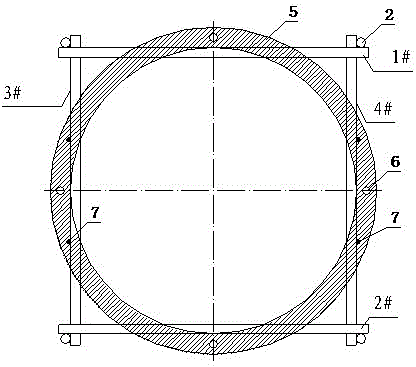

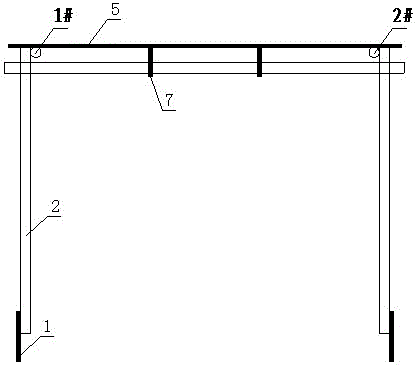

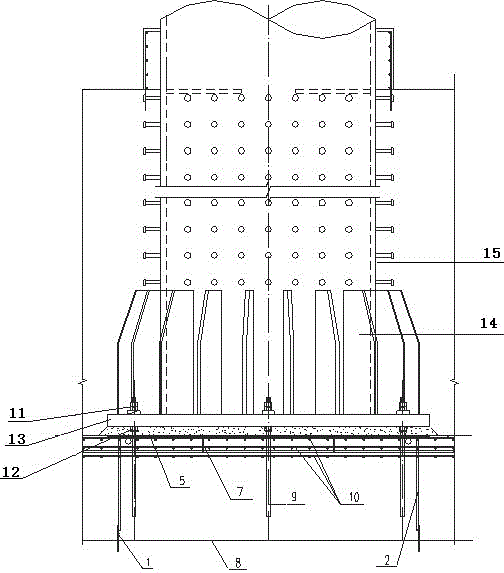

Installation and construction method of column base of large-diameter steel pipe column

A construction method and technology of steel pipe columns, which are applied in the directions of columns, piers, pillars, etc., can solve the problems of inconvenient positioning and complicated operation, and achieve the effects of convenient operation, high construction quality, and accurate and fast installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] During specific implementation: a method for installing the foot of a large-diameter steel pipe column, comprising the following steps:

[0023] a. After the acceptance of the foundation pit, pour C30 foundation concrete cushion in the foundation pit;

[0024] b. Bind the bottom reinforcement mesh and the side wall reinforcement mesh above the foundation pit cushion;

[0025] c. Install four anchor bolts;

[0026] The above step a and step b are both mature prior art and will not be described in detail here. Where this method makes improvements and contributions to the prior art lies in:

[0027] The anchor bolts are M36 anchor bolts. When the anchor bolts are installed, the pre-embedded positioning ring plate is used for positioning. 10mm circular steel plate to ensure the accuracy of anchor bolt installation; four anchor bolt installation holes ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com