Electric compressor

a compressor and electric technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of excessive cancellation of thrust load generation at the rotary shaft, etc., to achieve good surge property, reduce size, weight and cost, and high compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

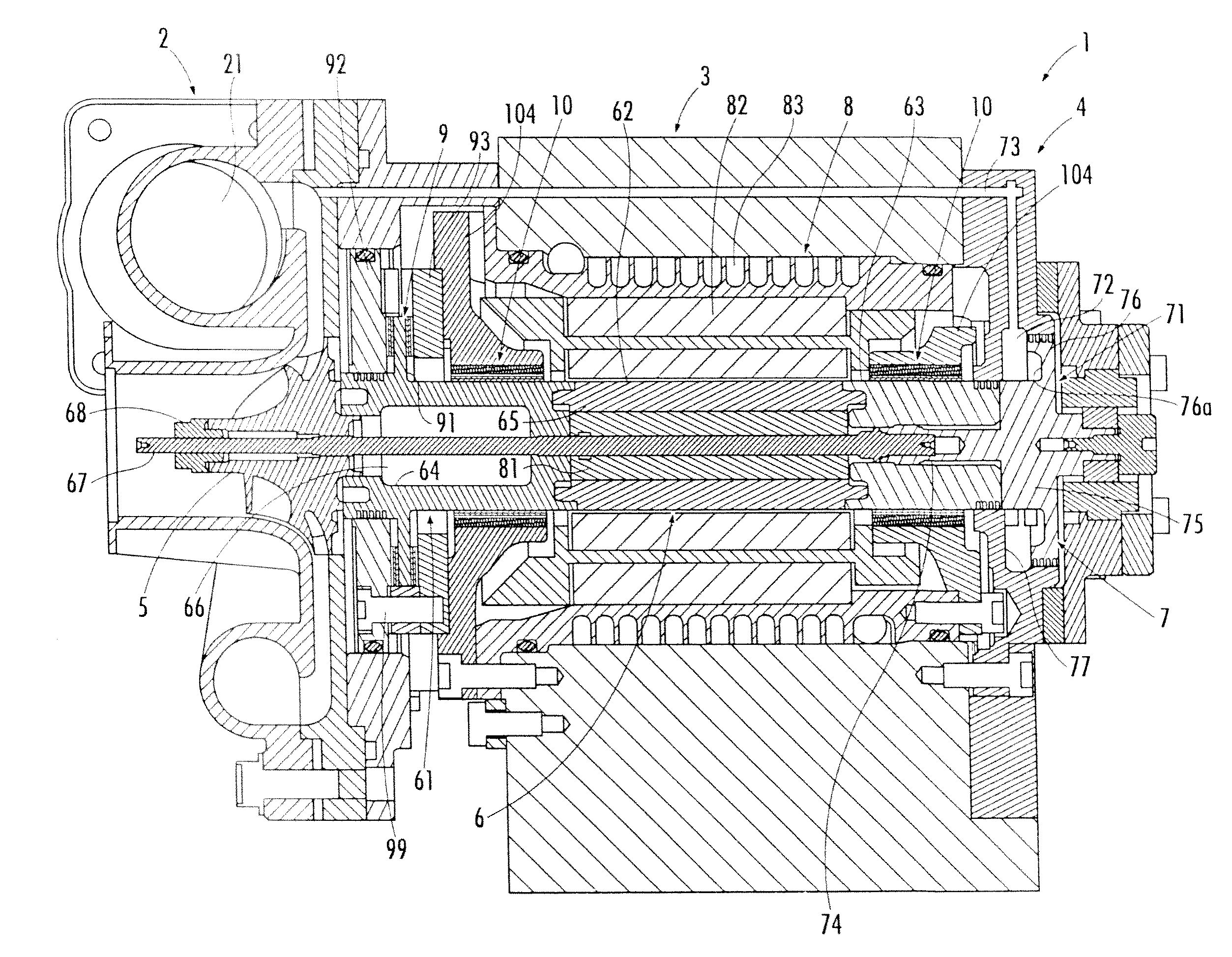

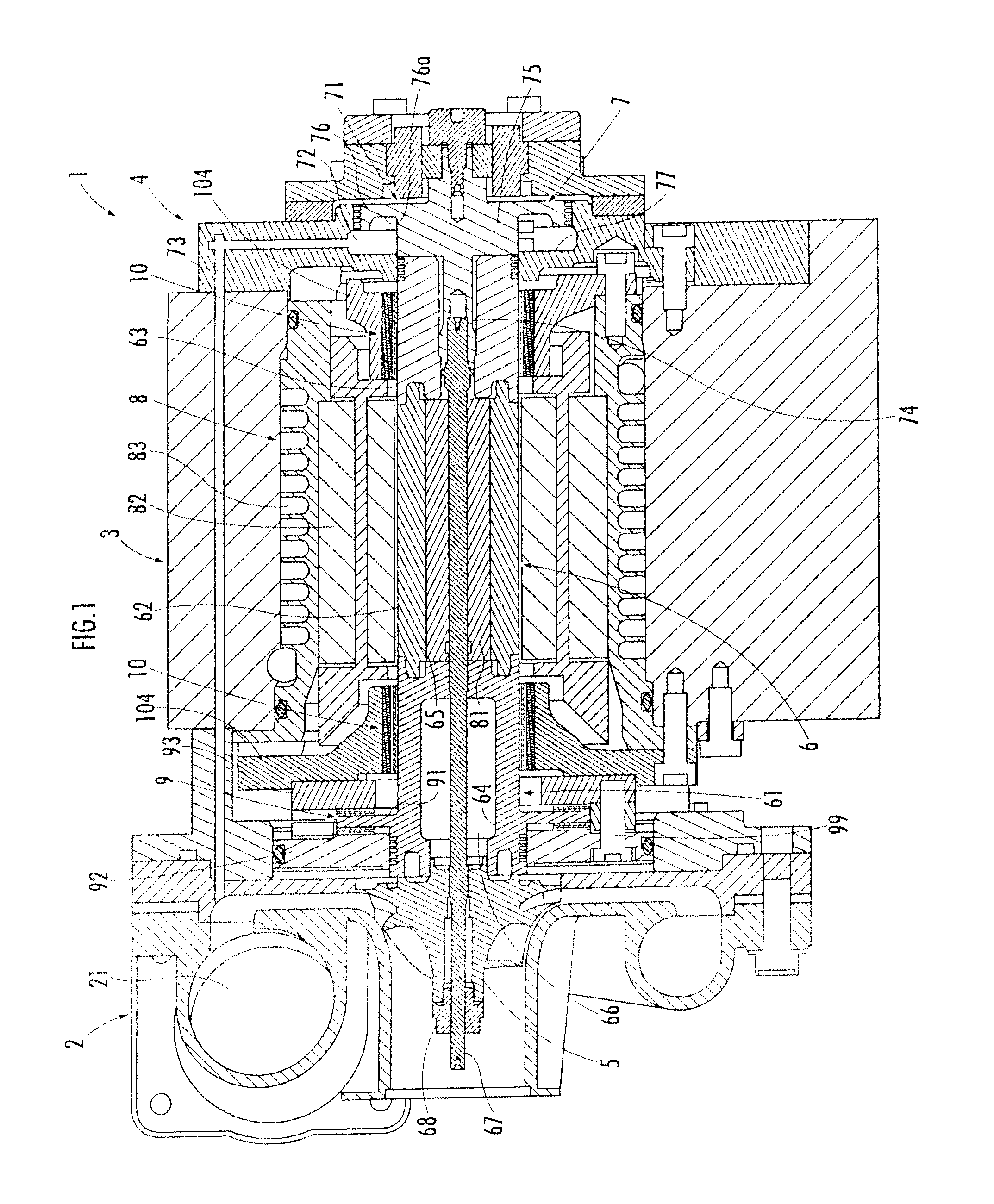

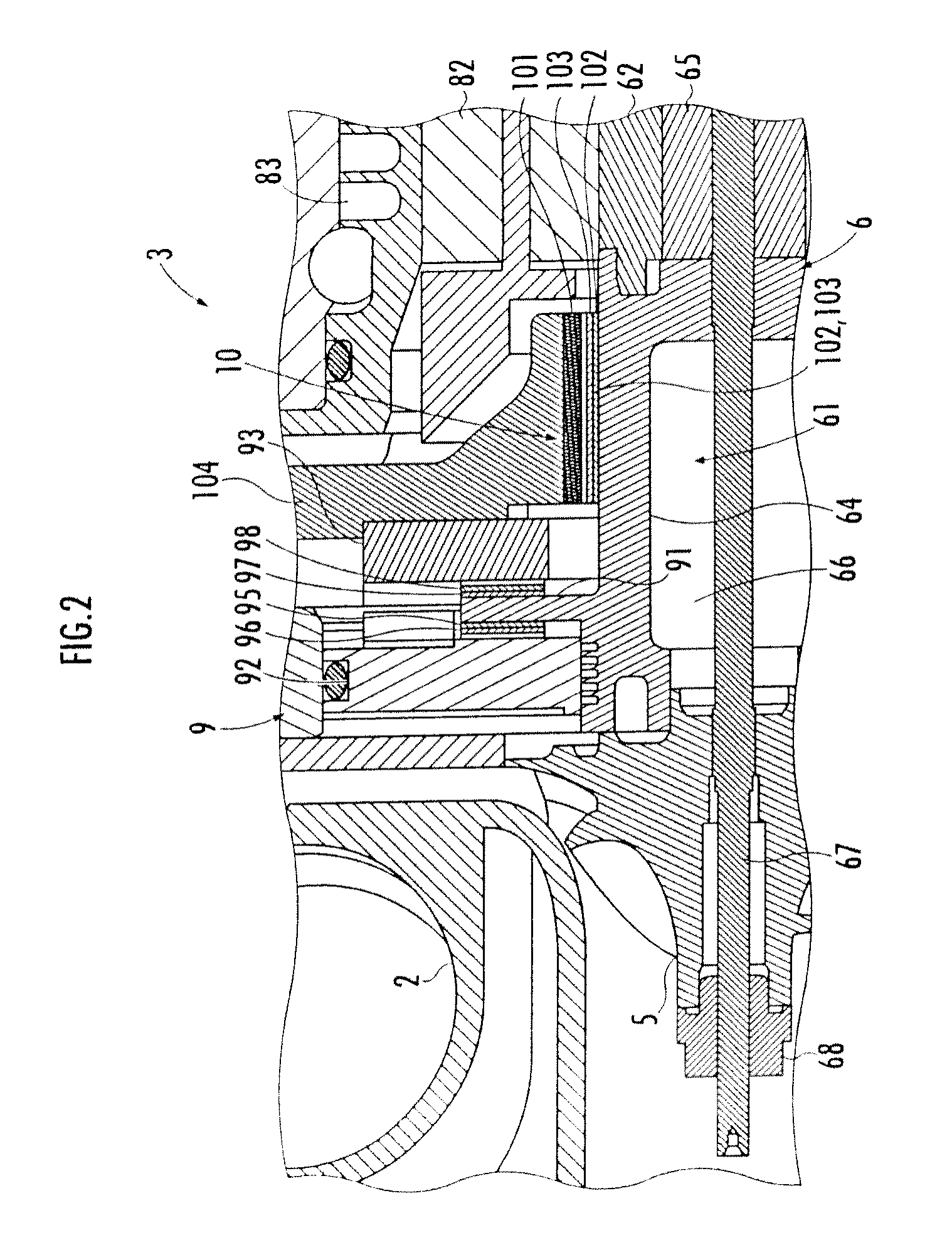

[0017] Hereinafter, an electric turbo compressor as an embodiment of an electric compressor of the present invention will be now explained with reference to FIG. 1 through FIG. 3. FIG. 1 is an explanatory cross-sectional view of an electric turbo compressor of the present embodiment, FIG. 2 is an enlarged view of a thrust bearing portion in FIG. 1, and FIG. 3 is a graph showing a relationship between a thrust load and the like generated at the rotary shaft and the number of rotations.

[0018] An electric turbo compressor 1 of the present embodiment is an air compressor used in a fuel cell system. As shown in FIG. 1, the electric turbo compressor 1 includes a housing comprised of a compression casing 2, a motor casing 3, and a canceller casing 4, the housing houses therein an impeller 5, a rotary shaft 6, a thrust canceller (a load cancellation section) 7, and a motor unit 8. Further, the rotary shaft 6 is supported by a thrust air bearing 9 in its thrust direction. Still further, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com