Multi-layered thickness eddy current testing device based on giant magnetoresistance sensor and intelligent algorithm

A giant magnetoresistive sensor and intelligent algorithm technology, applied in the field of multi-layer thickness eddy current detection devices, can solve the problems of insufficient sensitivity and spatial resolution, difficulty in the application of multi-layer materials, surface and sub-surface defect detection, etc., to achieve confidence The effect of high noise ratio, low power consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

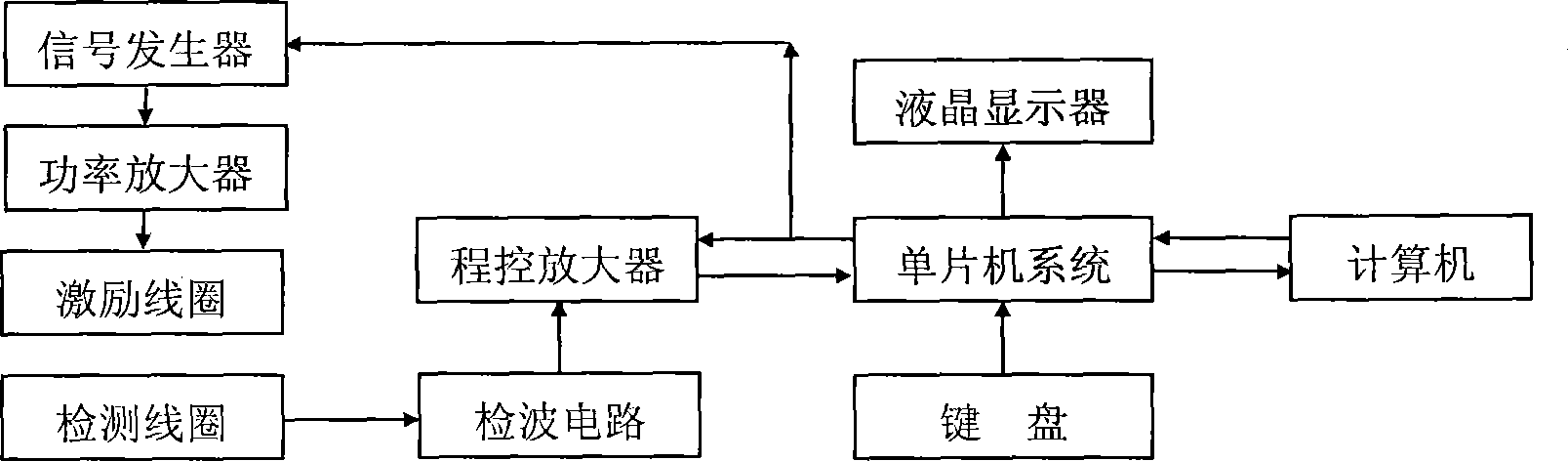

[0017] like figure 1 As shown in the figure, the single-chip microcomputer system in the multi-layer thickness eddy current detection device based on the giant magnetoresistive sensor and the intelligent algorithm is respectively connected with the computer, liquid crystal display, keyboard and program-controlled amplifier, and the single-chip computer system is connected with the signal generator, power amplifier and excitation coil in turn. The detection coil is connected with the detection circuit and the program-controlled amplifier in turn. Both the excitation coil and the detection coil are wound on the giant magnetoresistive chip and the magnetic steel.

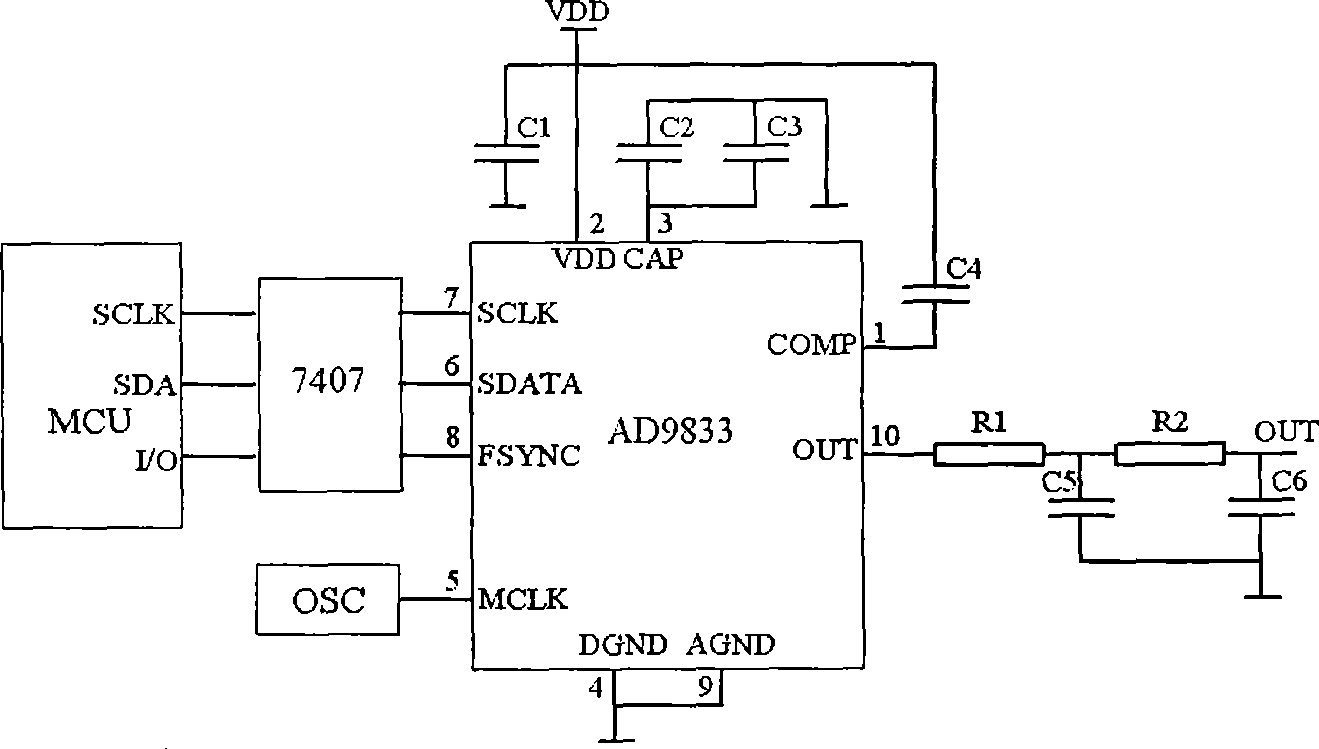

[0018] like figure 2 As shown, the signal generator circuit is: the first pin of the AD9833 chip is connected to the power supply VDD through the fourth capacitor, the second pin of the AD9833 is connected to the power supply VDD, and is grounded through the first capacitor, and the third pin of the AD9833 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com