Patents

Literature

64results about How to "Accurate clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

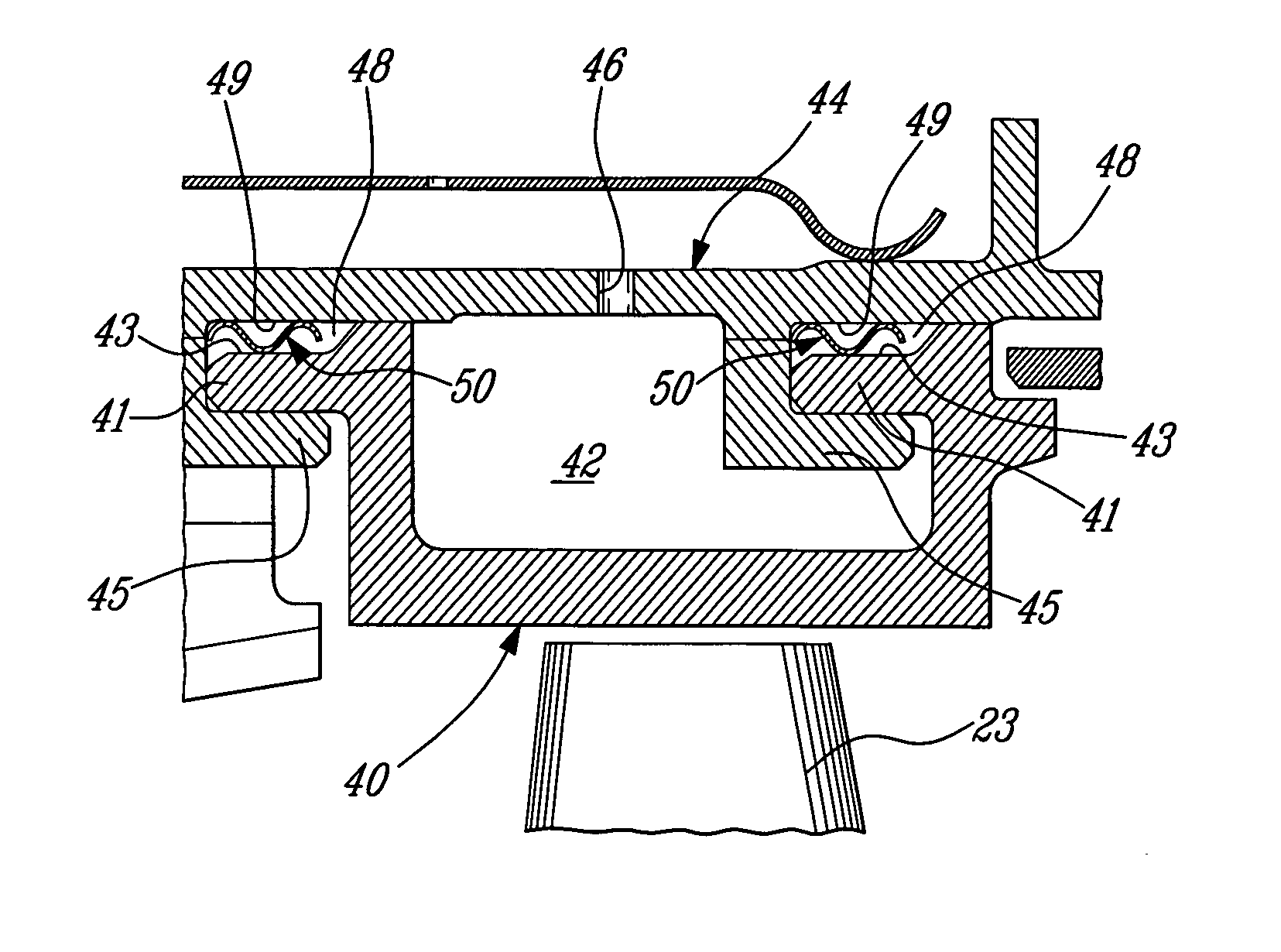

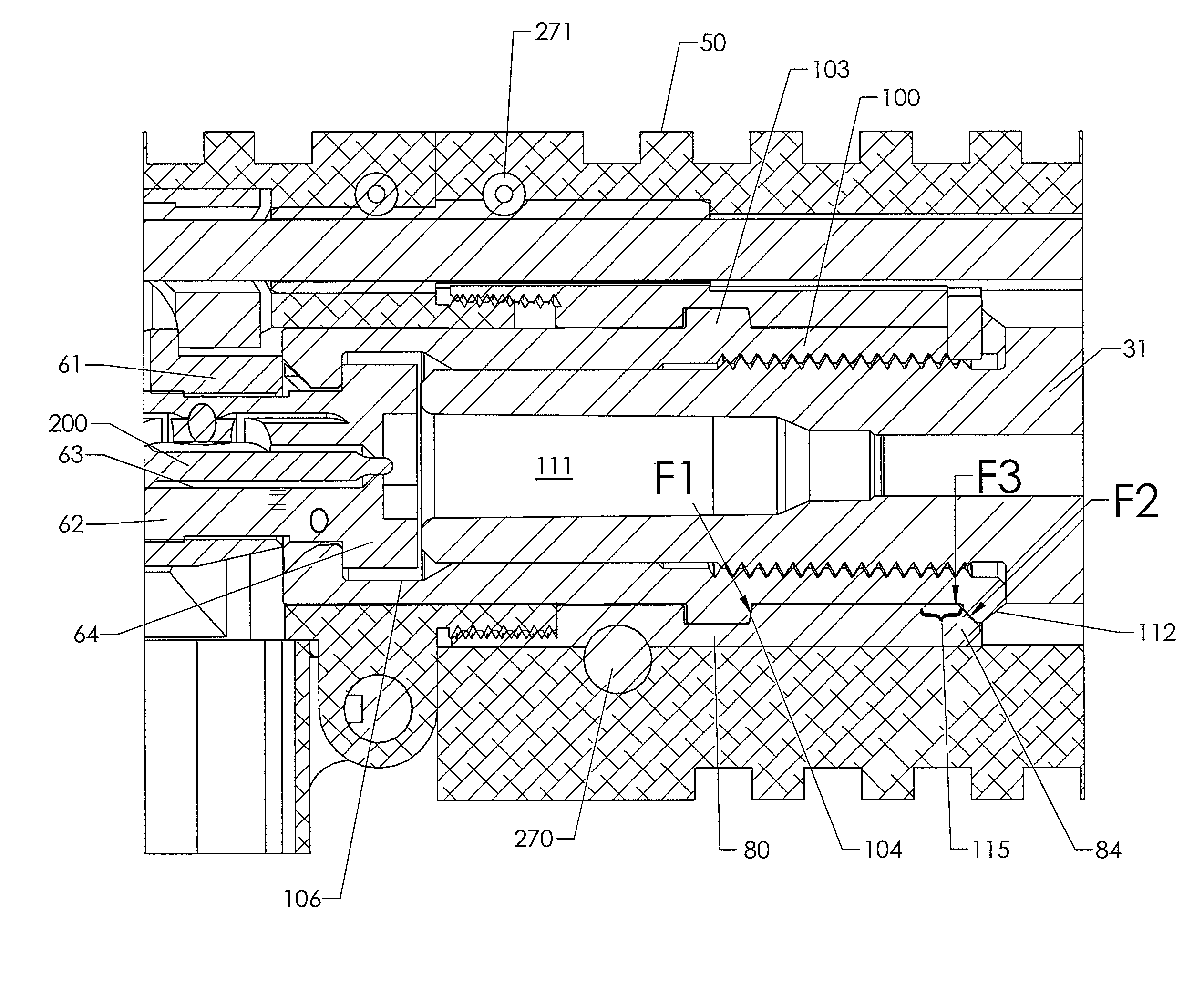

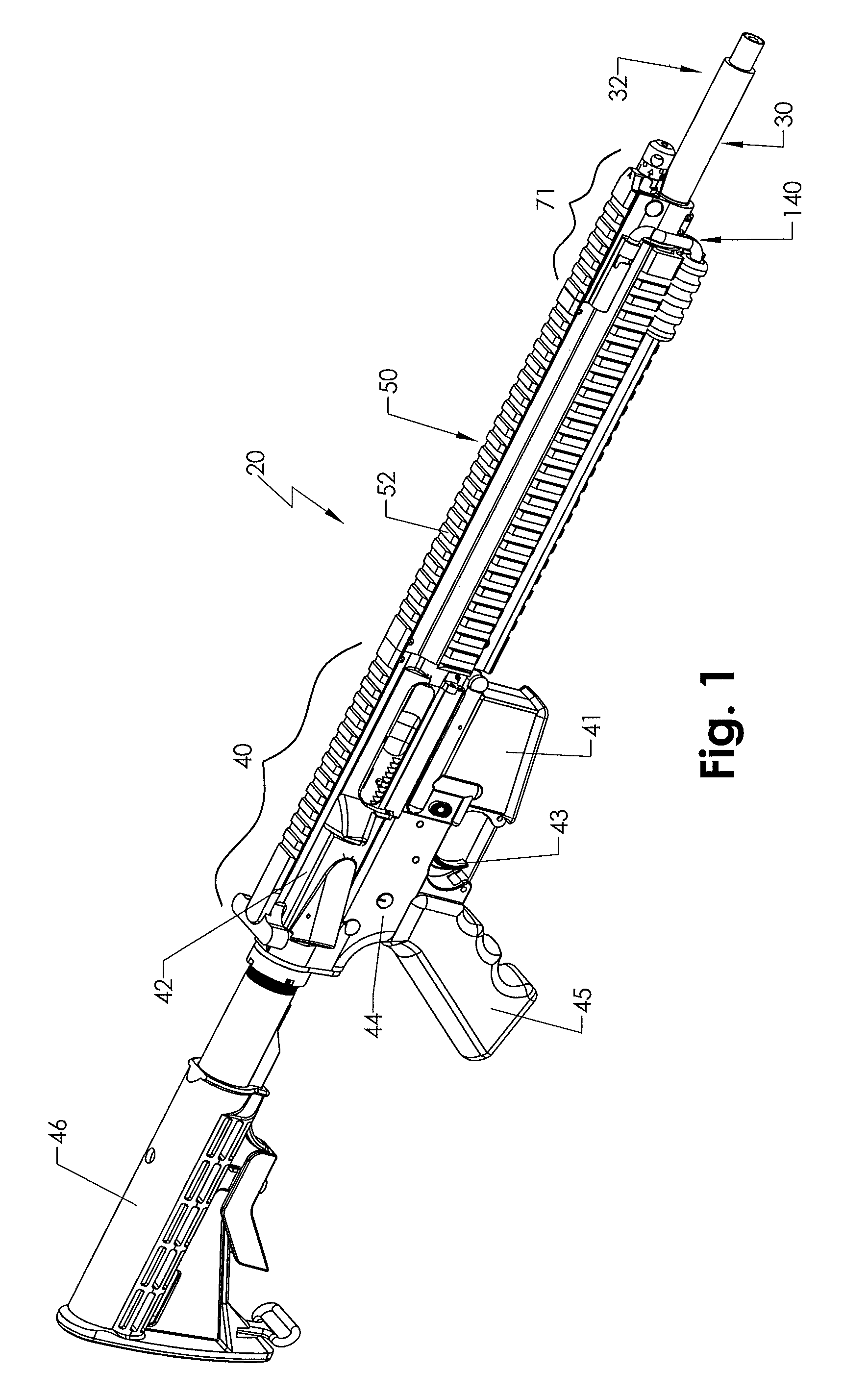

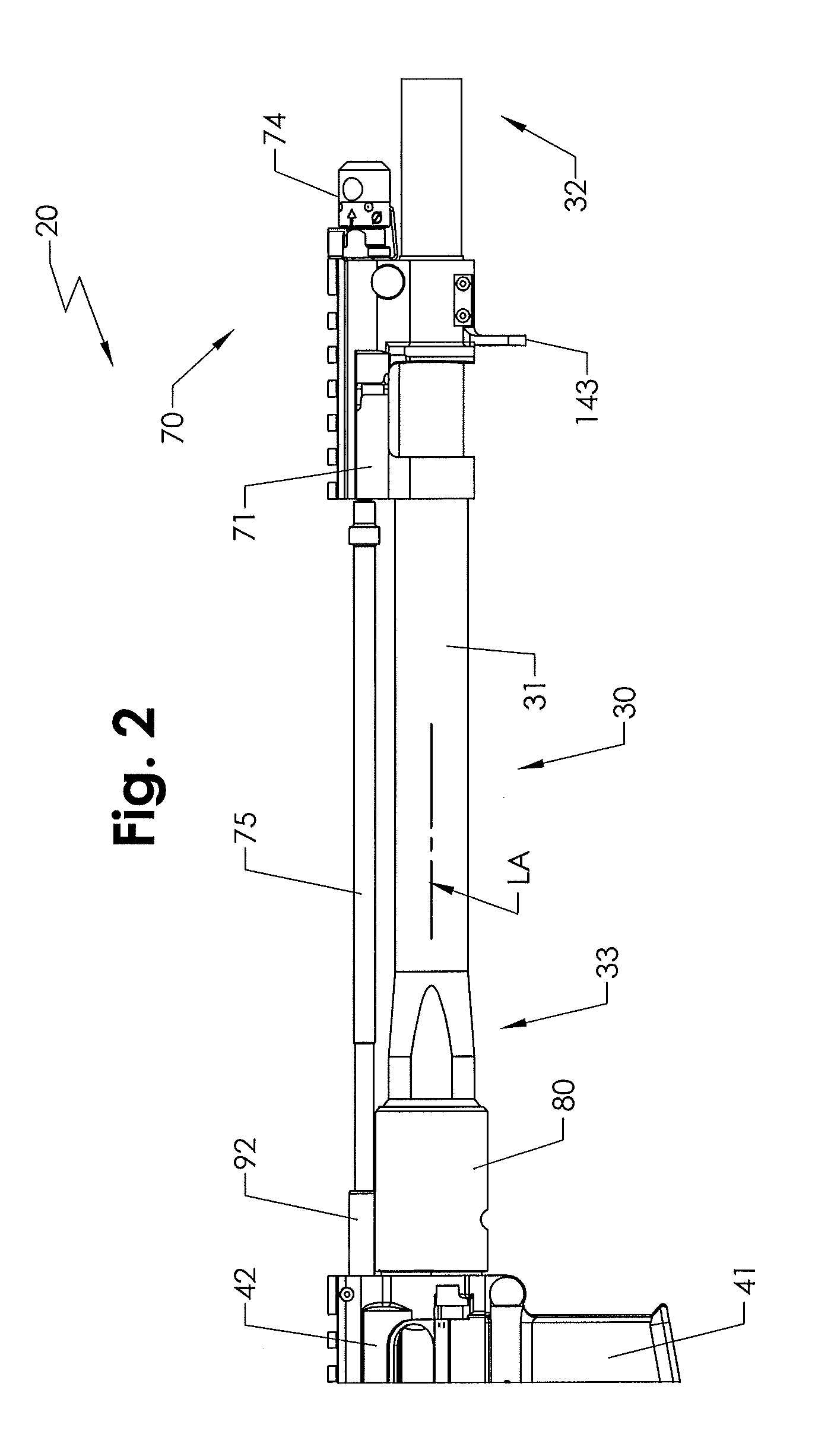

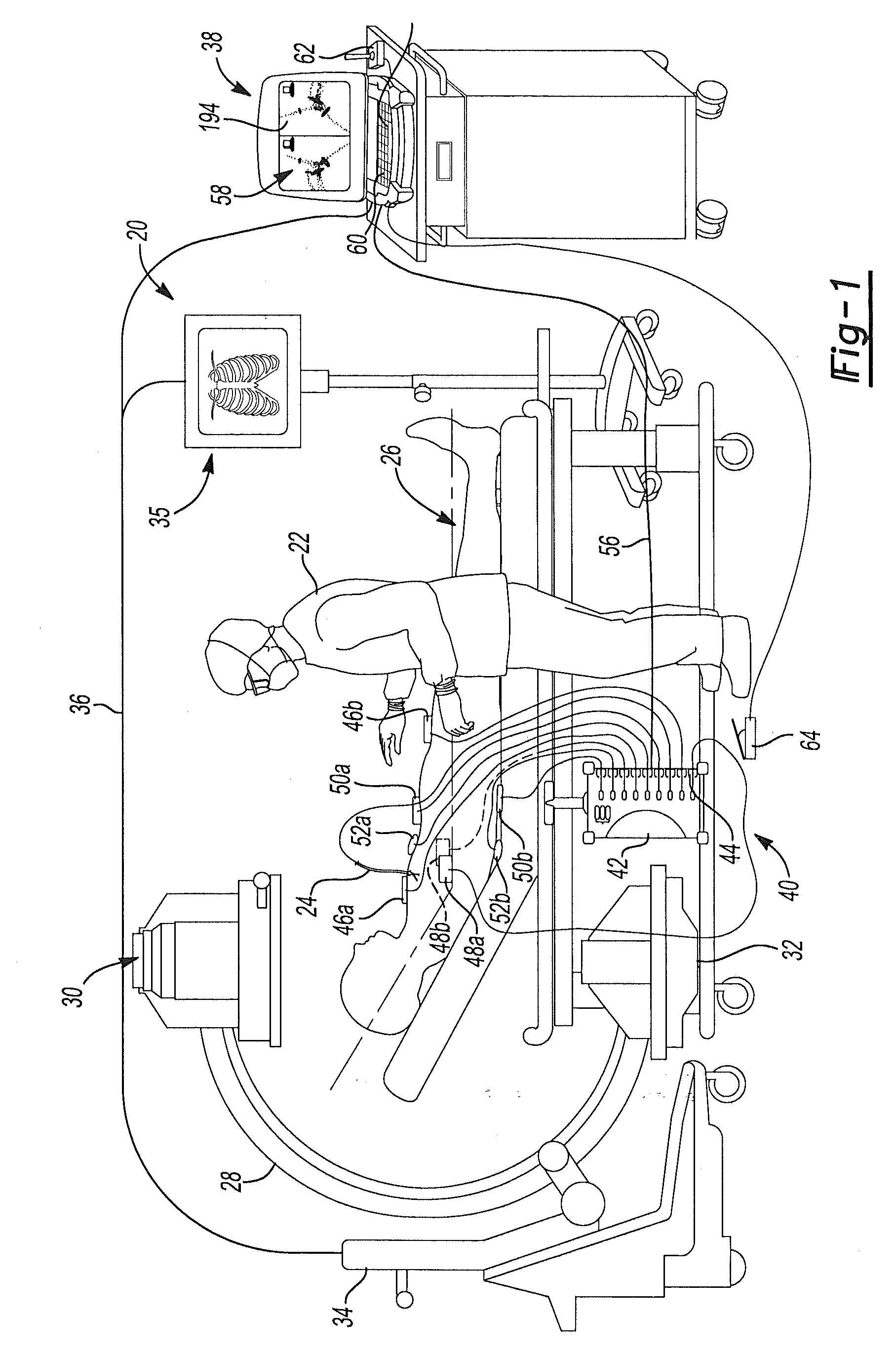

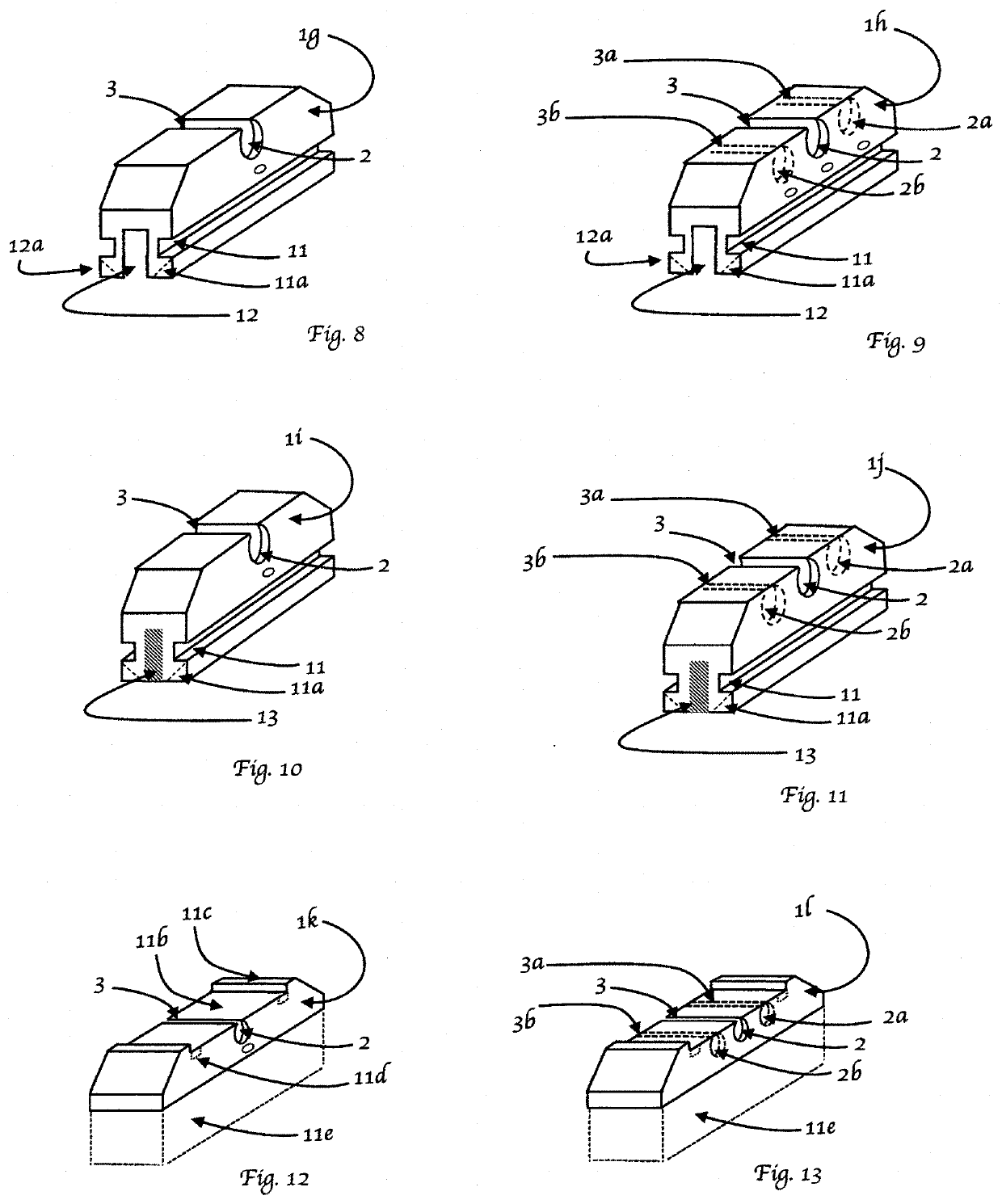

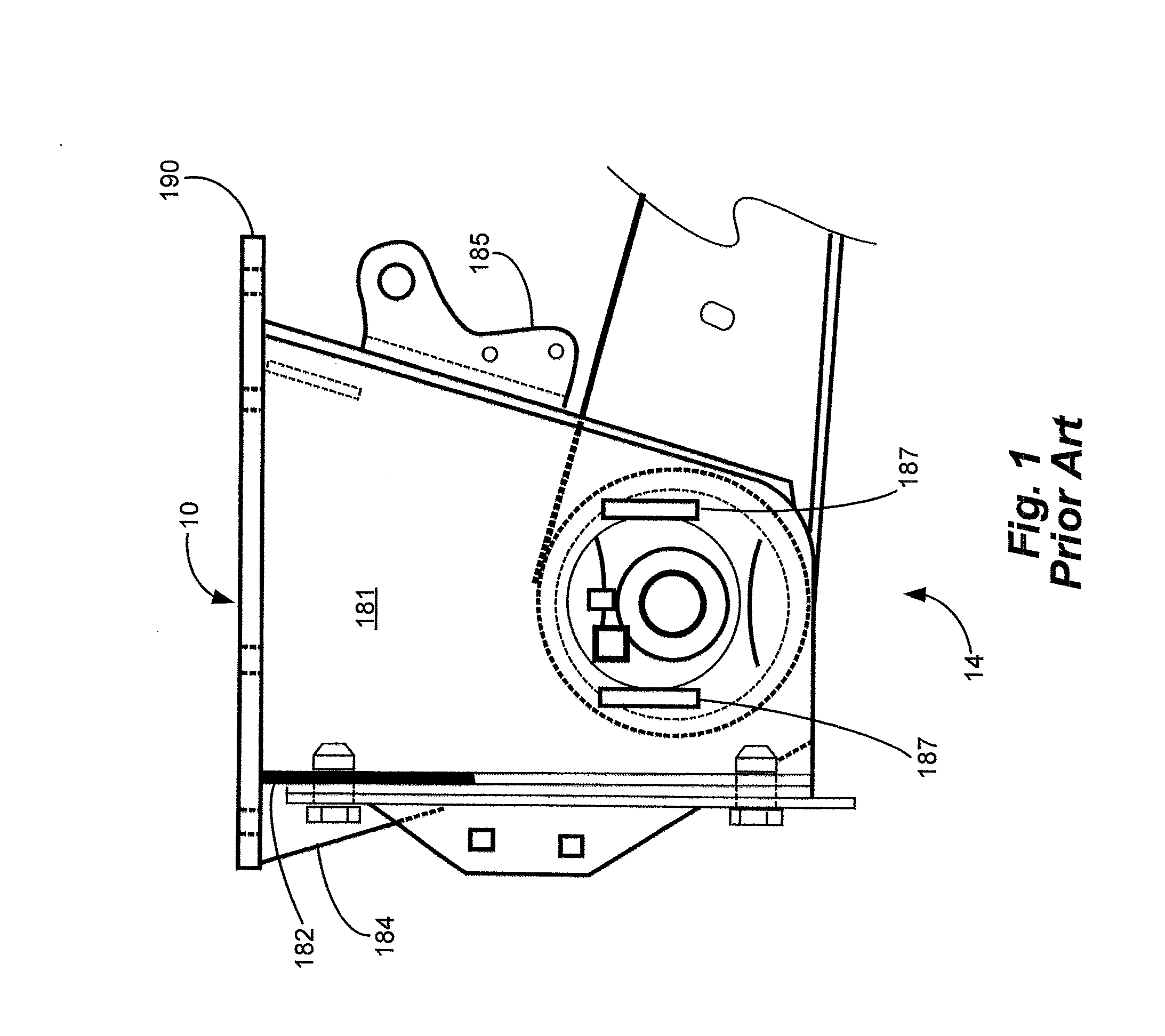

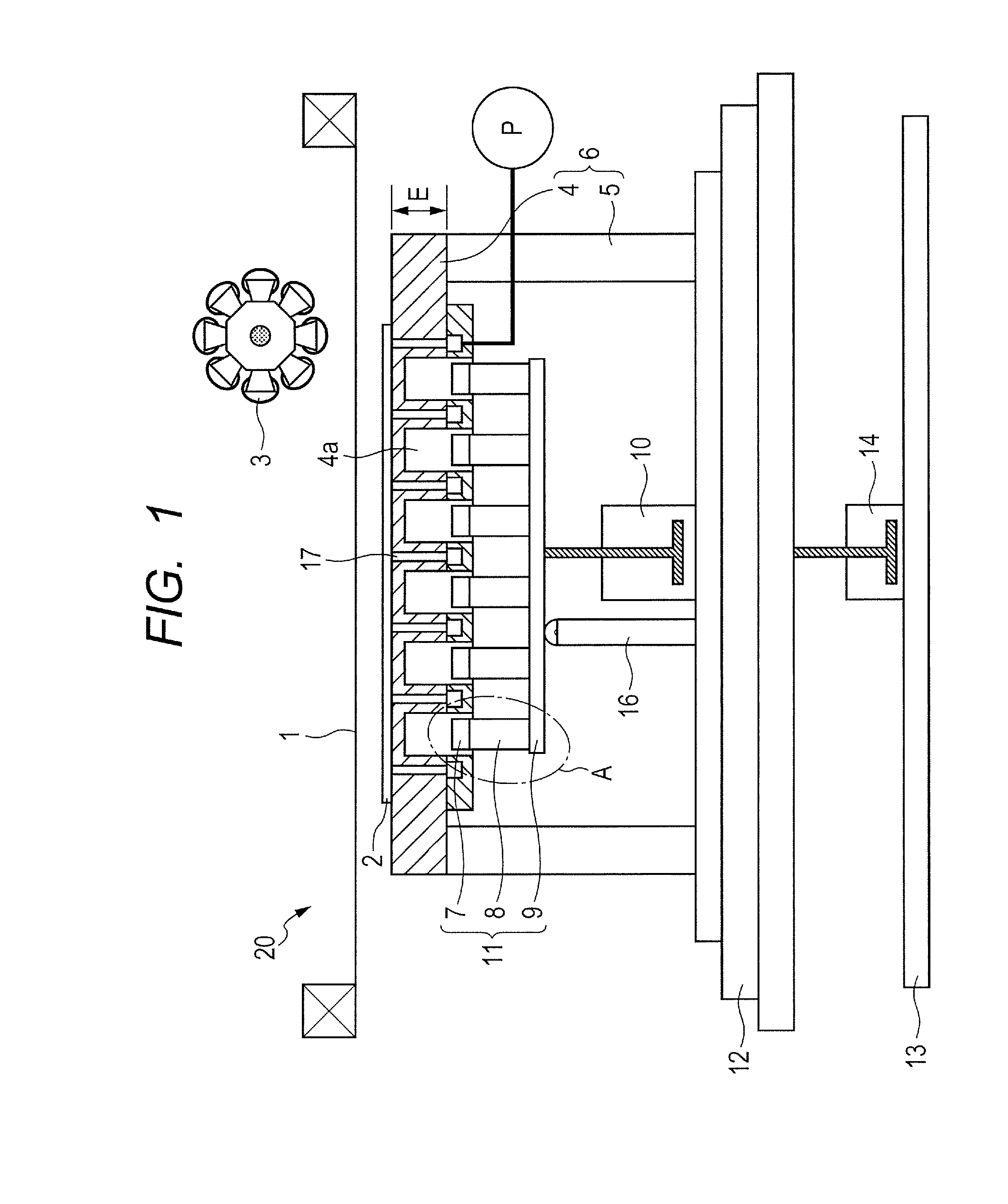

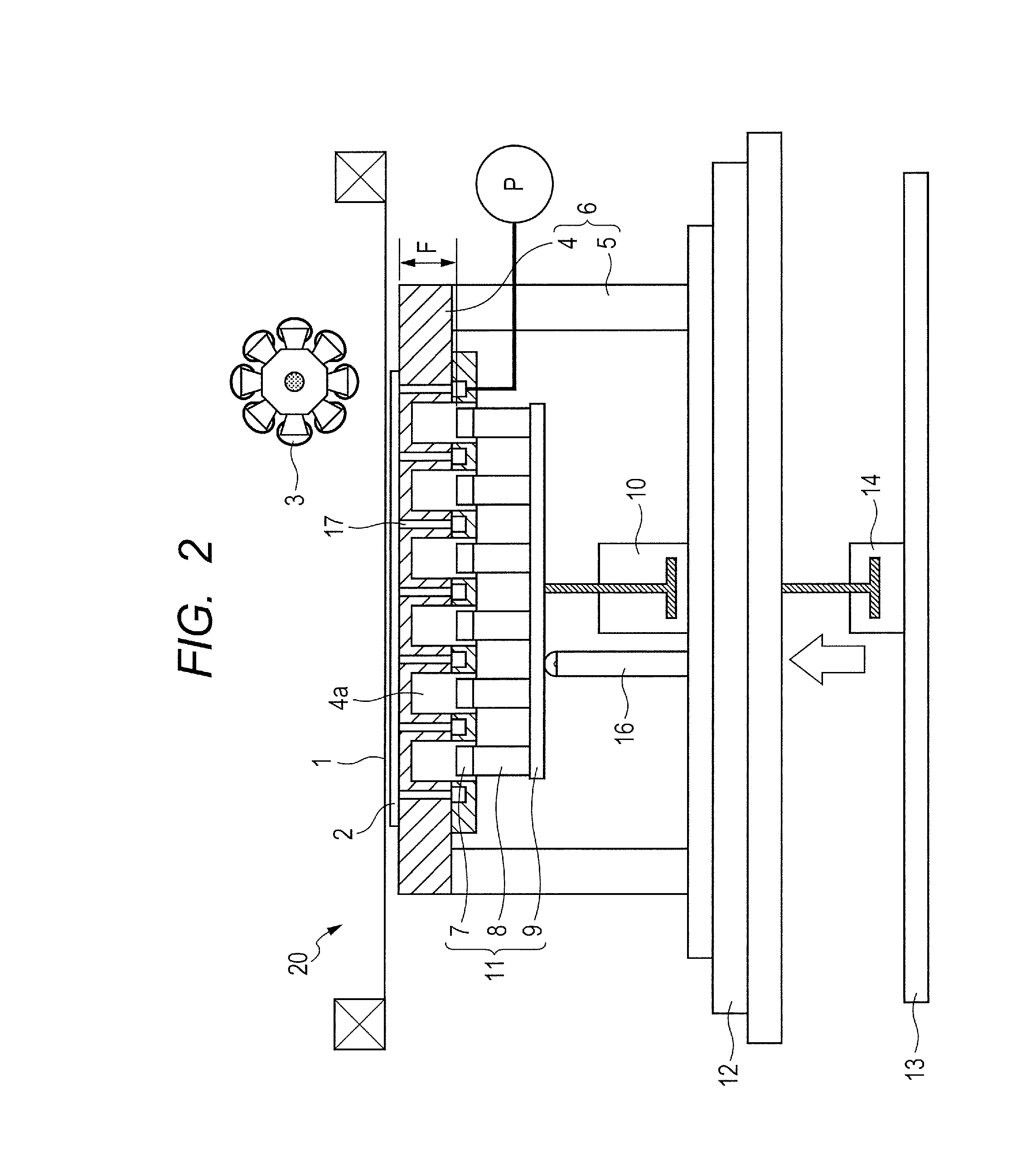

Bolt carrier for gas operated rifle

ActiveUS20100269682A1Engage with obstructionReduce and eliminate loose fitBreech mechanismsCombustionReciprocating motion

A gas operated autoloading firearm having an improved bolt carrier. The gas piston system may include a barrel defining a longitudinally-extending bullet pathway, a gas block defining a piston bore, a passageway fluidly connecting the bore with the bullet pathway for diverting combustion gas to the bore upon discharging the firearm, and a piston slidably disposed in the bore for reciprocating movement. The piston actuates a reciprocating bolt assembly including a bolt carrier slidably received in a receiver. The bolt carrier includes supporting and guiding surfaces configured to reduce receiver wear and bolt carrier drag.

Owner:STURM RUGER & CO INC

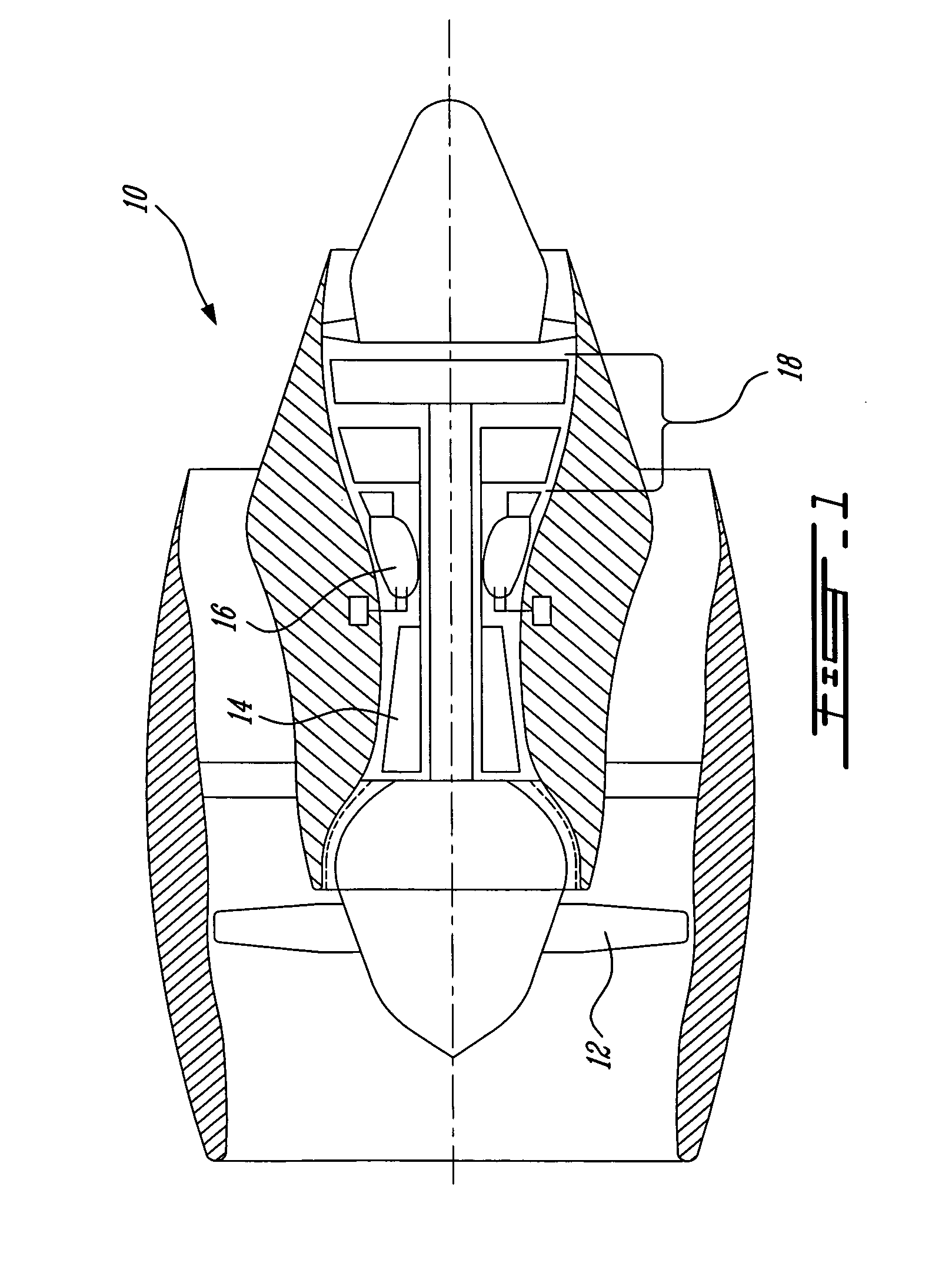

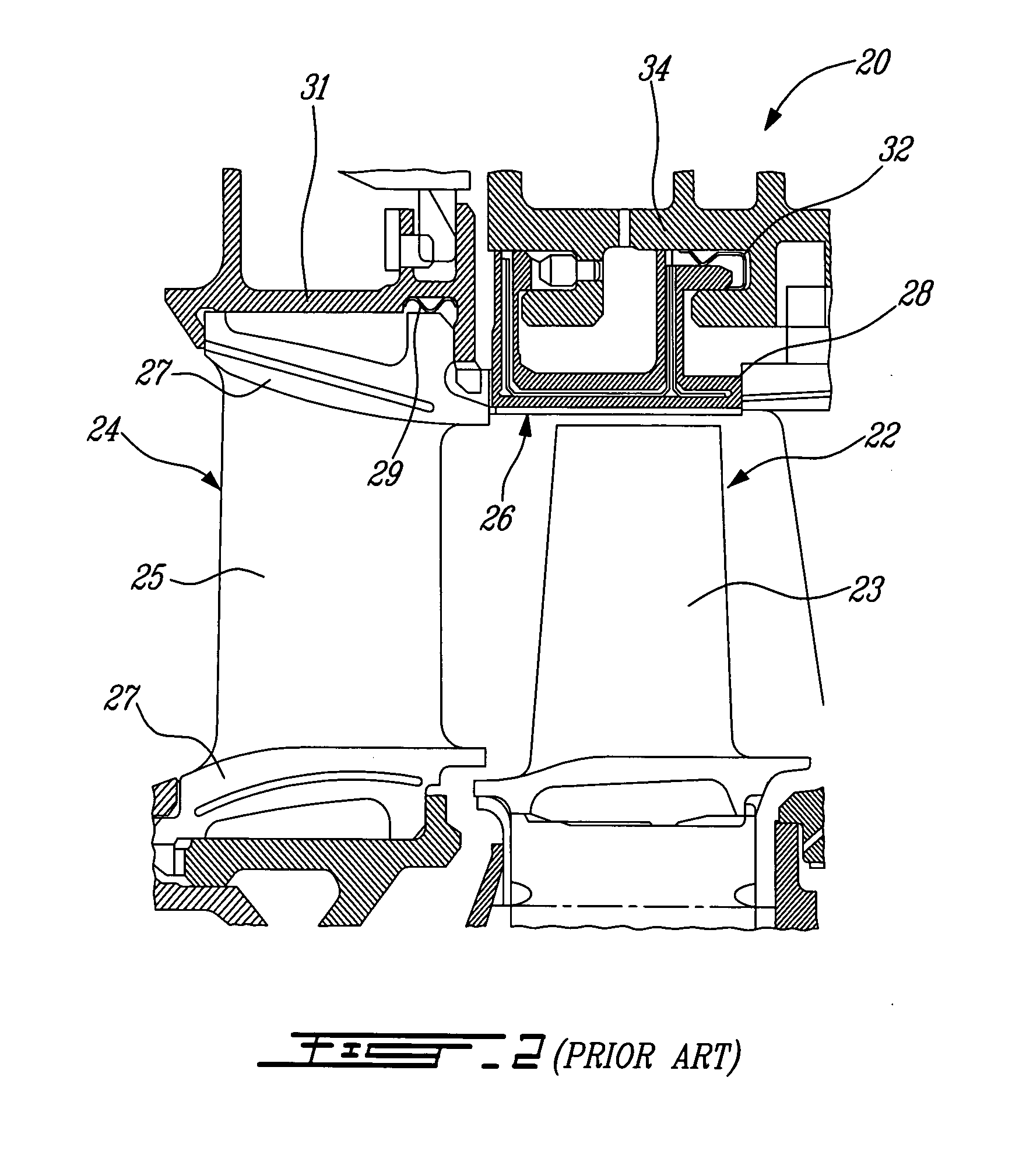

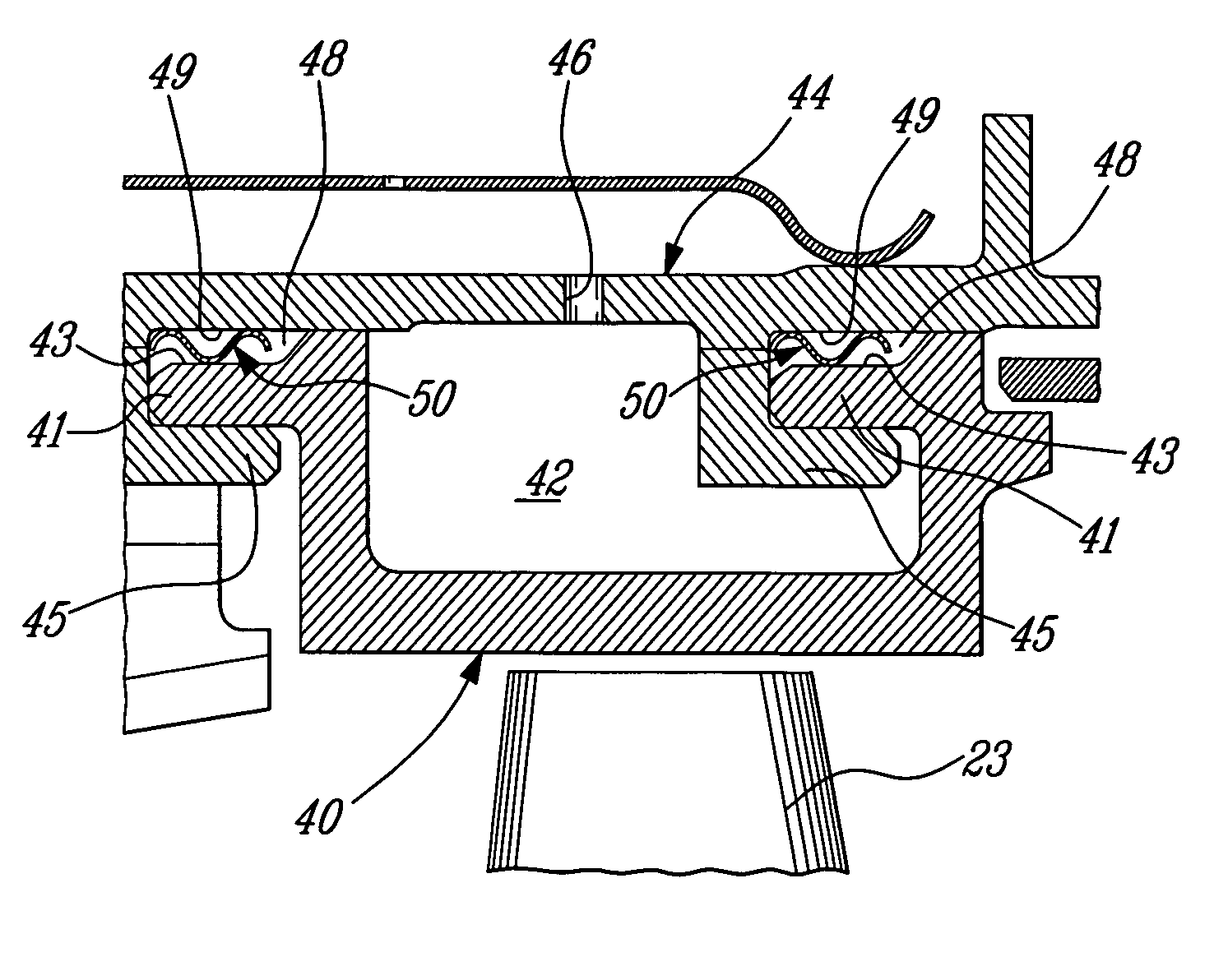

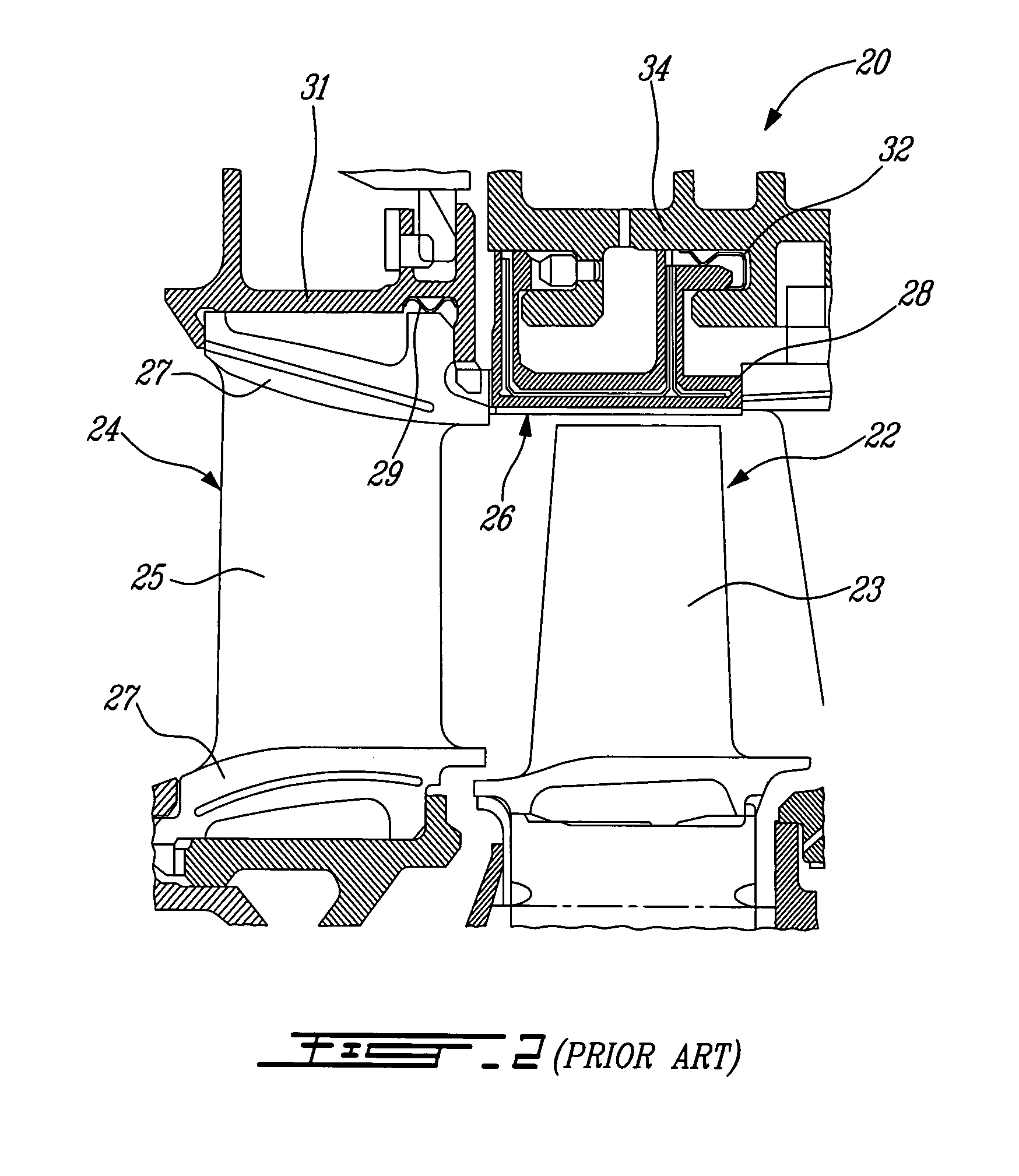

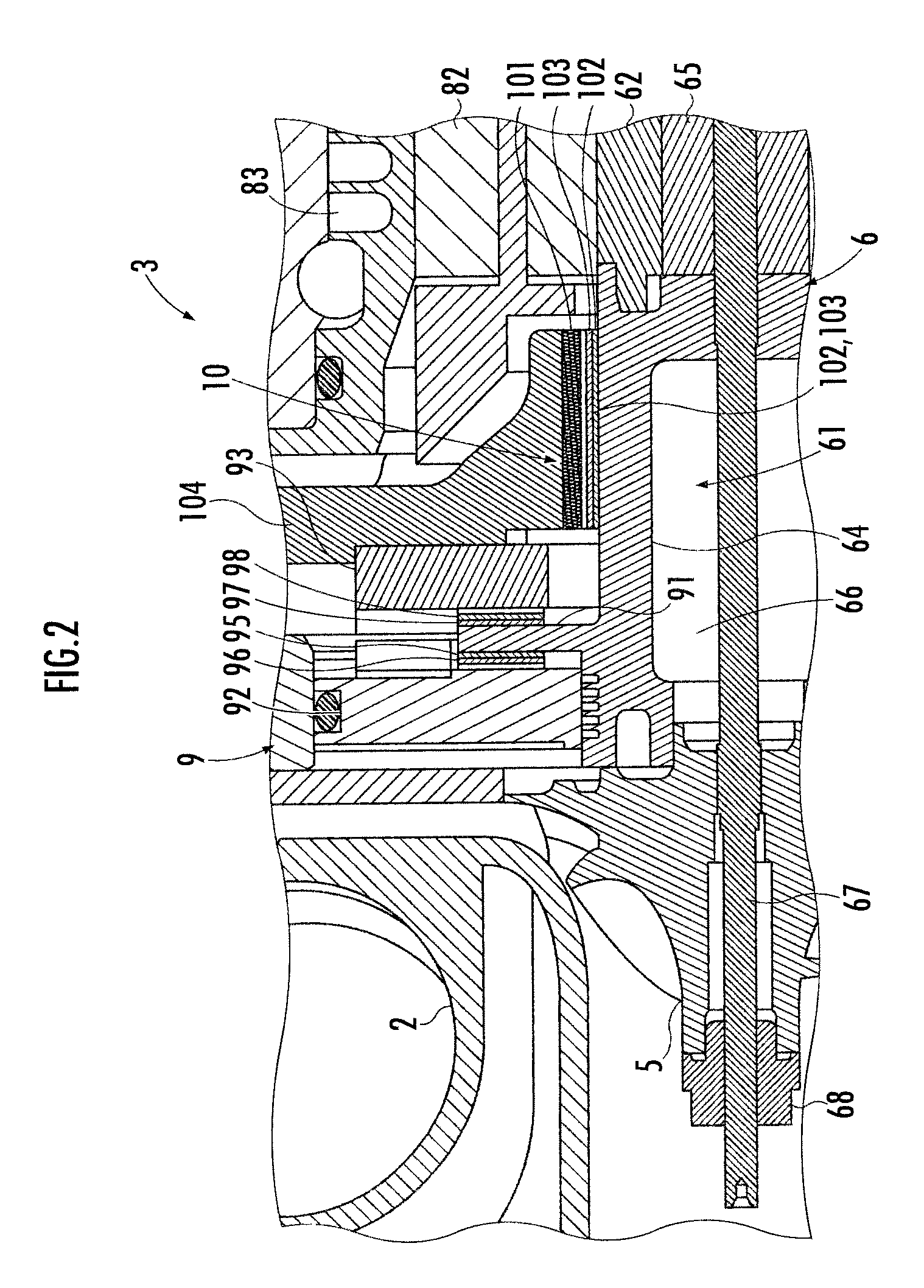

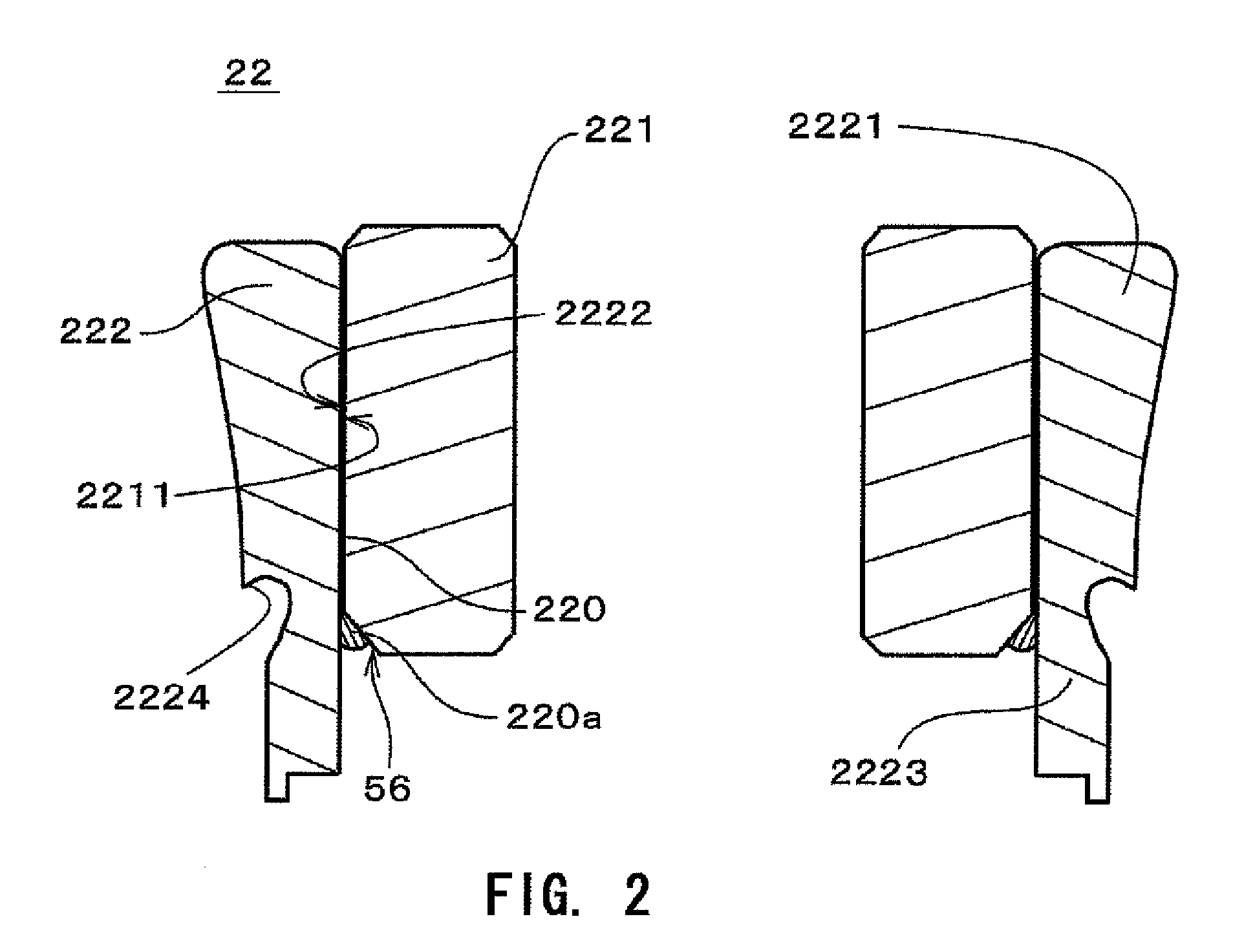

Turbine shroud segment seal

ActiveUS20060083607A1Accurate tip clearanceAccurate clearancePump componentsTurbine/propulsion engine coolingEngineeringTurbine

A ring seal for sealing an annular gap defined between opposed surfaces of concentric inner and outer annular engine parts in a gas turbine engine. The ring seal being wholly disposed within the annular gap and having a wave pattern with alternating peaks. The ring seal radially inwardly loads the inner engine part and provides a fluid seal between the inner and outer engine parts.

Owner:PRATT & WHITNEY CANADA CORP

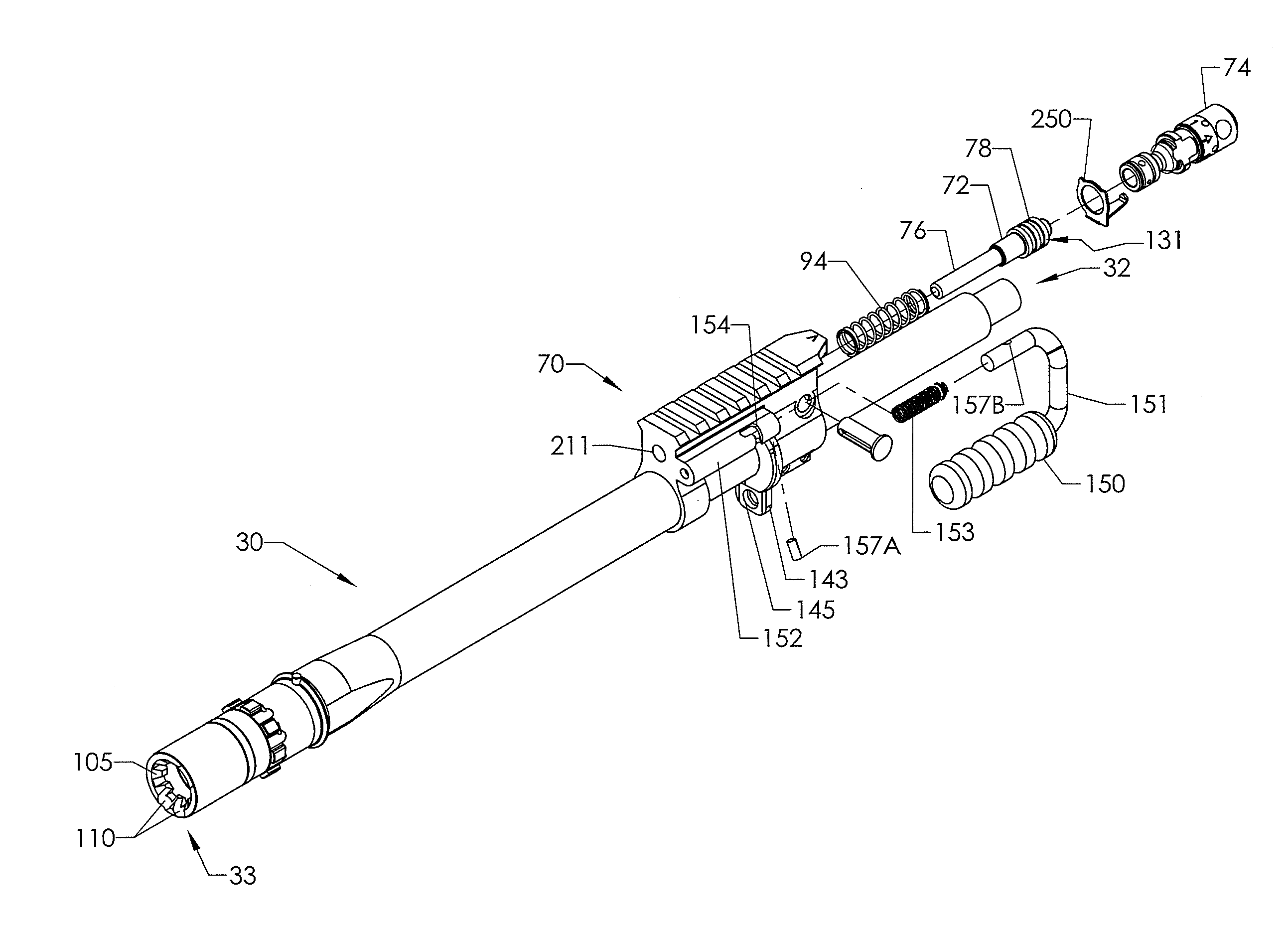

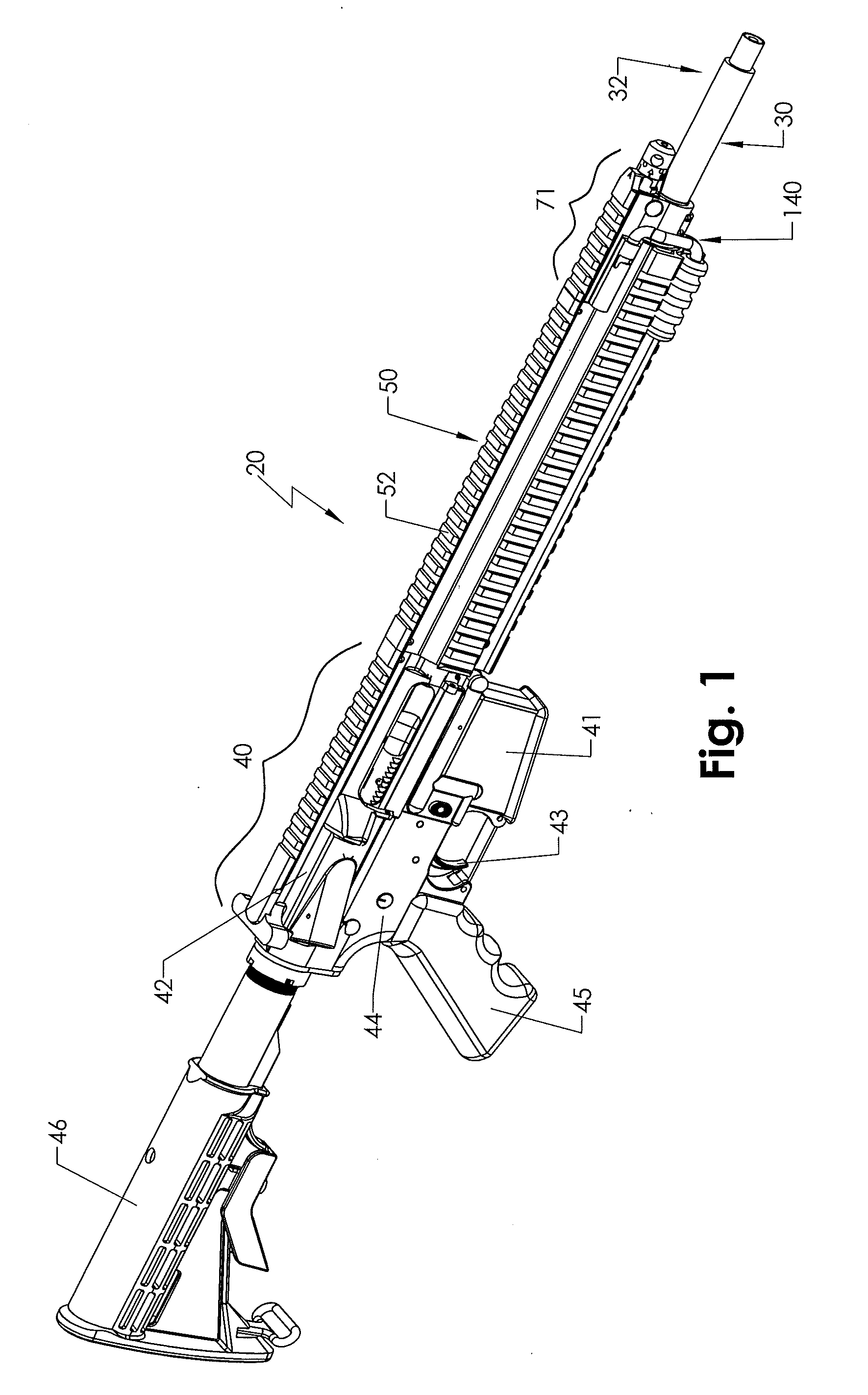

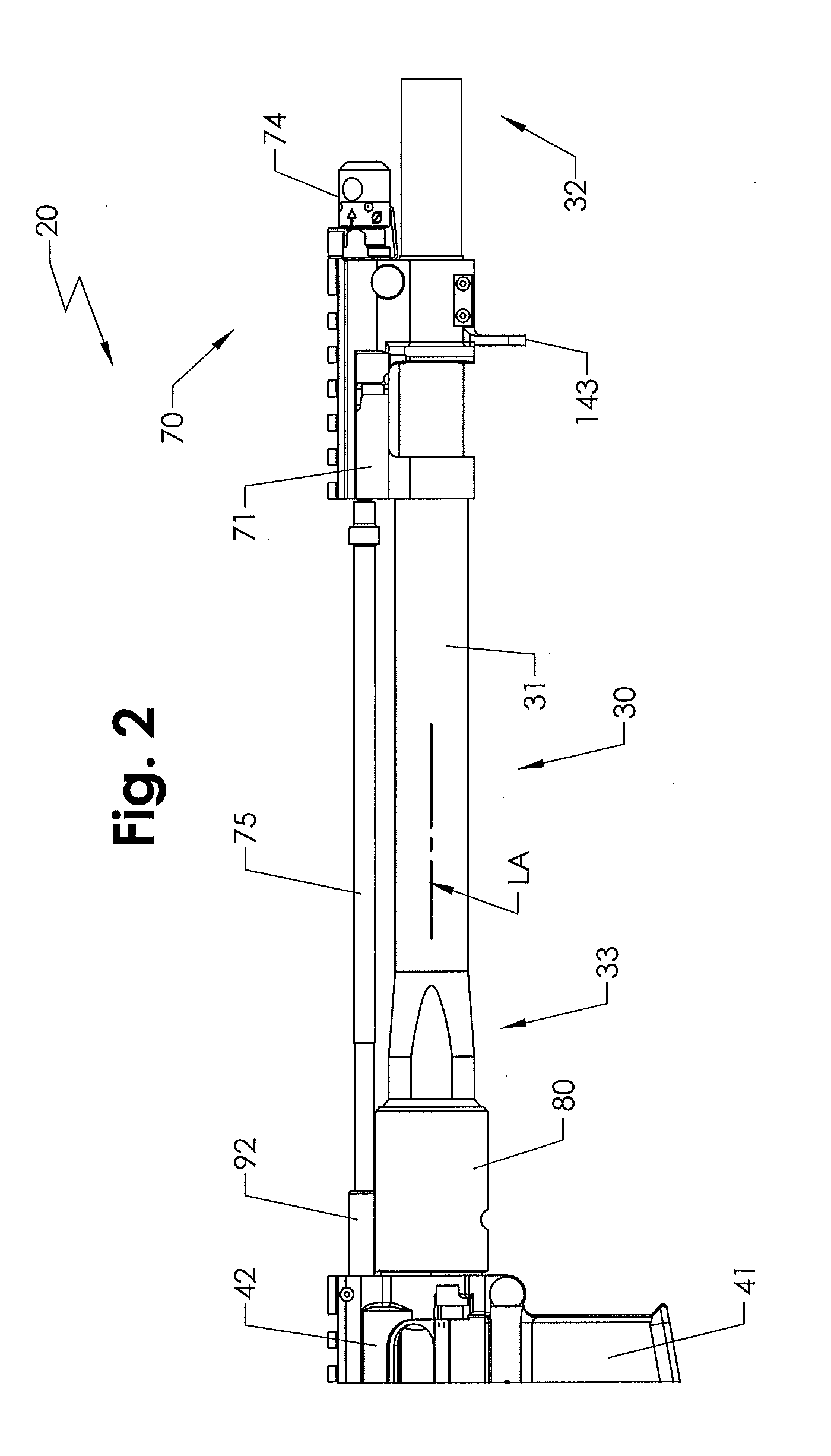

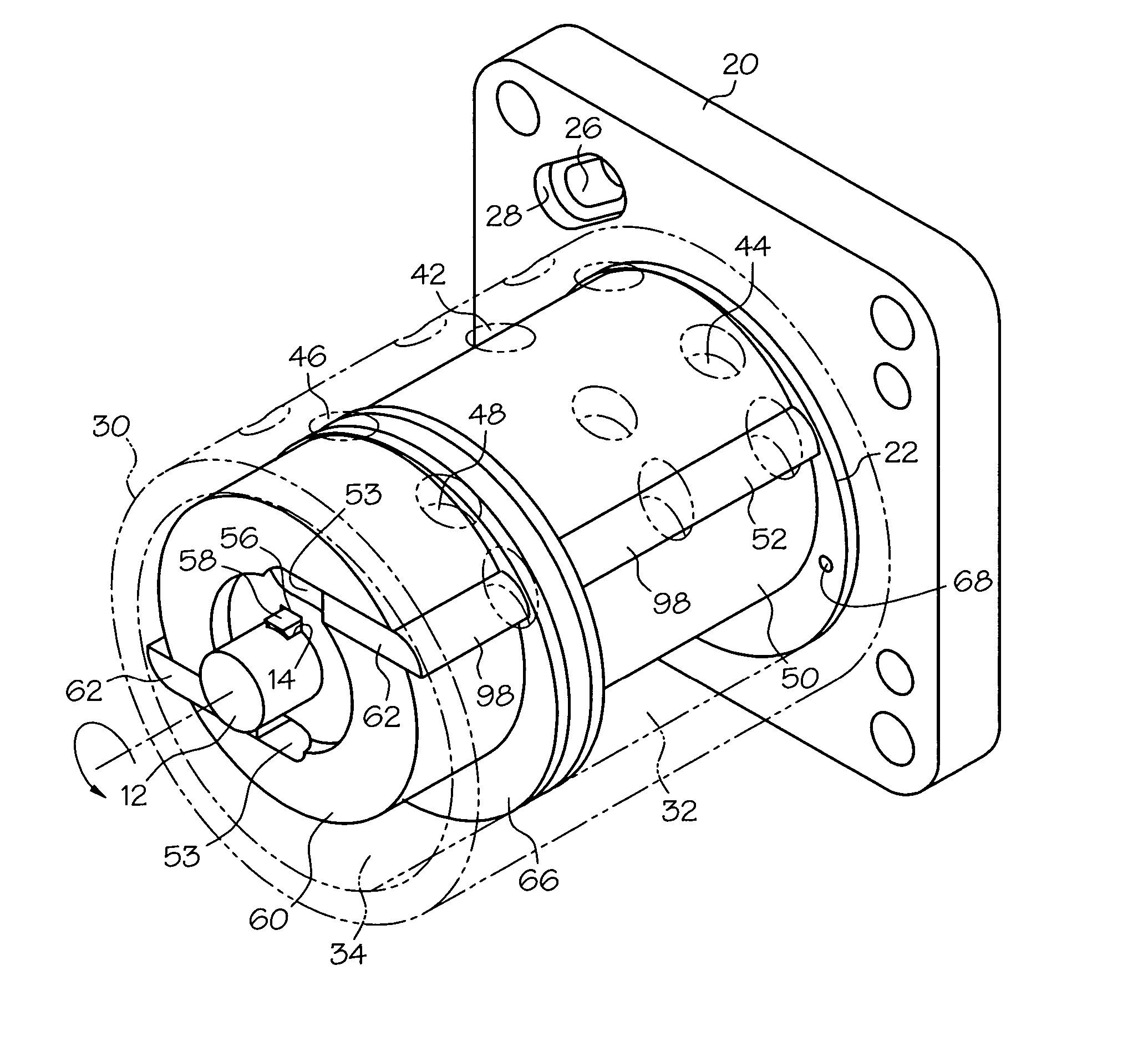

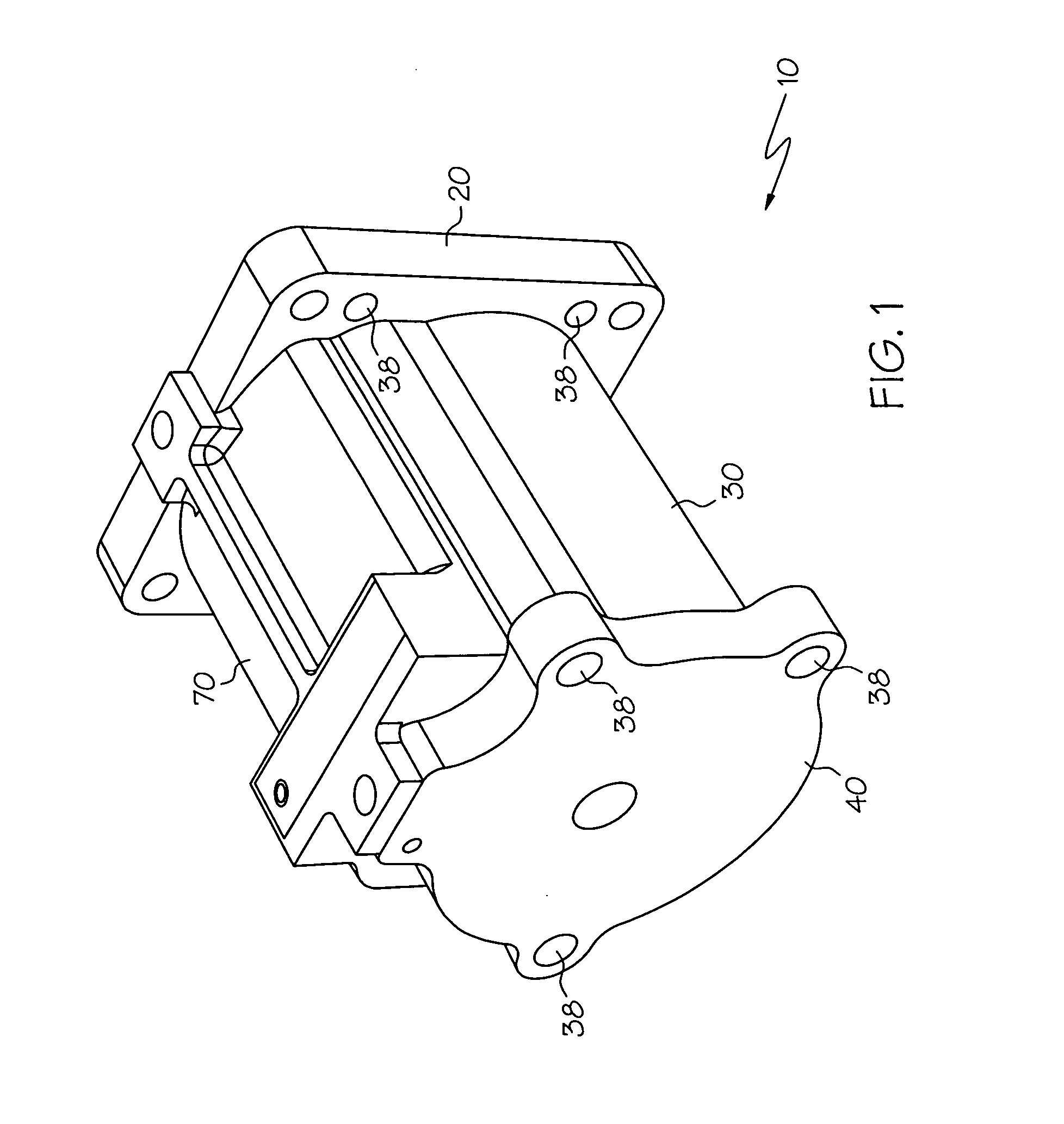

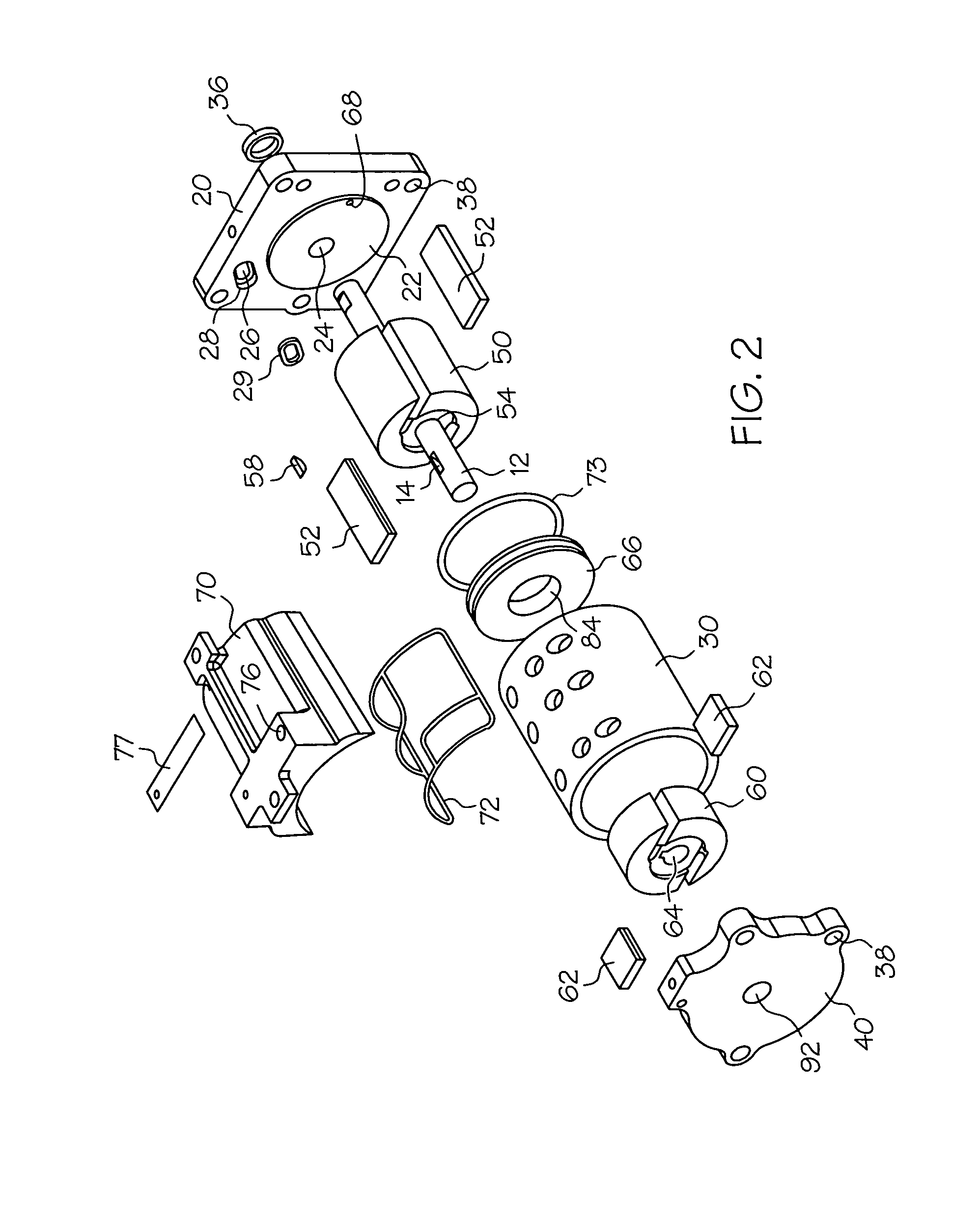

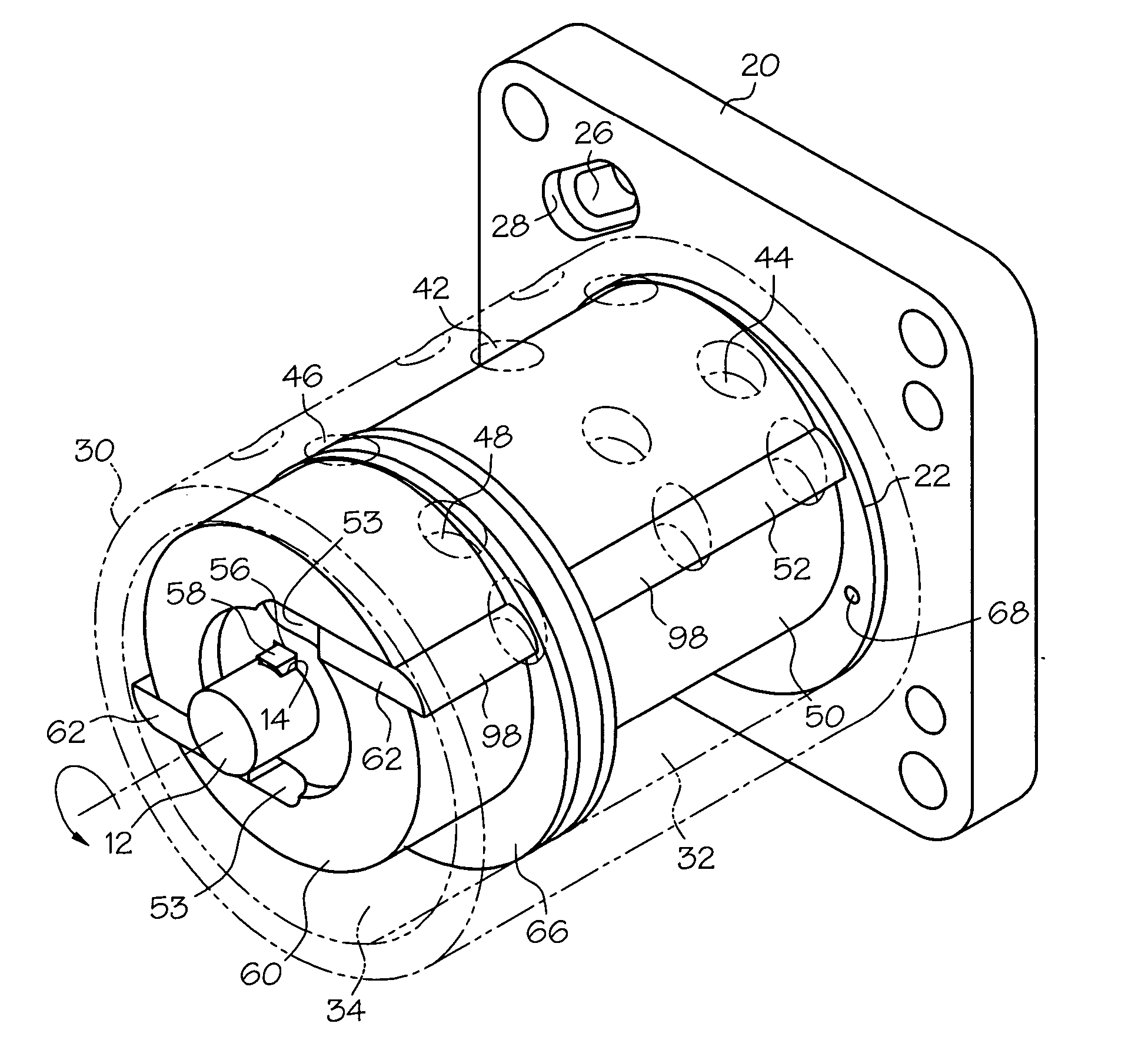

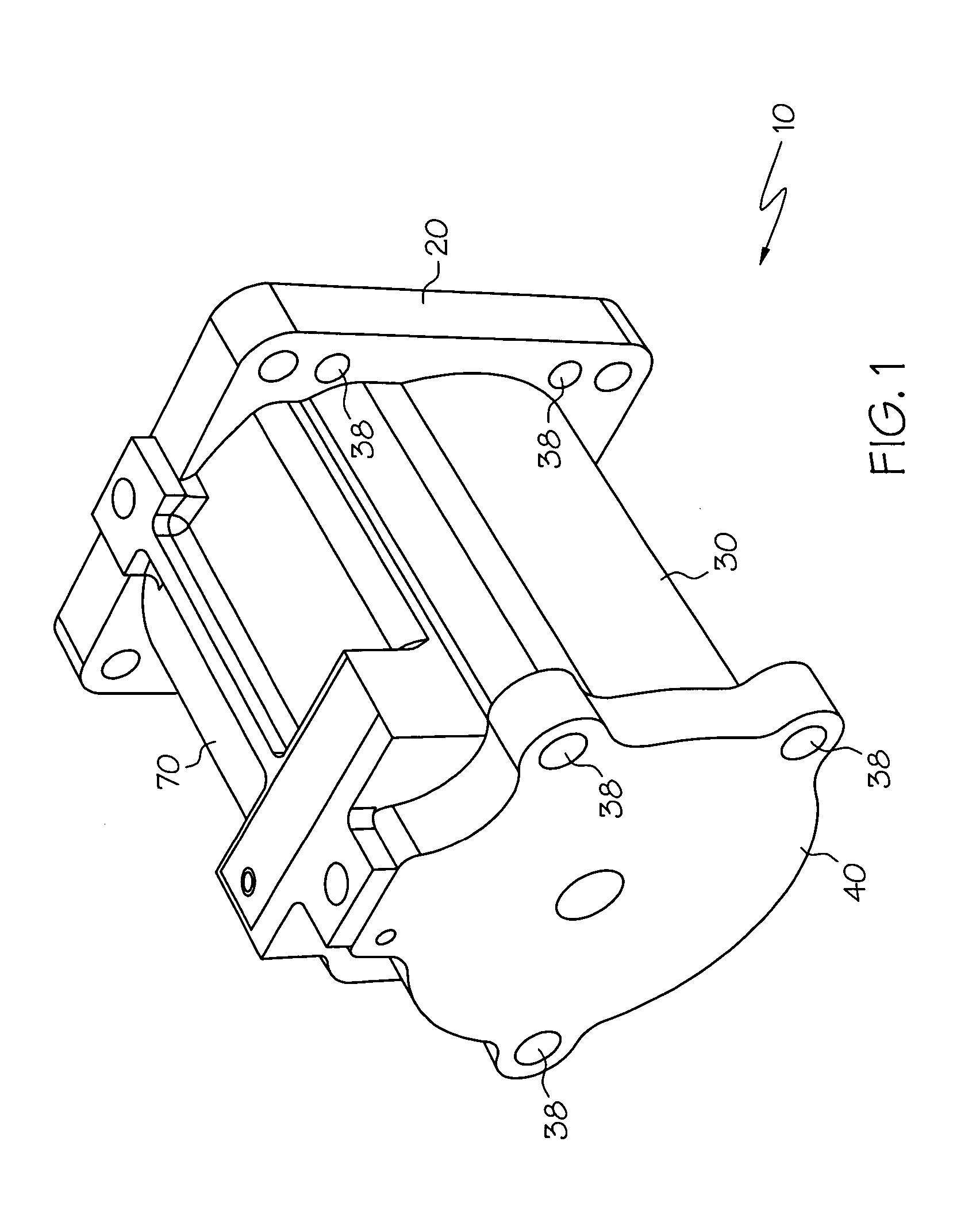

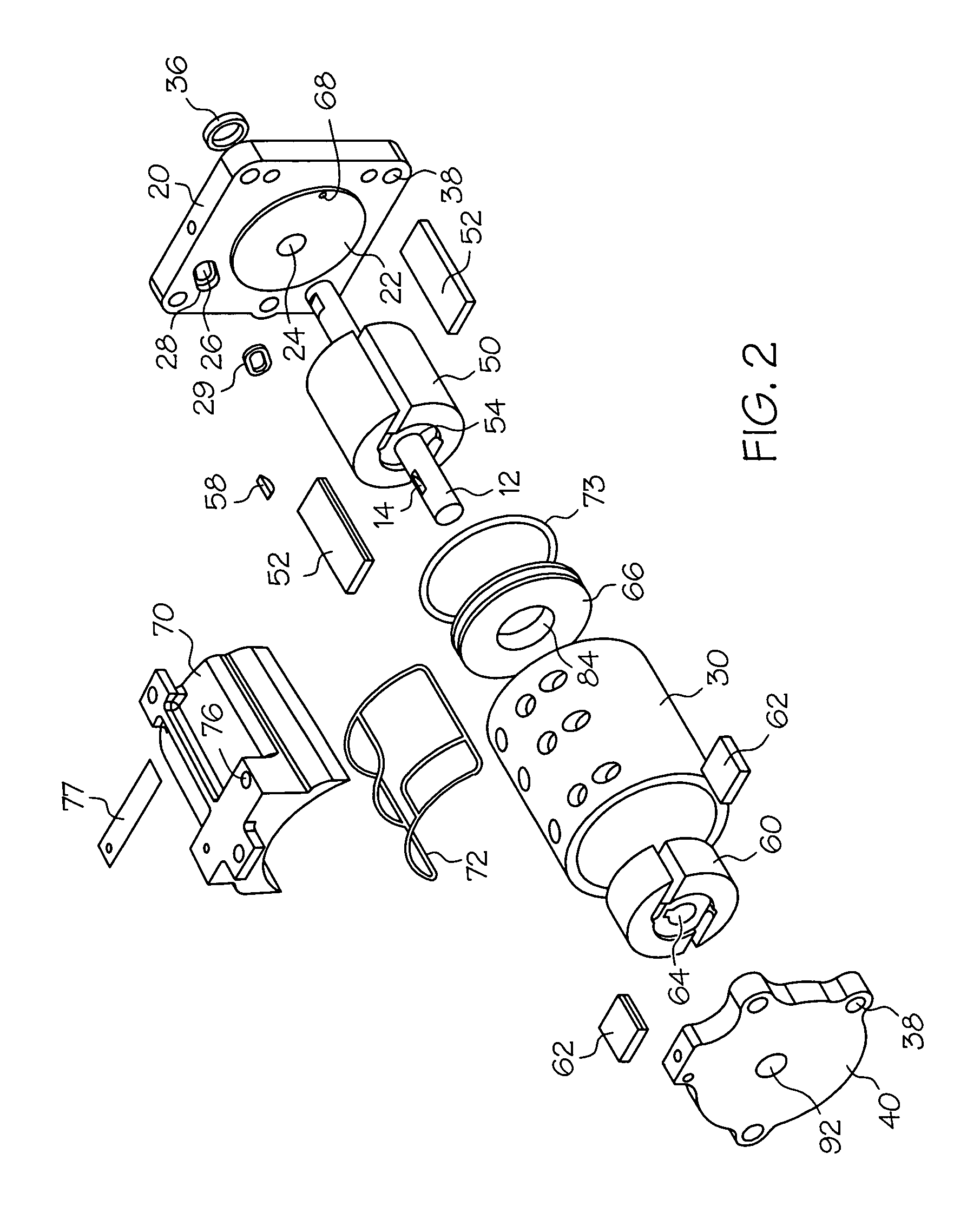

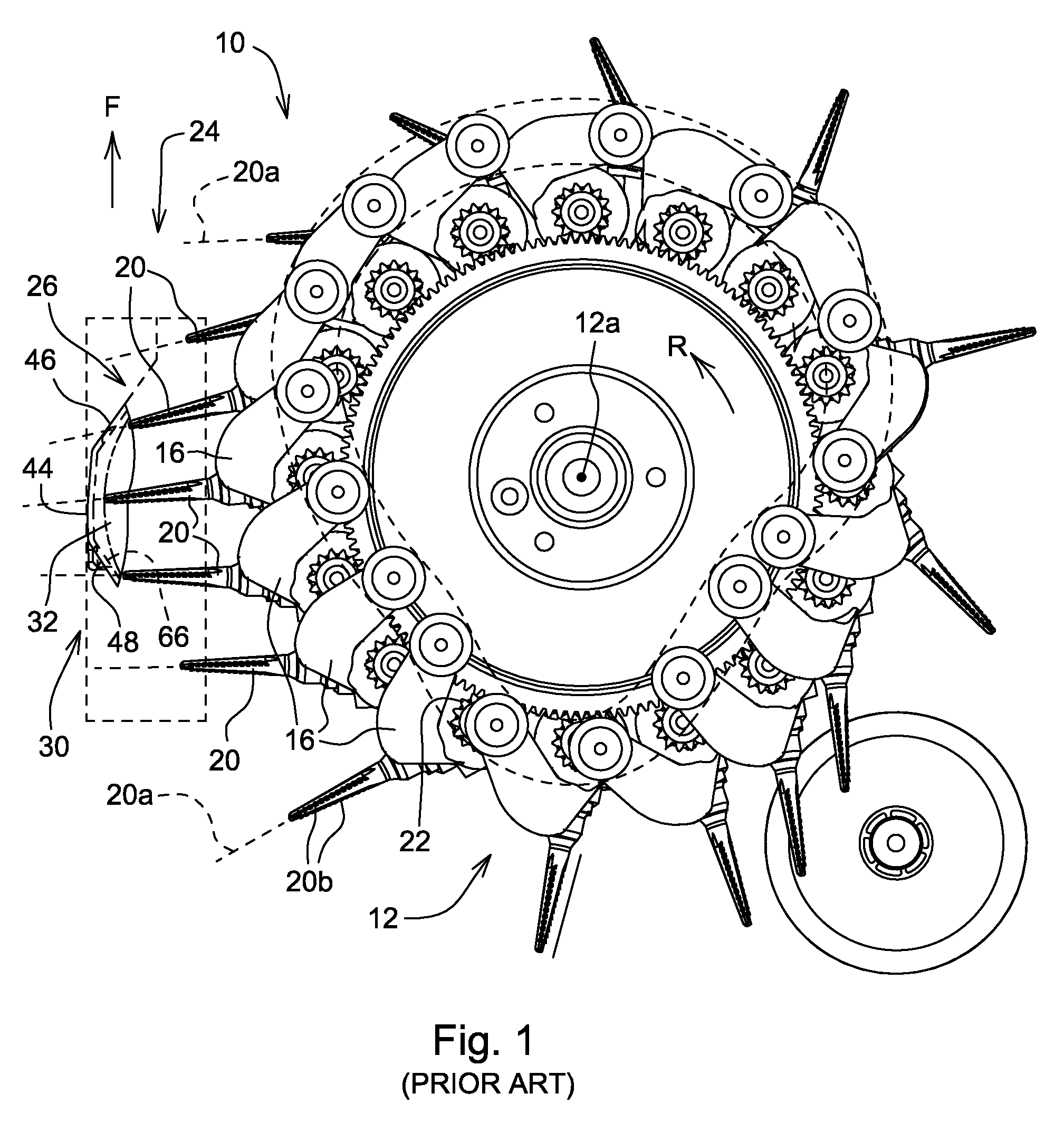

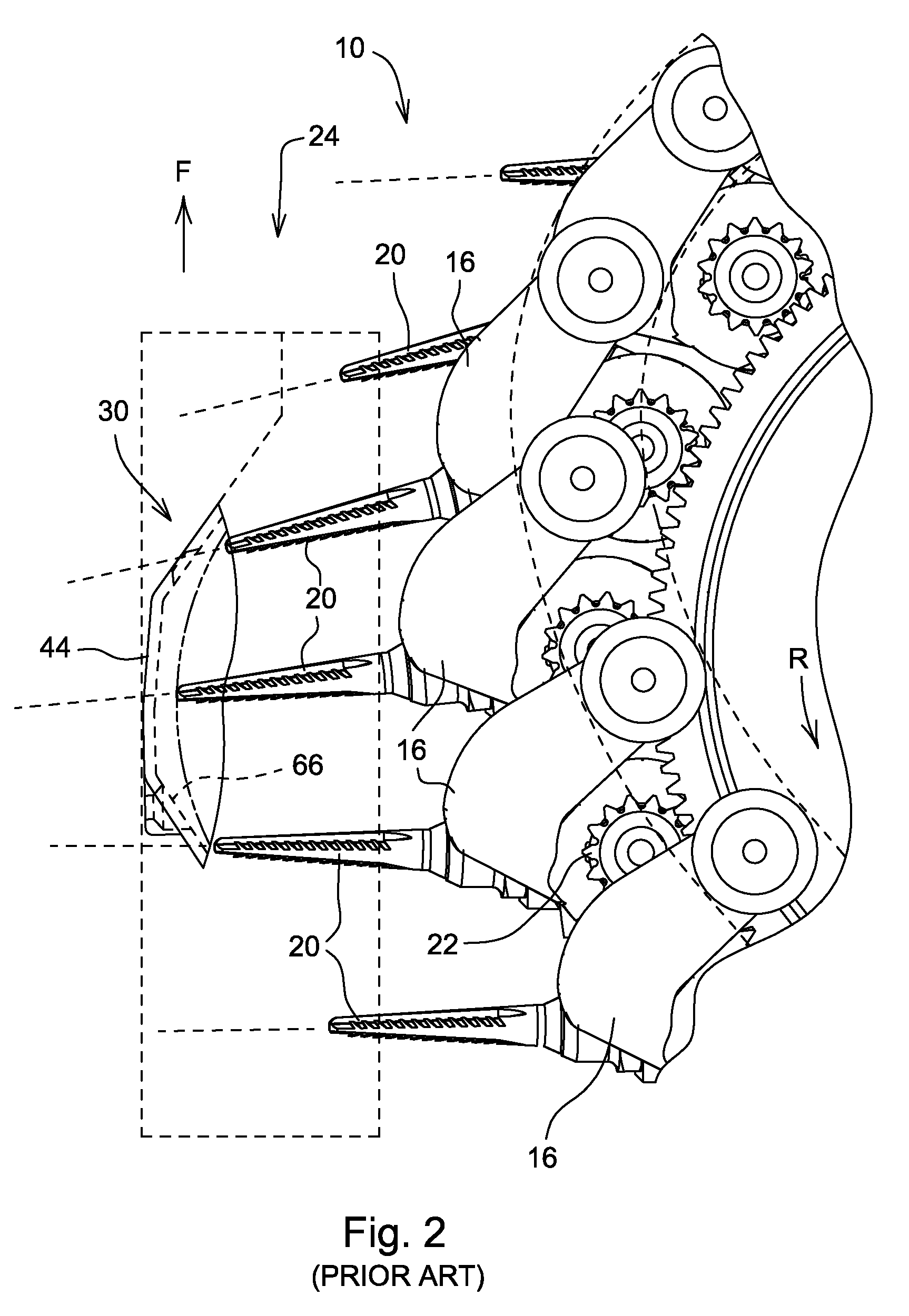

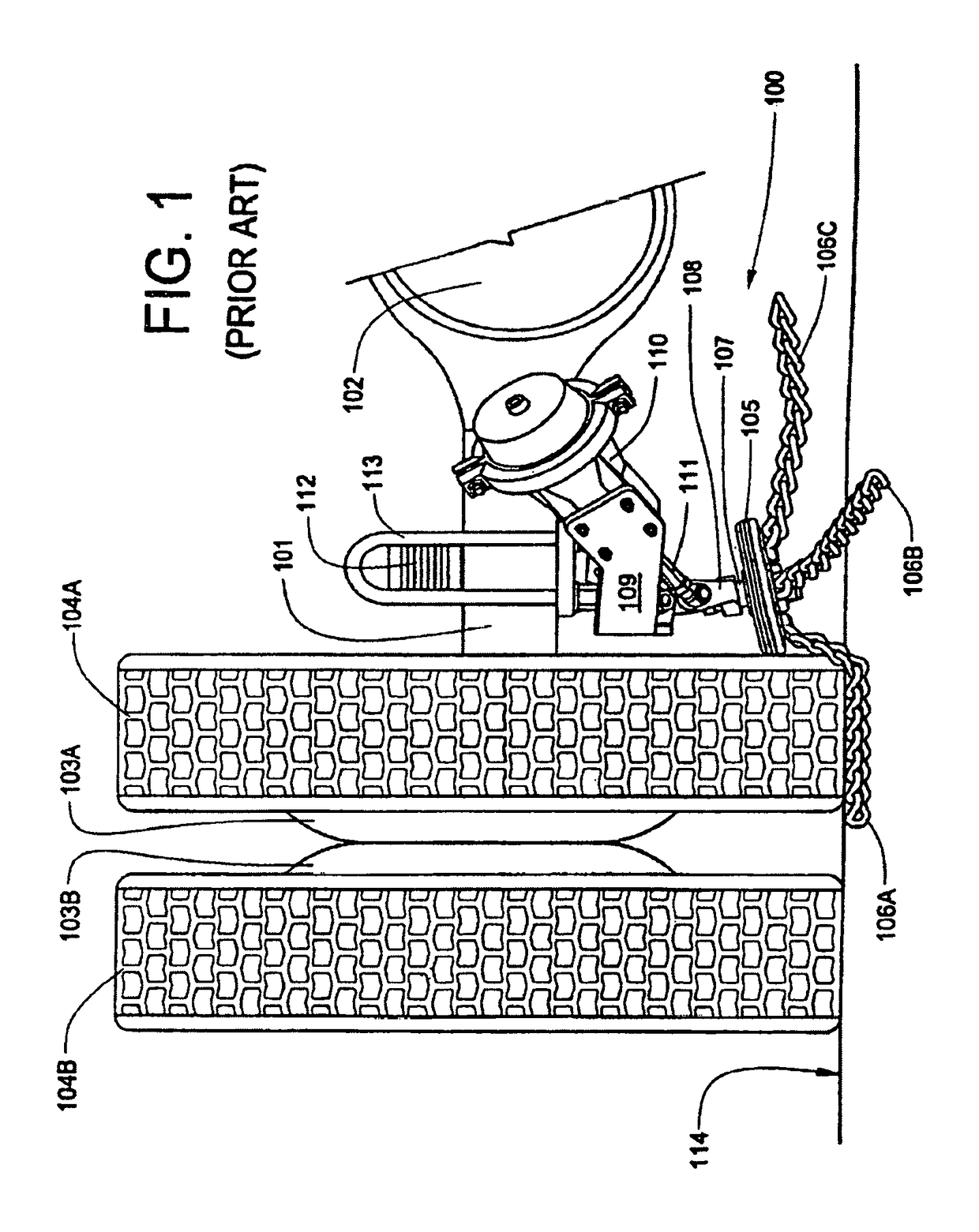

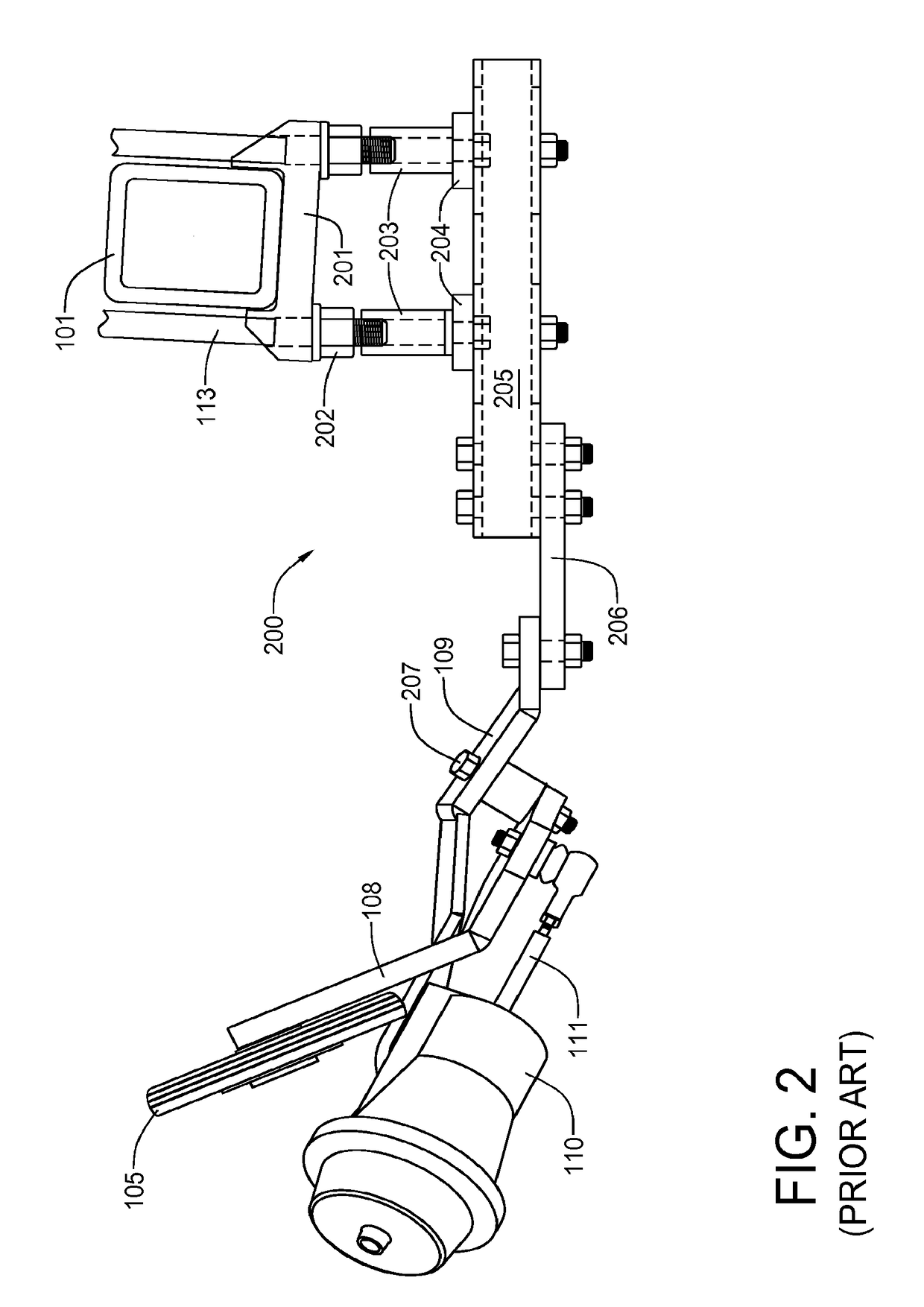

Gas operated rifle with bolt carrier and receiver assembly

ActiveUS8307750B2Reduce and eliminate loose fitReduce forceBreech mechanismsCombustionReciprocating motion

A gas operated autoloading firearm having an improved bolt carrier. The gas piston system may include a barrel defining a longitudinally-extending bullet pathway, a gas block defining a piston bore, a passageway fluidly connecting the bore with the bullet pathway for diverting combustion gas to the bore upon discharging the firearm, and a piston slidably disposed in the bore for reciprocating movement. The piston actuates a reciprocating bolt assembly including a bolt carrier slidably received in a receiver. The bolt carrier includes supporting and guiding surfaces configured to reduce receiver wear and bolt carrier drag.

Owner:STURM RUGER & CO INC

Turbine shroud segment seal

ActiveUS7207771B2Accurate clearancePump componentsTurbine/propulsion engine coolingEngineeringTurbine

A ring seal for sealing an annular gap defined between opposed surfaces of concentric inner and outer annular engine parts in a gas turbine engine. The ring seal being wholly disposed within the annular gap and having a wave pattern with alternating peaks. The ring seal radially inwardly loads the inner engine part and provides a fluid seal between the inner and outer engine parts.

Owner:PRATT & WHITNEY CANADA CORP

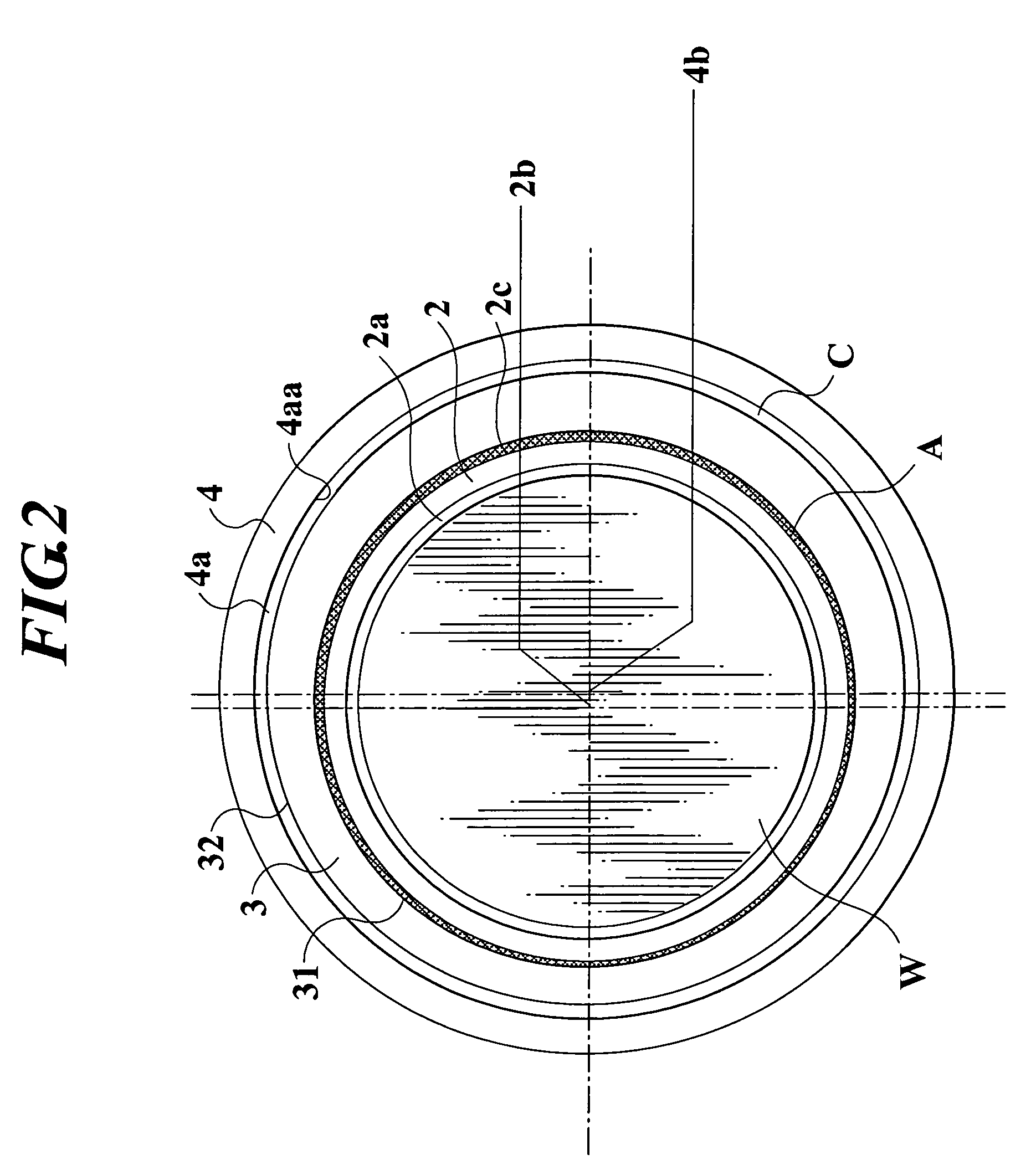

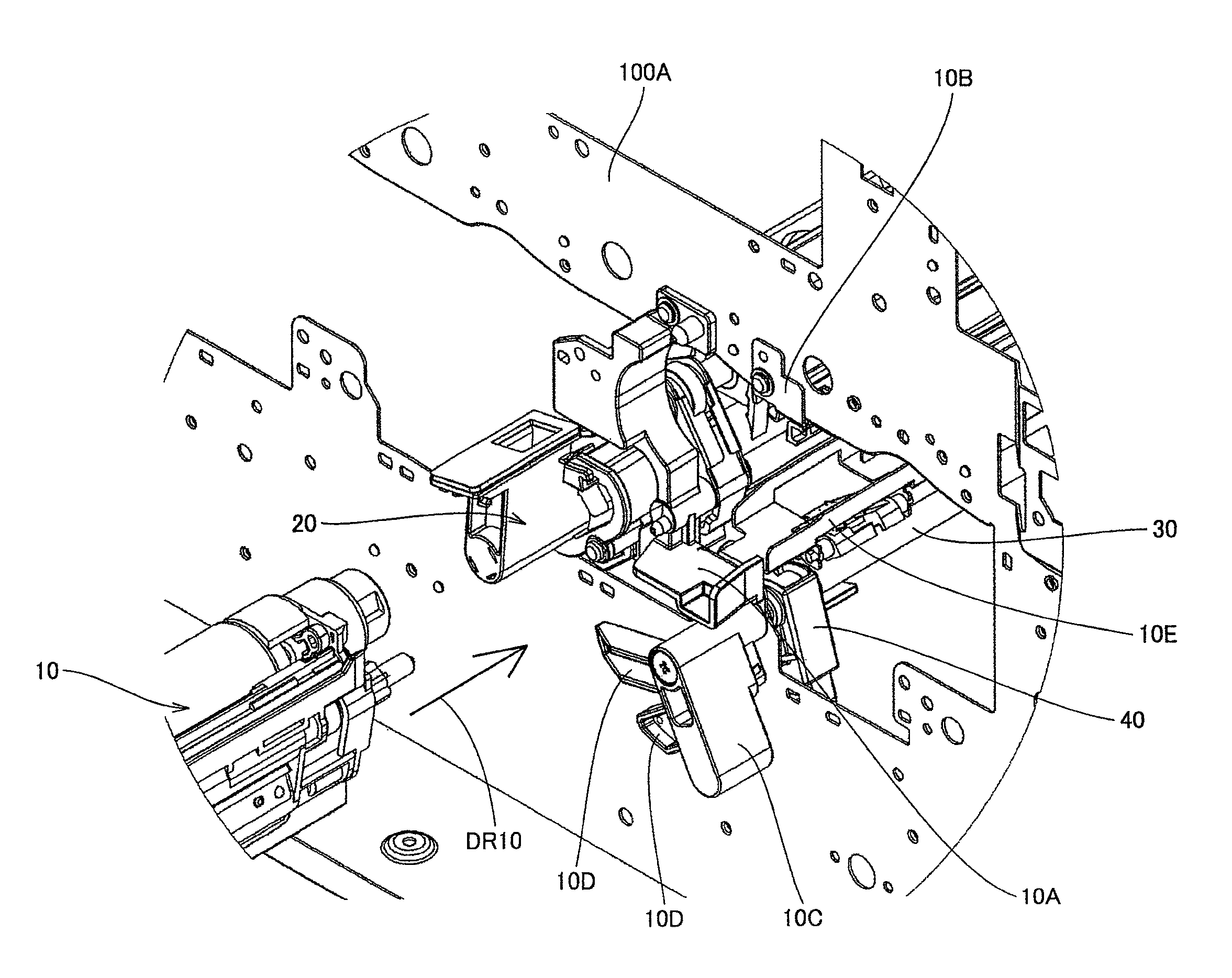

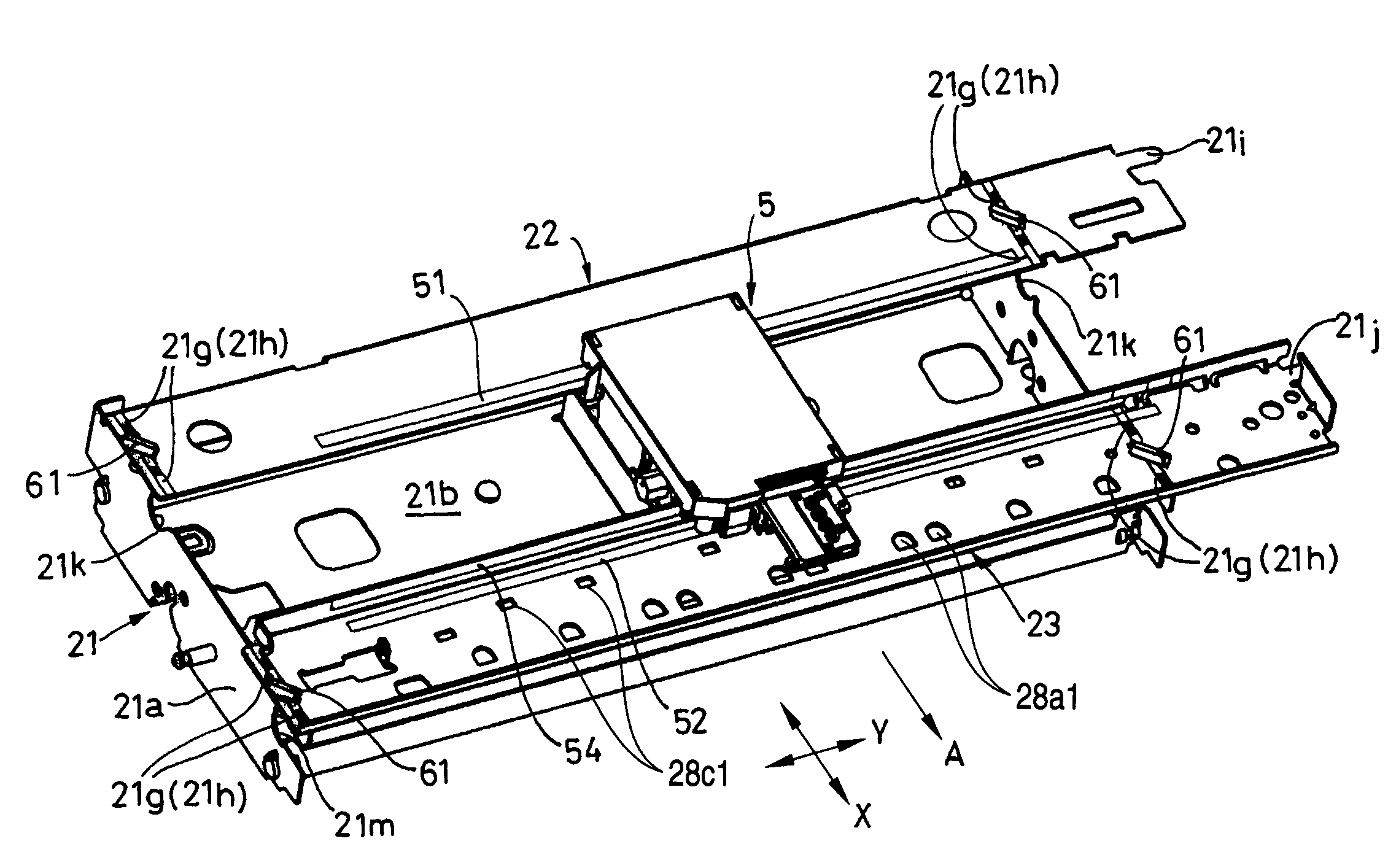

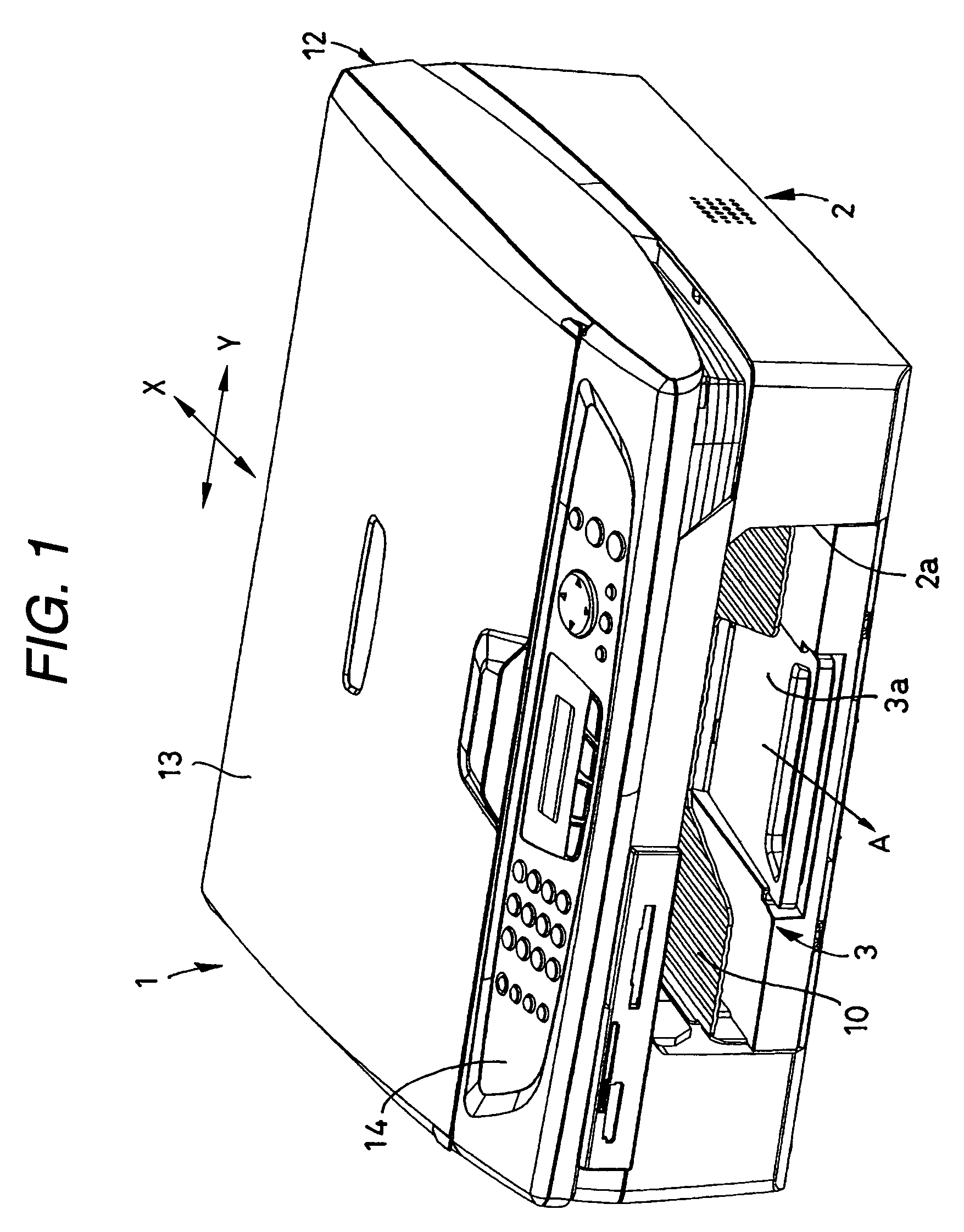

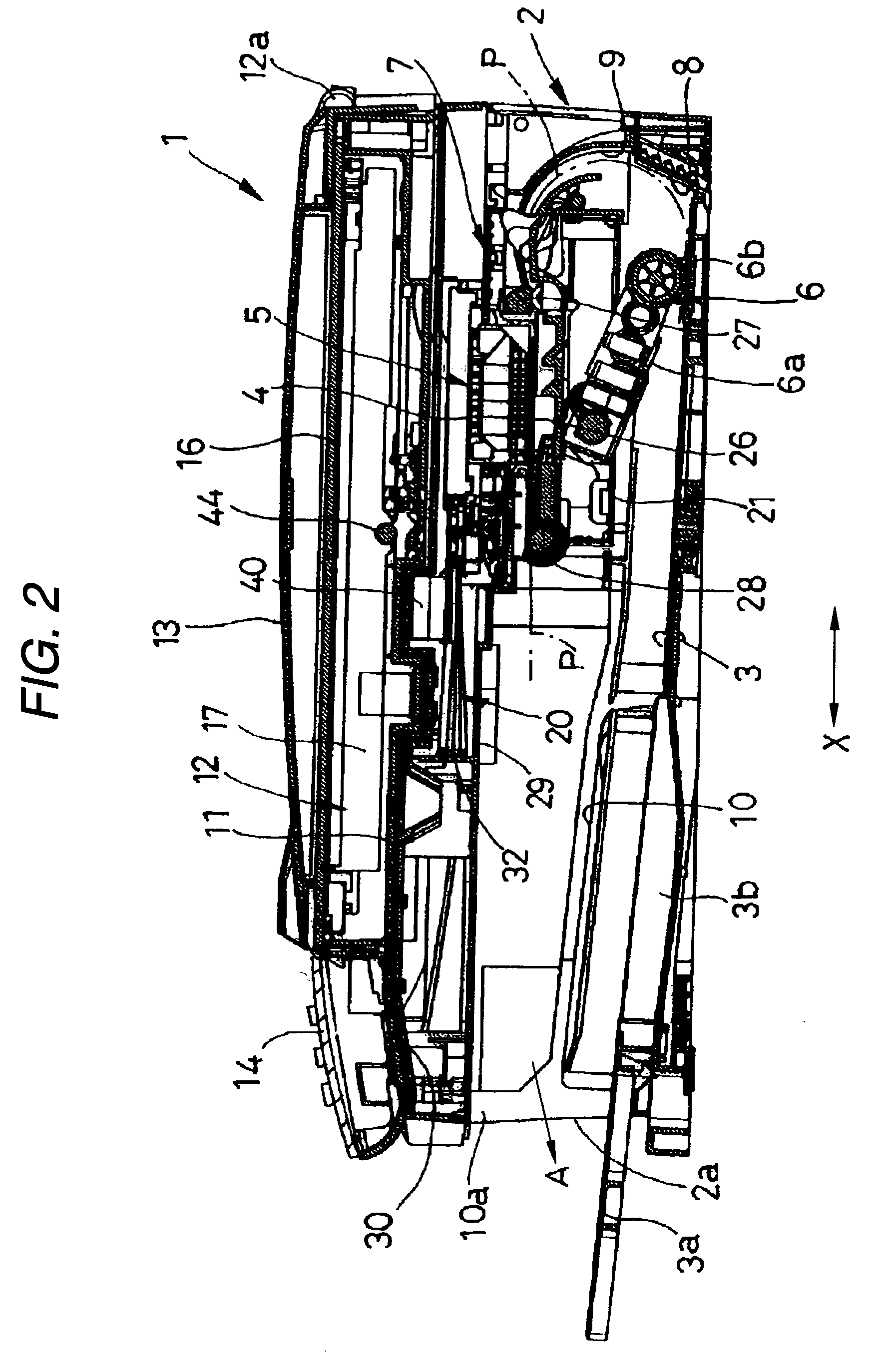

Image recording apparatus

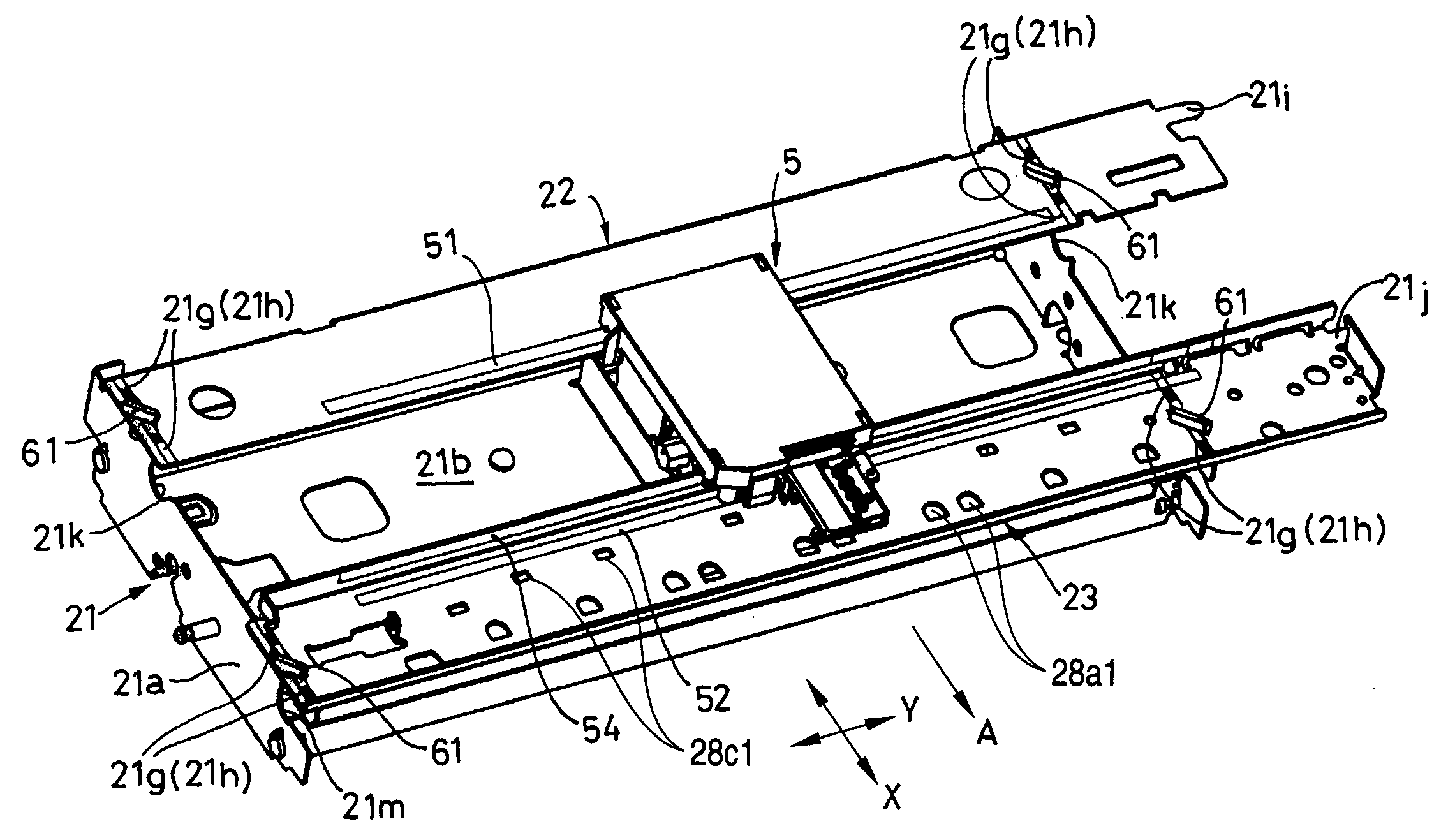

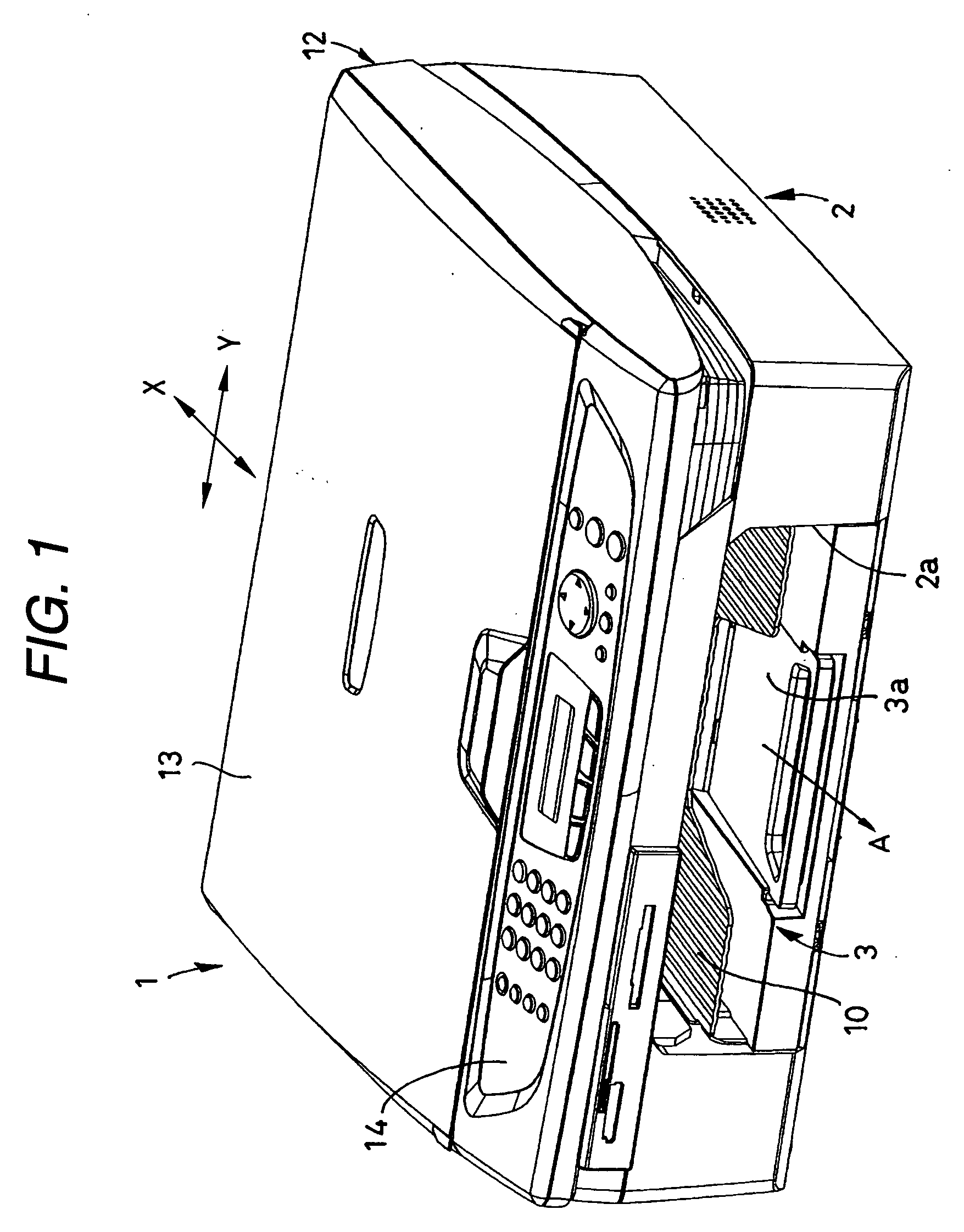

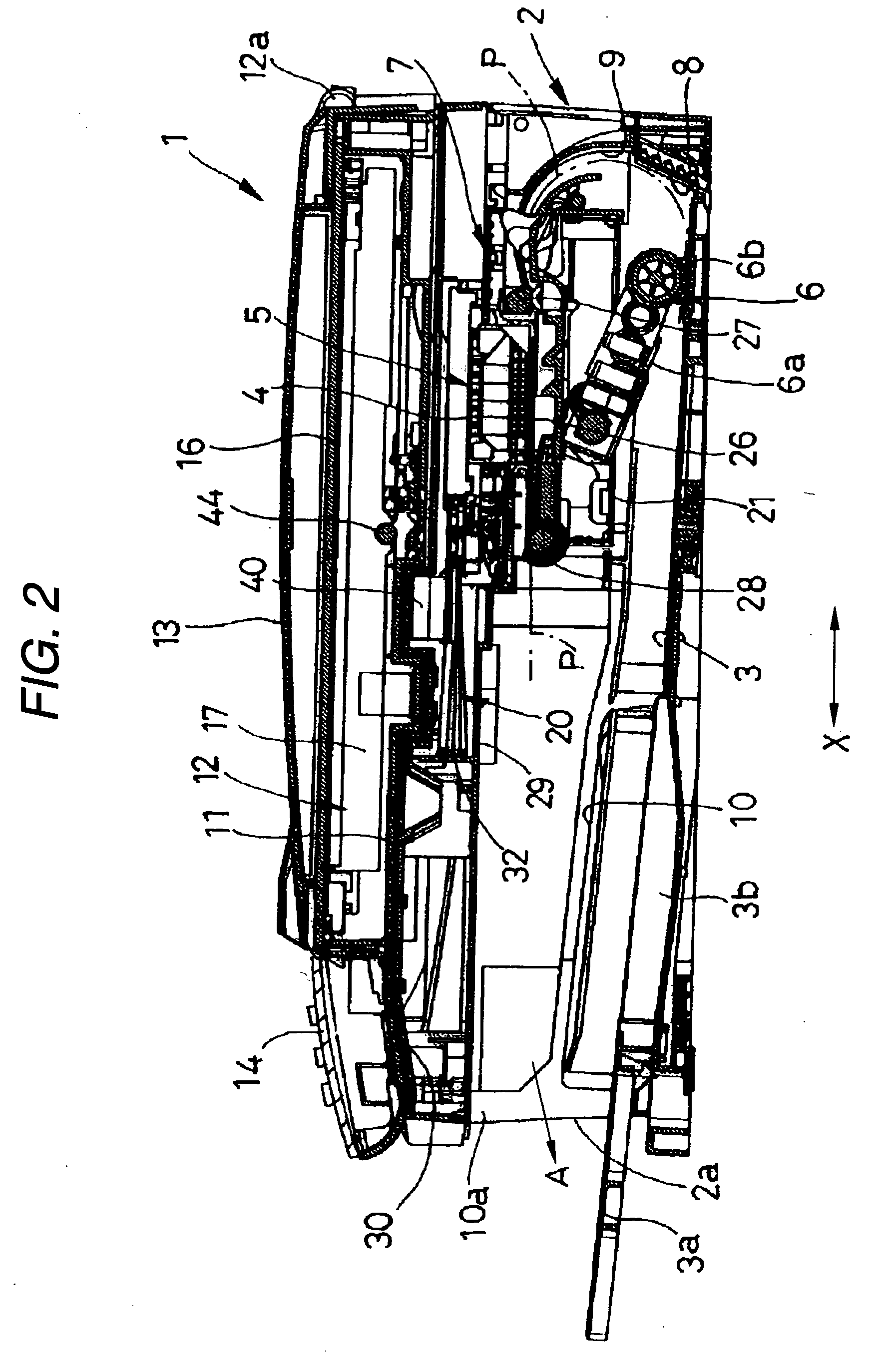

An image recording apparatus includes: a carriage that carries a recording head capable of recording an image on a recording medium and reciprocates in a main scanning direction; a substantially box-shaped main frame having an open upper side and a pair of side plates extending in a sub-scanning direction orthogonal to the main scanning direction; and first and second guide members over which the carriage extends and by which the carriage is guided, the first and second guide members being disposed to be apart from each other by a predetermined distance in the sub-scanning direction, extended in the main scanning direction at the upper side of the main frame and fixed to the pair of side plates.

Owner:BROTHER KOGYO KK

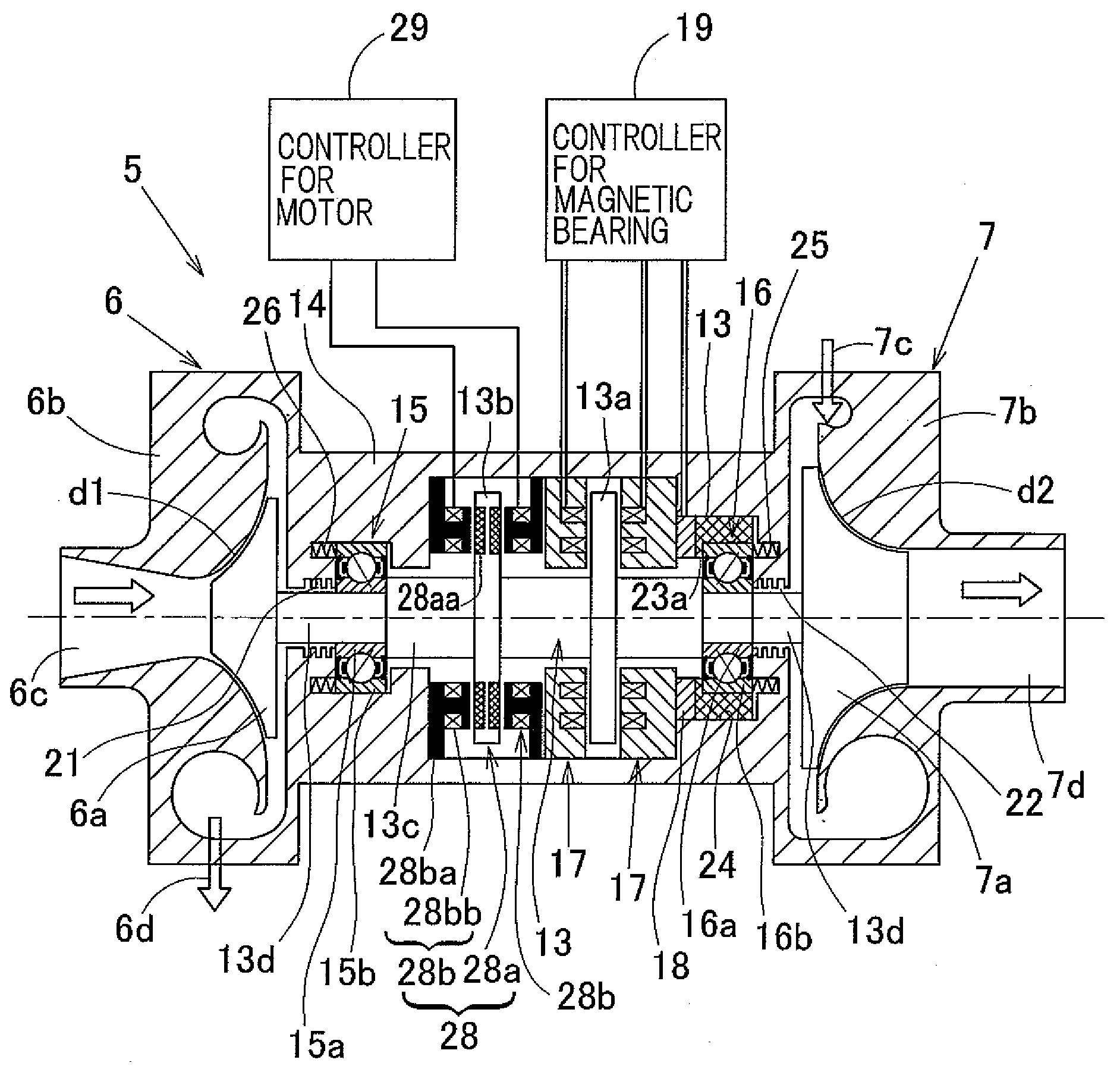

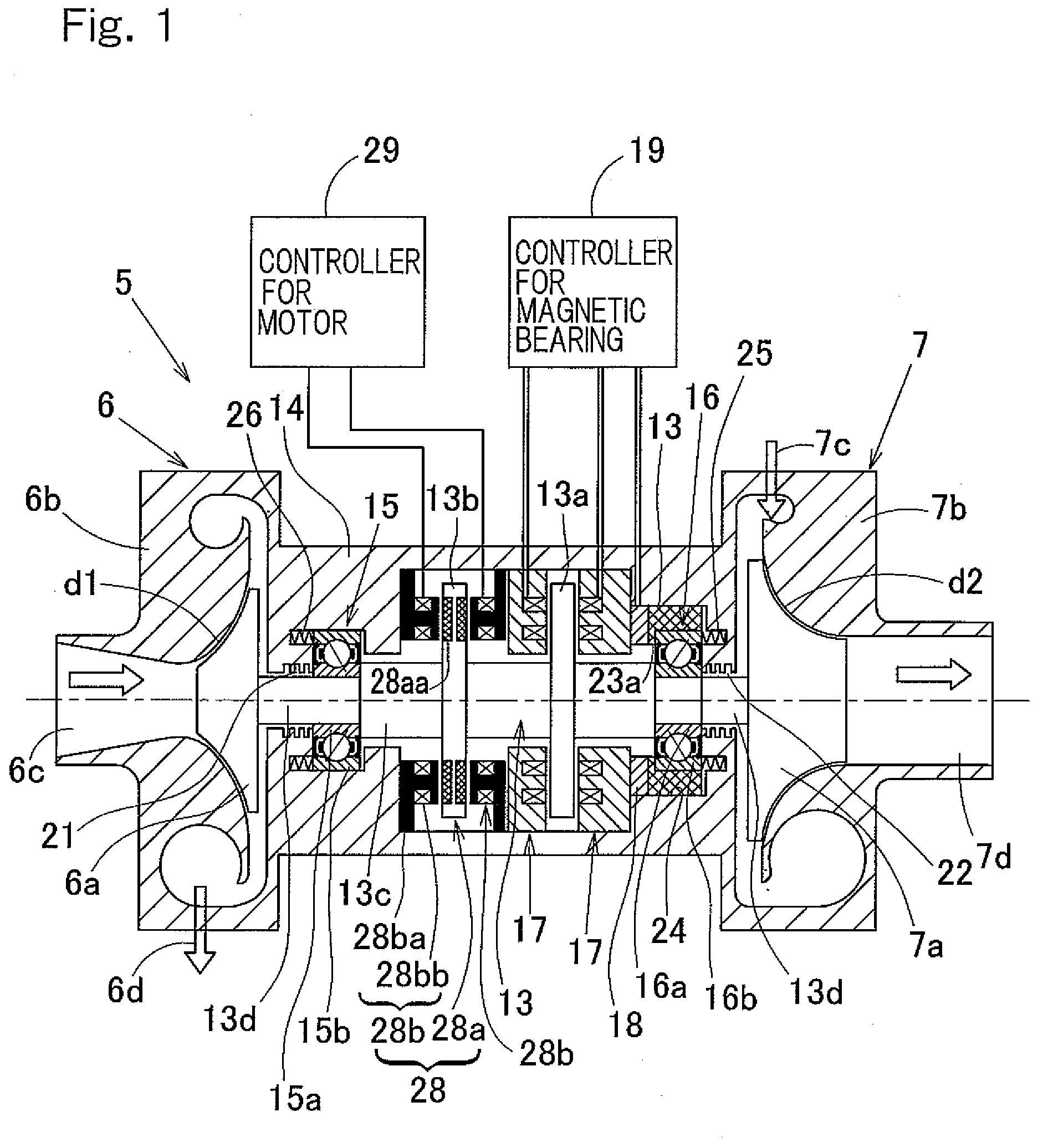

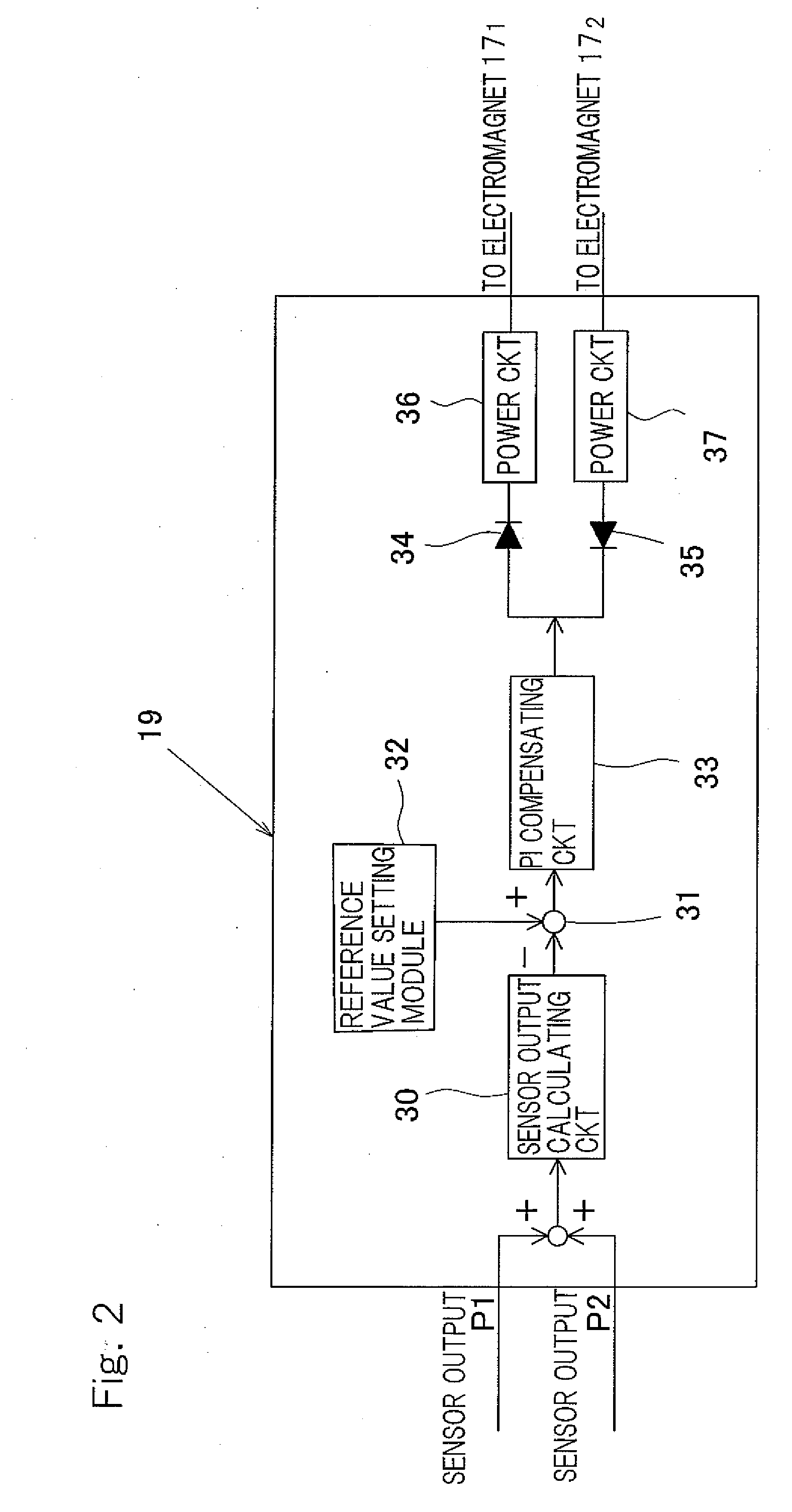

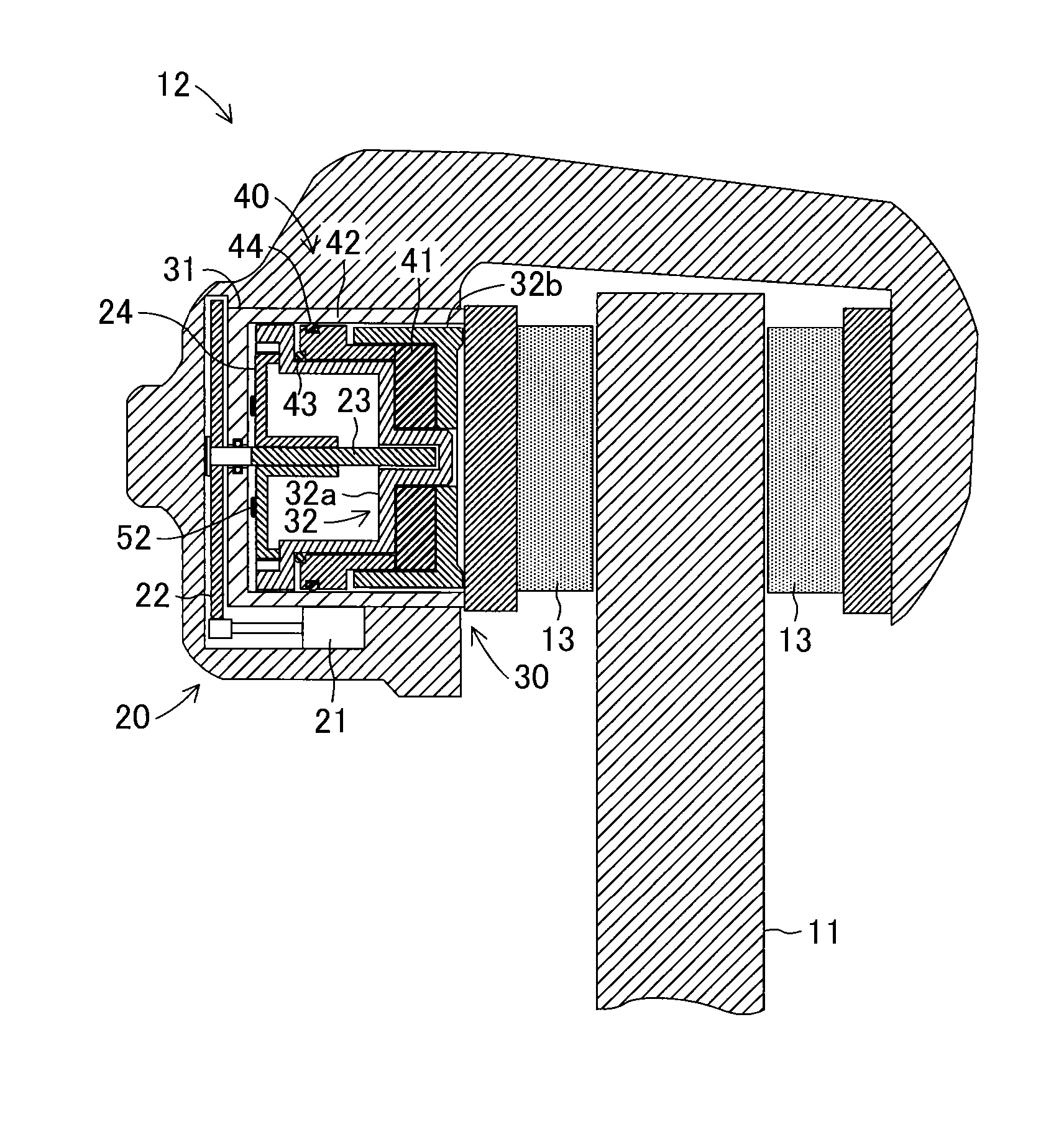

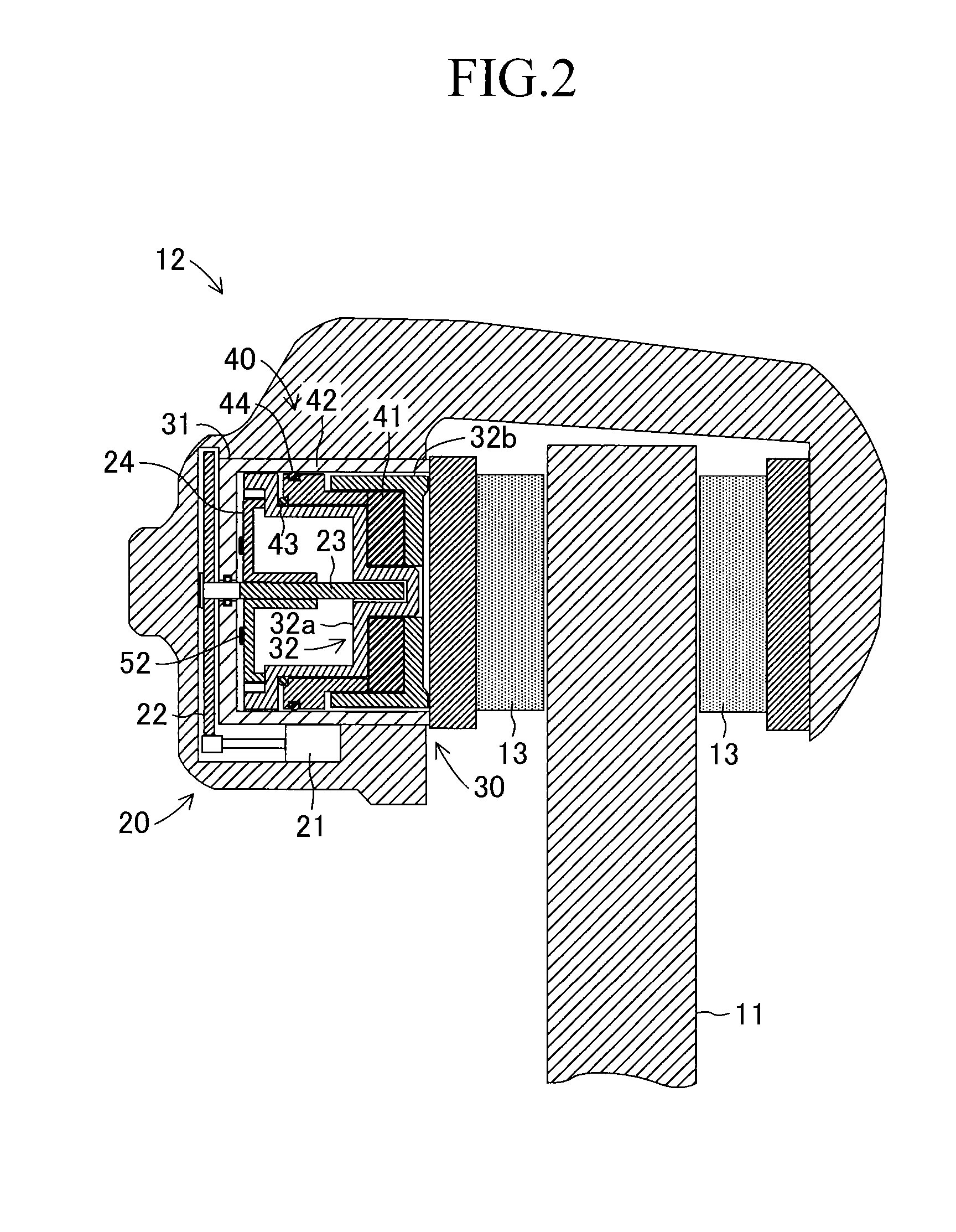

Motor built-in magnetic bearing device

InactiveUS20090127956A1Improve long-term durabilityReliabilityPump componentsFlexible member pumpsSupporting systemMagnetic bearing

The device includes a rolling bearing unit supporting a radial load and a magnetic bearing unit supporting an axial load and / or a bearing preload; an electromagnet fitted to a spindle housing so as to confront, on a non-contact basis, a flange shaped thrust plate mounted on a main shaft; a motor rotor of a motor for driving the shaft, and a motor stator opposed to the rotor, the shaft being driven by magnetic or Lorentz forces developed between the rotor and the stator; and a sensor detecting an axial force acting on the bearing unit, and a controller controlling the electromagnet. In this device, the stiffness of a composite spring formed by the bearing unit and a support system for the bearing unit is chosen to be higher than the negative stiffness of a composite spring of a motor part comprised of the electromagnet and the motor.

Owner:NTN CORP

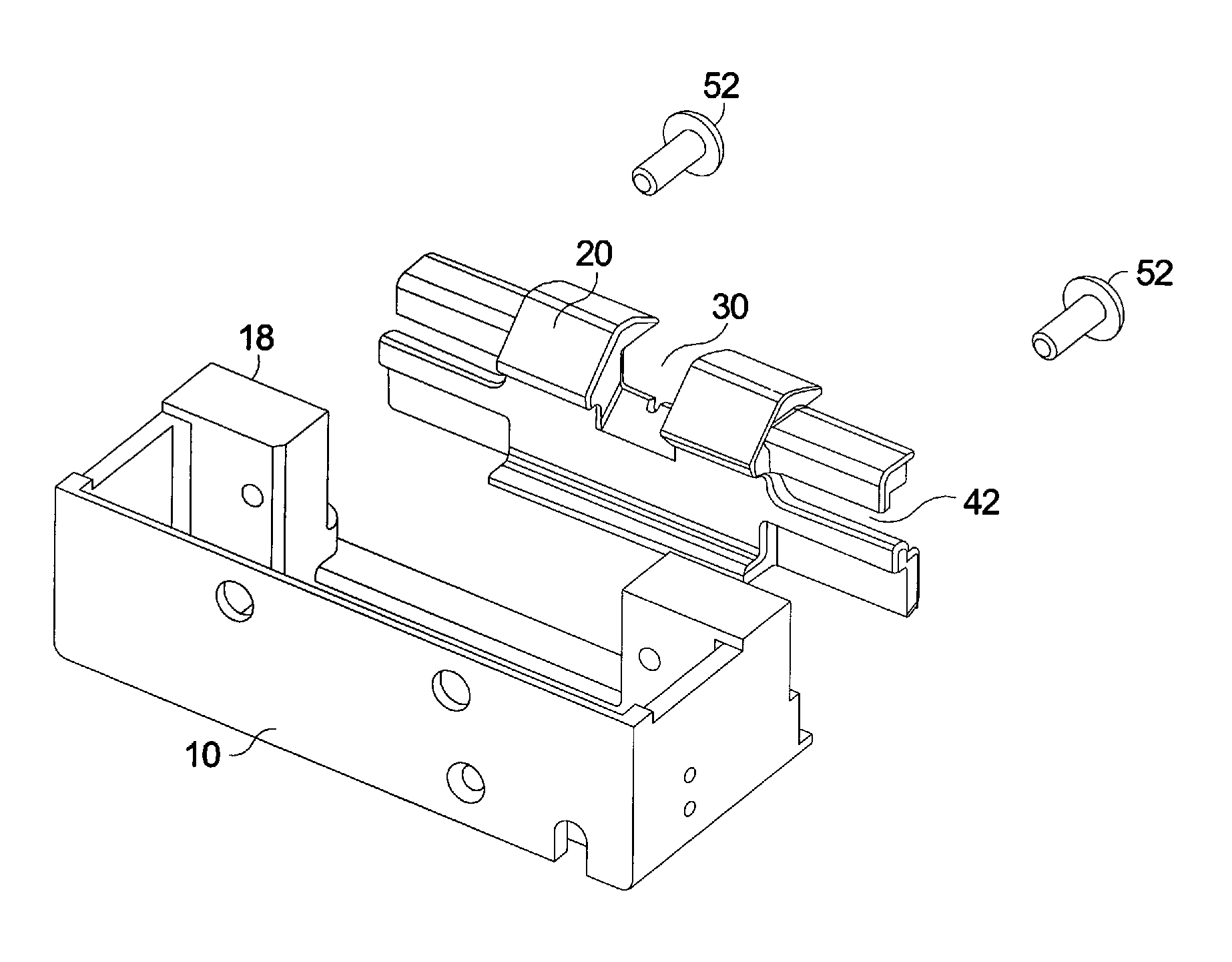

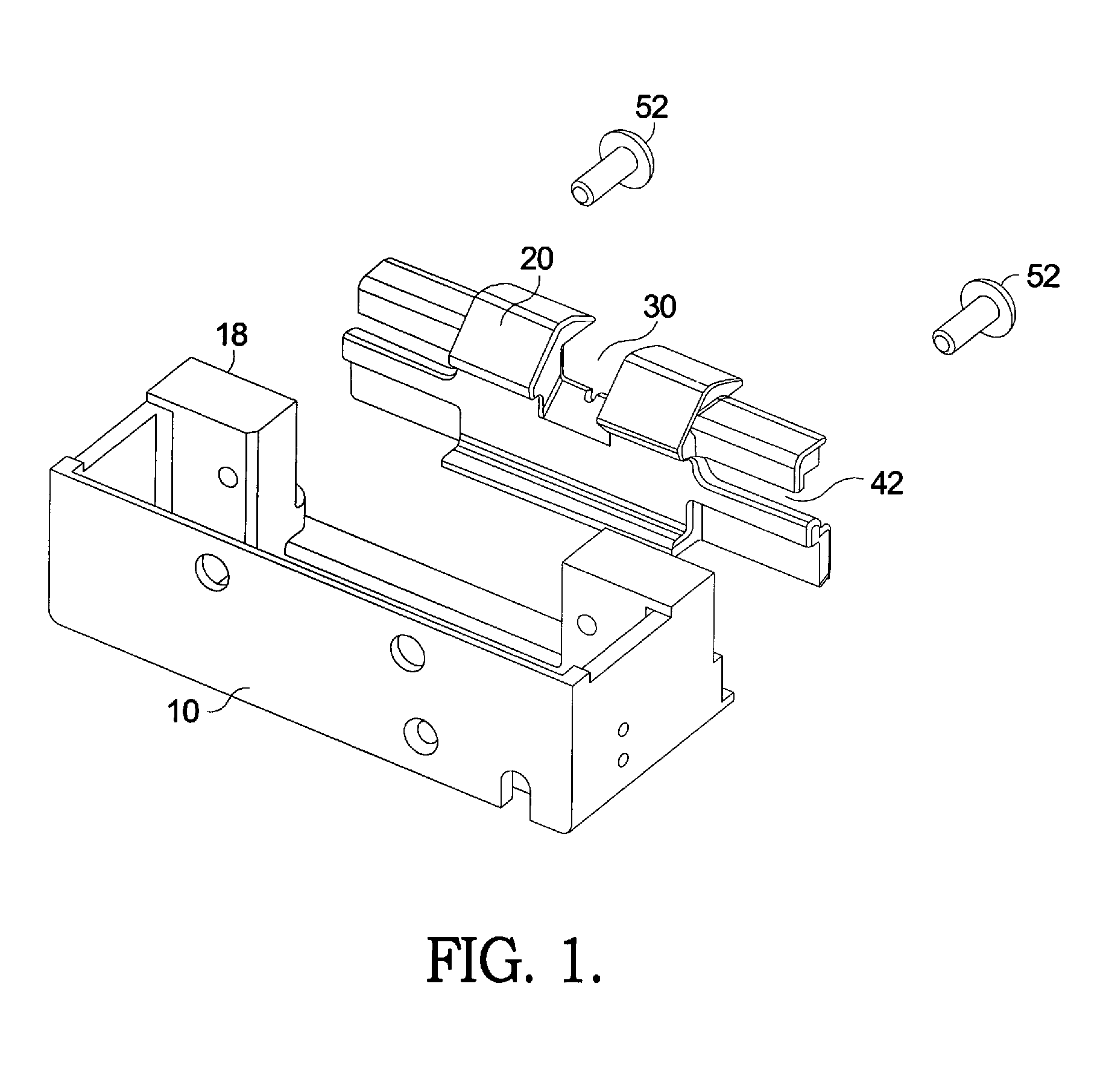

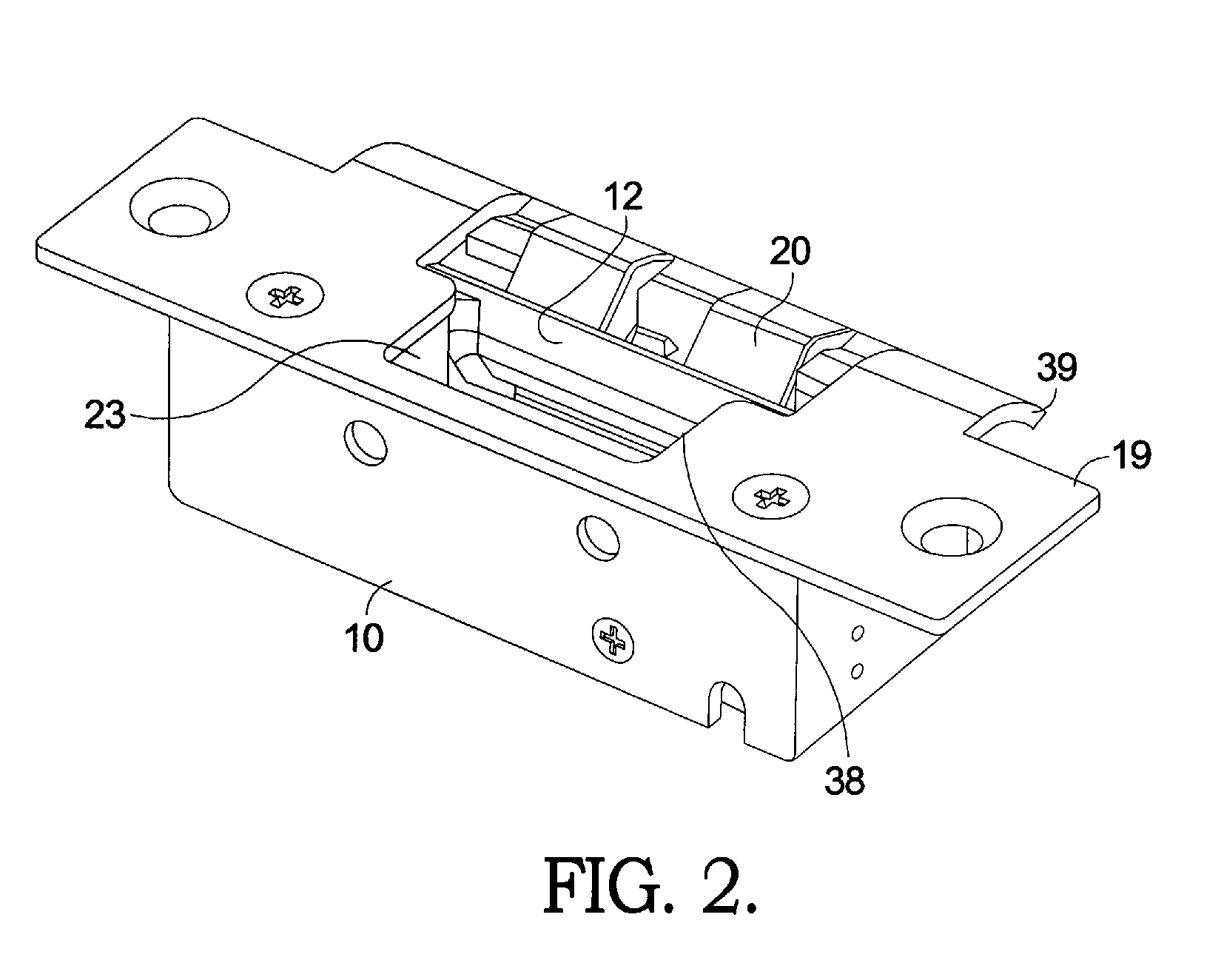

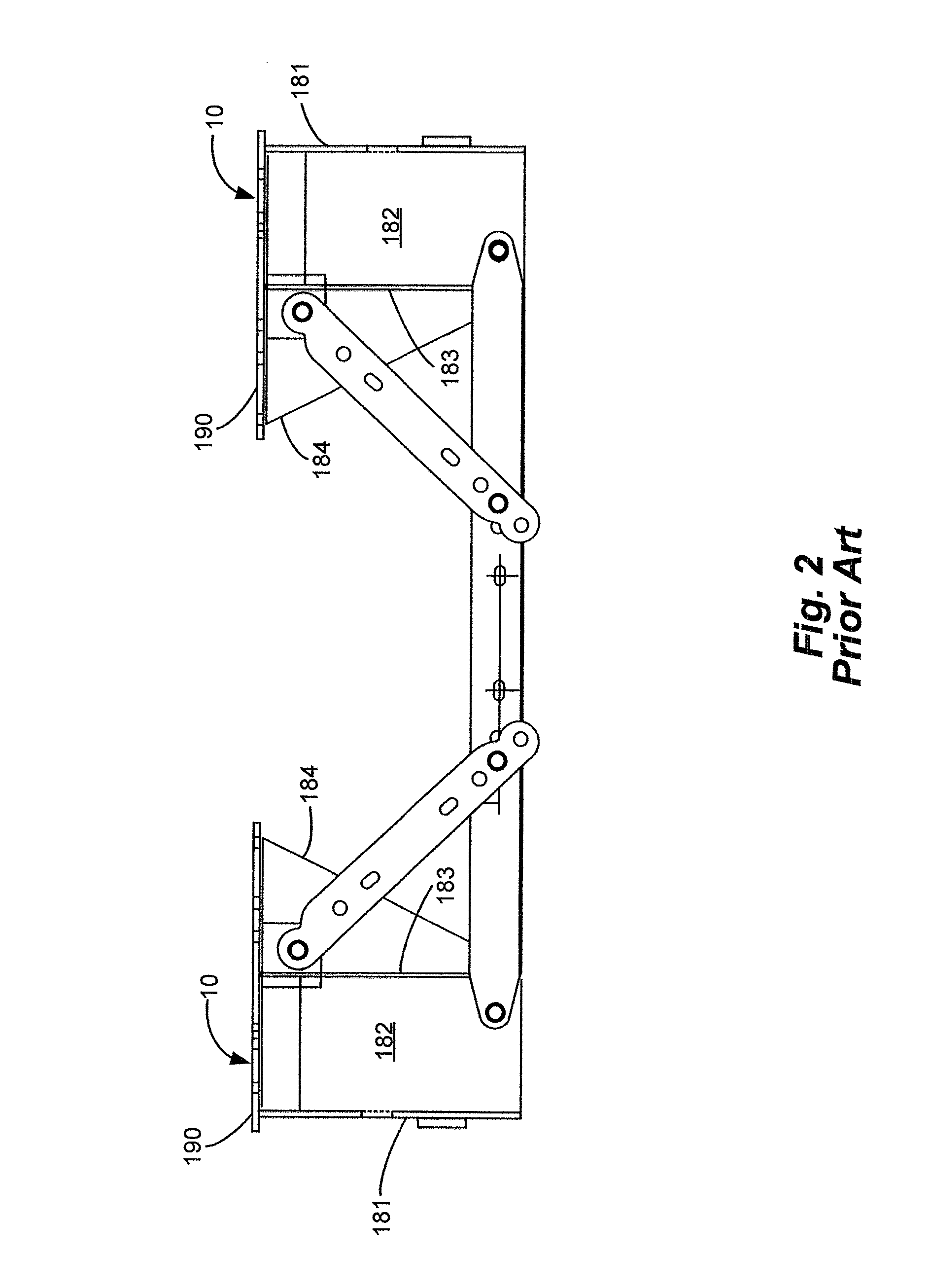

Integration of vertical adjustability in an electric strike

ActiveUS8157302B1Minimize installation processEasy to installNon-mechanical controlsFastening meansElectrical and Electronics engineeringEngineering

Owner:HANCHETT ENTRY SYST INC AZ CORP

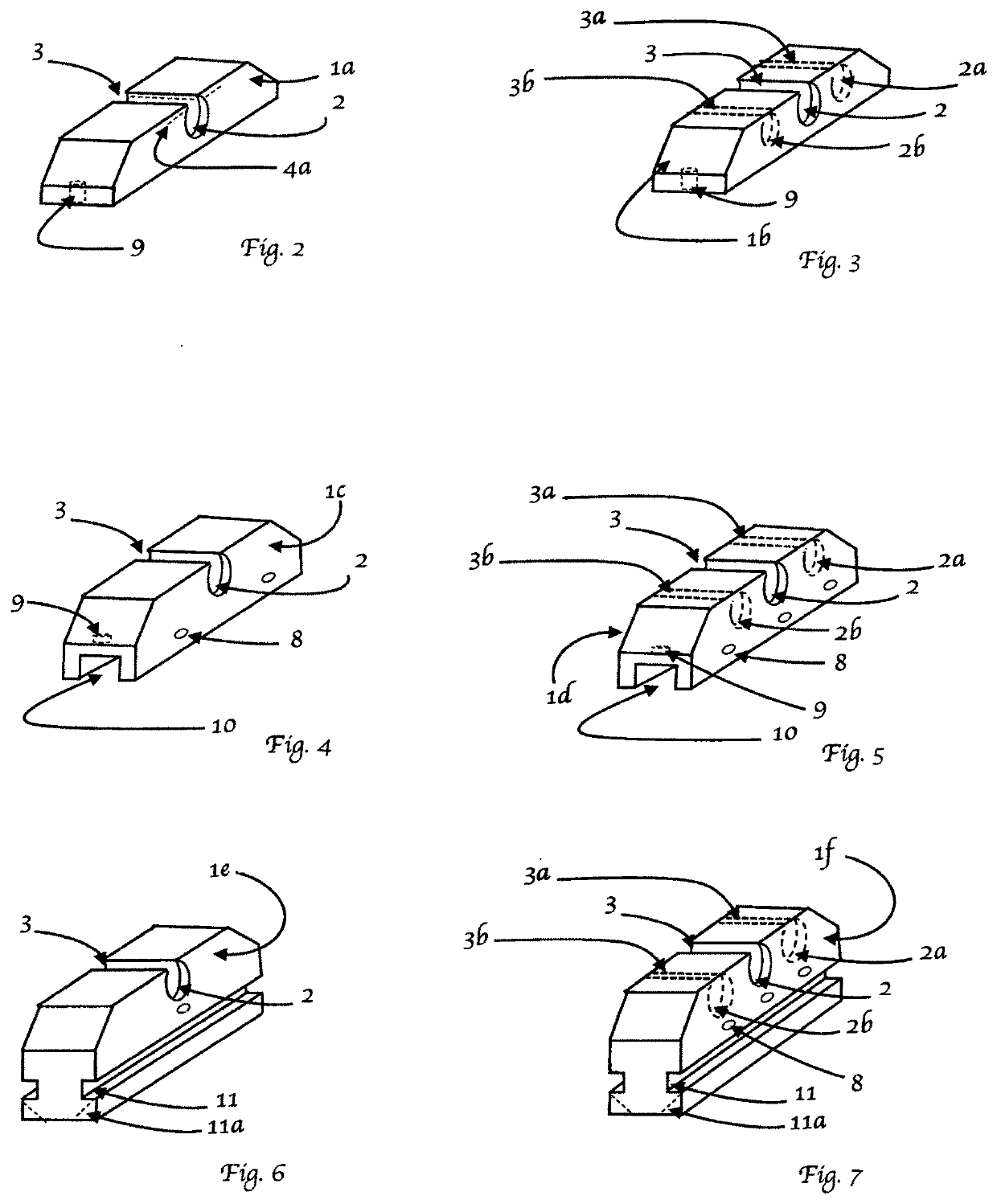

Vacuum pump

InactiveUS20060228246A1Accurate clearanceResists undesirable shifting of internal partRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesPump chamberEngineering

A vacuum pump may include a stator located between an intake plate and a back plate. Mating portions on the intake plate and back plate may be used to properly locate the stator. The stator may comprise a tubular piece of material. The stator may include two internal pump chambers separated by a divider plate. In some embodiments, the divider plate may have a fluid passageway extending therethrough. A rotor in each chamber may include vanes and may be offset from the center of the chamber. Each rotor may be fixed to a rotatable shaft for operation of the vacuum pump.

Owner:RITCHIE ENG

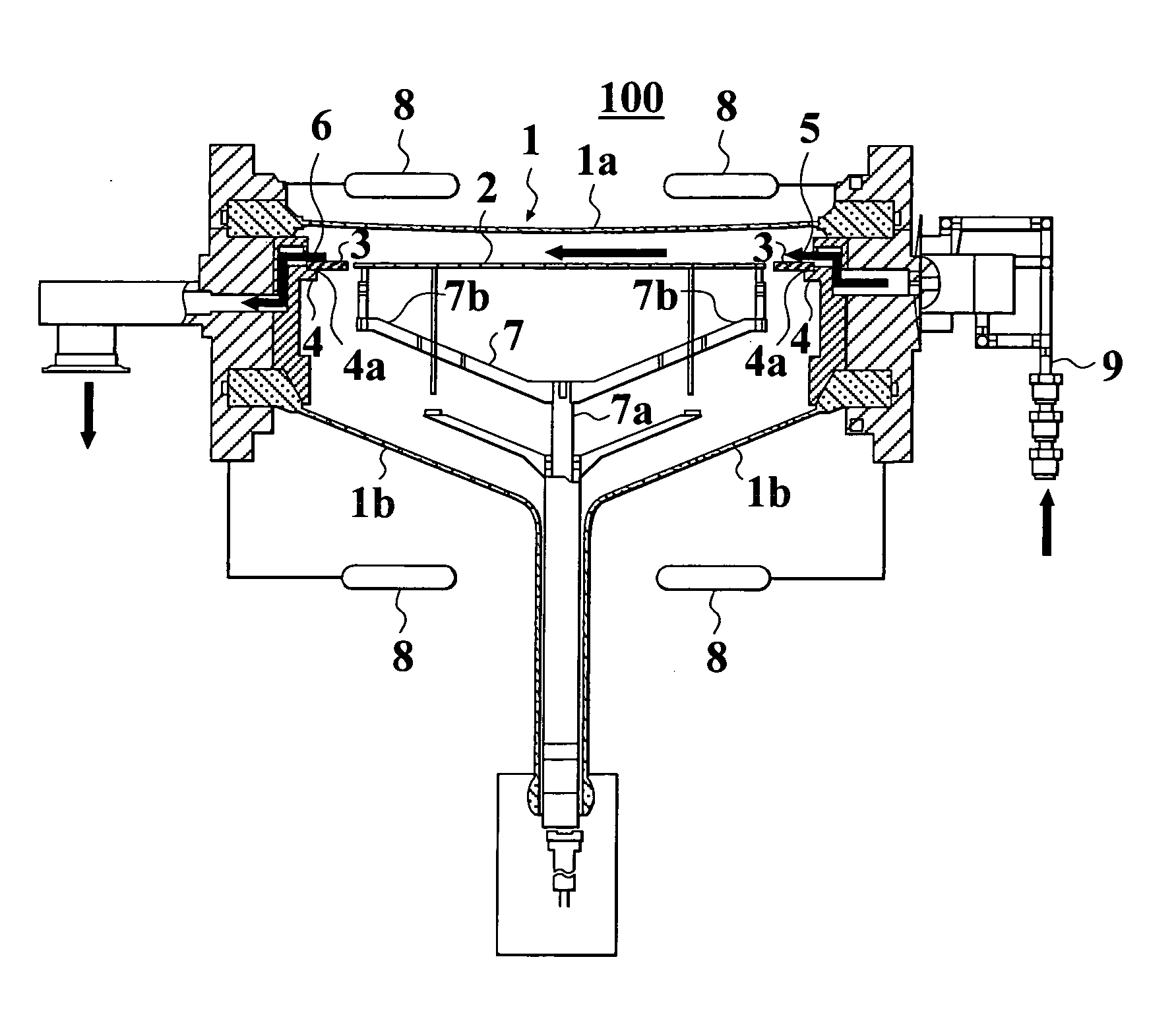

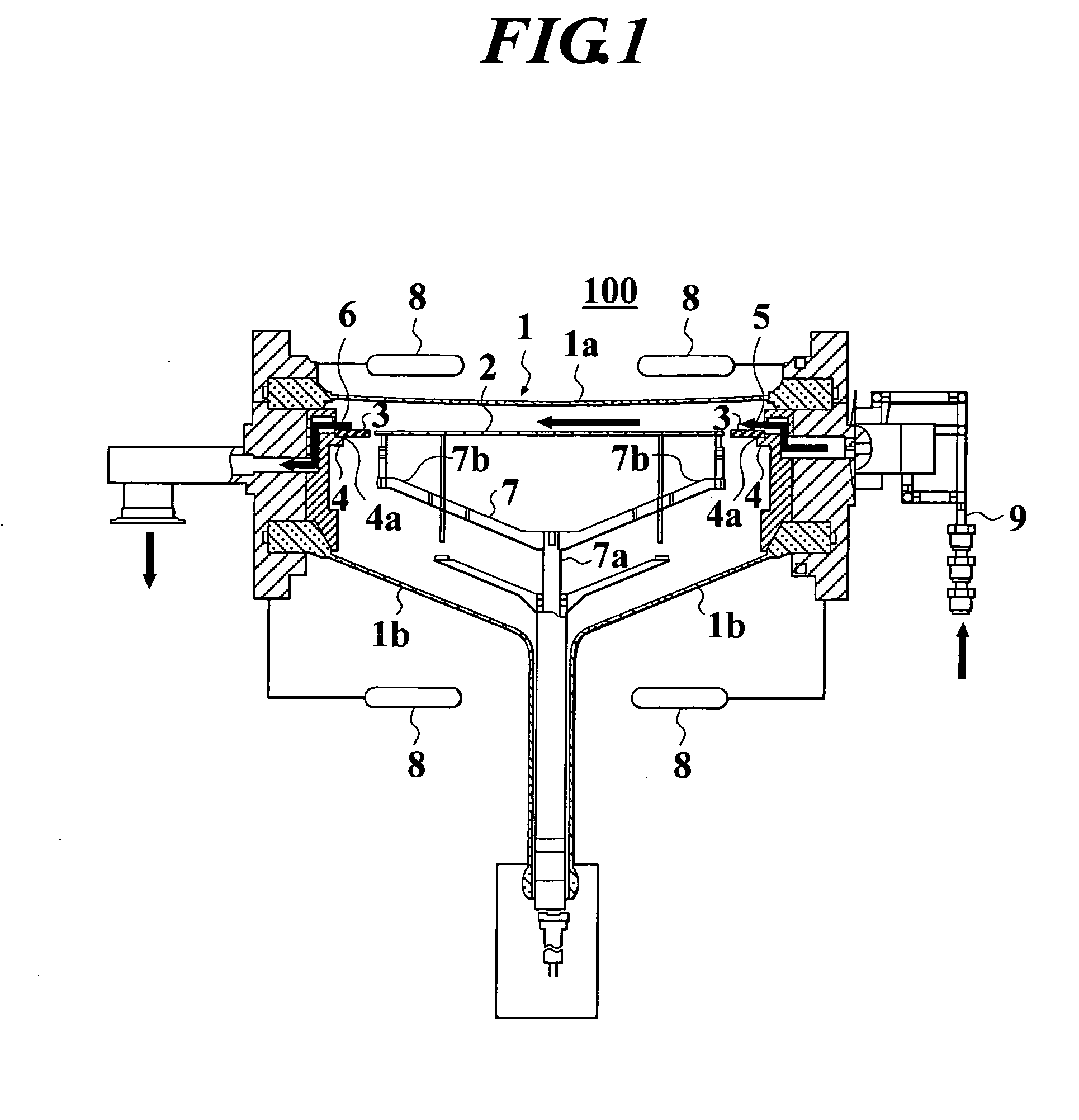

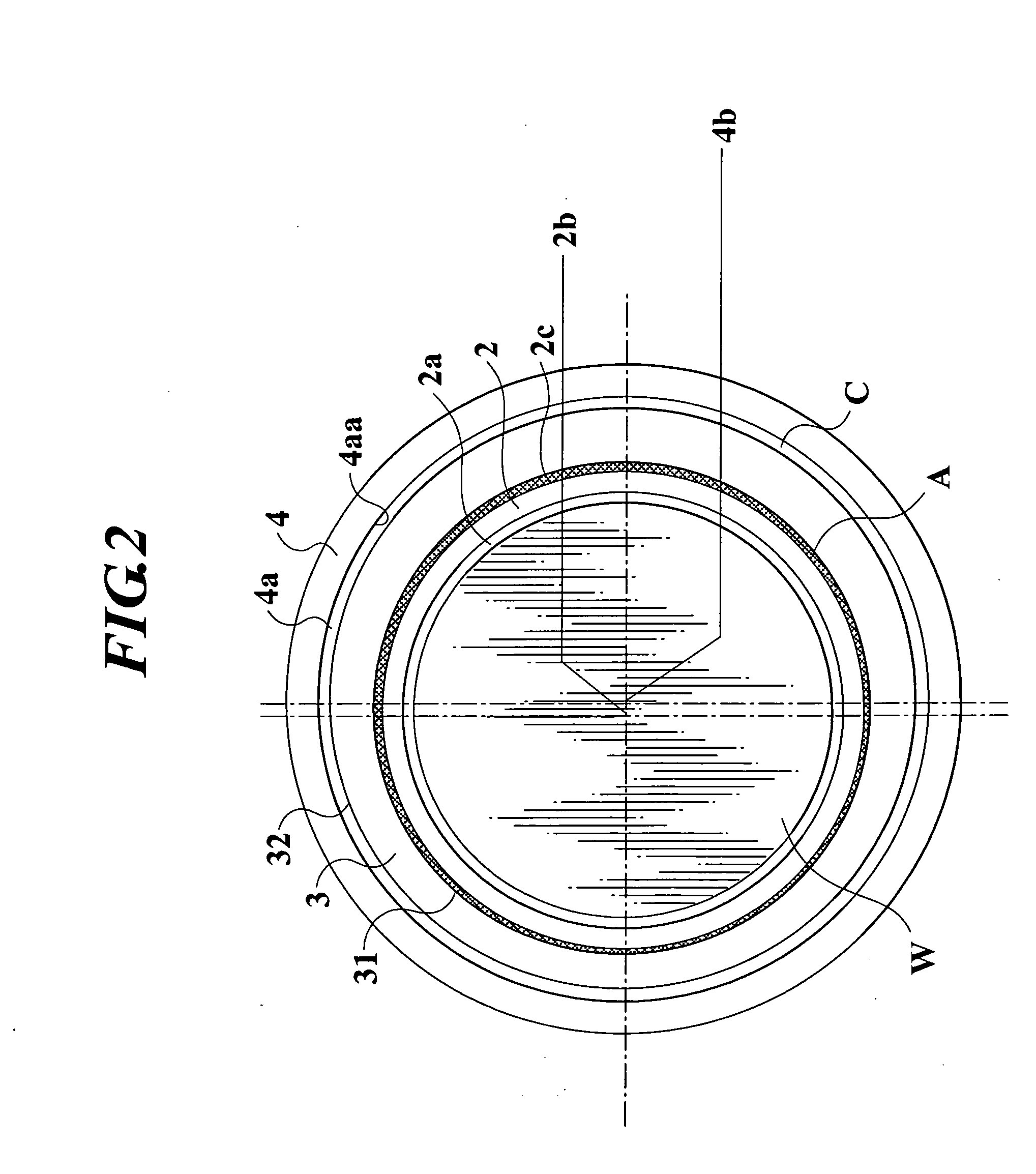

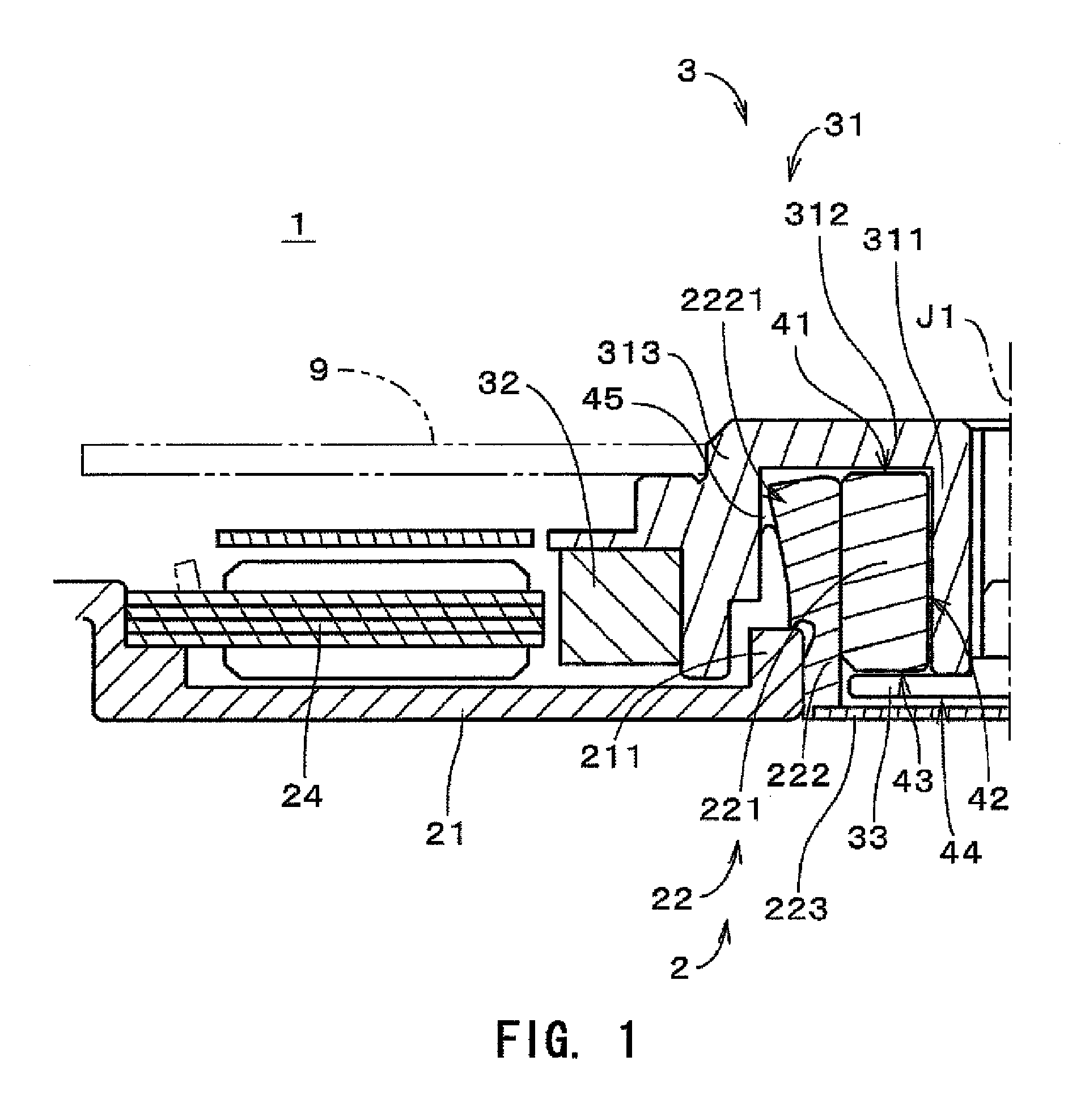

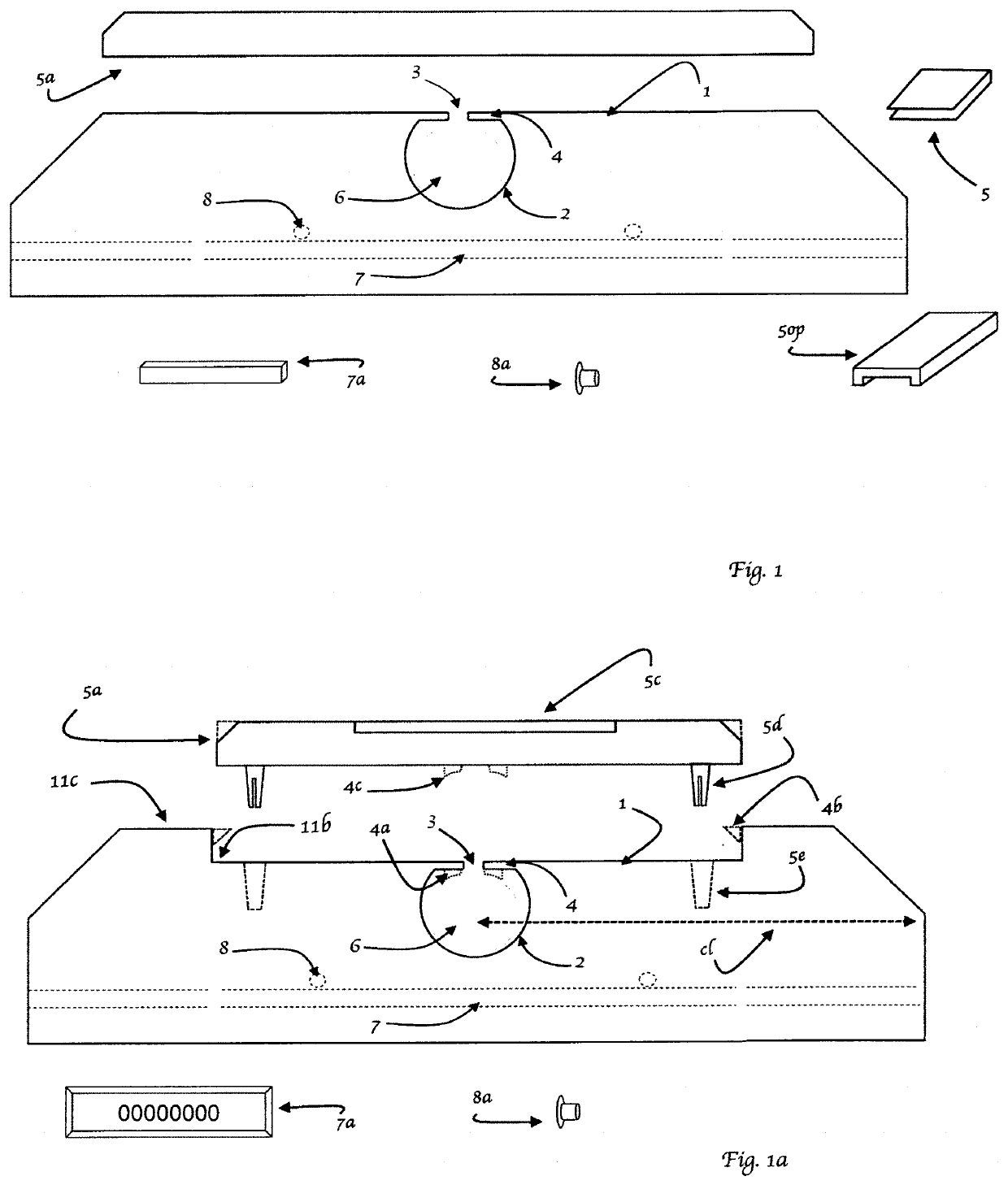

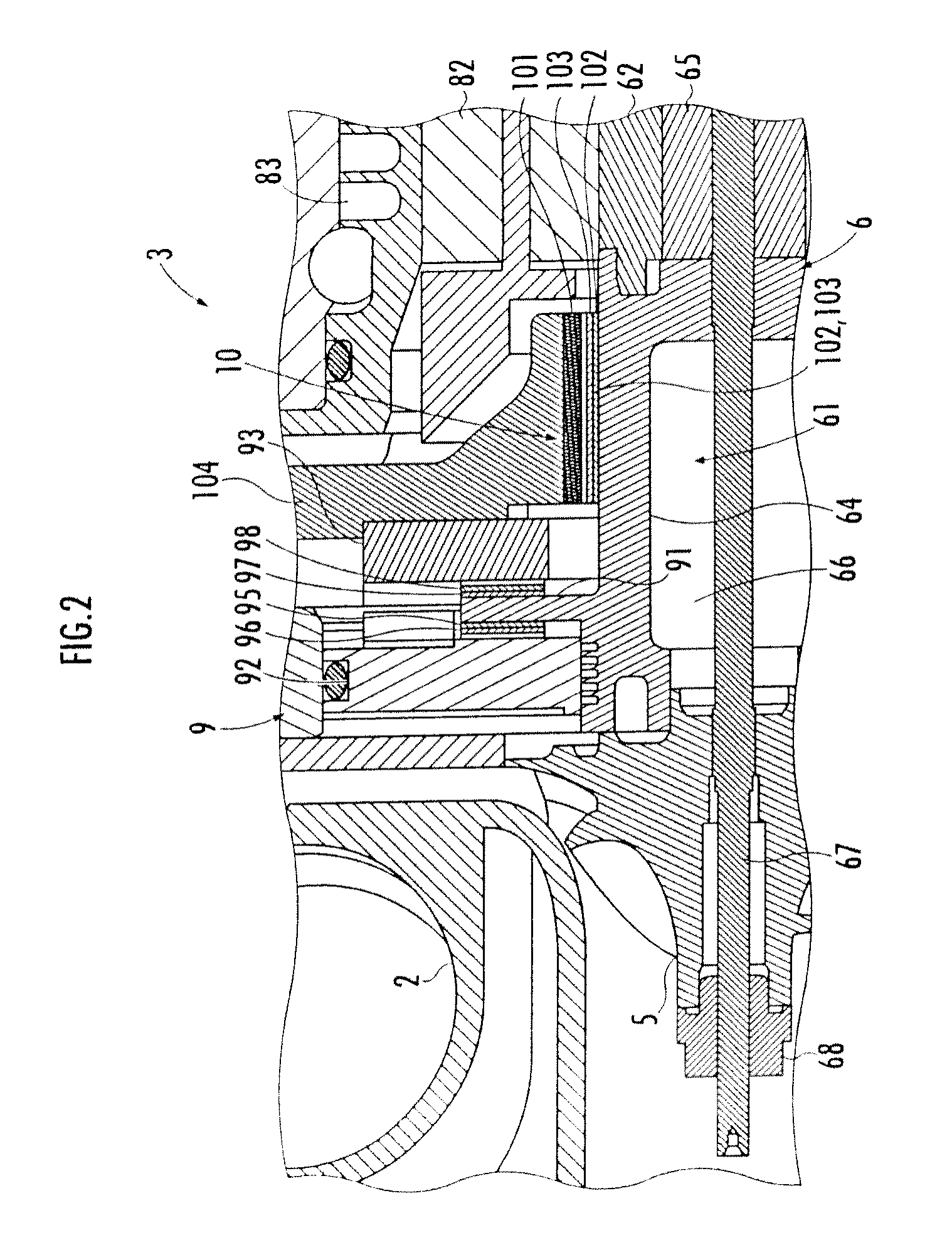

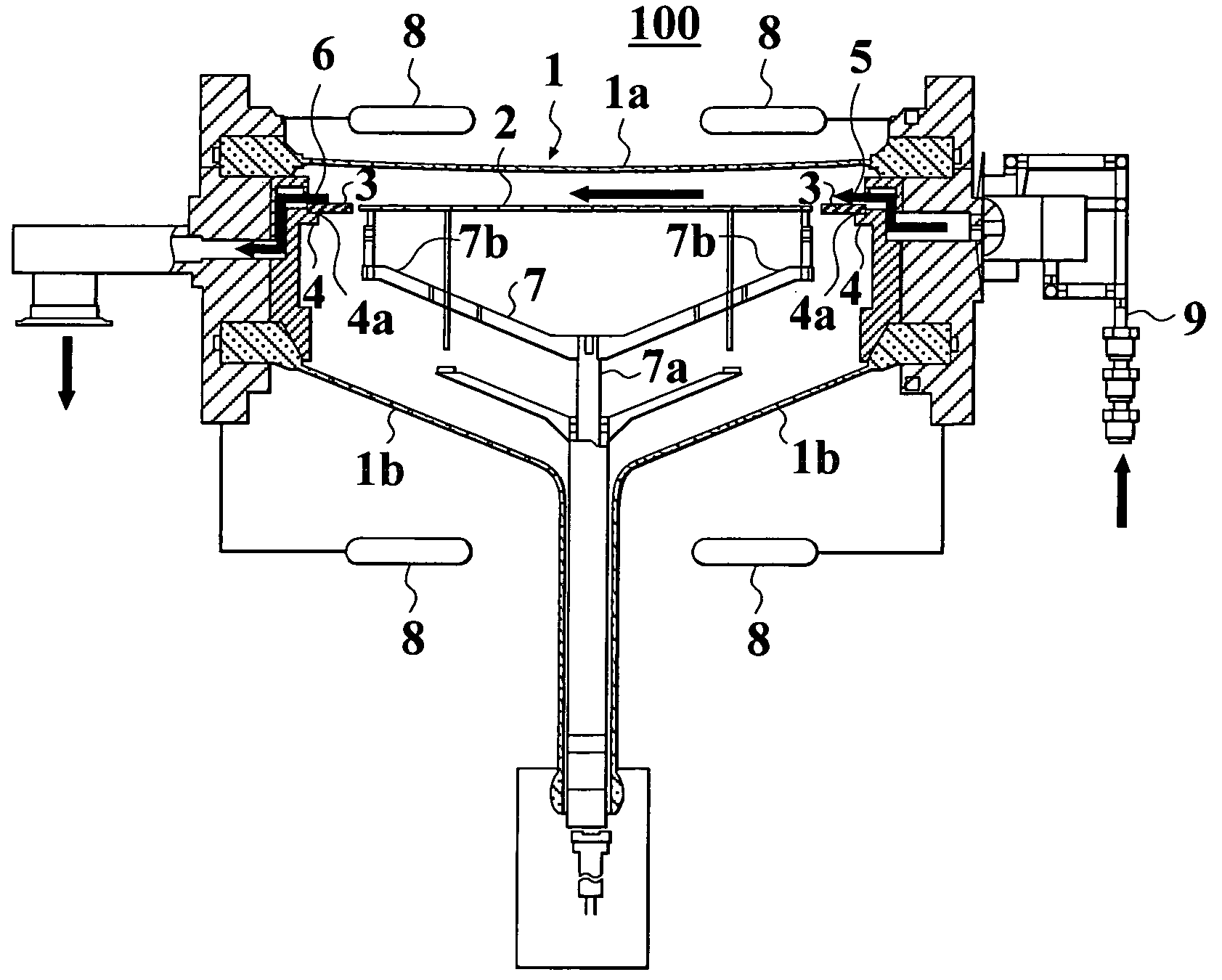

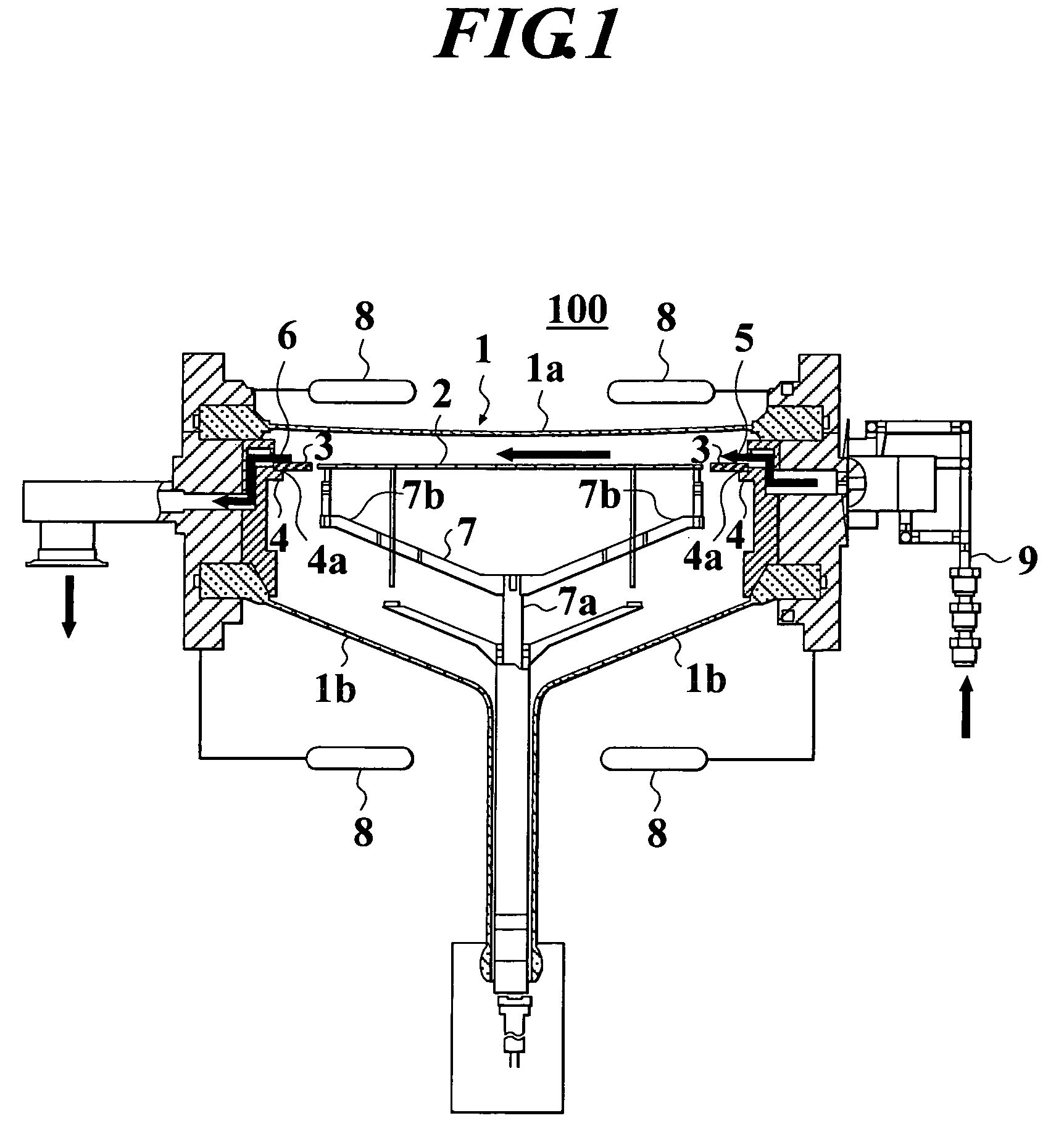

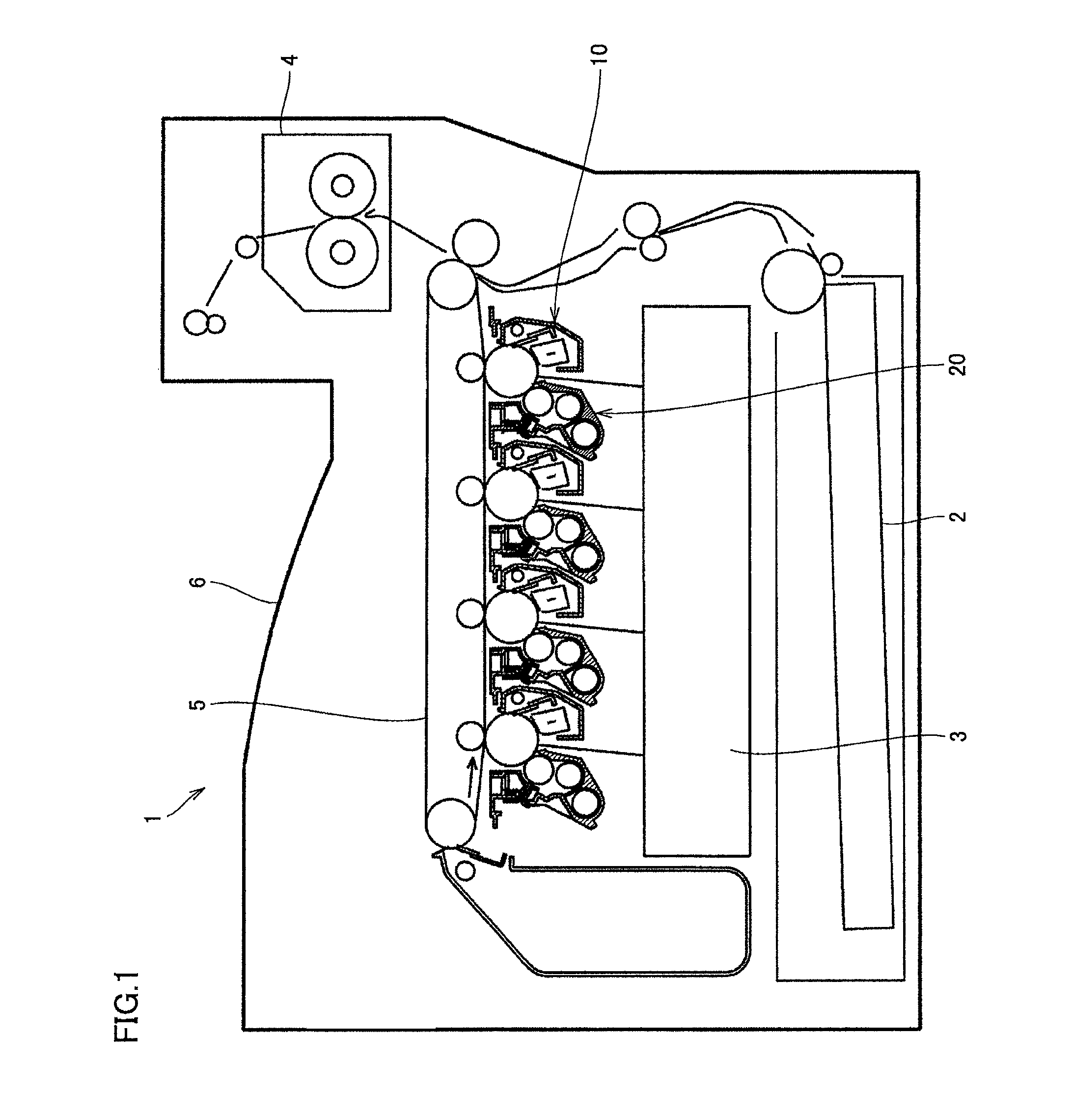

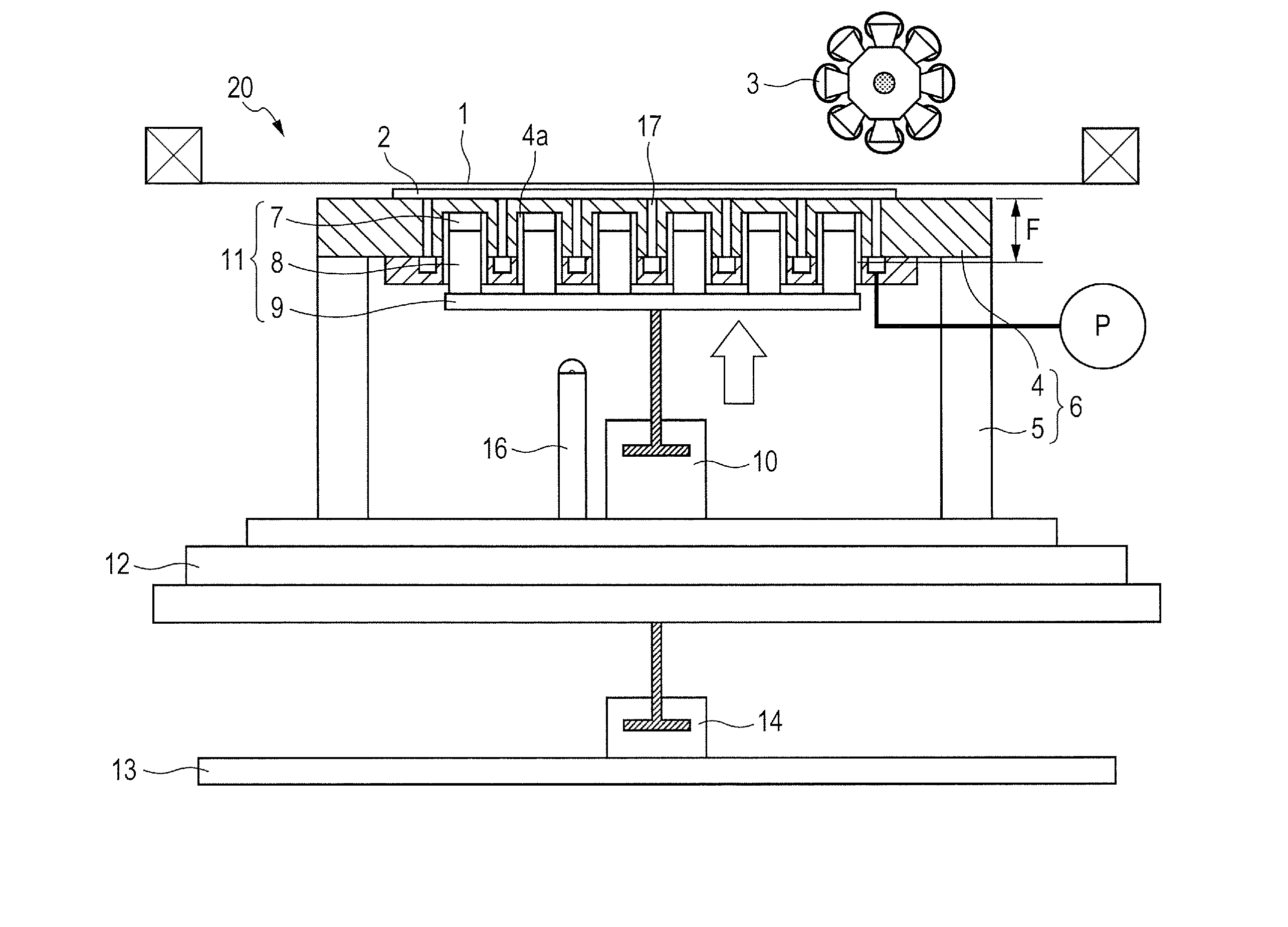

Heat treatment device and heat treatment method

InactiveUS20050106524A1Distance minimizationSuppress generationMuffle furnacesSemiconductor/solid-state device manufacturingEngineeringHeat treated

A heat treatment apparatus (100) having: a susceptor (2) rotatably provided in a heat treatment vessel (1), on which a wafer (W) is placed; a preheat ring (3) surrounding a periphery of the susceptor (2) to be close to and in non-contact with the susceptor, which is supported by a base (4) provided in the heat treatment vessel (1); and a heating apparatus (8) for heating a wafer (W) placed on the susceptor (2), wherein the preheat ring (3) is formed such that an inner peripheral center (31a) is eccentric to an outer periphery (32). The preheat ring (3) is moved around the susceptor (2); the preheat ring (3) is positioned to minimize a distance between the inner peripheral center (31a) of the preheat ring (3) and the center (2b) of the susceptor (2); and thereafter a heat treatment is performed to a wafer (W).

Owner:SHIN-ETSU HANDOTAI CO LTD

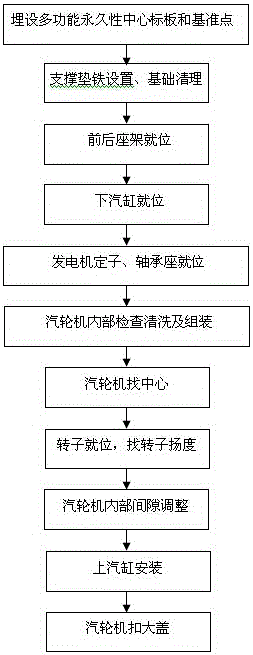

Method for mounting condensing steam turbines

ActiveCN106285793AReference measurement error minimizationReduce labor efficiencyMachines/enginesEngine componentsImpellerStator

The invention particularly discloses a method for mounting condensing steam turbines. The method is characterized by comprising embedding multifunctional permanent central standard plates and reference points; arranging support sizing blocks and cleaning foundations; mounting front and rear seat frames; mounting lower steam cylinders; mounting stators of power generators and bearing blocks; checking, cleaning and assembling the insides of the steam turbines and centering the steam turbines; finding up-rising inclination of rotors of the steam turbines and adjusting internal clearance of the steam turbines; mounting upper steam cylinders; assembling large covers of the steam turbines by means of fastening. The method has the advantages that reference measurement errors due to reference point and central standard plate embedding can be minimized; environmental influence on the labor efficiency when the steam cylinders are centered can be reduced; the accuracy of clearance between impellers and steam seals can be guaranteed; the mounting quality can be guaranteed by quality pre-control processes, accordingly, reworking phenomena can be completely eradicated, work can be effectively carried out at one step, the labor productivity can be improved, and the mounting construction periods can be guaranteed; the purpose of carrying out successful trial run at one step can be achieved, and excellent technical and economical effects can be realized.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

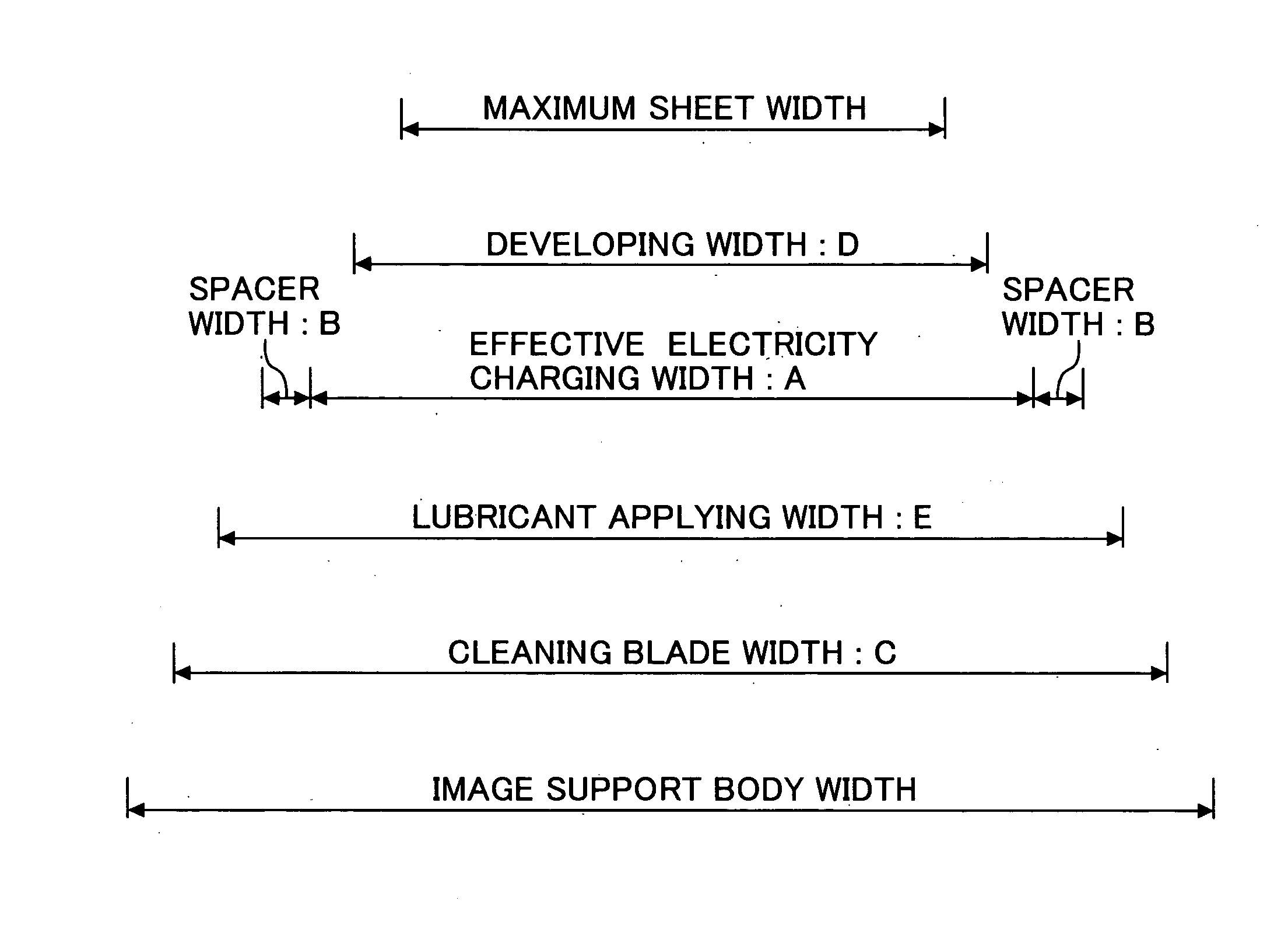

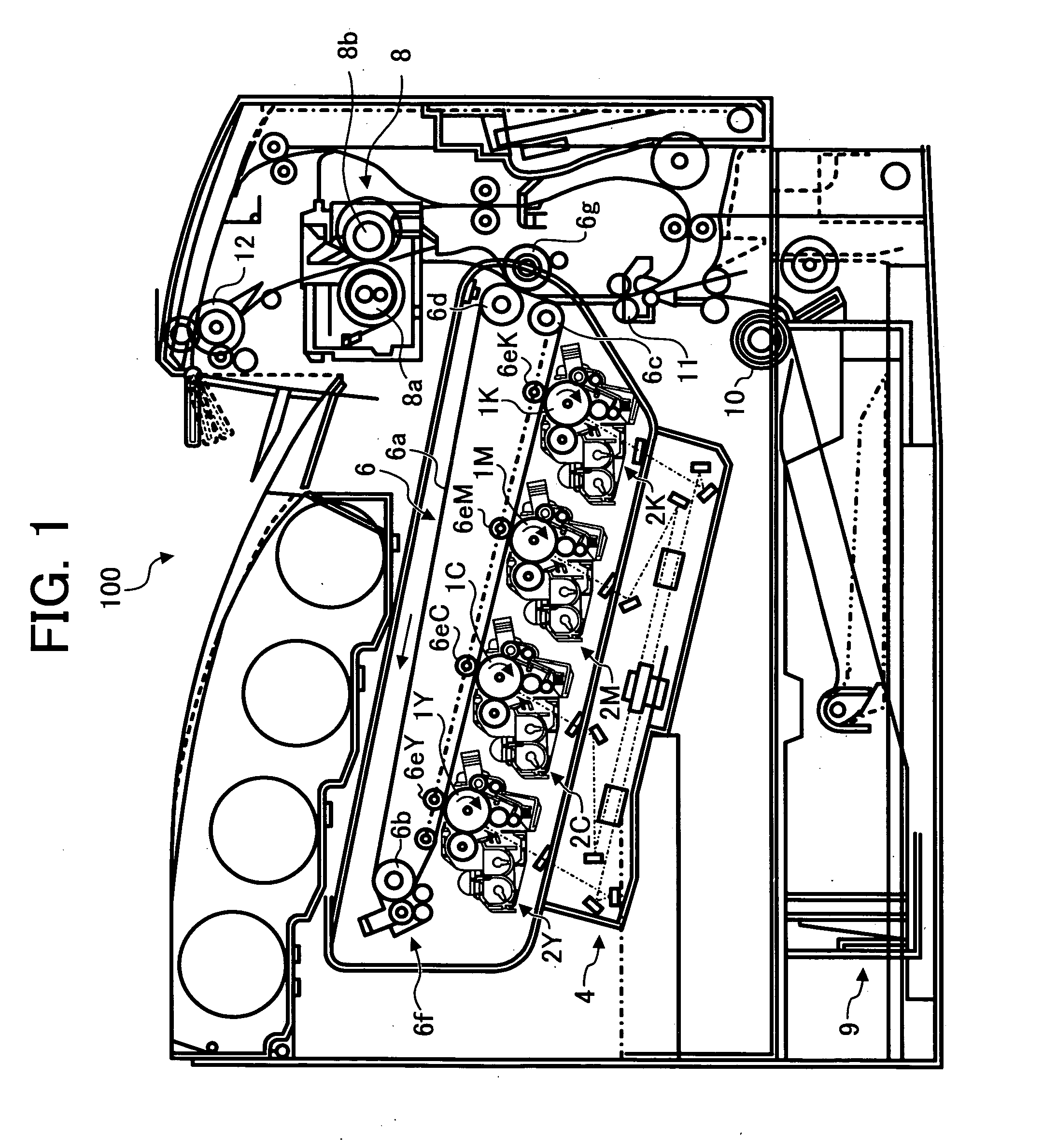

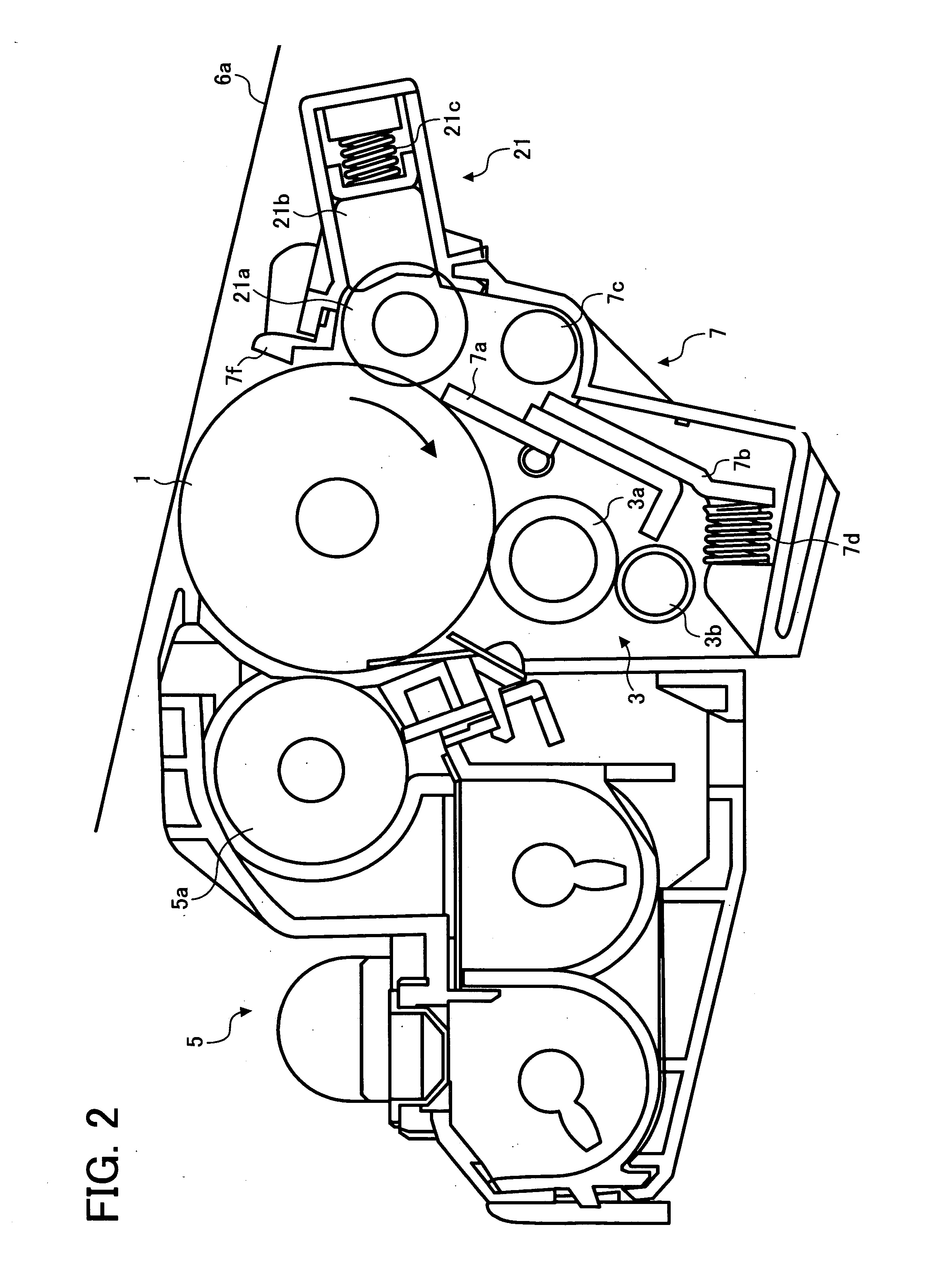

Image forming apparatus and toner

ActiveUS20060062594A1Reduce the amount requiredAccurate clearanceElectrographic process apparatusCorona dischargeLatent imageSpacer coupling

An image forming apparatus having an image support body configured to support a latent image, a charging member configured to provide a substantially uniform charge to a surface of the image support body and a spacer coupled to the charging member and configured to contact the image support body to maintain a gap between the image support body and the charging member. A cleaning part is configured to clean the surface of the image support body after developer is applied to the image support body and transferred to a recording medium. The cleaning part is configured to satisfy the relationship A+B≦C, where A is a width of the effective charging area of the charging member that charges a surface of the image support body, B is a total width of the spacer that contacts the image support body, and C is a width of cleaning part that contacts the image support body.

Owner:RICOH KK

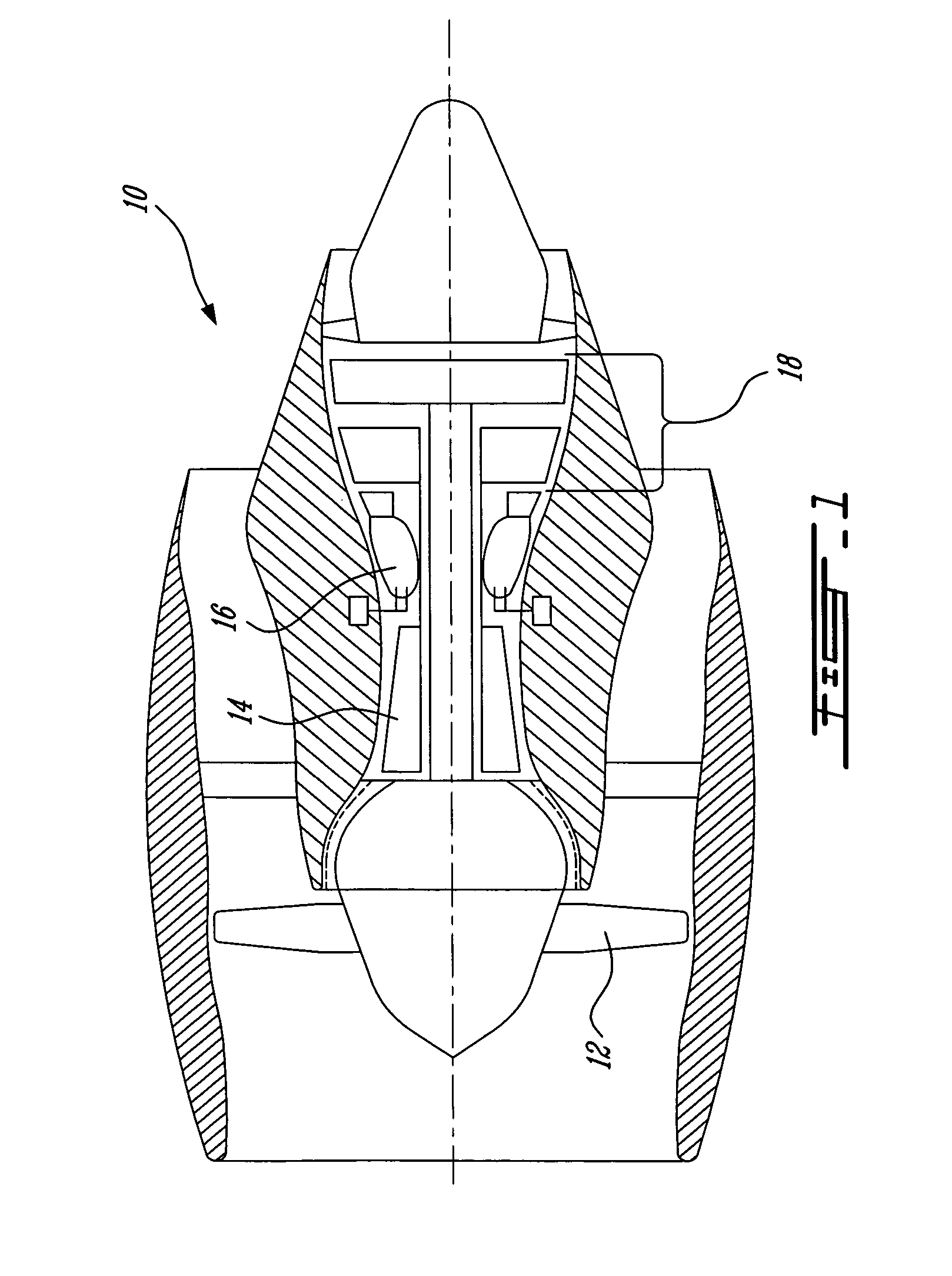

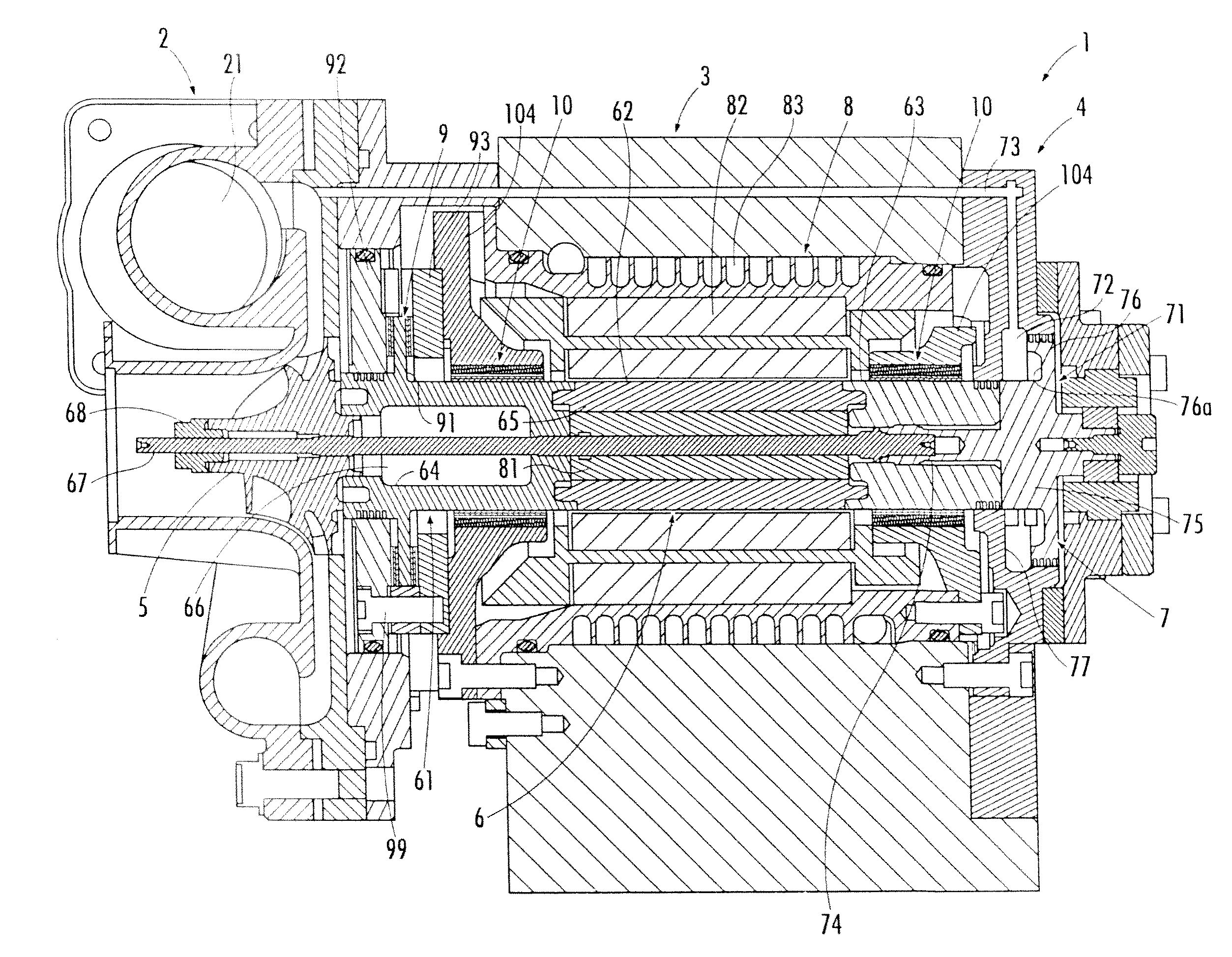

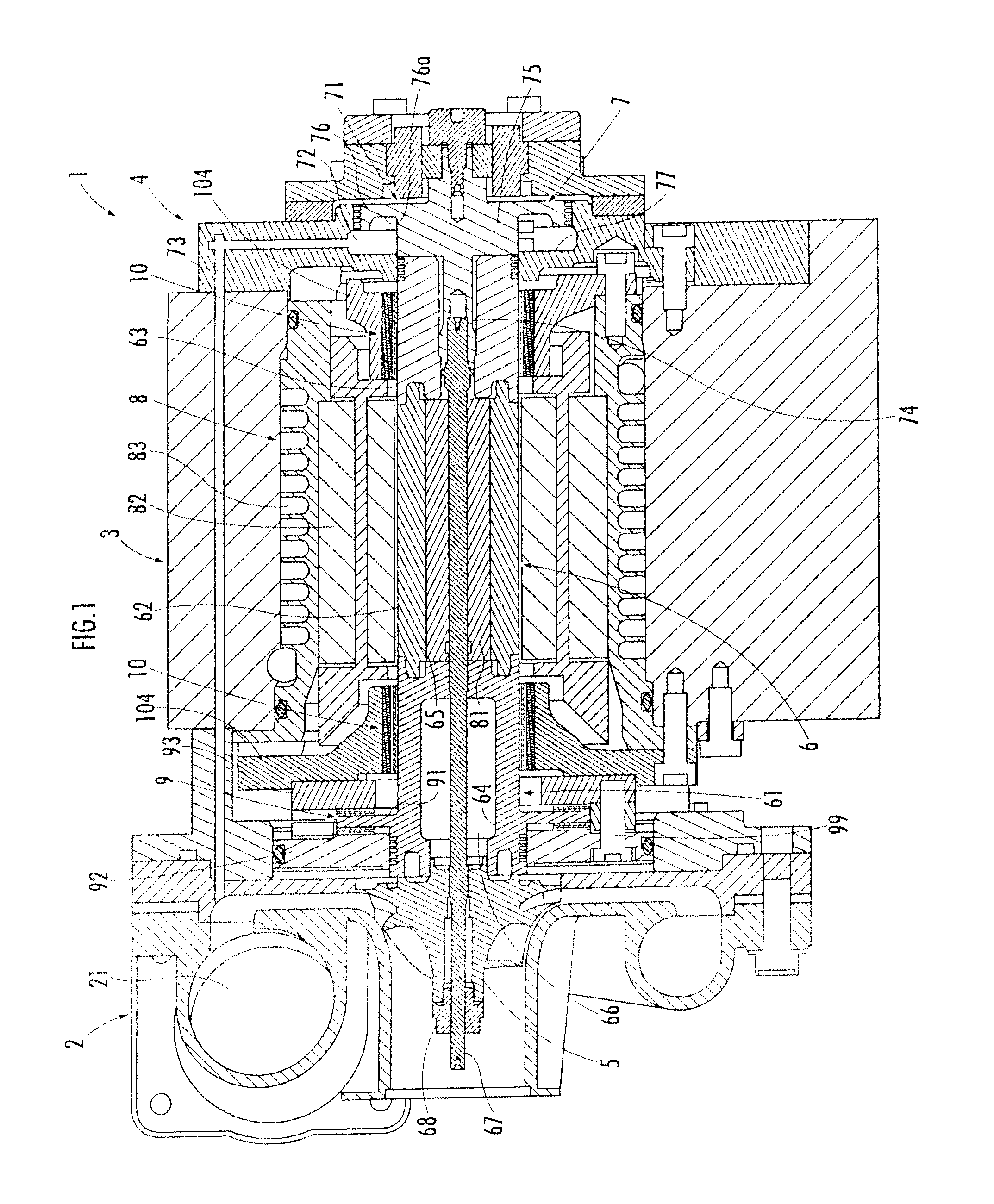

Electric compressor

ActiveUS20090257895A1Reduction in size and costHigh efficiencyPump componentsShaftsImpellerLinear compressor

An electric turbo compressor is an air compressor to be used in a fuel cell system, and includes a housing comprised o a compression casing, a motor casing, and a canceller casing, and the housing houses therein an impeller, a rotary shaft, a thrust canceller (a load cancellation section), and a motor unit. The rotary shaft is supported by a thrust air bearing in its thrust direction, and is axially supported by a radial air bearing in its rotating direction. A thrust load is generated at the rotary shaft when the number of rotations of the impeller increases. The pressure of the compressed air acts to the pressure chamber from the compressed air lead-out section of the compression casing via the compressed air passage, and this pressure acts on the canceller flange of the canceller shaft so as to generate a load towards the rear of the rotary shaft. Therefore, the thrust load is cancelled out.

Owner:HONDA MOTOR CO LTD

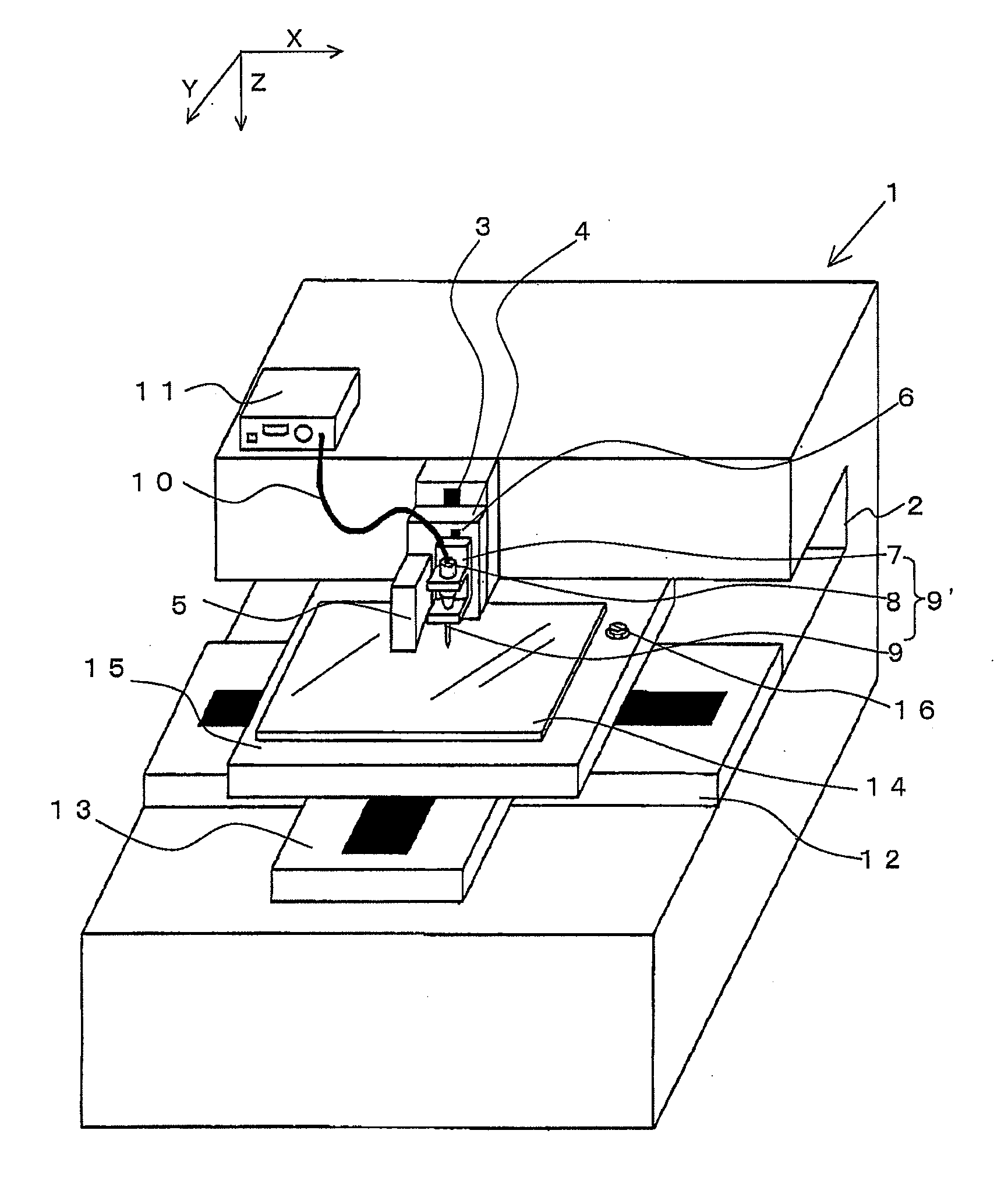

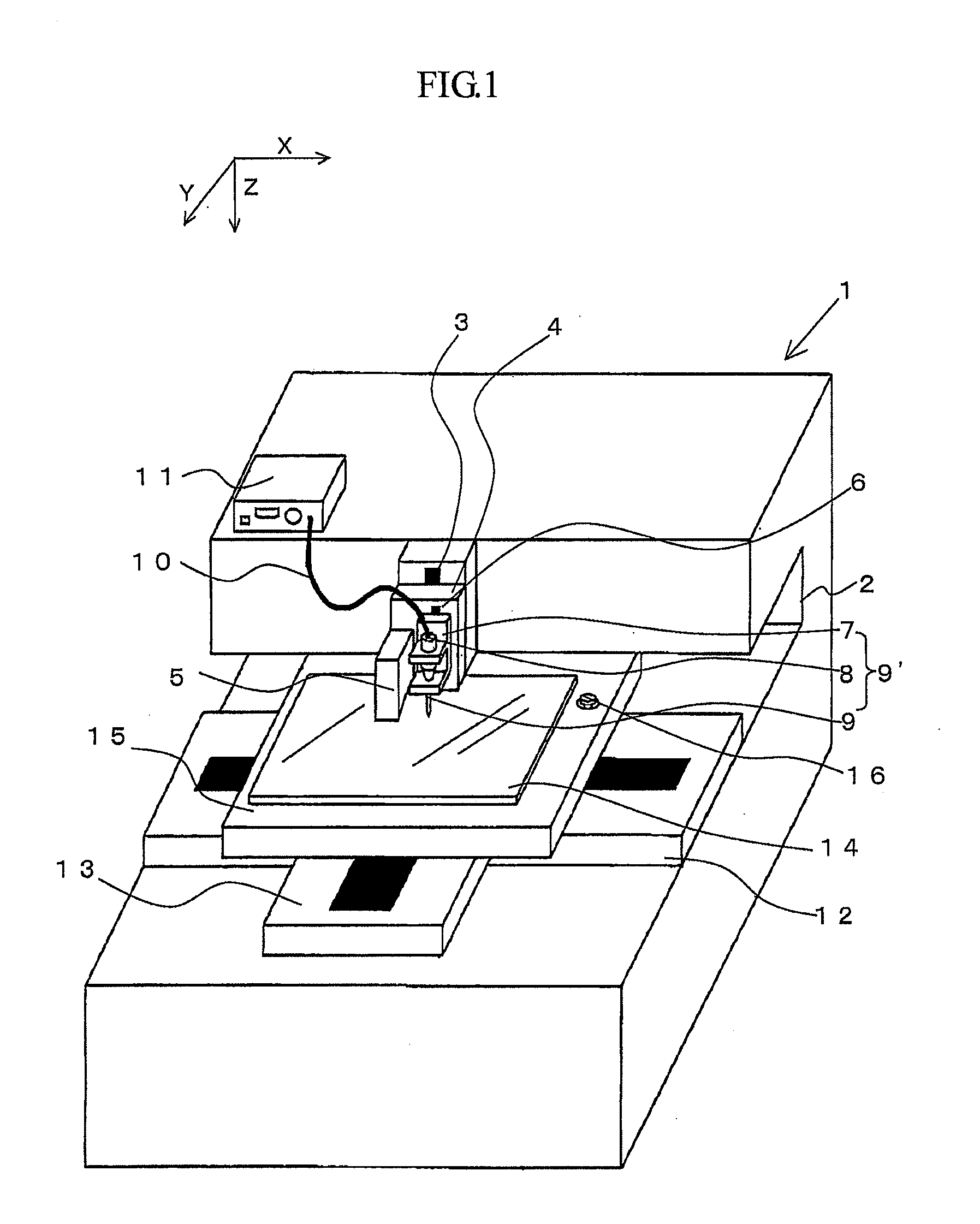

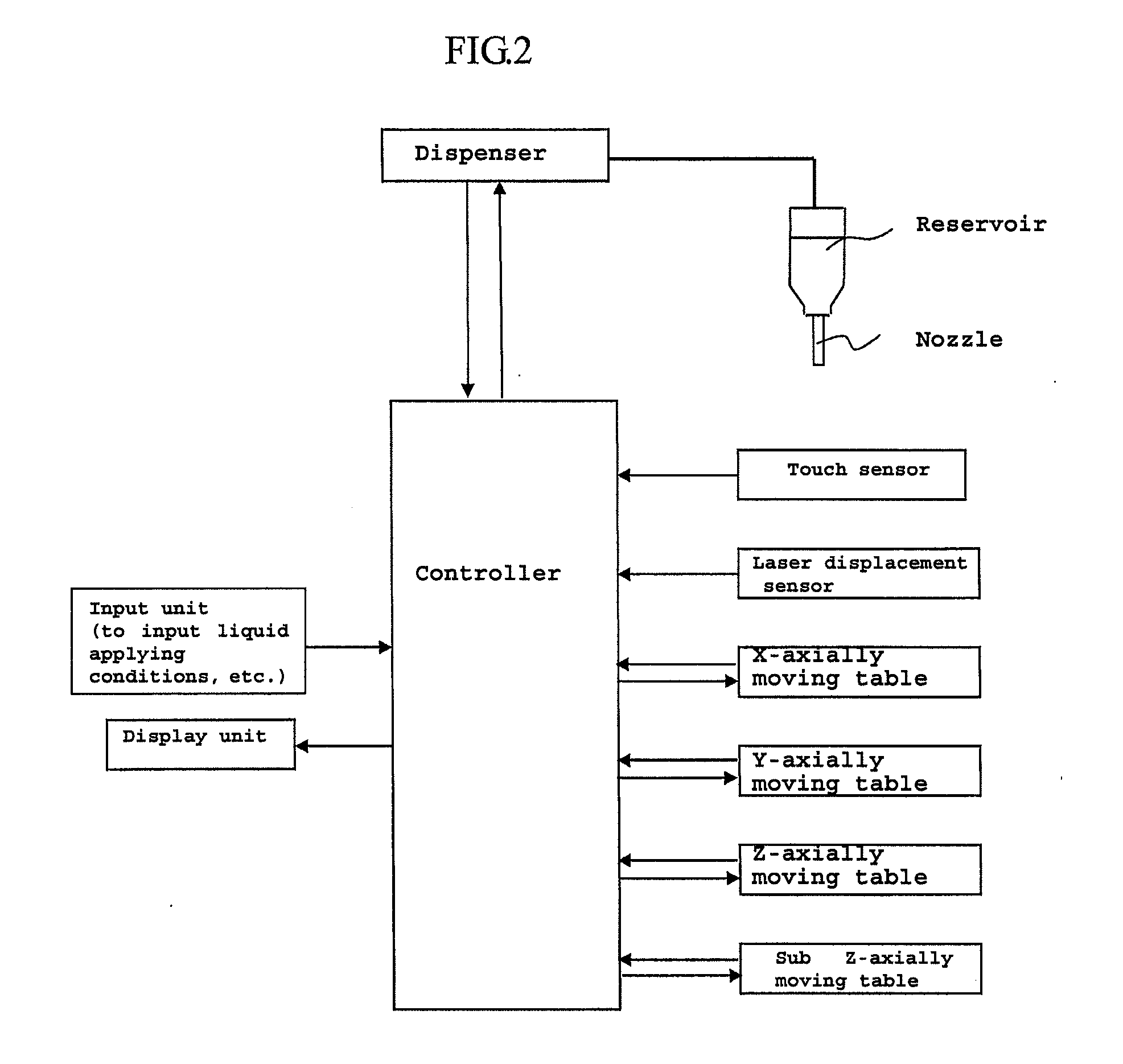

Method of adjusting nozzle clearance of liquid application apparatus, and liquid application apparatus

ActiveUS20100175759A1Accurate acquisitionReduce impactValve arrangementsLiquid surface applicatorsEngineeringConductor Coil

A method of adjusting a clearance between a nozzle and a work to a desired value in a liquid application apparatus wherein a liquid discharged from the nozzle is applied to the work, comprises (a) a distance measurement step of measuring, by using a non-contact distance sensor positioned in parallel with the nozzle, a distance from the non-contact distance sensor to a reference surface of a contact detection sensor detecting a contact of the nozzle front end with the reference surface opposite to the nozzle front end, (b) a nozzle contacting step of making contacts with the nozzle front end and the reference surface of the contact detection sensor to obtain a positional information of the nozzle, (c) a distance measurement step of measuring, by the non-contact distance sensor, a distance from the non-contact distance sensor to the work before applying the liquid to the work, and (d) a step of adjusting a nozzle clearance to a desired value based on the relative positional information between the nozzle and the non-contact distance sensor determined by the distance measurement step (a) and the nozzle contacting step (b), and the distance determined by the distance measurement step (c), thereby to enable the nozzle clearance adjustment based on accurate information of the relative position between the nozzle and the non-contact distance sensor in the nozzle clearance direction, which is less influenced by the work's windings, heaves or others.

Owner:MUSASHI ENG INC

Vacuum pump

InactiveUS20060228242A1Accurate clearanceResists undesirable shifting of internal partRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesPump chamberEngineering

A vacuum pump may include a tubular stator located between an intake plate and a back plate. Mating portions on the intake plate and back plate may be used to properly locate the stator. The stator may include two internal pump chambers separated by a divider plate. The divider plate may be located within an internal cavity of the stator. A rotor in each chamber may include vanes and may be offset from the center of the chamber. Each rotor may be fixed to a rotatable shaft for operation of the vacuum pump. In some embodiments, the divider plate may have a fluid passageway extending therethrough. The fluid passageway may be located within the area swept by the rotors. In some embodiments, an exhaust outlet may include a flutter valve having a shaped surface that prevents the flutter valve from fully closing.

Owner:RITCHIE ENG

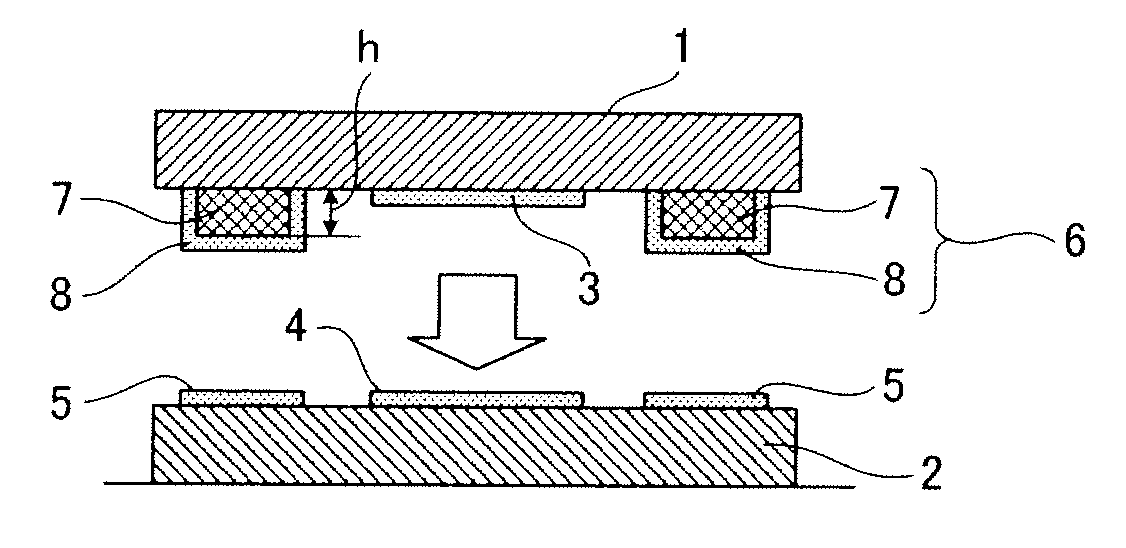

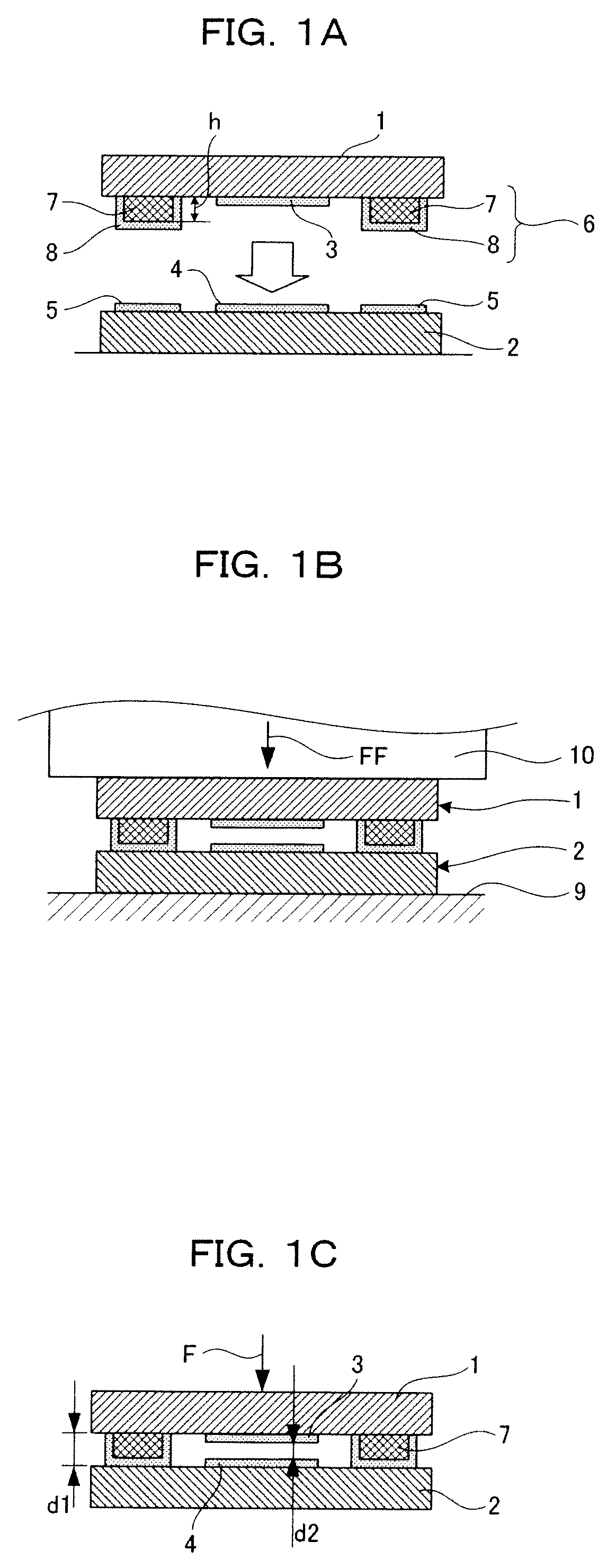

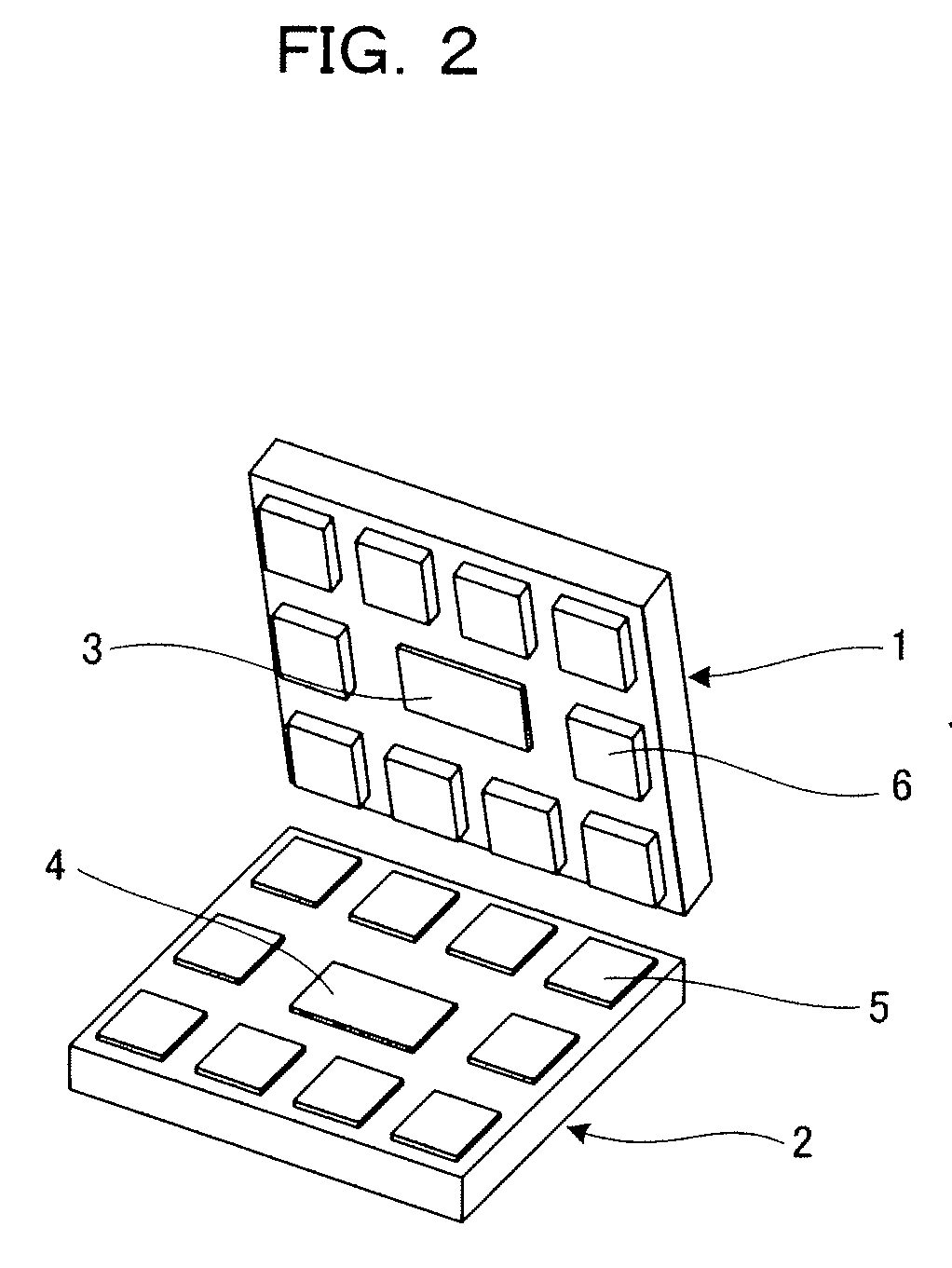

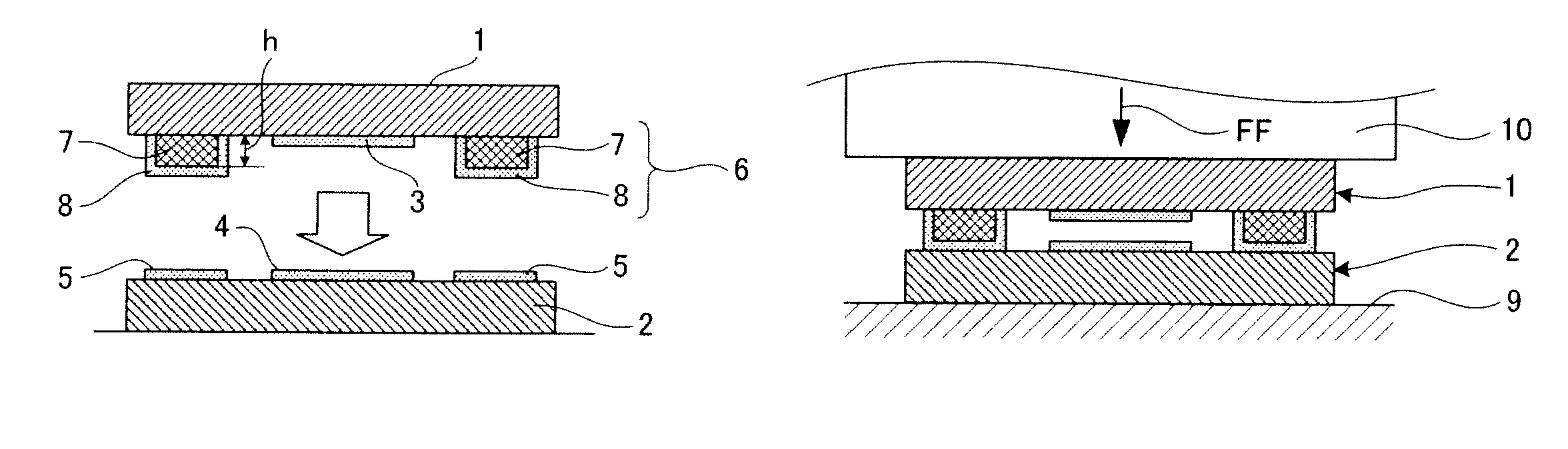

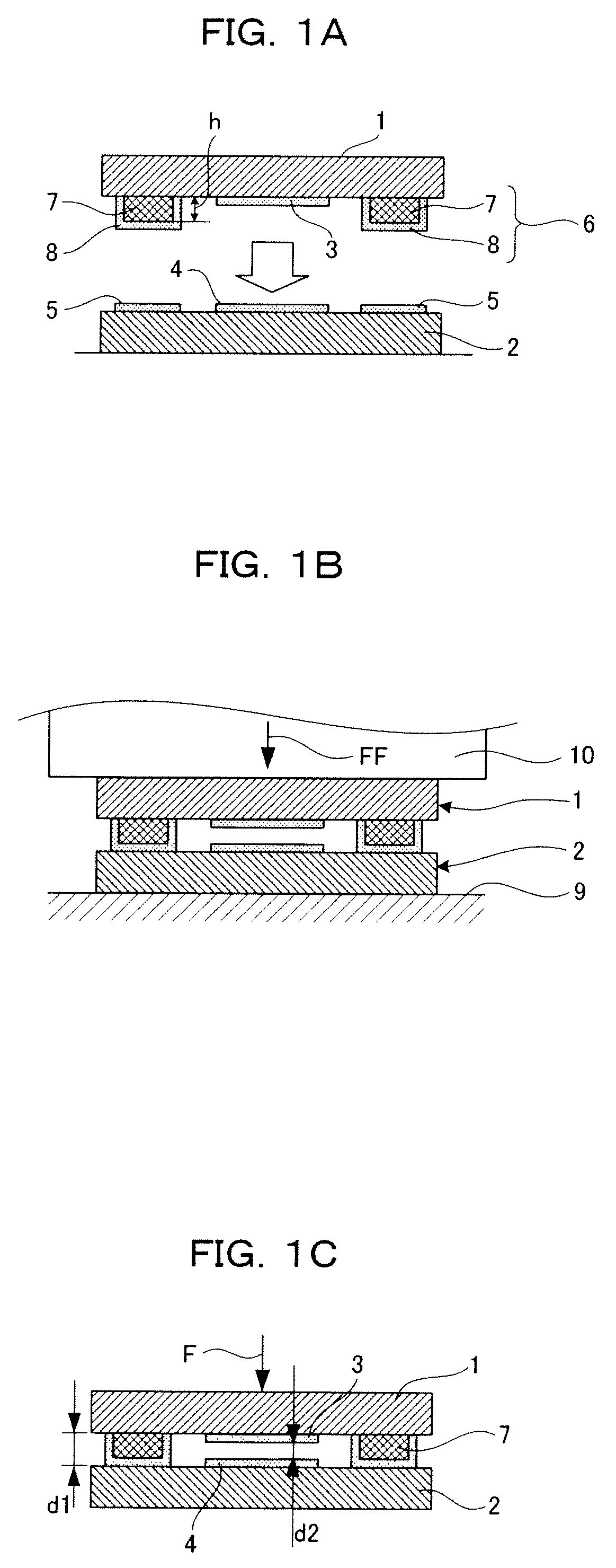

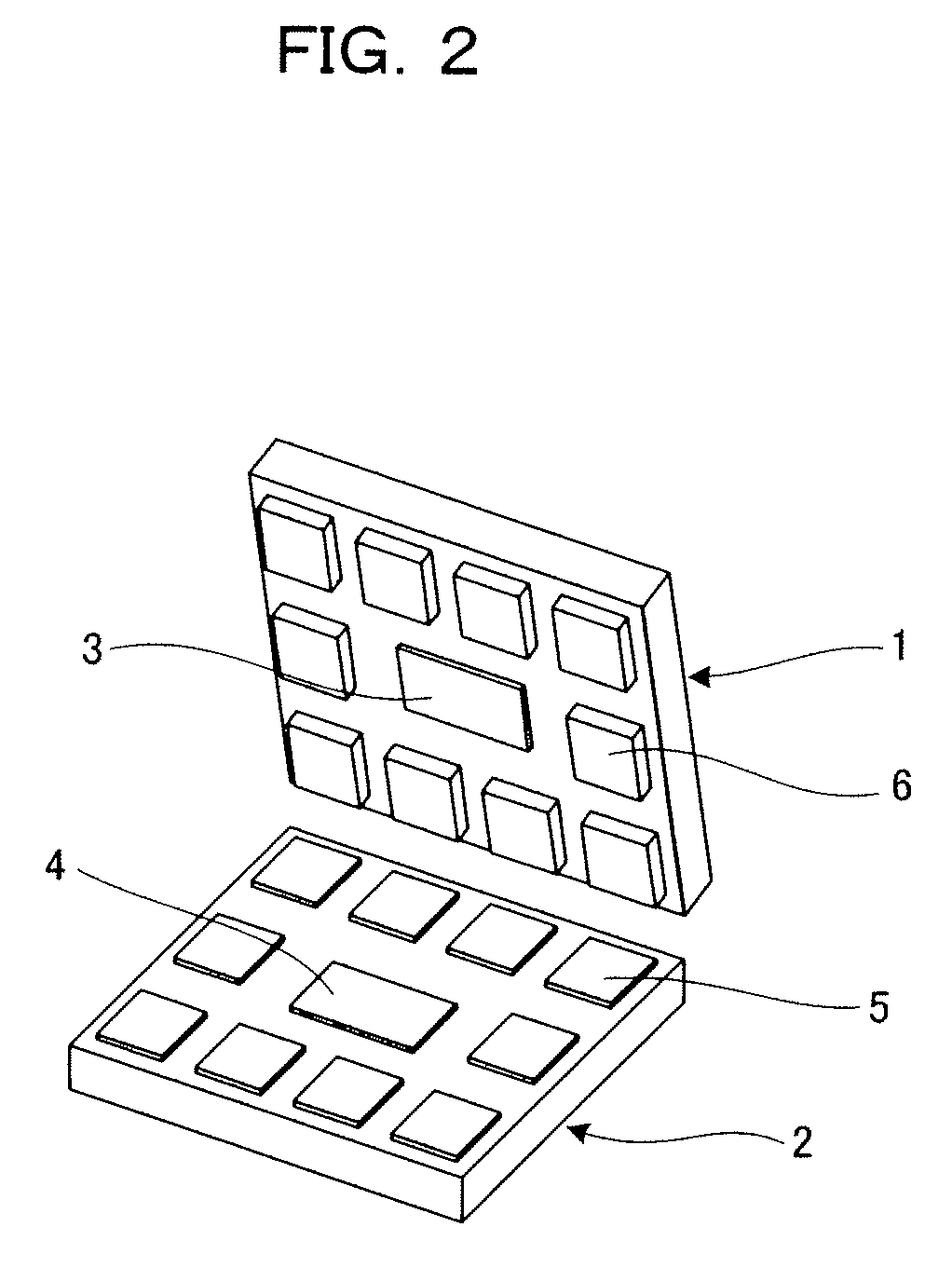

Electronic part and method of producing the same

InactiveUS20090140410A1Reduce areaAccurate clearanceSemiconductor/solid-state device detailsCapacitor with electrode distance variationEngineeringHardness

It is an object of the invention to provide an electronic part capable of forming an accurate gap between opposing substrates while also capable of decreasing the area of the electronic part, and a method of producing the same. A second electrode portion (6), having a core pattern (7) and a bump pattern (8) covering the surface thereof, is provided on a device substrate (1), the core pattern (7) is made of a material having hardness greater than that of the bump pattern (8), a first electrode portion (5) of the same material as the bump pattern (8) is provided on a bonding substrate (2), and a functional portion of the device substrate (1) and the first electrode portion (5) are electrically connected by direct bonding of the first electrode portion (5) and the bump pattern (8).

Owner:PANASONIC CORP

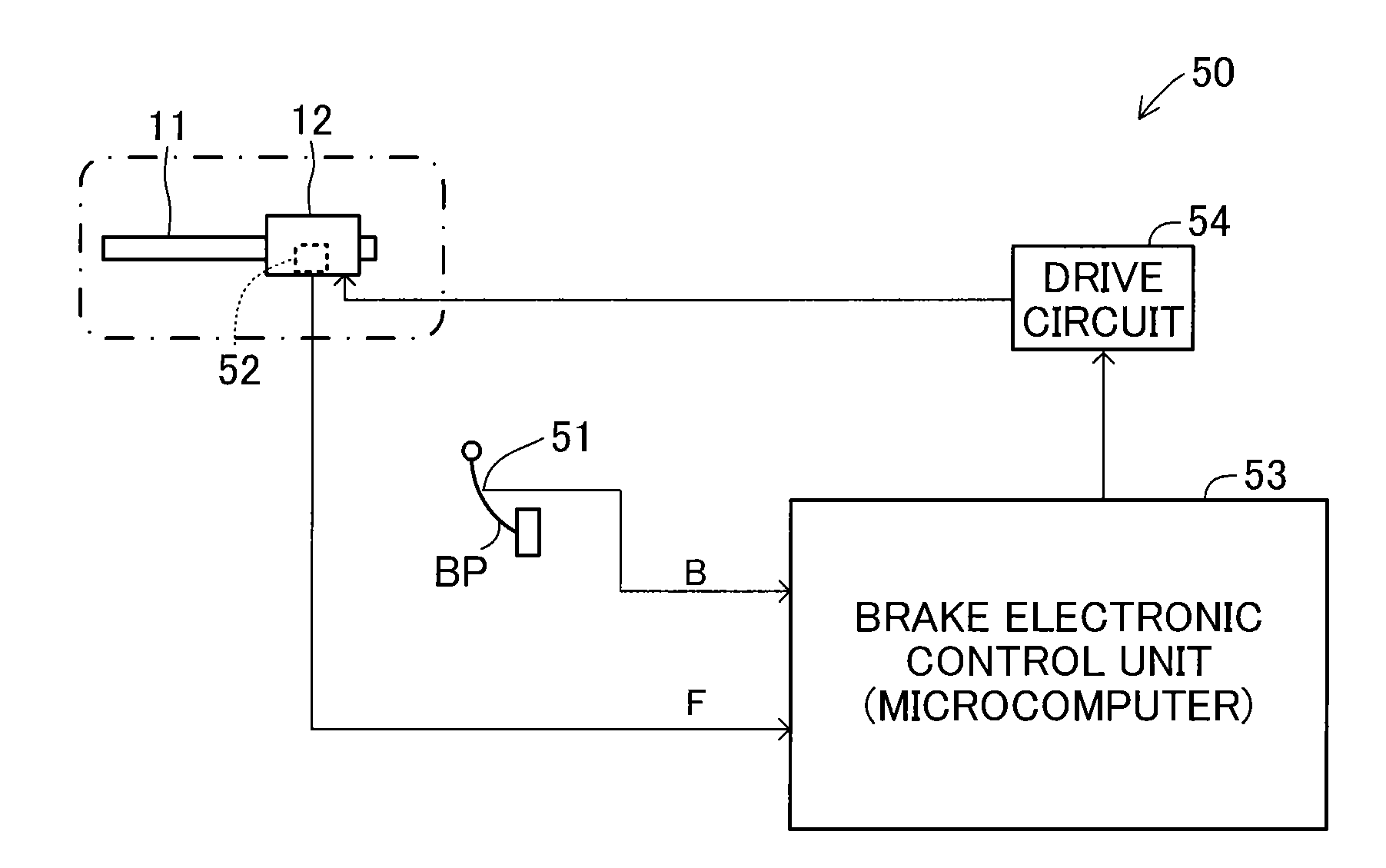

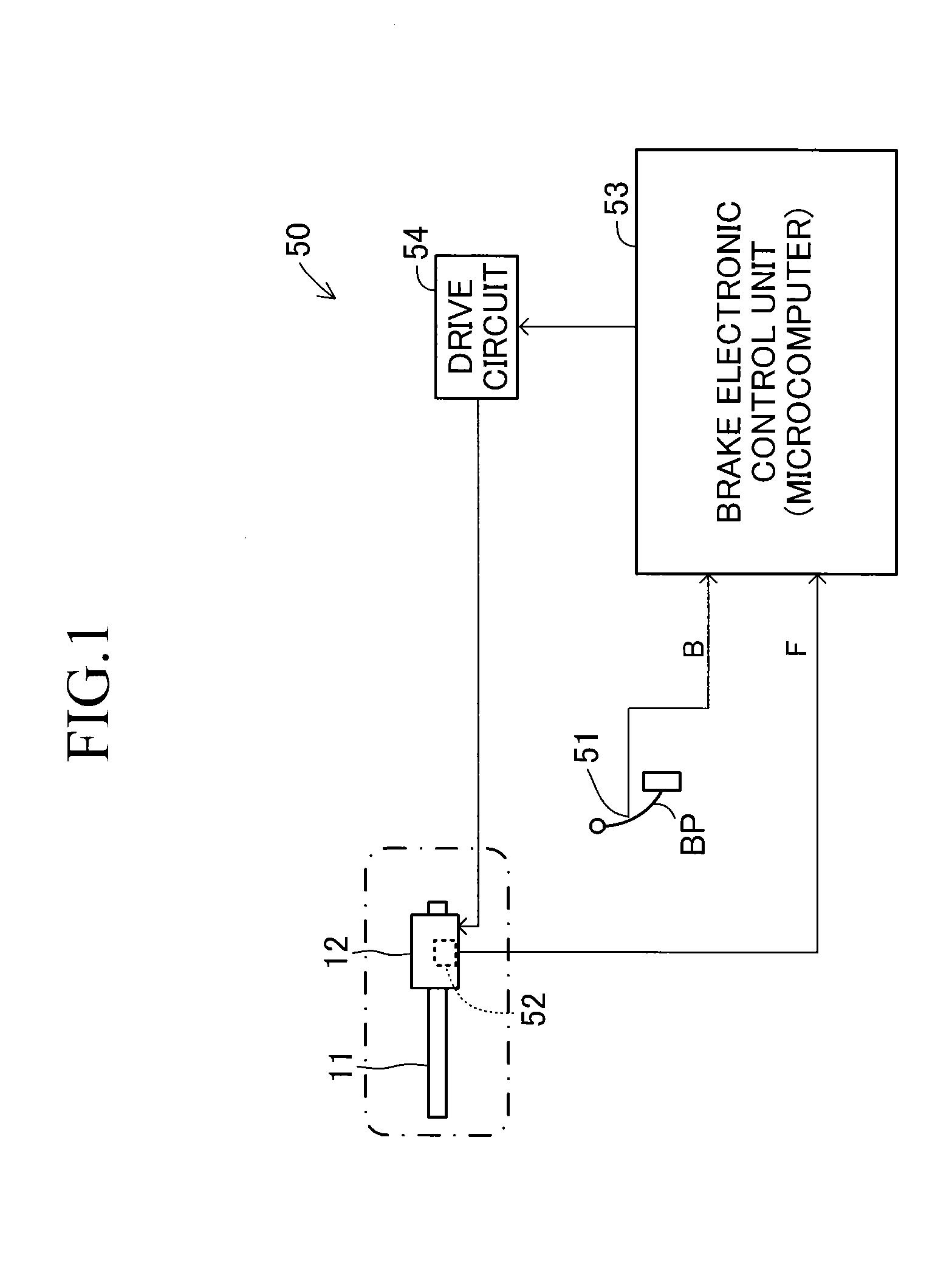

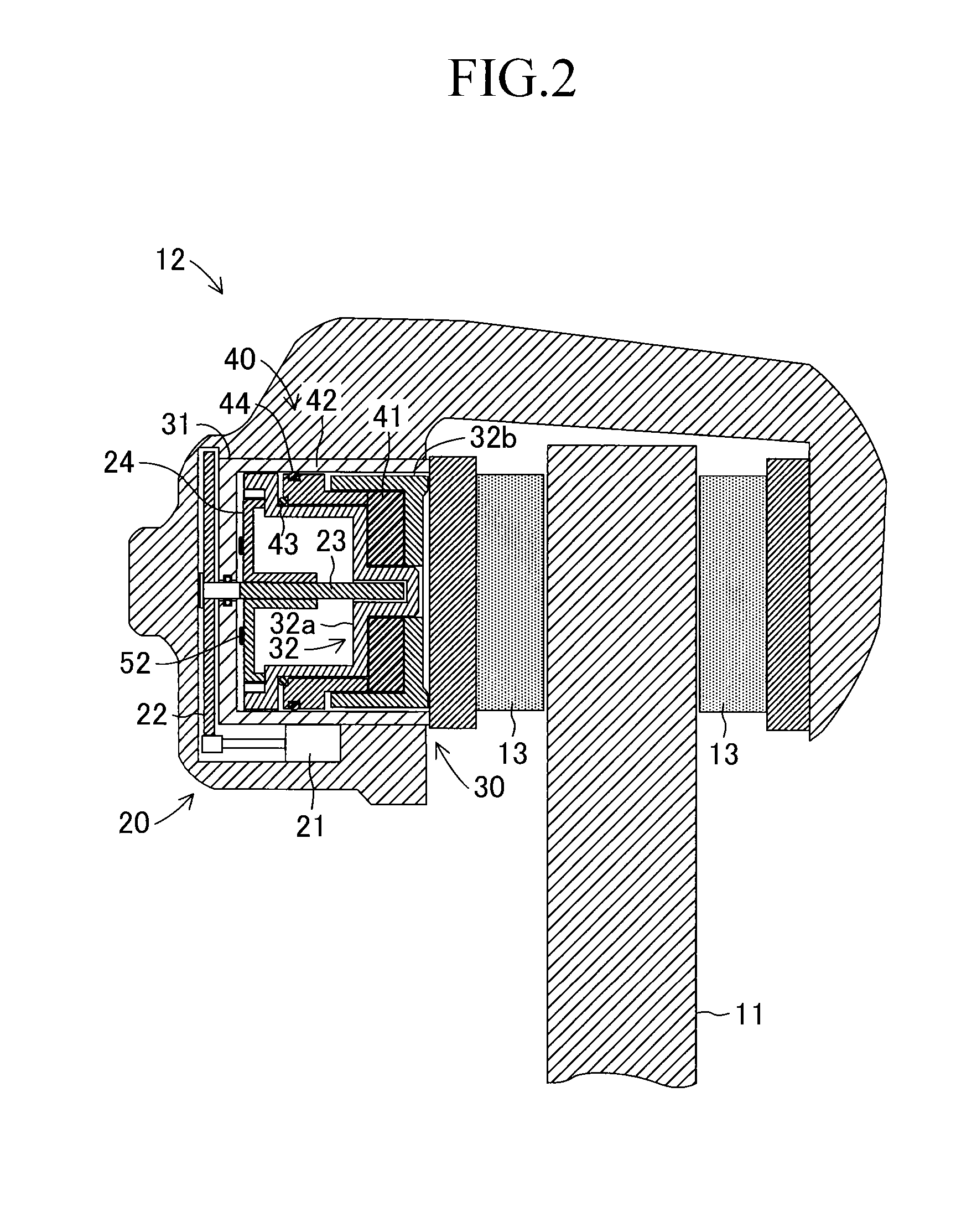

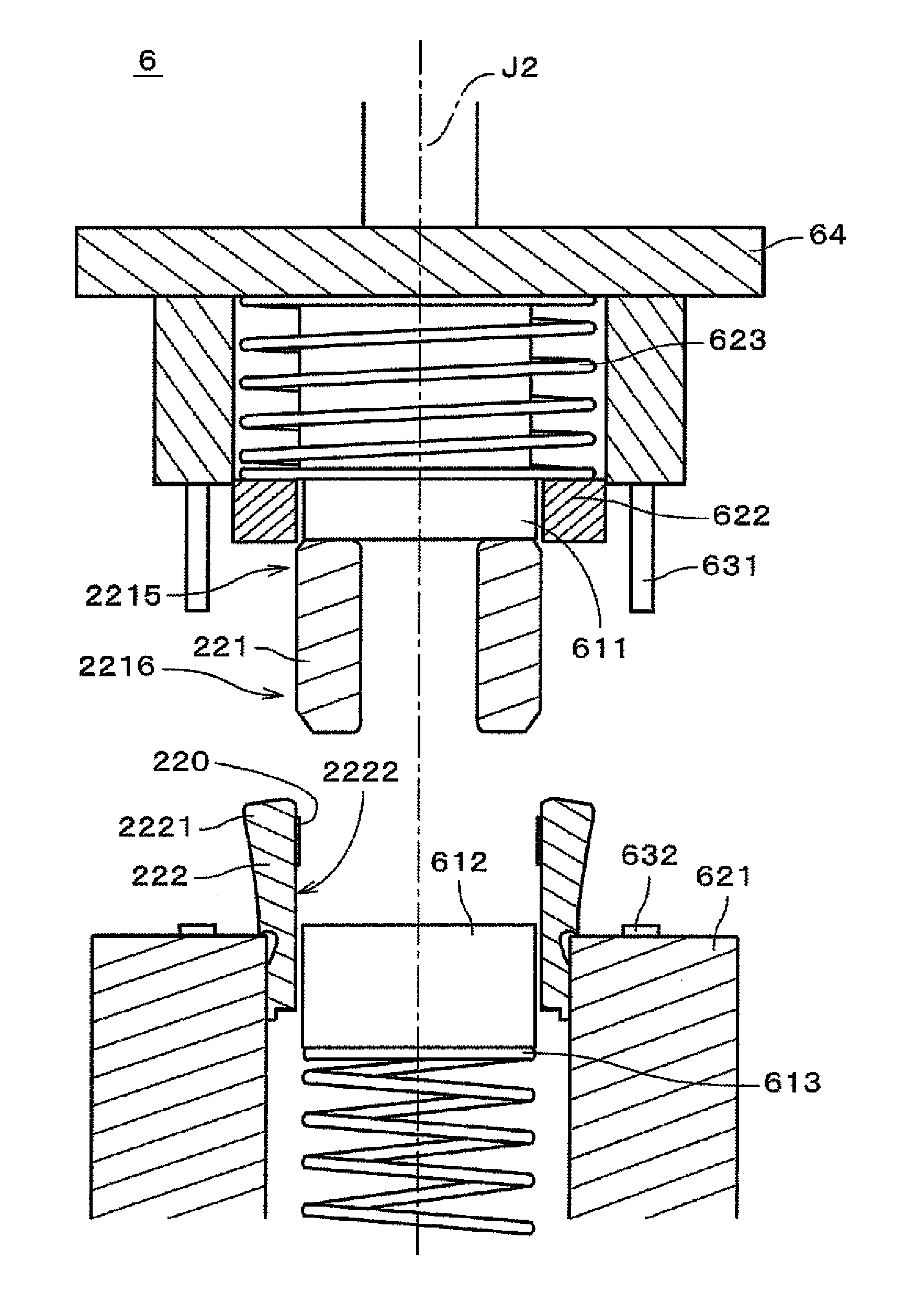

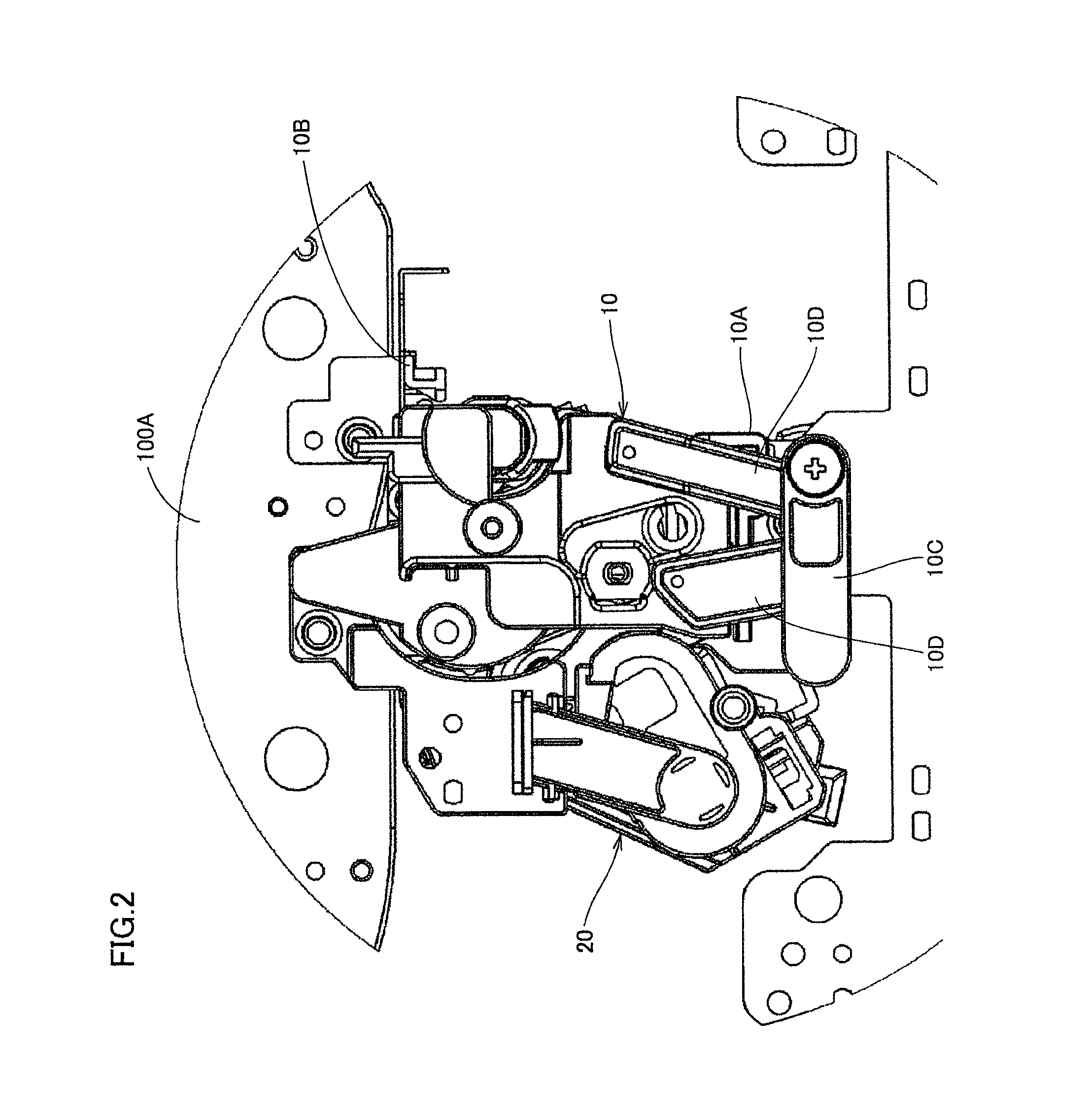

Electric brake apparatus for vehicle

ActiveUS20130105254A1Accurate detectionGood brake feelingAxially engaging brakesBraking action transmissionFree rotationElectric drive

An electric caliper includes an electric drive mechanism which generates a pressing force for pressing a friction pad against a disc rotor, and a retraction mechanism provided in a piston of a pressing mechanism. The mechanism includes a reversing member which is compressed by a force transmission portion and a pressing portion of the piston to thereby generate a reverse force. Also, the mechanism includes a movable element which relatively retracts due to the reverse force, and a first elastic member which is compressed by the movable element and the advancing force transmission portion to thereby apply a restoring force. Thus, in the mechanism, the reversing member generates the reverse force as a result of advancement of the force transmission portion, and the movable element relatively retracts due to the reverse force and compresses the first elastic member. When free rotation (no-load rotation) of a brake motor of the mechanism is permitted, the restoring force generated as a result of compression of the first elastic member is applied to the force transmission portion, whereby the piston is retracted.

Owner:TOYOTA JIDOSHA KK

Sleeve unit, method of manufacturing thereof, and motor using the sleeve unit

InactiveUS7988810B2Easily and accurately determinedPrevent pressureWindingsMechanical working/deformationAdhesiveEngineering

An adhesive is applied to an inner surface of a sleeve housing, and a sleeve is relatively moved toward the sleeve housing from inserted into the sleeve housing. The adhesive is cured while a predetermined distance is maintained between a first bearing surface of the sleeve and a lower surface of a flange portion of the sleeve housing.

Owner:NIDEC CORP

Conduit and component support system

InactiveUS20200080664A1Solve protection problemsDampening of conditionPipe supportsElectrical apparatusElastomerWire rod

A conduit and component support system for support of flexible, semi flexible or ridged conduit, pipe, wire, or similar, herein referred to as conduit which is comprised of one or more attachment points completing the underlying supporting framework for conduits. This system may be comprised of a nonmetallic elastomeric material or similar where a conduit can either be placed on the support or inserted into an insert opening within the support. This system provides support for conduit elongated runs and also to where the joining of conduits is made, where changes in direction are made, or where attachment points are made within a conduit system. Examples: 90 degree turns, tee fittings, couplings, valves, junction boxes, or similar to those previously mentioned. The system may also provide; physical protection, allowance for expansion and contraction, corrosion protection, dielectric protection, wear protection, identification, vibration and shock protection for conduits, the system, or structures.

Owner:PERRY SHAWN FREDERICK DOUGLAS

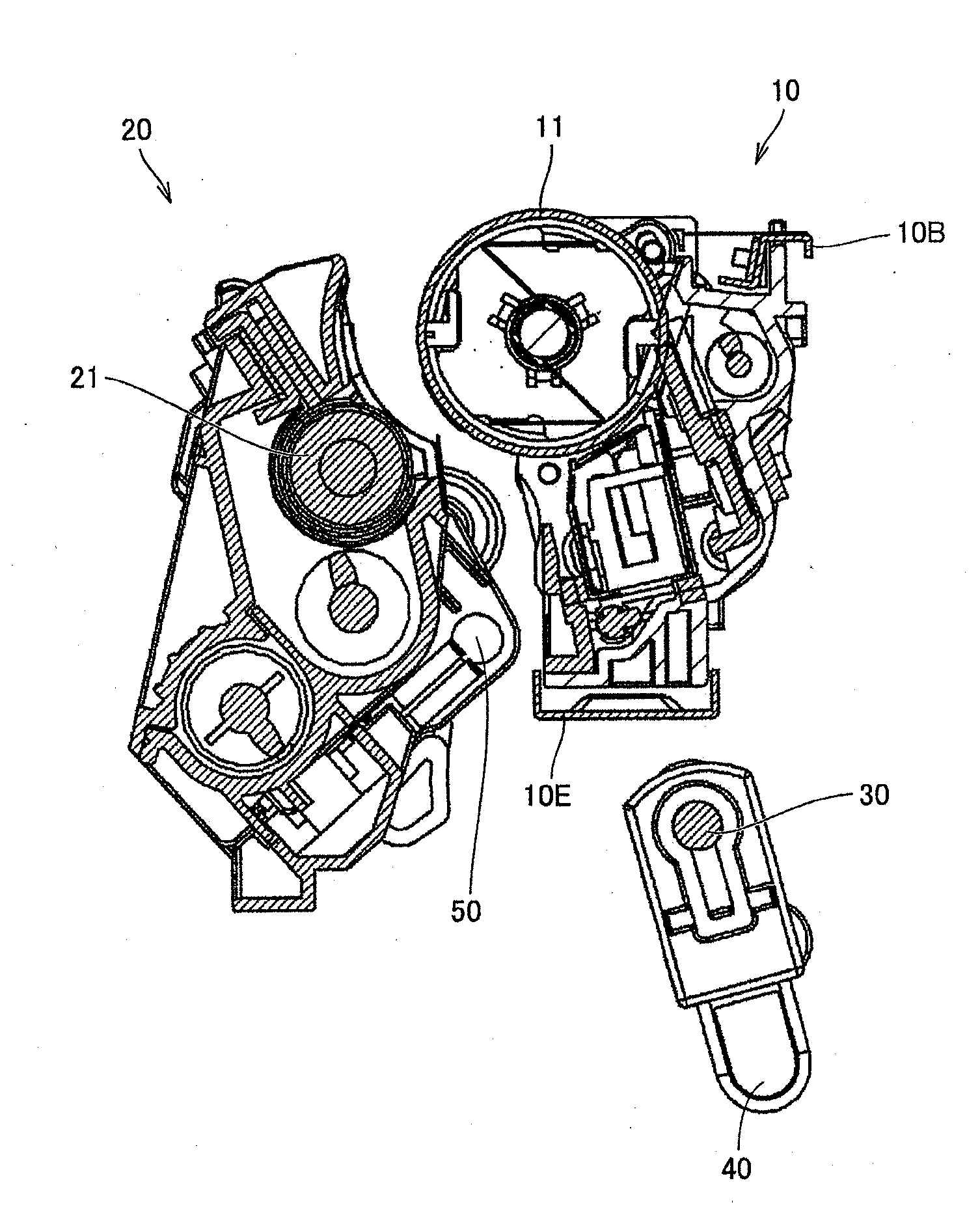

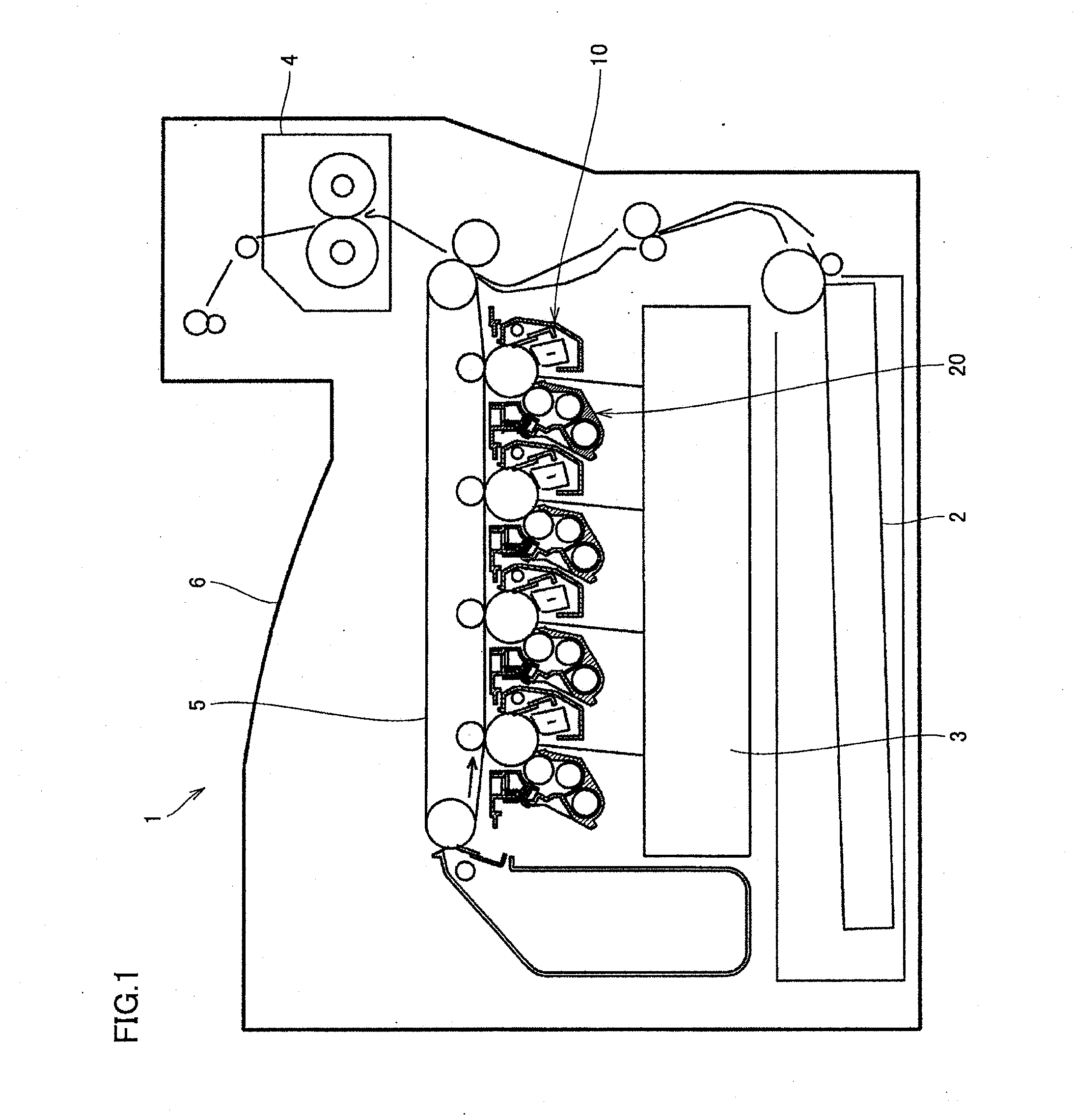

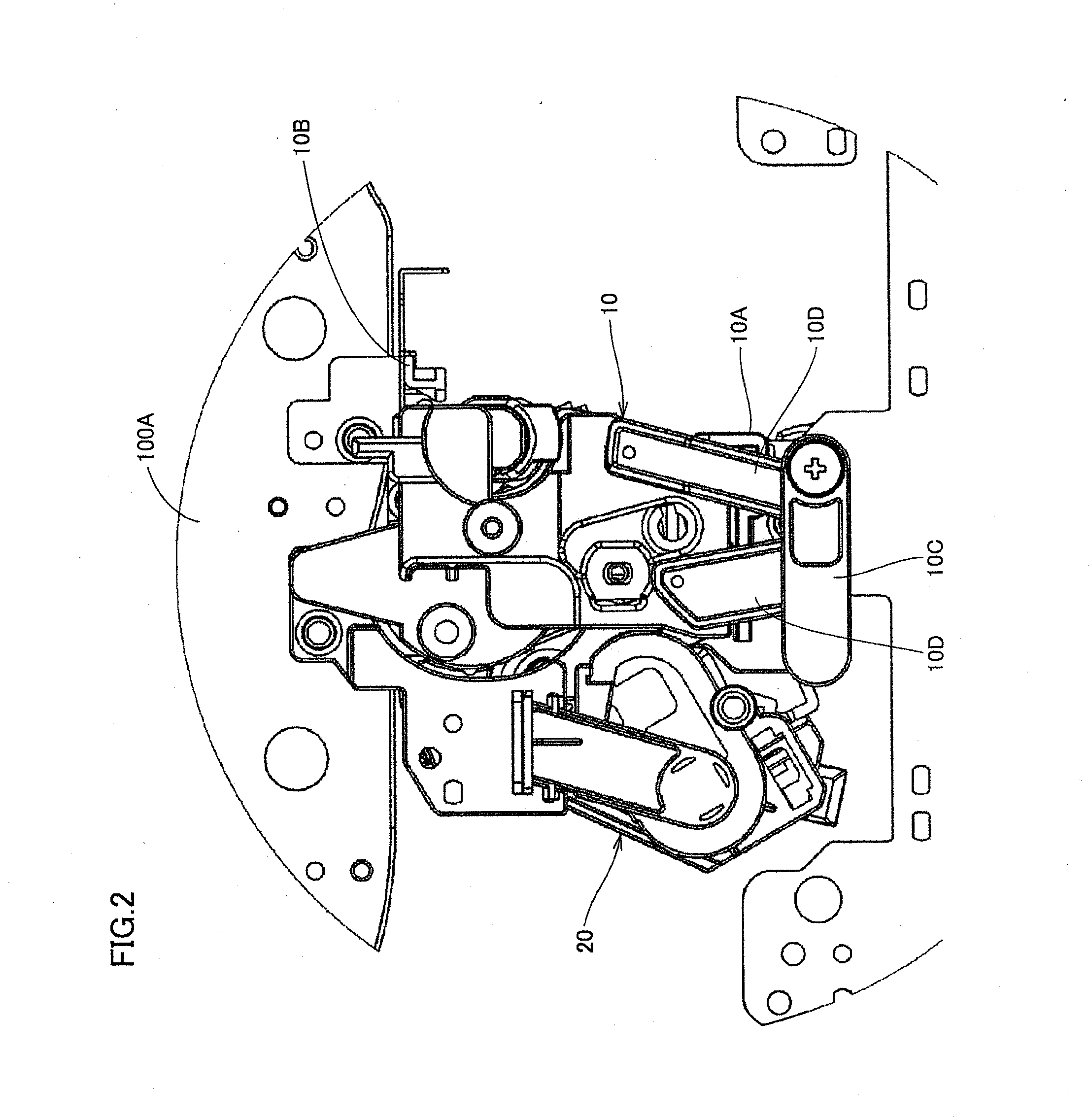

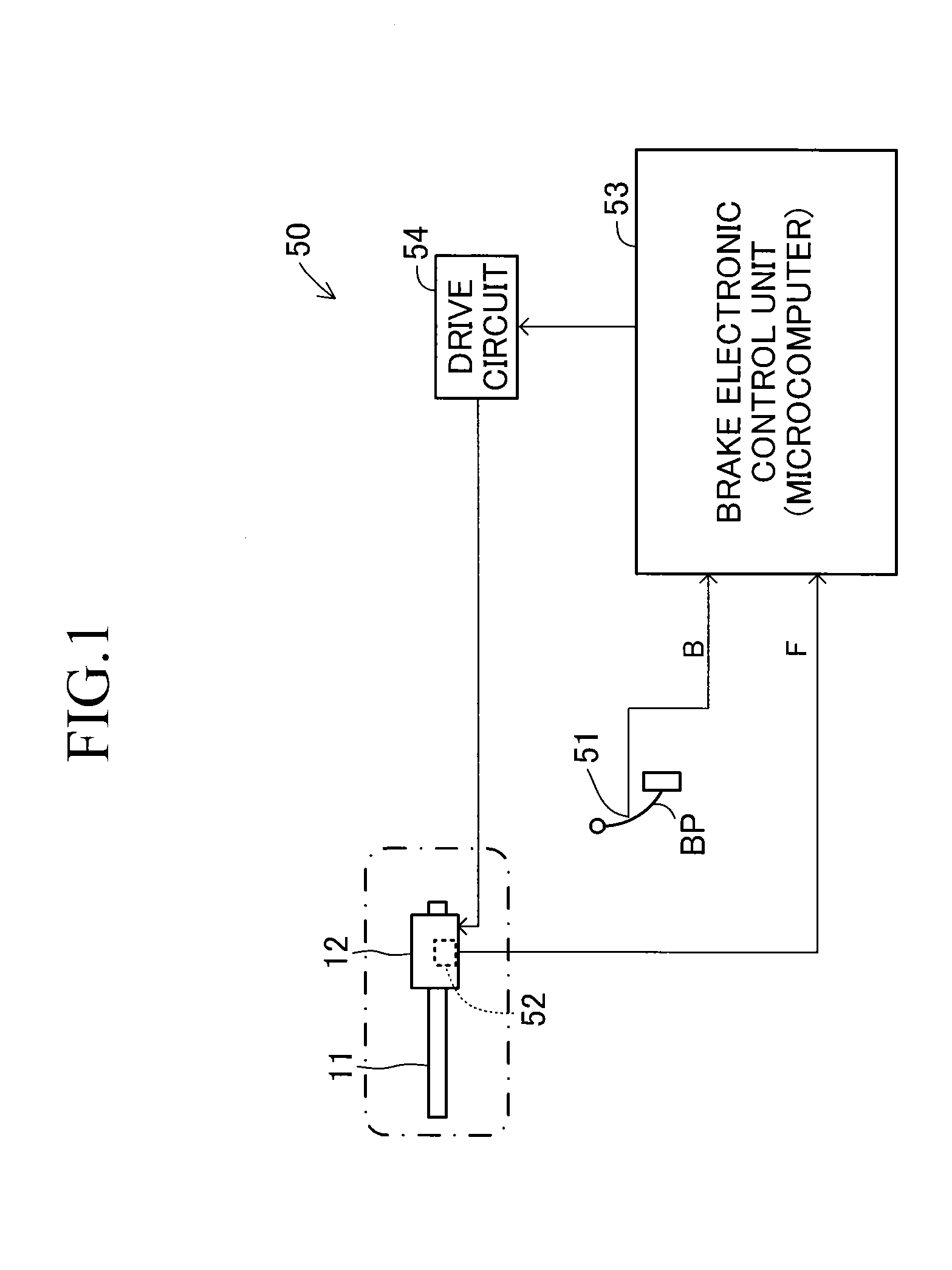

Image forming apparatus

ActiveUS20100142994A1Improve accuracyAccurate clearanceElectrographic process apparatusLatent imageImage formation

An image forming apparatus includes: a photoreceptor unit having a photoreceptor drum on which an electrostatic latent image is formed; a developing unit for developing the electrostatic latent image formed on the photoreceptor drum; a developing unit supporting shaft for rotatably supporting the developing unit; a pressing lever for pushing and rotating the developing unit to press the developing unit against the photoreceptor unit; a rotatable pressing lever shaft for supporting the pressing lever; and a holding member for holding the developing unit supporting shaft and the pressing lever shaft to maintain a fixed distance between the developing unit supporting shaft and the pressing lever shaft.

Owner:KONICA MINOLTA BUSINESS TECH INC

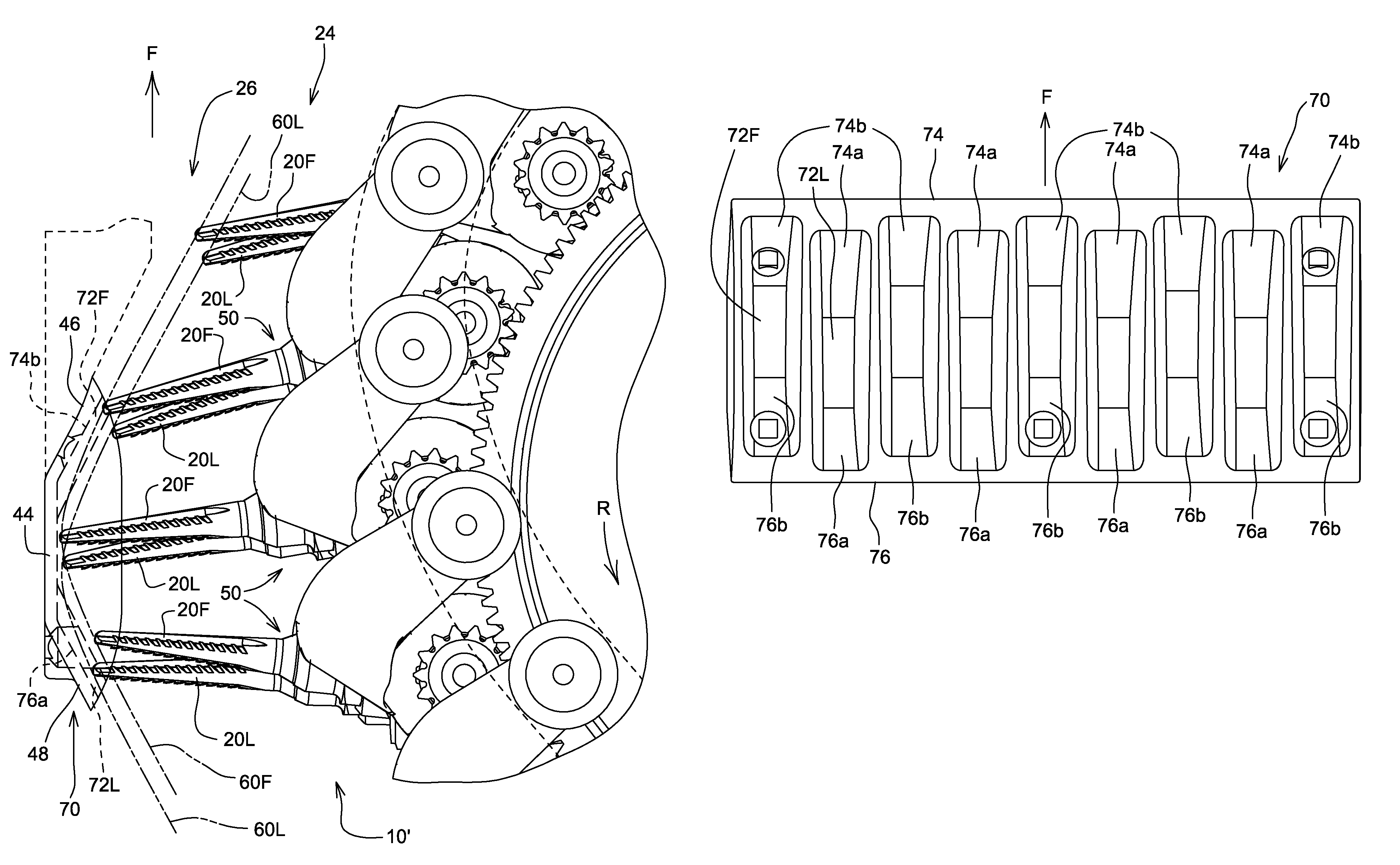

Scrapping plate for a cotton picker

Owner:DEERE & CO

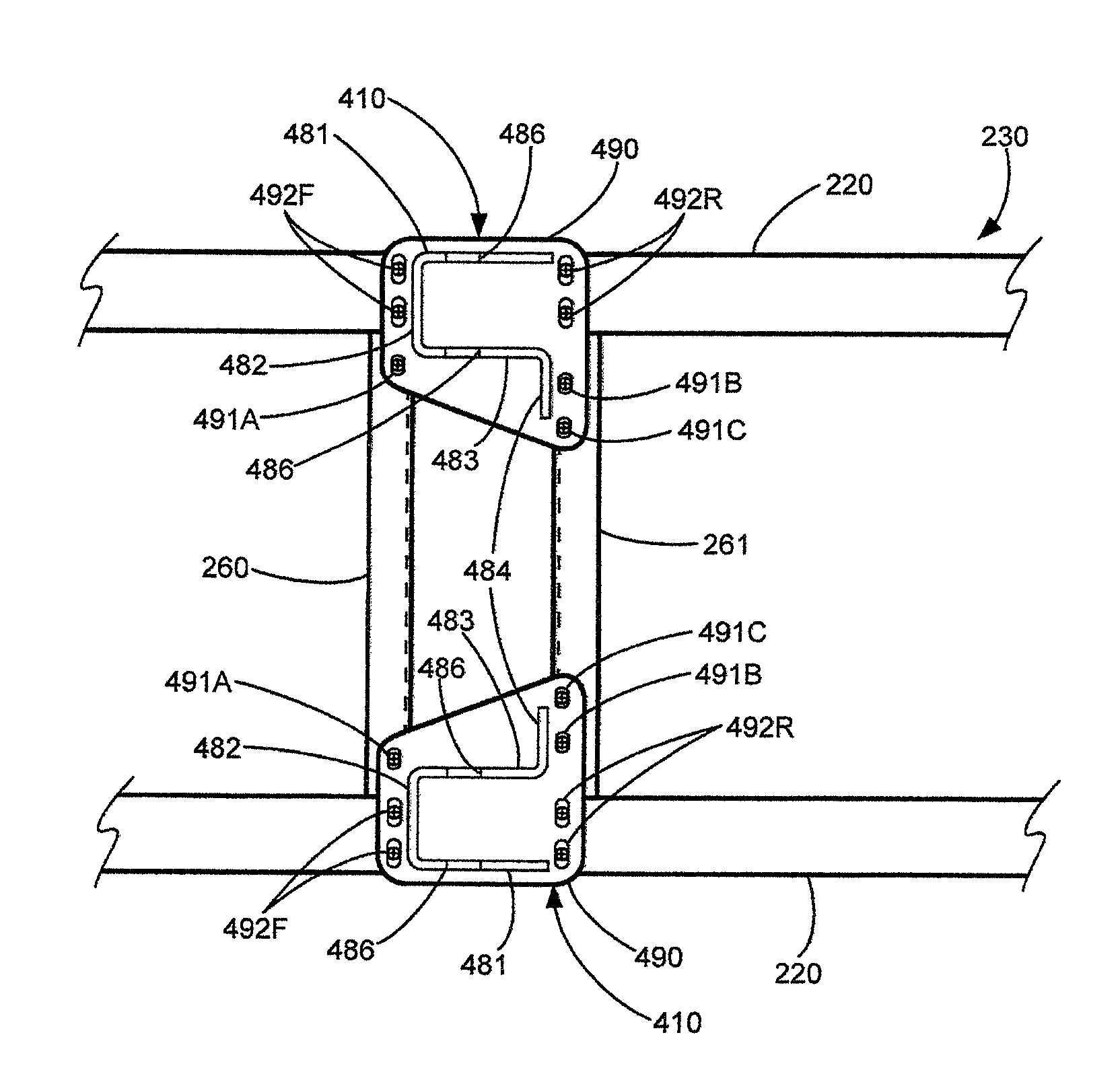

Hanger for axle/suspension systems

A hanger for axle / suspension systems of a heavy-duty vehicle includes an outboard wall spaced apart from an inboard wall. The outboard wall is connected to the inboard wall via a front wall. The outboard wall and the inboard wall are formed with an aligned opening extending through the outboard wall and the inboard wall. A top plate connected to the inboard wall, the outboard wall and the front wall. The top plate is formed with at least one circular opening or laterally oriented oblong-round opening and at least one laterally slotted opening. A fastener is disposed through the at least one circular opening or oblong-round opening. A second fastener is disposed through the at least one laterally slotted opening for mounting the hanger to a frame of the heavy-duty vehicle.

Owner:HENDRICKSON USA L L C

Electric compressor

An electric turbo compressor is an air compressor to be used in a fuel cell system, and includes a housing comprised of a compression casing, a motor casing, and a canceller casing, and the housing houses therein an impeller, a rotary shaft, a thrust canceller (a load cancellation section), and a motor unit. The rotary shaft is supported by a thrust air bearing in its thrust direction, and is axially supported by a radial air bearing in its rotating direction. A thrust load is generated at the rotary shaft when the number of rotations of the impeller increases. The pressure of the compressed air acts to the pressure chamber from the compressed air lead-out section of the compression casing via the compressed air passage, and this pressure acts on the canceller flange of the canceller shaft so as to generate a load towards the rear of the rotary shaft. Therefore, the thrust load is cancelled out.

Owner:HONDA MOTOR CO LTD

Heat treatment device and heat treatment method

InactiveUS7060944B2Avoid contactAccurate clearanceMuffle furnacesSemiconductor/solid-state device manufacturingEngineeringDistance minimization

A heat treatment apparatus (100) having: a susceptor (2) rotatably provided in a heat treatment vessel (1), on which a wafer (W) is placed; a preheat ring (3) surrounding a periphery of the susceptor (2) to be close to and in non-contact with the susceptor, which is supported by a base (4) provided in the heat treatment vessel (1); and a heating apparatus (8) for heating a wafer (W) placed on the susceptor (2), wherein the preheat ring (3) is formed such that an inner peripheral center (31a) is eccentric to an outer periphery (32). The preheat ring (3) is moved around the susceptor (2); the preheat ring (3) is positioned to minimize a distance between the inner peripheral center (31a) of the preheat ring (3) and the center (2b) of the susceptor (2); and thereafter a heat treatment is performed to a wafer (W).

Owner:SHIN-ETSU HANDOTAI CO LTD

Image forming apparatus with improved accuracy in forming a gap between a developing unit and a photoreceptor drum

ActiveUS8306454B2Accurate clearanceImprove accuracyElectrographic process apparatusLatent imageEngineering

An image forming apparatus includes: a photoreceptor unit having a photoreceptor drum on which an electrostatic latent image is formed; a developing unit for developing the electrostatic latent image formed on the photoreceptor drum; a developing unit supporting shaft for rotatably supporting the developing unit; a pressing lever for pushing and rotating the developing unit to press the developing unit against the photoreceptor unit; a rotatable pressing lever shaft for supporting the pressing lever; and a holding member for holding the developing unit supporting shaft and the pressing lever shaft to maintain a fixed distance between the developing unit supporting shaft and the pressing lever shaft.

Owner:KONICA MINOLTA BUSINESS TECH INC

Electric brake apparatus for vehicle

ActiveUS9205825B2Accurate clearanceAccurate detectionBraking action transmissionMechanically actuated brakesFree rotationEngineering

An electric caliper includes an electric drive mechanism which generates a pressing force for pressing a friction pad against a disc rotor, and a retraction mechanism provided in a piston of a pressing mechanism. The mechanism includes a reversing member which is compressed by a force transmission portion and a pressing portion of the piston to thereby generate a reverse force. Also, the mechanism includes a movable element which relatively retracts due to the reverse force, and a first elastic member which is compressed by the movable element and the advancing force transmission portion to thereby apply a restoring force. Thus, in the mechanism, the reversing member generates the reverse force as a result of advancement of the force transmission portion, and the movable element relatively retracts due to the reverse force and compresses the first elastic member. When free rotation (no-load rotation) of a brake motor of the mechanism is permitted, the restoring force generated as a result of compression of the first elastic member is applied to the force transmission portion, whereby the piston is retracted.

Owner:TOYOTA JIDOSHA KK

Solder ball printing apparatus and solder ball printing method

InactiveUS8919634B2Reliably and accurately mountAvoid position shiftWelding/cutting auxillary devicesAuxillary welding devicesSolder ballEngineering

A solder ball printing apparatus fills plural openings formed in a mask with solder balls using a squeegee and prints the solder balls on plural electrode portions formed on a surface of a substrate facing the mask. The solder ball printing apparatus includes: a substrate mounting table on which the substrate is mounted and on the back surface side of which plural hole portions are formed; a print table on which the substrate mounting table is mounted; an XYθ stage which can drive the print table in a horizontal plane; a print table cylinder which can vertically drive the print table; a mask absorption portion which has members that can be fitted into the substrate mounting table; and a mask absorption cylinder which can vertically drive the mask absorption portion.

Owner:HITACHI LTD

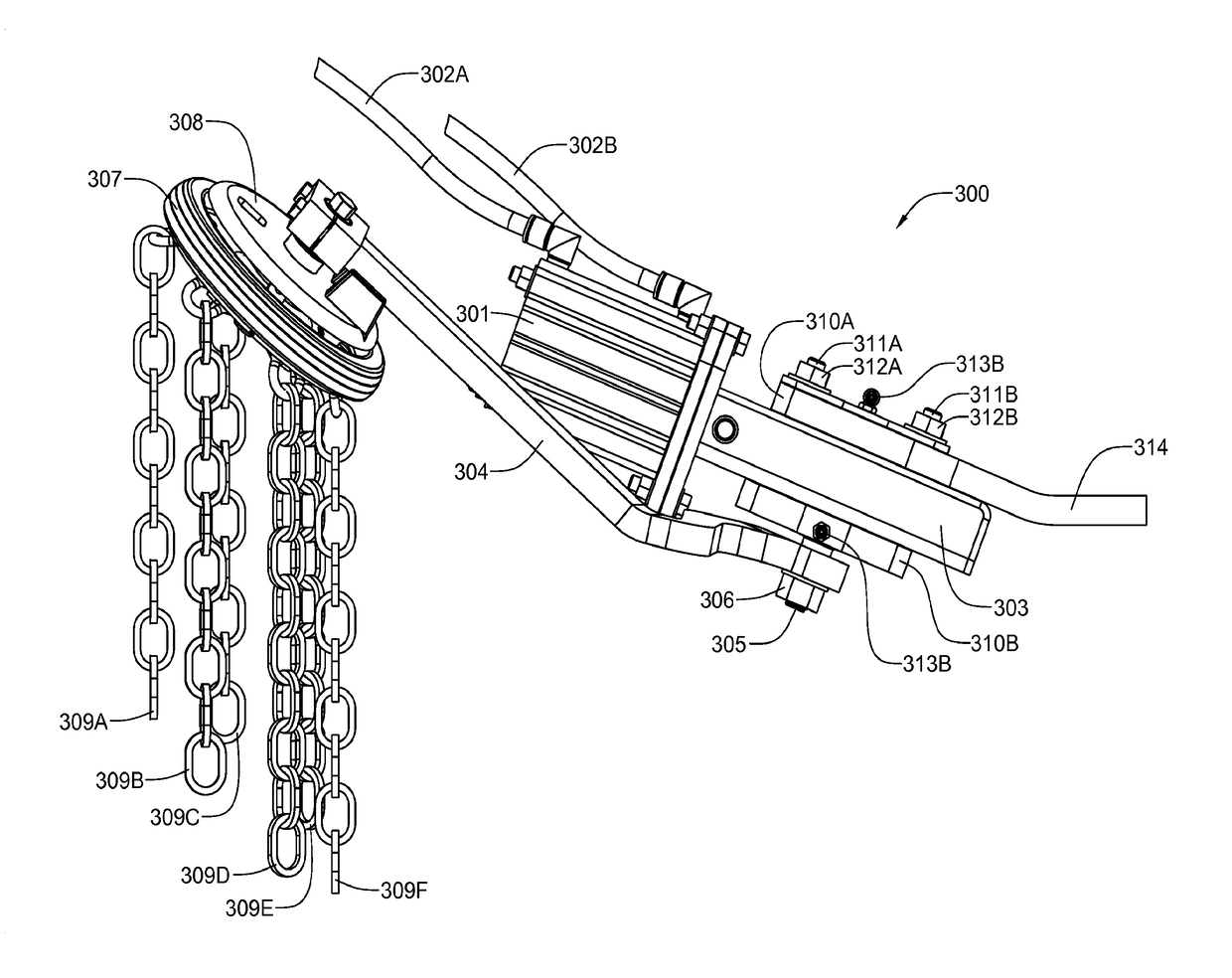

Pneumatically-operated rigid linear chain and sprocket actuator for deploying a vehicle snow chain traction system

InactiveUS9731553B2Rapid deploymentReduce frictionWheel adhesionNon-skid devicesTraction systemSnow chains

A unit for rapid deployment and retraction of chain traction systems for vehicles includes a pneumatic cylinder having a cylindrical chamber enclosing a piston that is pneumatically-movable bidirectionally. A control rod coupled at one end to the piston passes through an end of the chamber and is coupled to a rack linearly movable within a sealed, grease-containing case. The rack is formed from a series of equally-spaced roller pins secured between parallel walls of a rack frame. The roller pins of the rack engage a sprocket affixed to a rotatable shaft to which is rigidly coupled an actuator arm of the rapidly-deployable vehicle ice and snow chain traction system. As the rack is moved back and forth, the actuator arm swings through an arc that—depending on the displacement of the control rod and the length of the rack, can be greater than 180 degrees.

Owner:MCKENNA SHANE EVAN +1

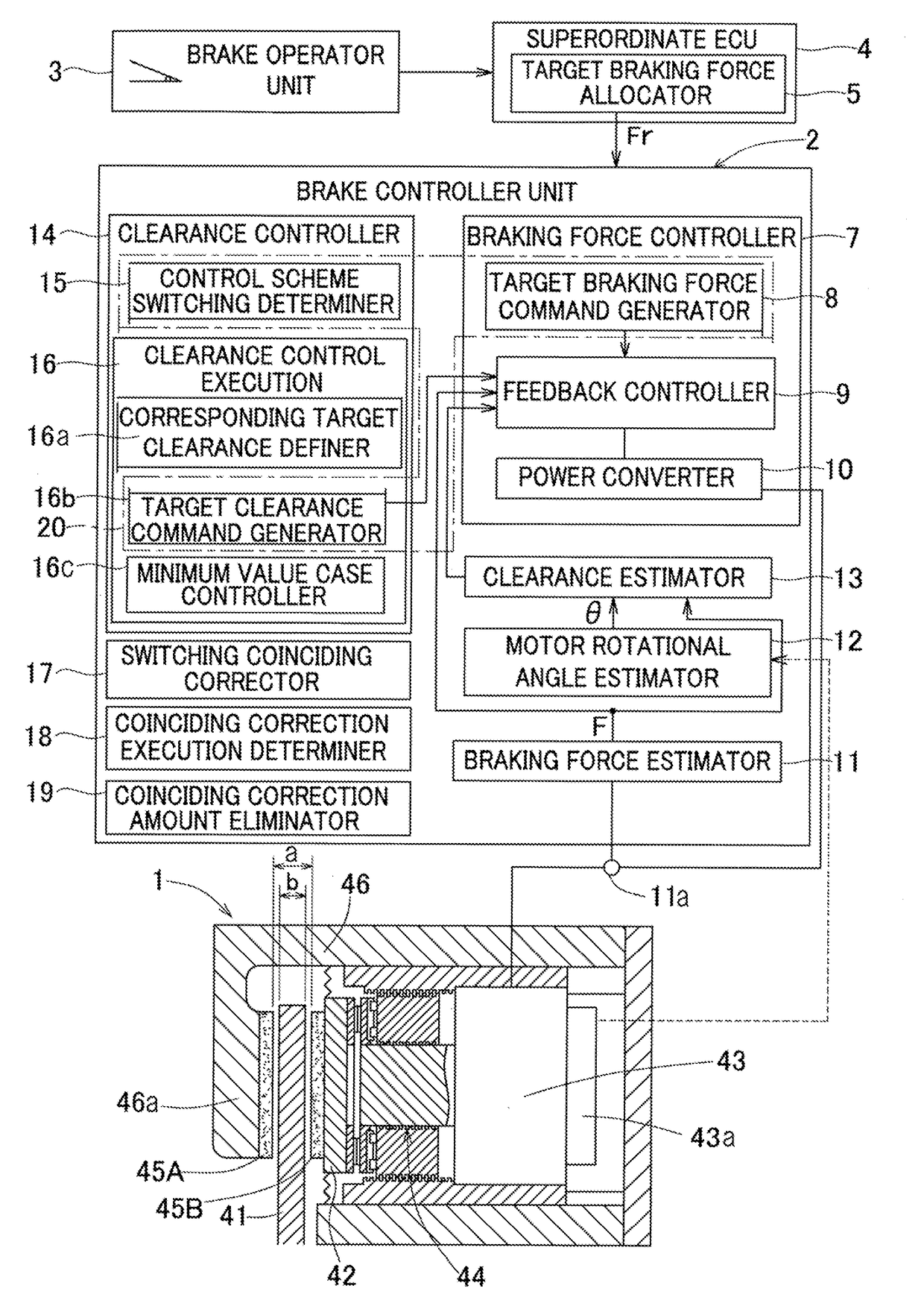

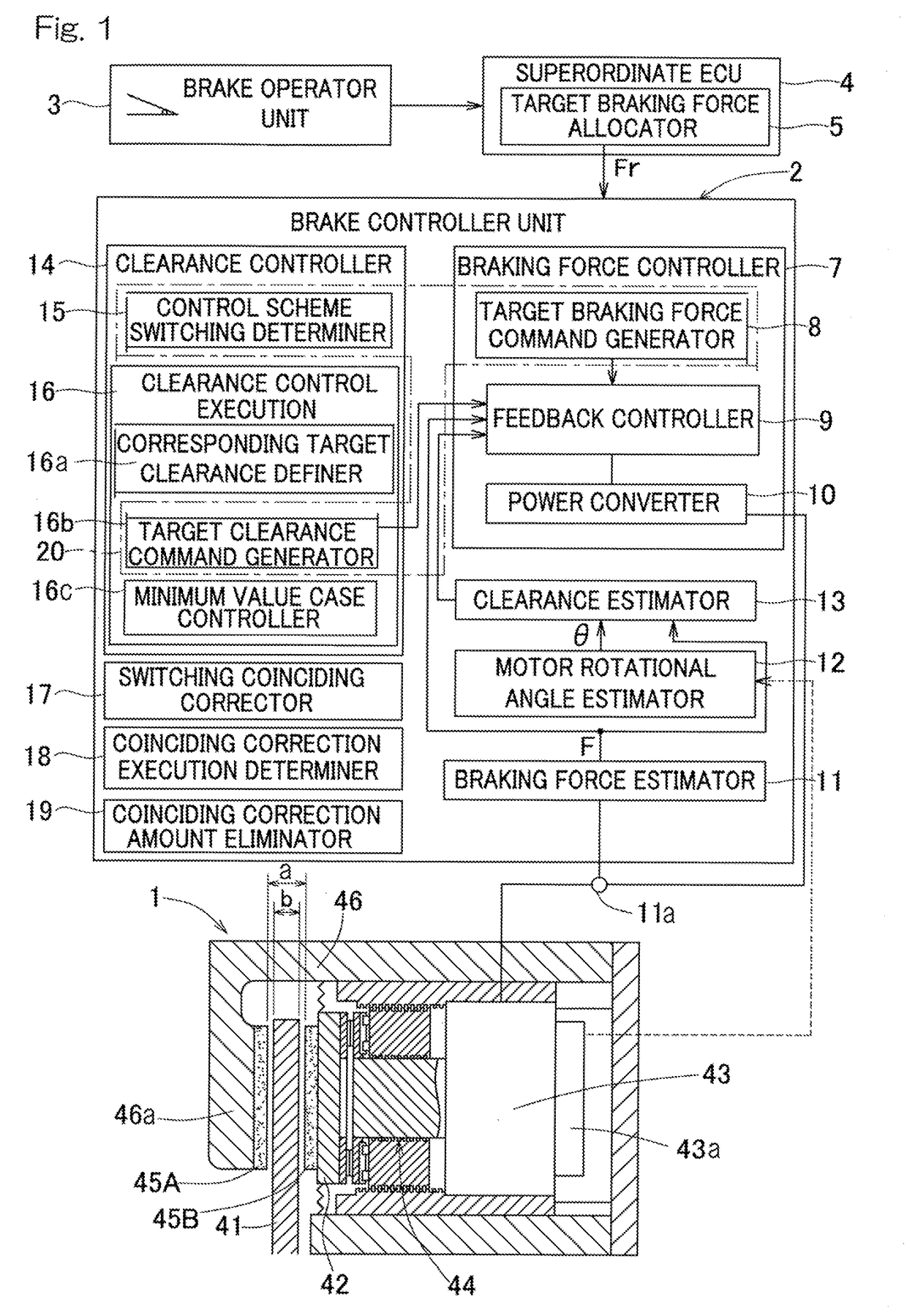

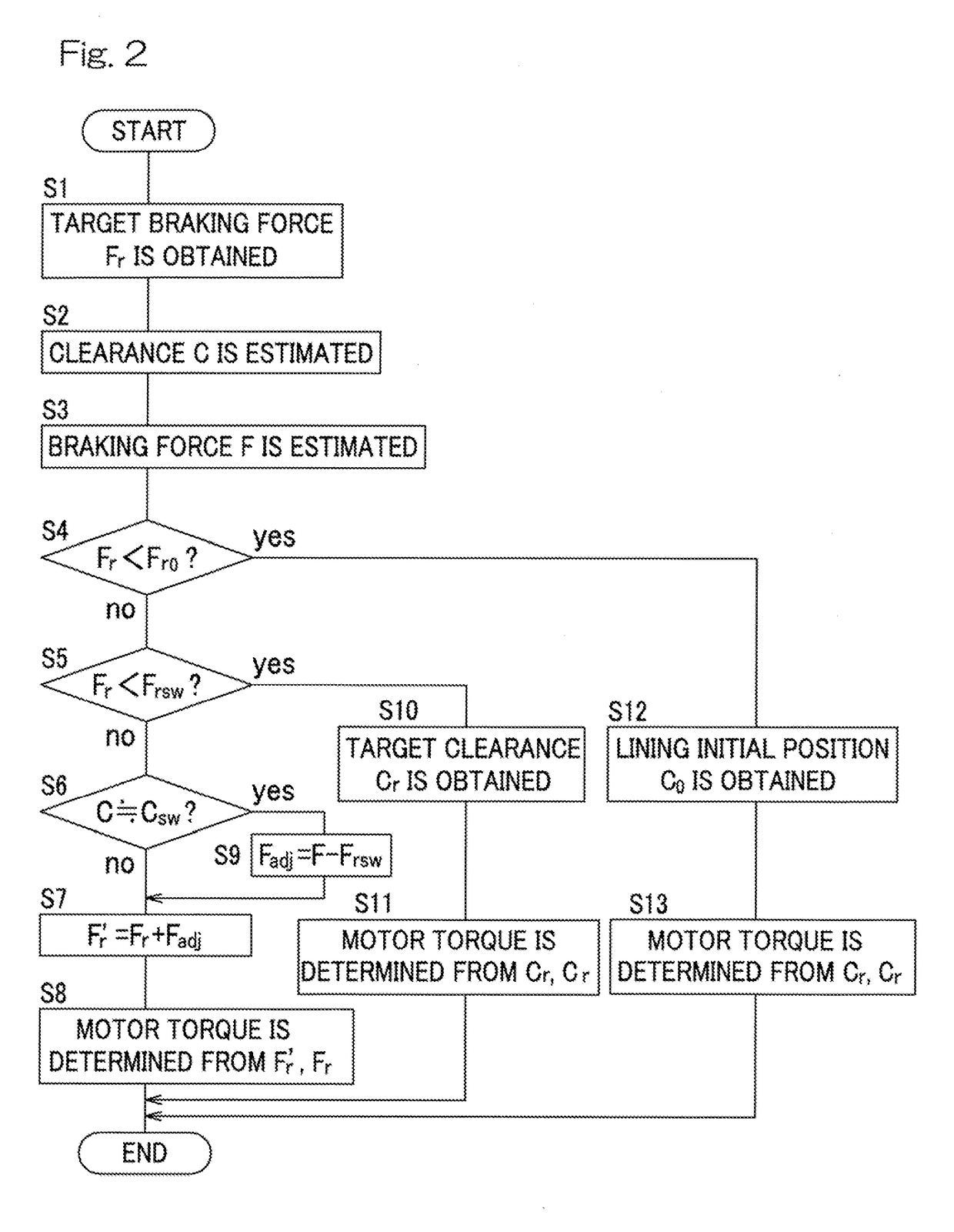

Electric brake device

ActiveUS20170217409A1Accurate clearancePossible of braking forceAxially engaging brakesBraking action transmissionEngineeringBrake force

Improved maneuverability, improved followability towards a target braking force and enhanced brake feeling when a low braking force is being effected may be achieved. A brake controller unit may include a clearance estimator which may be configured to use a rotational angle θ of a motor to estimate a clearance, inclusive of negative values, between a frictional material and a brake. A target braking force Fr may be compared with a switch-determining braking force Frsw, so that clearance control based on a target clearance Cr may be performed when the frictional material is in approximate-contact state corresponding to the target braking force Fr being low, and so that braking force control may be performed when it is equal to or greater than the switch-determining braking force Frsw.

Owner:NTN CORP

Electronic part and method of producing the same

InactiveUS7790594B2Accurate clearanceReduce areaSemiconductor/solid-state device detailsCapacitor with electrode distance variationHardnessEngineering

It is an object of the invention to provide an electronic part capable of forming an accurate gap between opposing substrates while also capable of decreasing the area of the electronic part, and a method of producing the same. A second electrode portion (6), having a core pattern (7) and a bump pattern (8) covering the surface thereof, is provided on a device substrate (1), the core pattern (7) is made of a material having hardness greater than that of the bump pattern (8), a first electrode portion (5) of the same material as the bump pattern (8) is provided on a bonding substrate (2), and a functional portion of the device substrate (1) and the first electrode portion (5) are electrically connected by direct bonding of the first electrode portion (5) and the bump pattern (8).

Owner:PANASONIC CORP

Image recording apparatus

An image recording apparatus includes: a carriage that carries a recording head capable of recording an image on a recording medium and reciprocates in a main scanning direction; a substantially box-shaped main frame having an open upper side and a pair of side plates extending in a sub-scanning direction orthogonal to the main scanning direction; and first and second guide members over which the carriage extends and by which the carriage is guided, the first and second guide members being disposed to be apart from each other by a predetermined distance in the sub-scanning direction, extended in the main scanning direction at the upper side of the main frame and fixed to the pair of side plates.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com