Reverse-blowing tribo-electrostatic separation method and device for fly ash decarburization

A technology of triboelectric separation and fly ash, which is applied in chemical instruments and methods, electrostatic effect separation, solid separation, etc., can solve the problem of poor decarbonization effect of fly ash triboelectric separation, affecting particle friction and collision effect, and motion offset Difficult to separate and other problems, to achieve the effect of broad market application prospects, easy control, and efficient sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the following, the embodiments of the present invention will be described in detail with reference to the accompanying drawings.

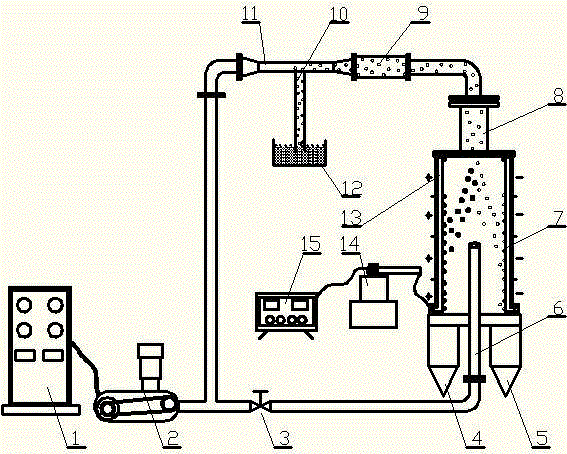

[0020] The back-injection triboelectric separation method used for fly ash decarbonization, the Roots blower 2 works to generate airflow to form a negative pressure in the nozzle 11, and under the adsorption of the negative pressure, the fly ash particles pass through the negative pressure suction pipe 10 into the nozzle 11; the fly ash is sprayed into the gas-solid mixing pipe 9 under the action of the air flow to form a gas-solid two-phase flow, and the feed particles are mixed evenly; since the composition of the fly ash is mainly inorganic ash particles and carbon particles, the gas-solid When the particles in the two-phase flow pass through the friction charger 8, they frictionally collide in the friction charger 8 and carry electric charges of unequal electric quantity and opposite polarity; the charged fly ash particles enter the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com