Vacuum pump

a vacuum pump and vacuum technology, applied in the direction of liquid fuel engines, rotary/oscillating piston pump components, machines/engines, etc., can solve the problems of expensive grinding and lapping operations, and achieve the effect of resisting undesirable shifting of internal parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] While this invention may be embodied in many different forms, there are described in detail herein specific preferred embodiments. This description is an exemplification of the principles of the invention and is not intended to limit the invention to the particular embodiments described.

[0039] For the purposes of this disclosure, like reference numerals in the Figures shall refer to like features unless otherwise indicated.

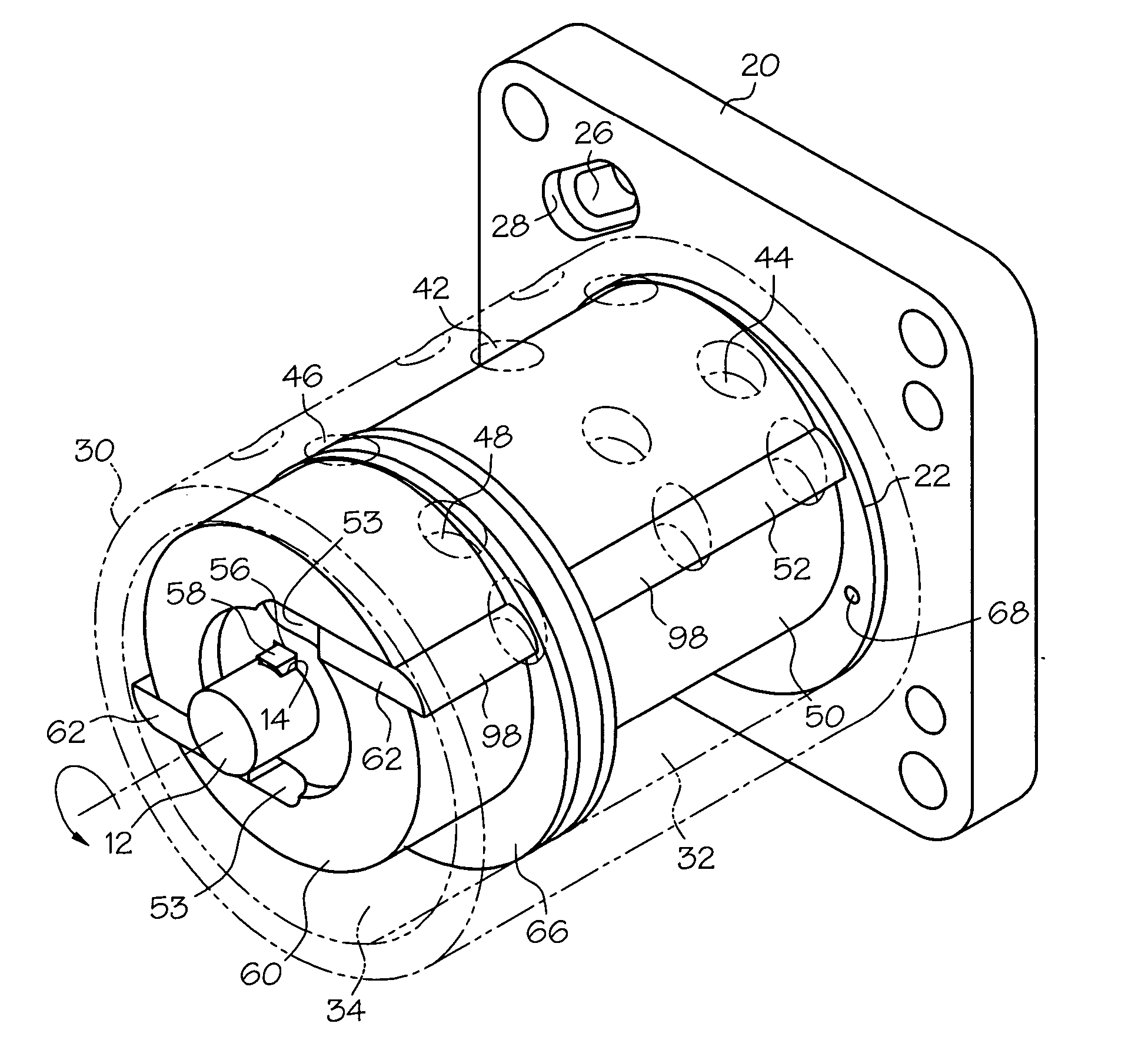

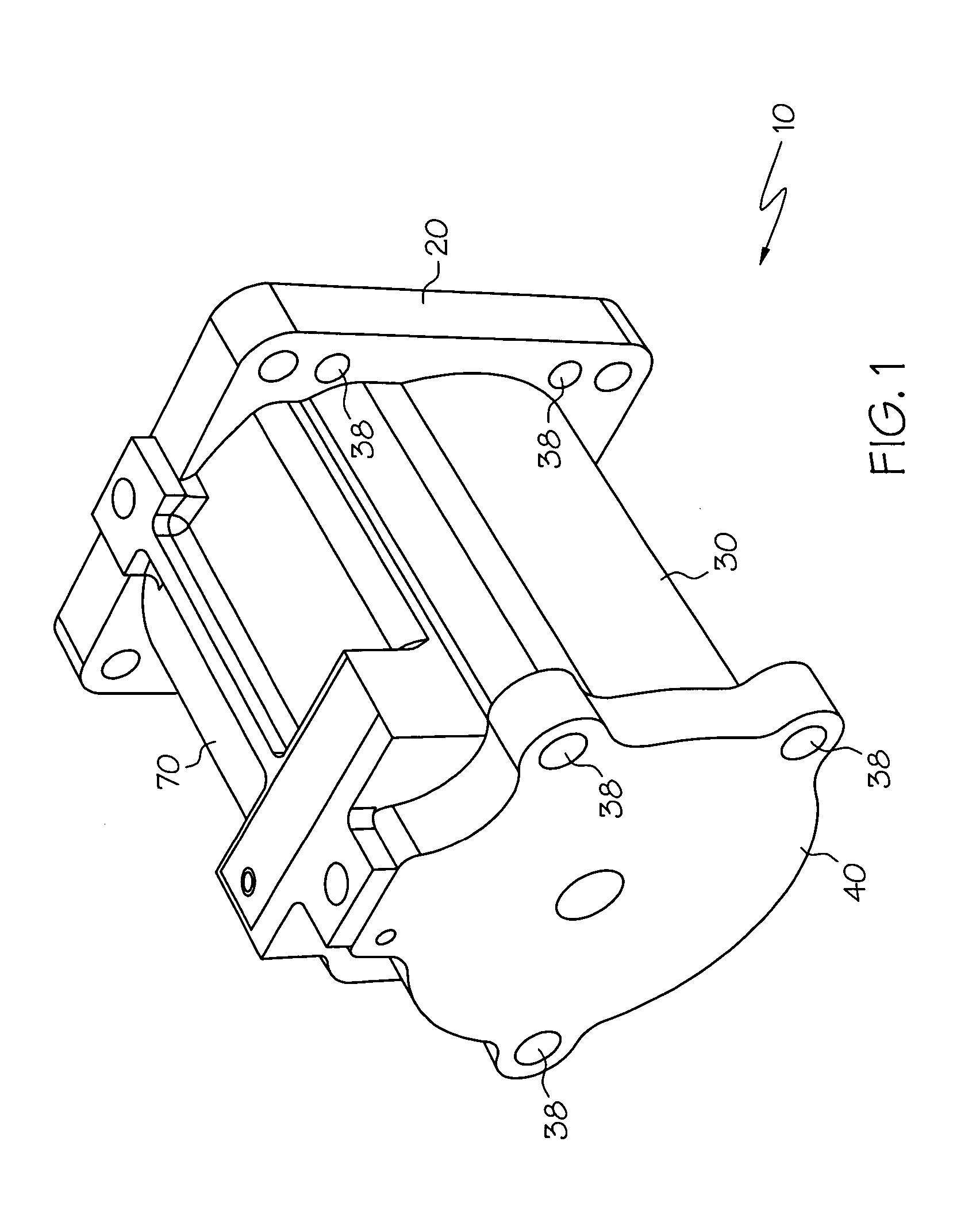

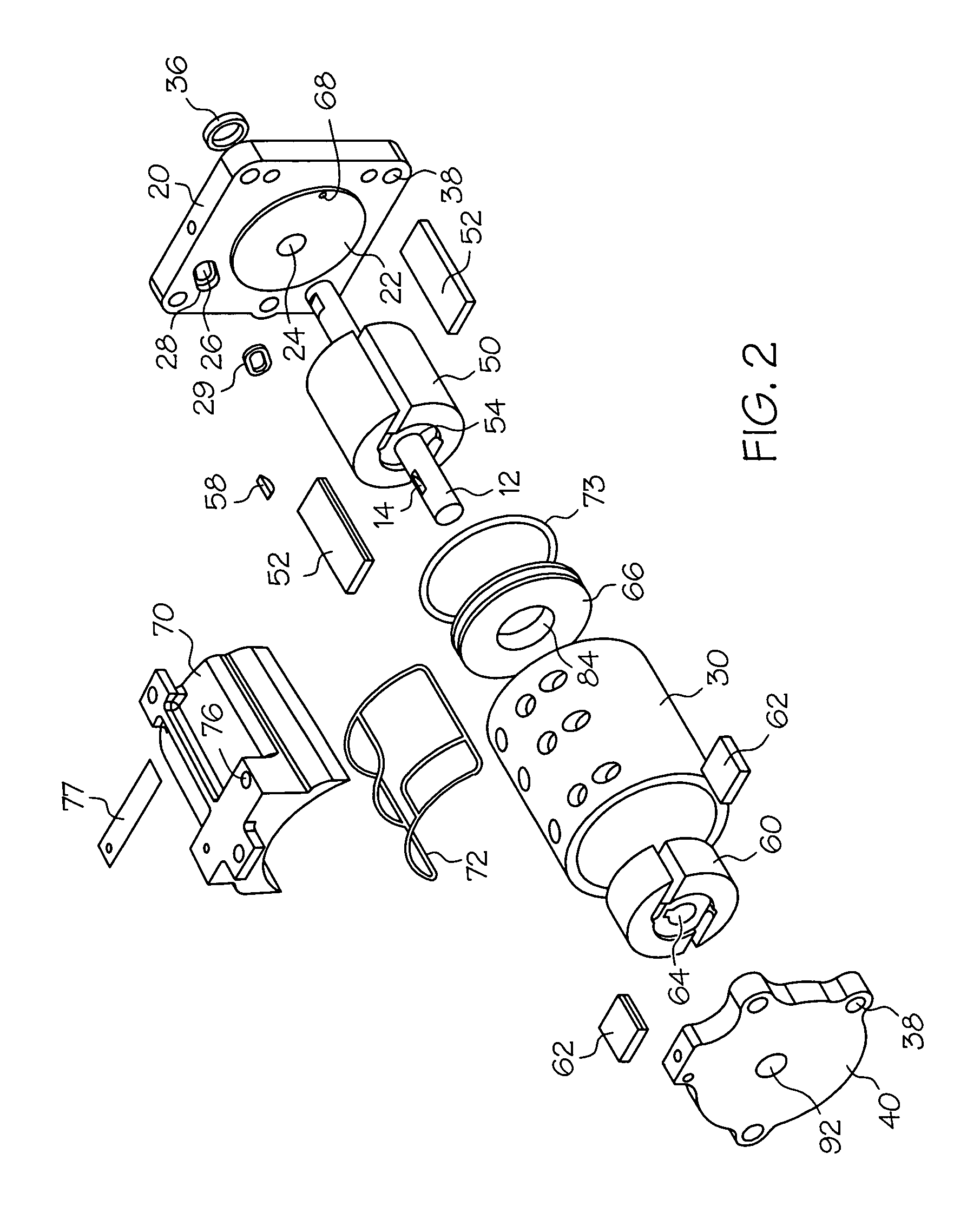

[0040]FIGS. 1 and 2 show an embodiment of an inventive vacuum pump 10, which may include a first or intake plate 20, a stator 30 having an internal cavity, a second or back plate 40, a shaft 12, a first rotor 50, a second rotor 60, a divider plate 66 and a cap 70. Each rotor 50, 60 may include at least one and desirably a plurality of vanes 52, 62. Each rotor 50, 60 may further include a longitudinal aperture 54, 64 for receiving the shaft 12. The longitudinal aperture 54, 64 of each rotor 50, 60 may be oriented along the central longitudinal axis of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com