Method for manufacturing high-quality SCr420 HB automobile gear steel

A manufacturing method and scr420hb technology, applied in the field of metal material manufacturing, can solve the problems of steel surface quality, composition segregation, affecting surface quality, etc., and achieve the effect of reducing the fluctuation of quenching hardness and reducing composition segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

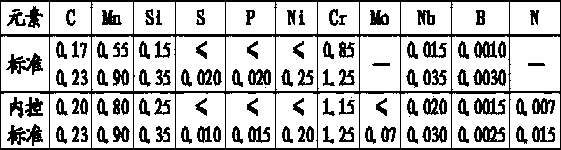

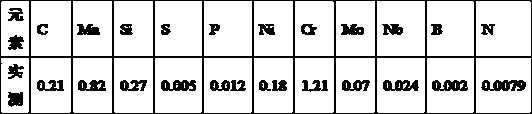

Embodiment 1

[0061] Steel specification: φ30mm, processing ratio 81.5;

[0062] The technological process adopted is: 60-ton ultra-high power electric furnace → LF → VD → continuous casting → continuous furnace heating → continuous rolling mill rolling → finishing → straightening and chamfering → surface eddy current flaw detection → packaging;

[0063] (1) The charging capacity of the electric furnace is 68 tons, and the furnace materials are scrap steel and pig iron, of which the amount of scrap steel is 38 tons, and the amount of pig iron is 30 tons; the tapping temperature is 1665°C, the P content is 0.013%, the end carbon is 0.10%, and 3 minutes before tapping Reduce the intensity of oxygen consumption, and the amount of carbon injection is 350kg; add 60kg of aluminum for final deoxidation, 100 kg of calcium carbide; 900kg of lime, 100kg of pre-melted slag, and no oxidation slag;

[0064] ⑵The LF furnace is in place to feed the aluminum wire 300m, the whole process uses SiC powder + A...

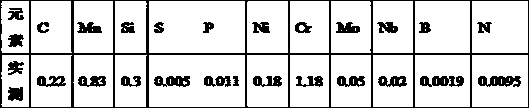

Embodiment 2

[0082] Steel specification: φ45mm, processing ratio 36.2;

[0083] The technological process adopted is: 60-ton ultra-high power electric furnace → LF → VD → continuous casting → continuous furnace heating → continuous rolling mill rolling → finishing → straightening and chamfering → surface eddy current flaw detection → packaging;

[0084] (1) The charging capacity of the electric furnace is 65 tons, and the furnace materials are scrap steel and pig iron, of which the amount of scrap steel is 35 tons, and the amount of pig iron is 30 tons; the tapping temperature is 1670 ° C, the P content is 0.010%, the end point carbon is 0.12%, and 3 minutes before tapping Reduce the intensity of oxygen consumption, and the amount of carbon injection is 400kg; add 60kg of aluminum for final deoxidation, 100 kg of calcium carbide; 1000kg of lime, 100kg of pre-melted slag, and no oxidation slag;

[0085] ⑵The LF furnace feeds 300m of aluminum wire in place, and adopts SiC powder + Al particl...

Embodiment 3

[0099] Steel specification: φ60mm, processing ratio 20.3;

[0100] The technological process adopted is: 60-ton ultra-high power electric furnace → LF → VD → continuous casting → continuous furnace heating → continuous rolling mill rolling → finishing → straightening and chamfering → surface eddy current flaw detection → packaging;

[0101] (1) The charging capacity of the electric furnace is 65 tons, and the furnace materials are scrap steel and pig iron, of which the amount of scrap steel is 25 tons, and the amount of pig iron is 40 tons; the tapping temperature is 1668°C, the P content is 0.010%, the end carbon is 0.10%, and 3 minutes before tapping Reduce the intensity of oxygen consumption, and the amount of carbon injection is 400kg; add 60kg of aluminum for final deoxidation, 100 kg of calcium carbide; 1185kg of lime, 100kg of pre-melted slag, and no oxidation slag;

[0102] ⑵The LF furnace feeds 300m of aluminum wire in place, and uses SiC powder + Al particle diffusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com