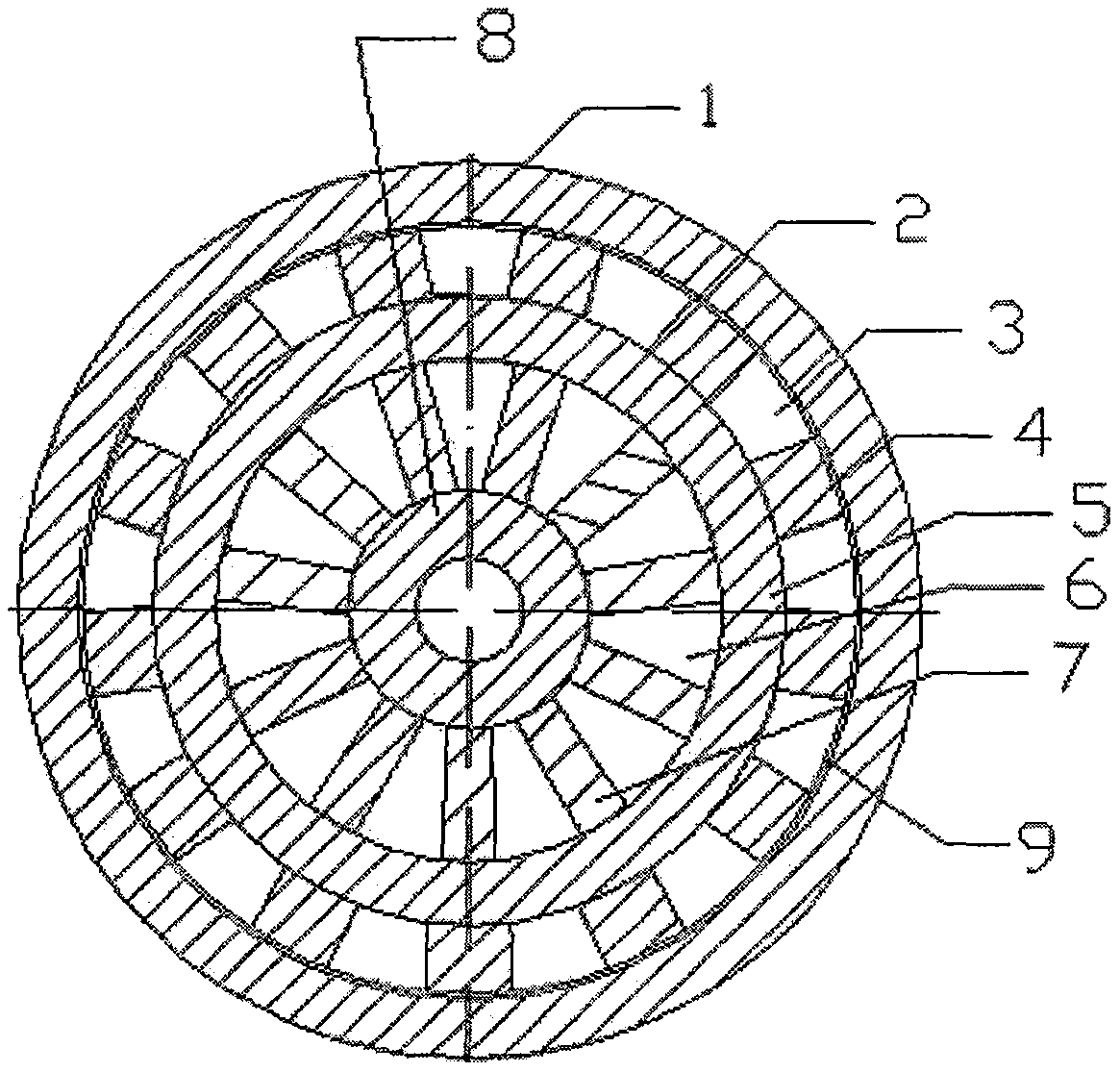

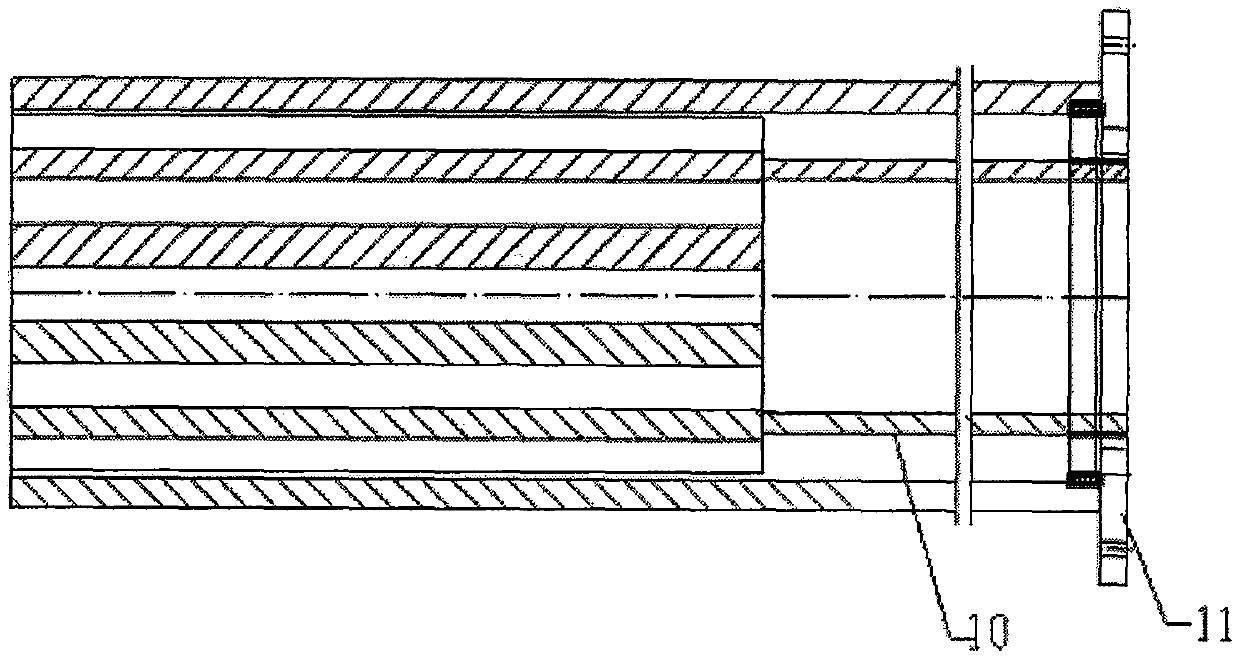

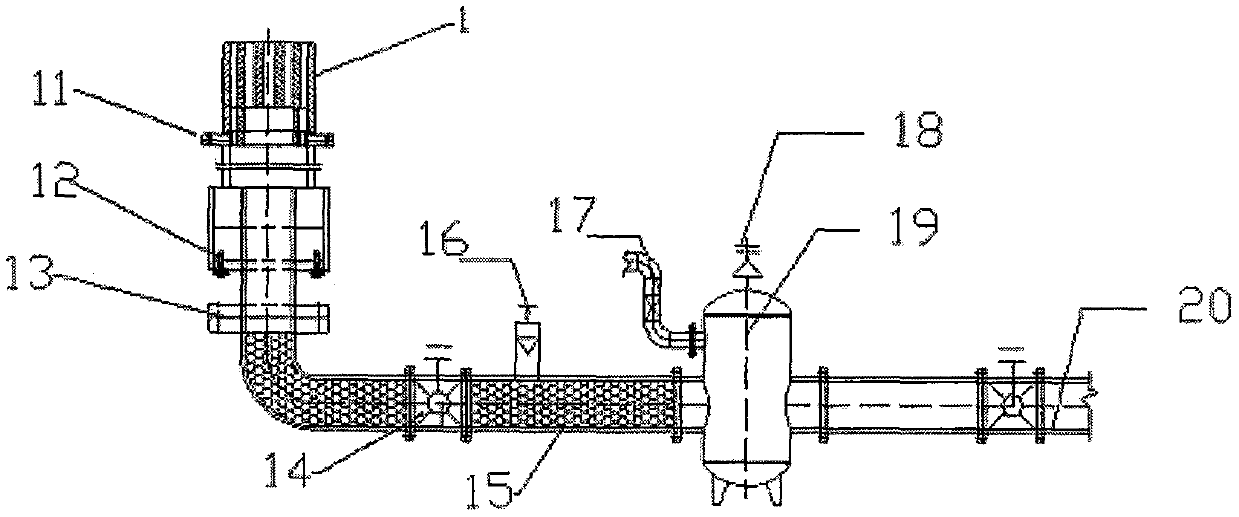

Copper smelting continuous blowing furnace oxygen lance nozzle

A technology for oxygen lance nozzles and blowing furnaces, applied in furnaces, furnace types, etc., can solve problems such as insufficient oxygen distribution density, iron removal, long sulfur time, failure to achieve energy saving and emission reduction, and achieve short blowing time, The effect of fast iron speed and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Taking copper smelting φ3.8×15mm continuous blowing furnace oxygen lance as an example, copper smelting φ3.8×15mm continuous blowing furnace oxygen lance is the key equipment of copper smelting continuous blowing furnace, the present invention is developed according to continuous blowing furnace parameters A suitable oxygen lance nozzle for this type of furnace.

[0026] Basic parameters of continuous converting furnace (see Table 1)

[0027]

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com