A jig for making led silicone lens

A silicone lens and fixture technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of easy damage to accessories, long time consumption, inconvenient clamping and disassembly, etc., to achieve the effect of not easy to damage, short time consumption, and lower production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further elaborate on the technical solution of the present invention, a detailed description is given below in conjunction with the accompanying drawings.

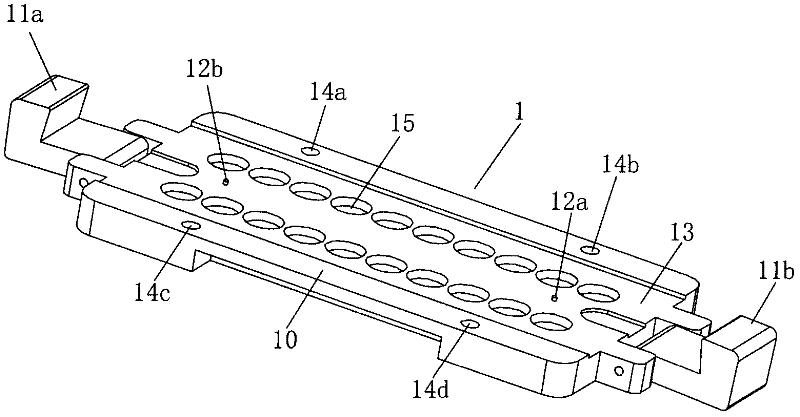

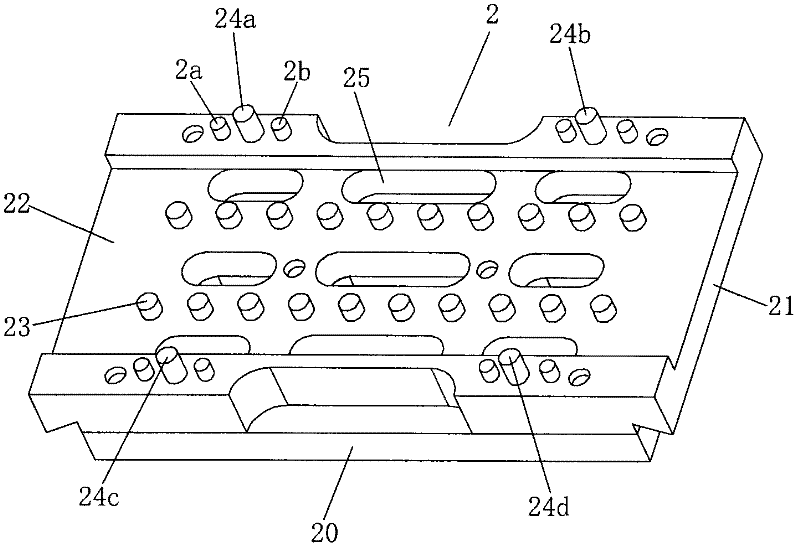

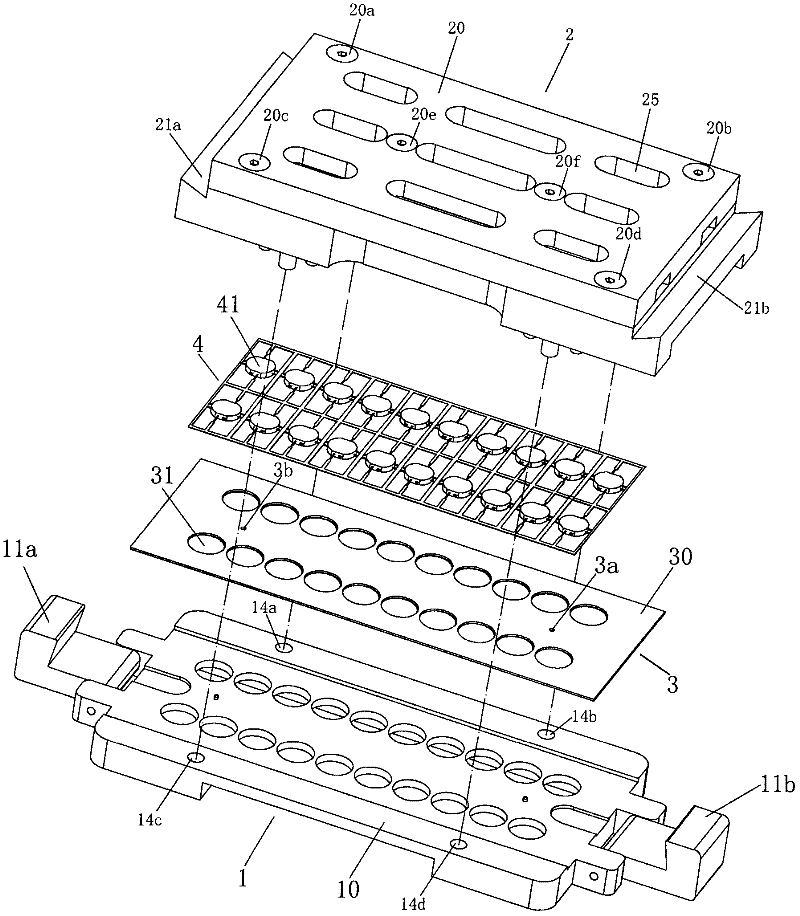

[0027] The invention discloses a fixture for making LED silica gel lenses, see figure 1 , figure 2 , image 3 As shown, it includes an upper platen 2 and a lower platen 1, the upper platen 2 and the lower platen 1 are two-piece split structures independent of each other, and the mold strips are placed sequentially between the upper platen 2 and the lower platen 1 from bottom to top 3 and a bracket bar 4; the mold bar 3 includes a carrier plate 30 and a plurality of lens mold cavities 31 evenly spaced on the carrier plate 30, and the lens mold cavity body 31 is a hemispherical cavity; the lower pressing plate 1 is provided with a first mounting groove 13 matching the carrier plate 30, and the first mounting groove 13 is provided with mold holes 15 matching the plurality of lens mold cavities 31, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com