Method for preventing vibration of steel bar under high-speed rolling station of ultra-thin plate

A strip, high-speed technology, used in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of ultra-thin plate chatter, affecting the normal rolling of ultra-thin plates, tension fluctuations, etc., achieving significant rolling and reducing ultra-thin plates. Vibration and thin strip thickness difference control has remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

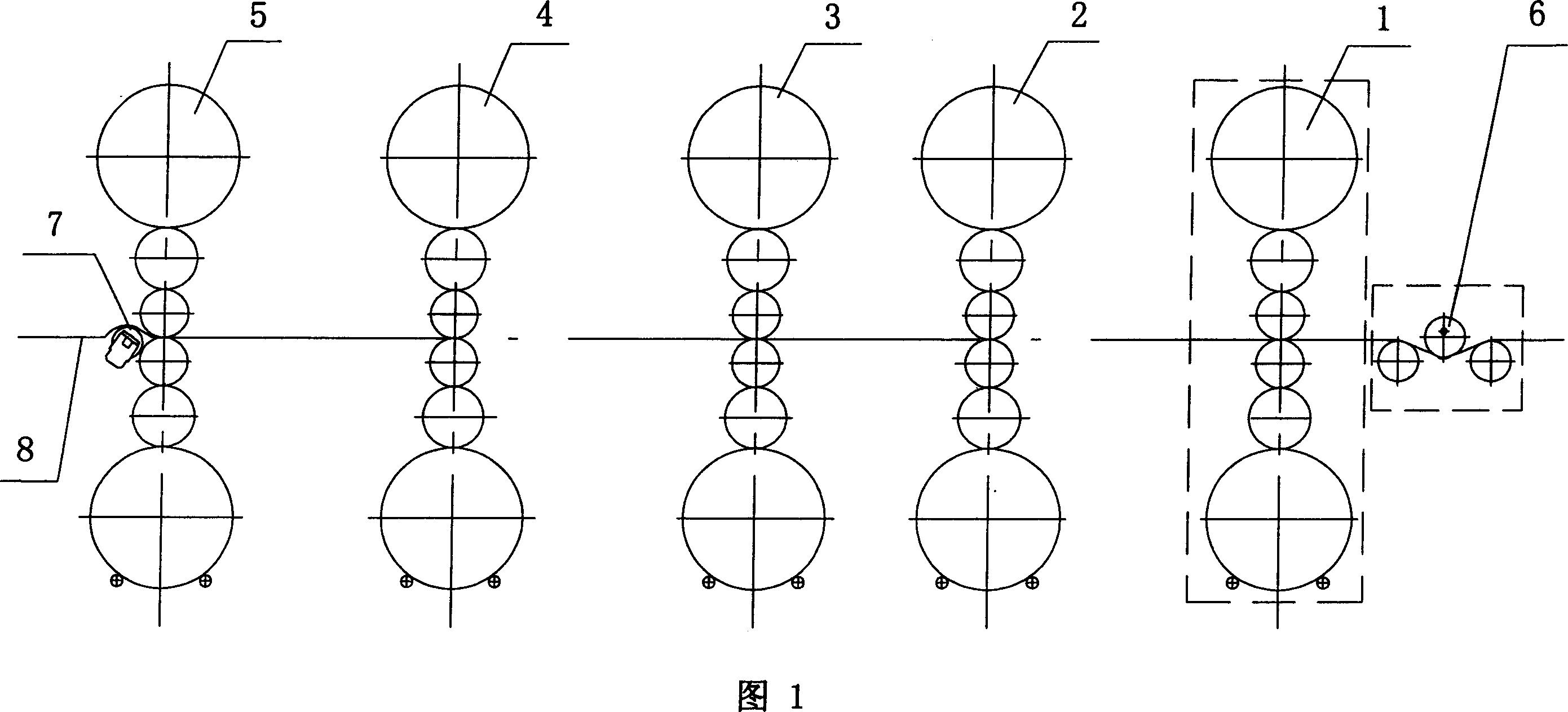

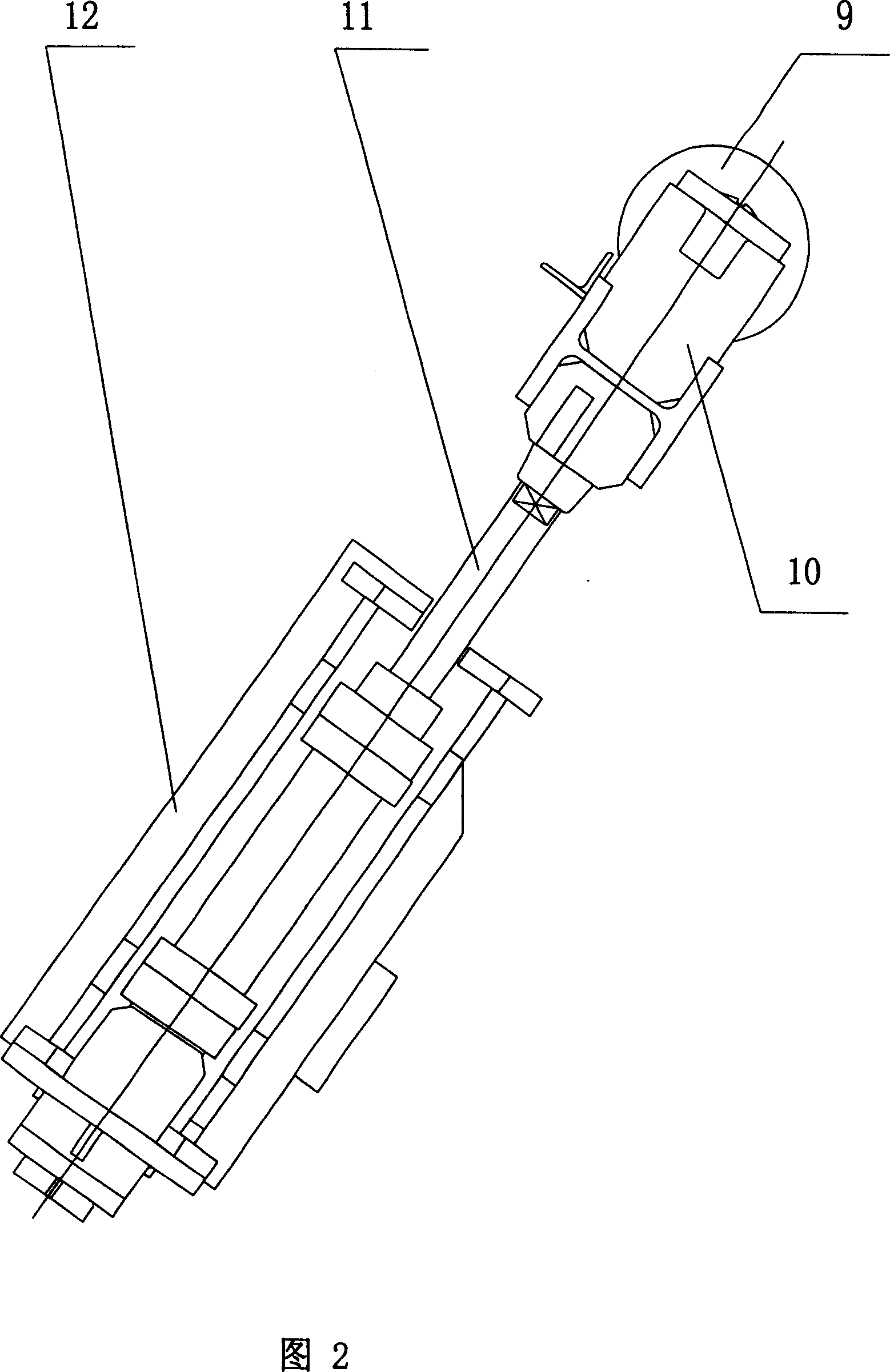

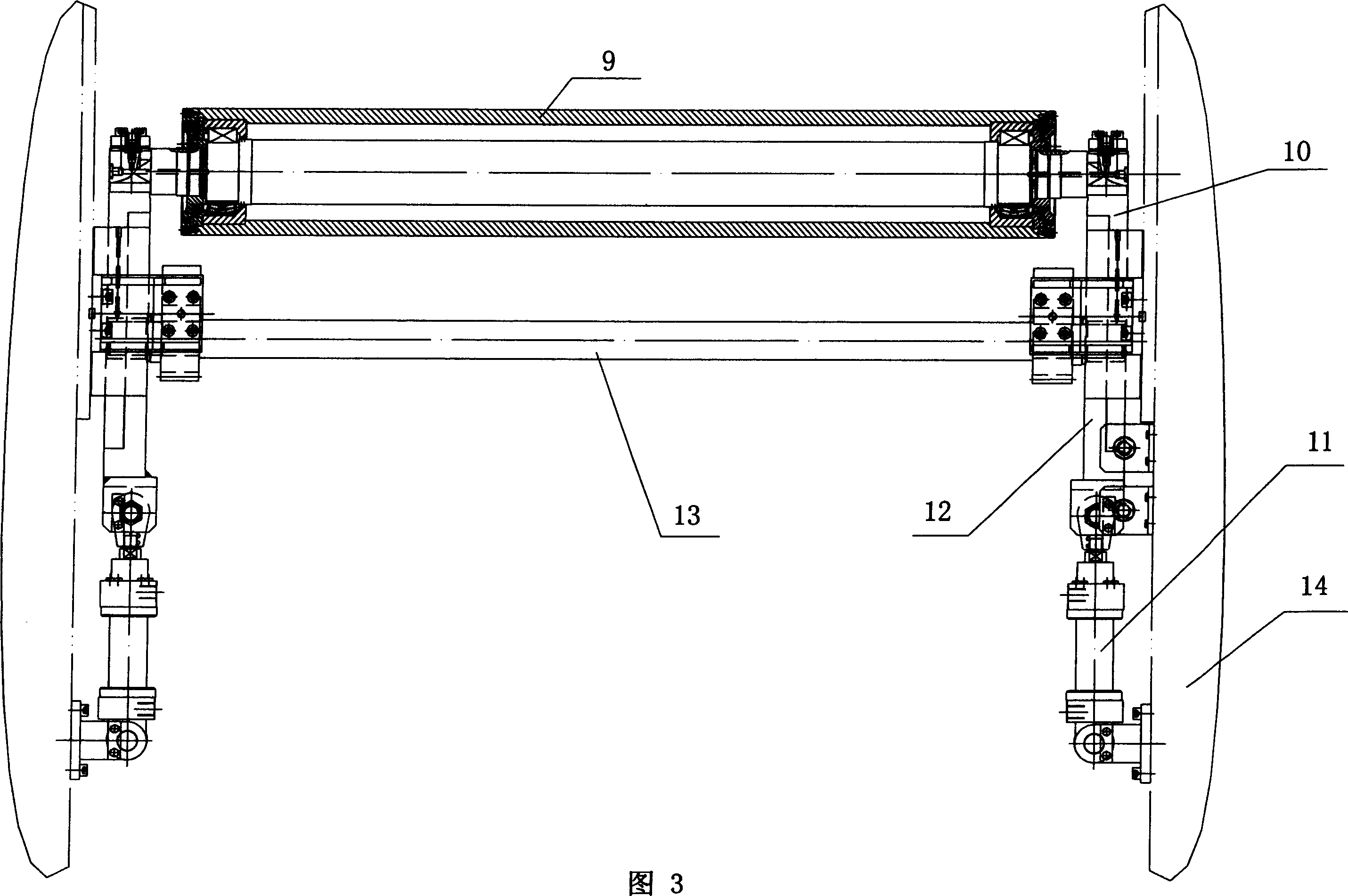

[0015] As shown in Figure 1, a kind of method that prevents the steel strip from vibrating under the high-speed rolling condition of extremely thin plate, in the first stand (being the first stand 1 of tandem cold rolling mill; the tandem cold rolling mill of the present embodiment includes 5 racks, i.e. the first rack 1, the second rack 2, the third rack 3, the fourth rack 4, the fifth rack 5) add a three-roller stabilizing device 6 at the entrance, and a three-roller stabilizing device 6 Comprising left lower roll 20, right lower roll 18 and an upper intermediate roll 19, upper intermediate roll is positioned at the center of left lower roll, right lower roll, and the upper intermediate roll of three-roll stabilizer is positioned at rolling line 21 (i.e. first rolling mill 1 and the strip center line between the fifth rolling mill 5), the lower left roll 20 and the lower right roll 18 of the three-roller stabilizing device 6 are positioned under the rolling line 21, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com