Eddy current testing recognition and evaluation method for defects of inner wall and outer wall of steel pipe under direct current magnetization

A DC magnetization and eddy current detection technology, applied in the direction of material magnetic variables, etc., can solve the problems of signal aliasing, inability to distinguish and identify defects on the inner and outer walls of steel pipes, poor shielding effect, etc., to suppress the fluctuation of magnetic permeability and easy to realize automation , the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

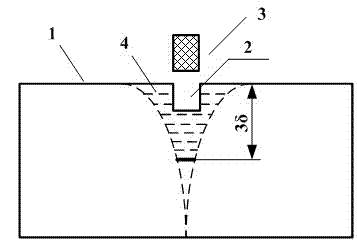

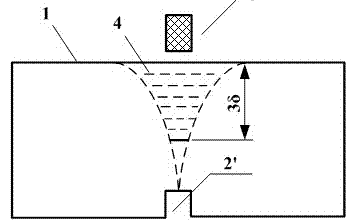

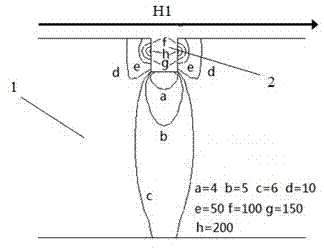

[0045] Such as figure 1 , 2 As shown, in the eddy current testing of steel pipe magnetic saturation method, the conventional view is that the magnetic permeability of the outer wall defect 2 or inner wall defect 2′ area after the steel pipe 1 is magnetized is uniformly distributed, so according to the skin depth calculation formula of eddy current testing (where, is the excitation signal frequency; is the magnetic permeability of the steel pipe; is the electrical conductivity of the steel pipe), the eddy current field 4 generated by the eddy current probe 3 can penetrate into the outer wall defect 2, so it can be detected, but the inner wall defect 2′ of the thick-walled steel pipe cannot be detected because the eddy current field 4 cannot penetrate to this position. However, the simulation calculation results of the magnetic permeability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com