Baking device used for removing trace of organic pollutants on surface of light machine element

A technology of organic pollutants and baking devices, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of difficult removal, long molecular chains of organic pollutants, large adhesion, etc., and achieve simple structure and high removal effect Good, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

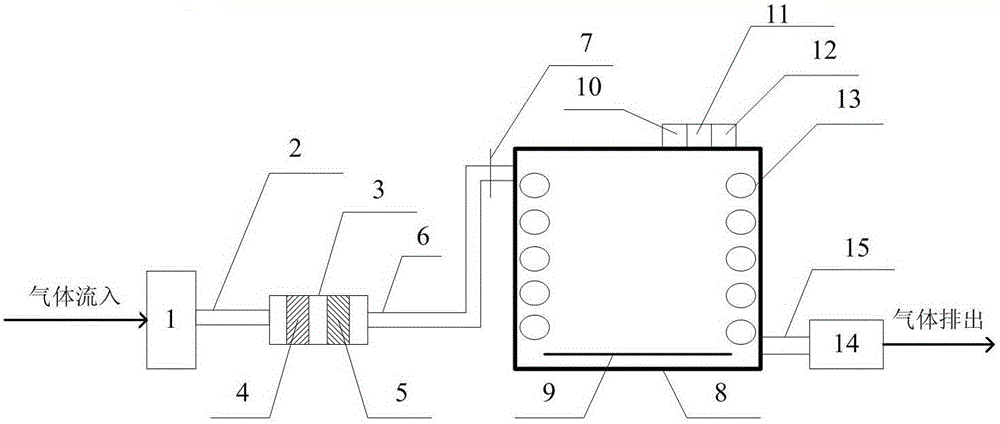

[0027] see figure 1 . The baking device for removing trace organic pollutants on the surface of optical mechanical components of the present invention includes an infrared baking system, a trace air circulation system and a control system;

[0028] The infrared baking system includes an infrared baking lamp 13, a vacuum box 8 and a worktable 9; the infrared baking lamp 13 is arranged around the inner wall of the vacuum box 8, and the workbench 9 is installed on the vacuum box 7 the bottom of the cavity;

[0029] The micro-air circulation system includes a fan 1, an air pipeline 2, a sealed casing 3, an air filter 4, an AMC filter 5, a gas pipeline I6, a gas valve 7, a gas pipeline II15 and a vacuum unit 14; The filter 4 and the AMC filter 5 are sequentially connected and packaged in the sealed casing 3; the fan 1, the air pipeline 2, the sealed casing 3, the gas pipeline I6, the vacuum box 8, the gas pipeline II15, and the vacuum unit 14 Sequential connection; the gas valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com