Automatic electromagnetic nondestructive testing method and device for in-use steel rail

A non-destructive testing and rail technology, which is used in measuring devices, material analysis by electromagnetic means, material magnetic variables, etc., can solve the problems of suspended operation of facilities and equipment, difficulty in manual testing, and low testing efficiency, and achieves elimination of vibration and improvement. The effect of avoiding interference effects, convenient and quick installation and maintenance, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

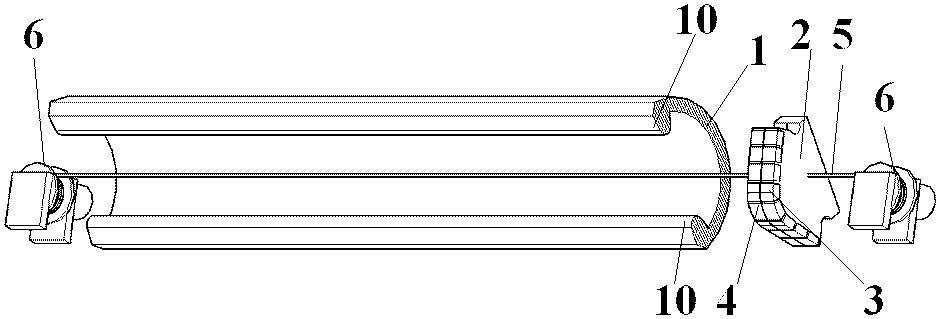

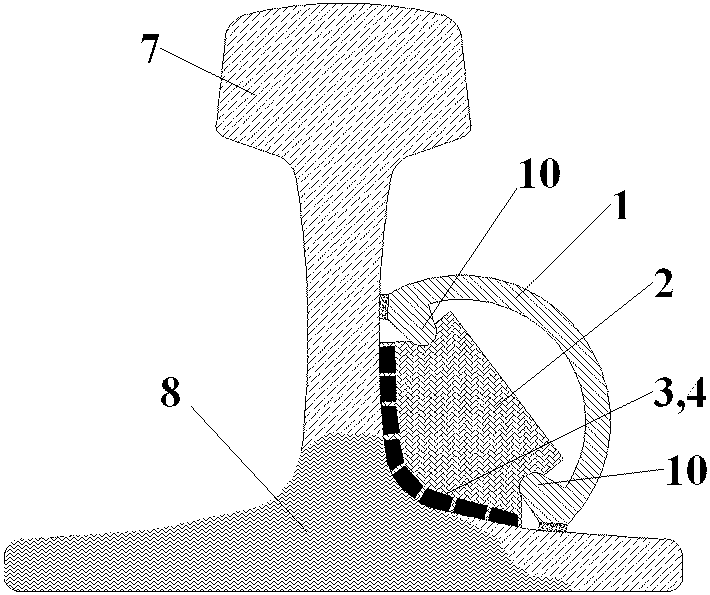

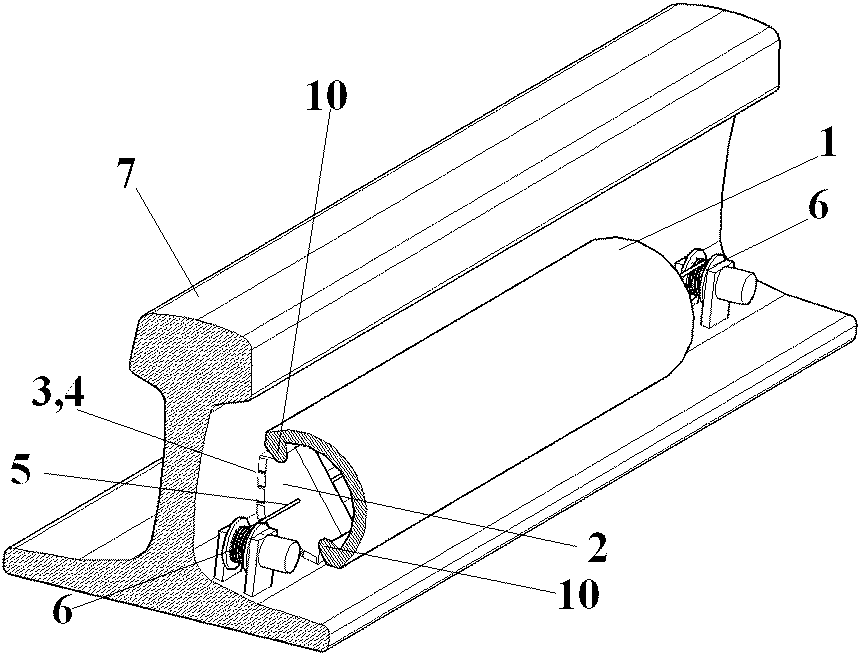

[0017] figure 1 In the shown embodiment, an automatic electromagnetic non-destructive testing device for rails in use includes a semicircular tubular rail frame 1, a slider 2, an array eddy current probe 3, an array metal magnetic memory probe 4, and an electronically controlled take-up and release wire frame 6 , steel wire rope 5, it is characterized in that: described slide block 2 is stuck on the slide rail 10 on the semi-circular tubular track frame 1; Described array eddy current probe 3 and array metal magnetic memory probe 4 are fixed side by side on the scan of slide block 2 On the surface; there are two electric control take-up and release racks 6, which are fixed on both sides of the semicircular track frame 1 in the axial direction; there are two steel wire ropes 5, which connect the slider 2 and the electric control take-up and take-off racks on both sides 6. The material of the semicircular tubular track frame 1 is aluminum alloy or wear-resistant engineering pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com